Hydraulic blasting method for angle steel structure power transmission tower in mountainous area

A technology for hydraulic blasting and power transmission towers, applied in the field of blasting, can solve problems such as poor blasting effect, high risk, and inability to carry out welding, so as to improve the degree of blasting damage, ensure the blasting effect, and shorten the blasting cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

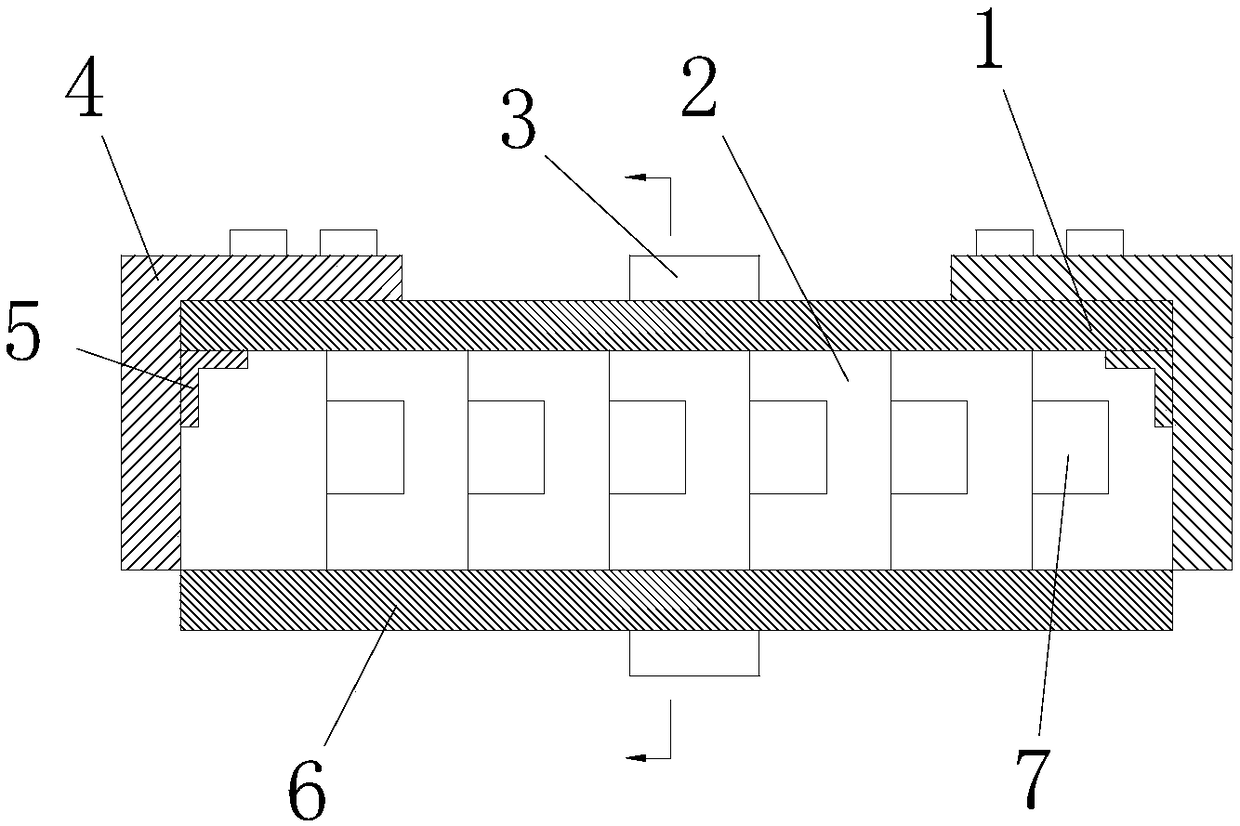

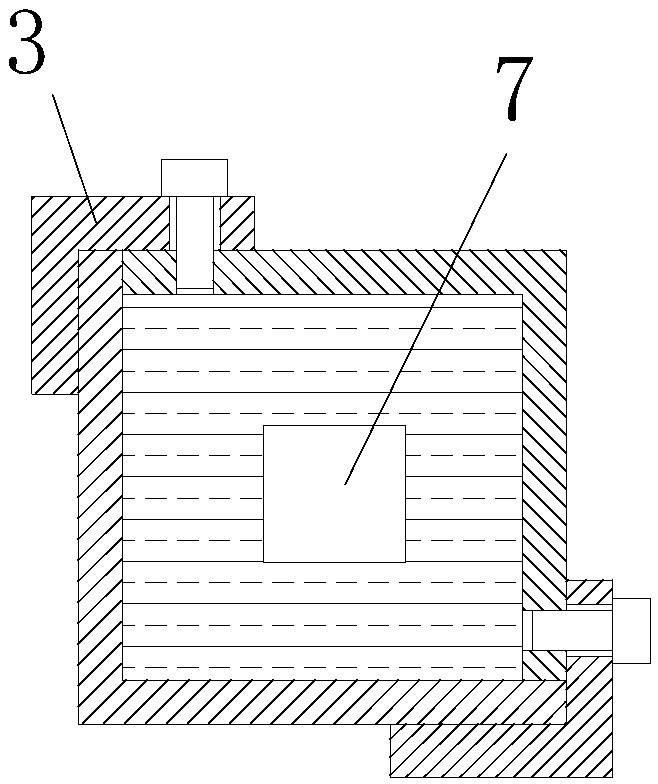

[0018] Such as figure 1 and figure 2 As shown, the hydraulic blasting method of the angle steel structure transmission tower located in the mountainous area of the present invention comprises the following steps:

[0019] (1) According to the structure of the transmission tower, process the first angle steel 1, the second angle steel 3, the third angle steel 4 and the fourth angle steel 5 of suitable size, and weld the fourth angle steel 5 to the two ends inside the first angle steel 1;

[0020] (2) punch holes at the first angle steel 1, the second angle steel 3, the third angle steel 4 and the fourth angle steel 5 at suitable positions, prepare water bag 2, charge bag 7, nonel detonator;

[0021] (3) The blasting device is transported to the transmission tower, the first angle steel 1 is connected with the angle steel 6 to be blasted through the second angle ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com