Method for comprehensively treating construction waste

A technology for comprehensive treatment of construction waste, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of poor treatment and recycling of construction waste, ecological environmental pollution, waste of non-renewable resources, etc. , to achieve the effect of promoting application, saving land, and orderly management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

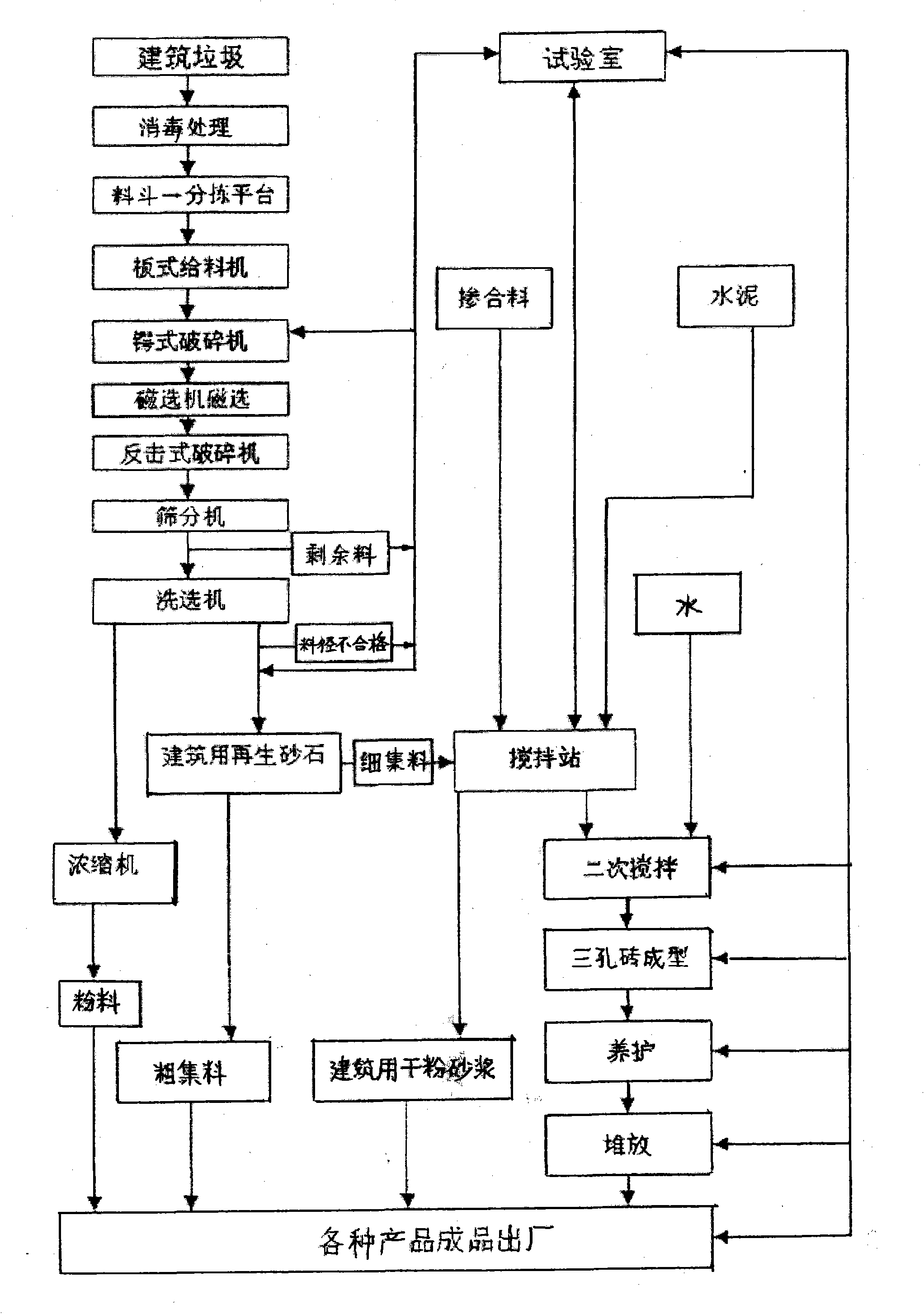

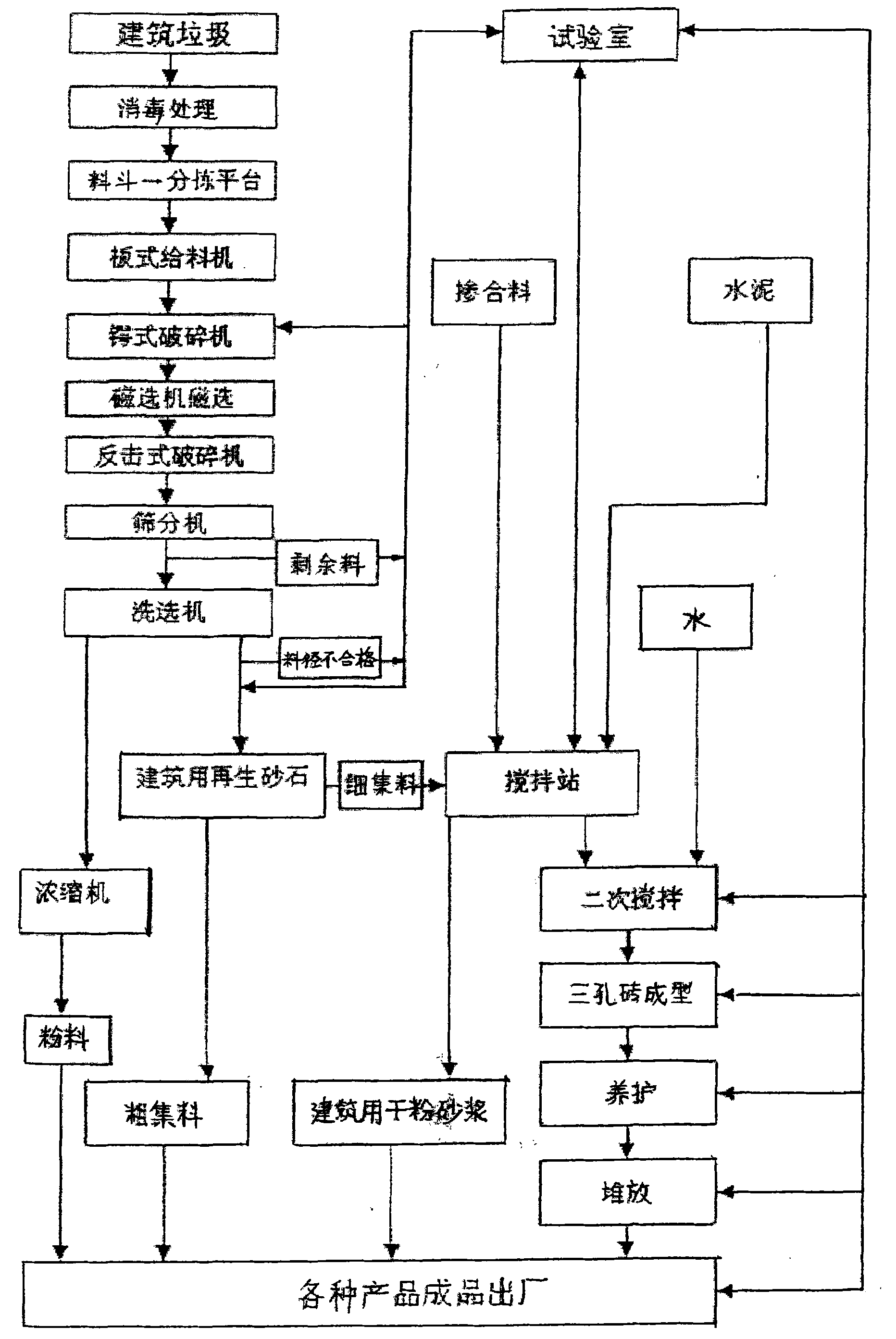

[0025] Embodiment 1: as attached figure 1 Shown, the processing method of the present invention is as follows, construction waste is transported in the factory by dump truck, pours into construction waste storage yard, super-large block is broken with machinery, disinfects through medicine chlorine dioxide (also can select for use similar harmless Disinfectants are disinfected and loaded into the hopper with a loader, sent to the sorting platform, and artificial or intelligent sorting machines are used to sort out waste wood boards, cartons and waste paper, waste paint buckets and plastic sheets, and waste gypsum boards and other materials (the sorted materials are regenerated separately), the sorted construction waste is sent to the shredder by the apron feeder for primary crushing and separation, and the primary crushed construction waste is selected by the magnetic separator Iron materials (sent to the ironworks in production), the construction waste fragments after magneti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com