Water pressure blasting method employing angle steel-steel welded drum

A technology of hydraulic blasting and steel structure, which is applied in blasting, building construction, building maintenance, etc. It can solve the problems of blasting shock wave, blasting flying stones and noise, which are difficult to prevent and control, and cannot produce large openings, so as to increase the blasting action time, The harmful effect of blasting is less harmful and easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

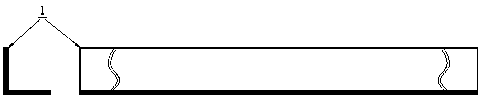

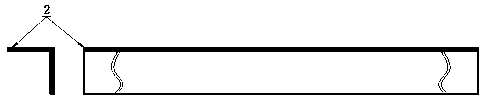

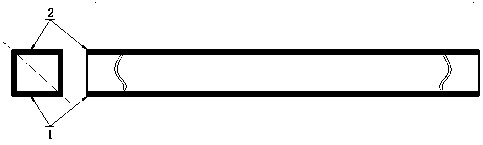

[0046] Embodiment: the size of the welding accessory angle steel 2 is 80mm*80mm*8mm, and the length is 150cm; the size of the back cover steel plate 3 is 10cm*10cm*1cm; the pre-cut seam 4 is 40mm long and 5mm wide, along the right angle back of the angle steel 1 to be removed; the glue is AB glue; pre-embedded PVC pipe 6 with a length of 150cm, a diameter of 40cm, and a wall thickness of 3mm; every 15cm of water space is filled with 50g of explosives, and 1 round of detonators is used. A total of 150g of 2# rock emulsion explosives and 3 rounds of ms-3 detonators are used Detonator; the final test result cut length is 62cm, and the destruction length is 73cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com