Demolition blasting method of cylindrical steel column structure building

A technology for buildings and steel columns, which is applied in the direction of building construction, construction, building maintenance, etc. It can solve the problems of poor blasting effect, high risk, and high labor intensity, so as to improve the degree of blasting damage and ensure the blasting effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

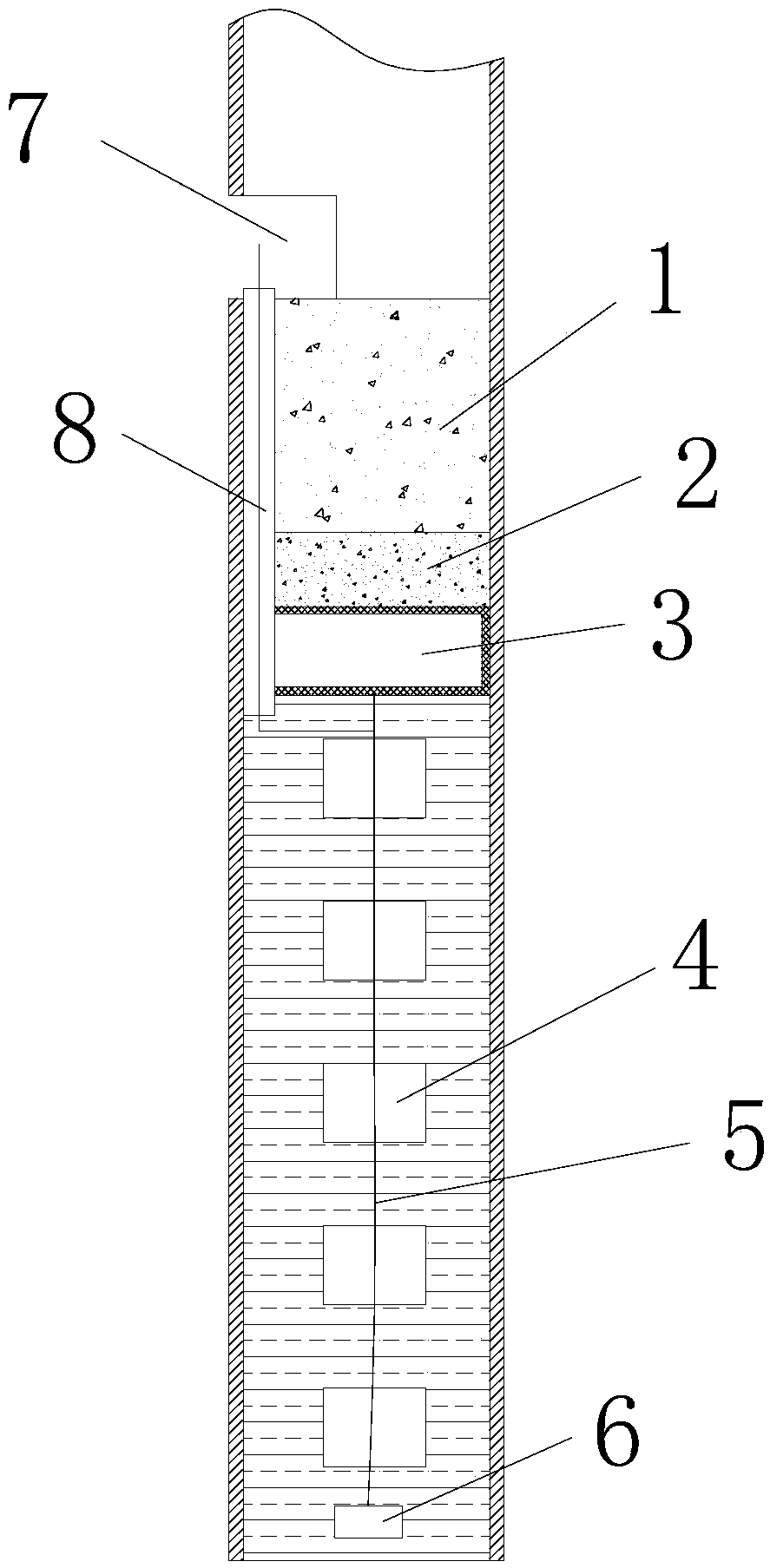

[0019] Such as figure 1 Shown, the blasting demolition method of tubular steel column structure building of the present invention comprises the following steps:

[0020] (1) Cut a notch 7 on the cylindrical steel column to be blasted, and the height and size of the notch 7 are determined according to the size of the cylindrical steel column to be blasted;

[0021] (2) pour water into the cylindrical steel column from the gap 7;

[0022] (3) The detonator detonator is penetrated in the conduit 8, and the string is connected to the inflatable bag, and the conduit 8, the inflatable bag, the string 5, the charge bag and the sinker 6 connected with the string are put into the cylindrical steel column Inside, a detonator can be connected between a plurality of charge packs, and each charge pack can also be connected with a detonator and pass through the conduit 8 at the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com