A hydraulic blasting device for an angle steel structure transmission tower located in a mountainous area

A technology of hydraulic blasting and power transmission towers, which is applied in blasting and other directions, can solve problems such as high risk, poor blasting effect, and high labor intensity, and achieve the effects of ensuring blasting effect, improving blasting damage, and facilitating transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

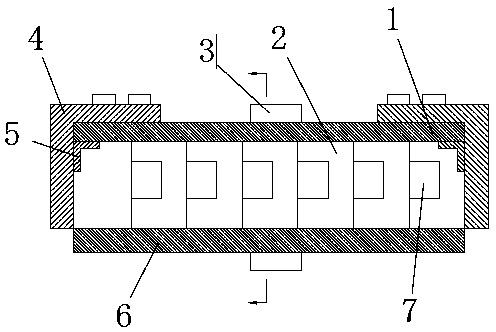

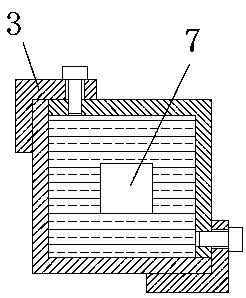

[0014] Such as figure 1 and figure 2 As shown, the hydraulic blasting device of the angle steel structure transmission tower located in the mountainous area of the present invention comprises the first angle steel 1, and the two sides of the first angle steel 1 are connected with the angle steel 6 to be blasted by the second angle steel 3, and the first angle steel 1 is connected with the angle steel 6 to be blasted. The angle steel 6 to be blasted constitutes a cylindrical structure, and both ends of the cylindrical structure are sealed by the third angle steel 4, and the water bag 2 and the drug bag 7 are arranged alternately in the cylindrical structure, and the water bag 2 is provided with a groove , the charge package 7 is located in the groove, and the charge package 7 is drawn out of the cylindrical structure through the nonel detonator.

[0015] In the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com