Blasting demolition method for reinforced concrete water retaining cofferdam

A reinforced concrete and cofferdam technology, which is applied in blasting, construction, infrastructure engineering, etc., can solve the problems of large dosage of single hole, single detonation method, large blasting fragmentation, etc., achieve uniform crushing effect, reduce blasting dust, Controlling the effect of blasting vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

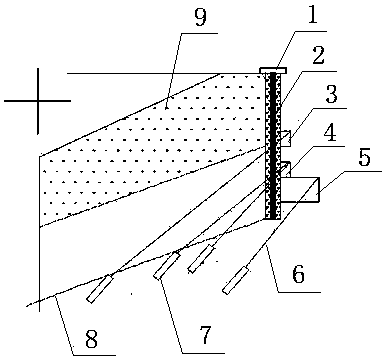

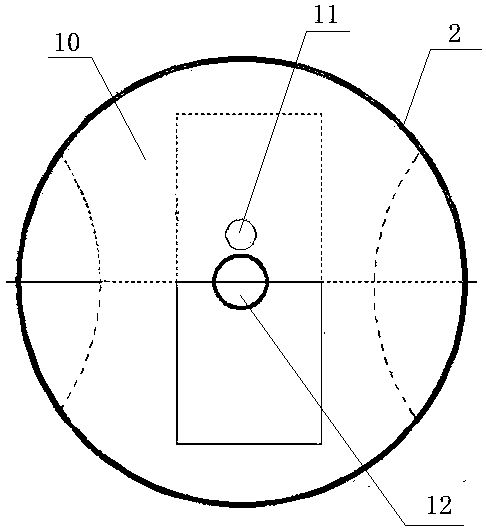

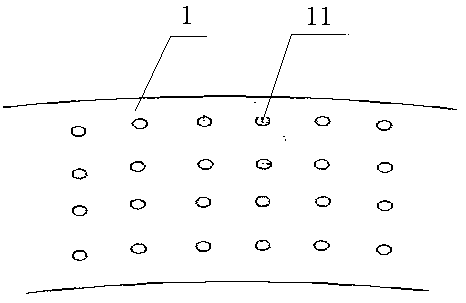

[0023] The present invention will be further described below in conjunction with specific embodiment: as Figure 1-7 As shown, a reinforced concrete water retaining cofferdam needs to be demolished by blasting. The anchor block of the reinforced concrete water retaining cofferdam is 3 m thick, 3 m wide, and 11.25 m long; the anchor cable 6 is 15-18 m long; the bottom ring beam 4 and the middle The ring beam 3 has a thickness of 1.2 m and a width of 0.8 m. The main reinforcement of the ring beam is 7 Φ32mm steel bars, and the stirrups are Φ12mm steel bars with a spacing of 200 mm. The top ring beam 1 is 2.1 m wide and 0.5 m thick. The main reinforcement of the ring beam is 16 Φ32mm steel bars, the stirrups are Φ12mm steel bars, and the spacing is 250 mm. 4 distribution bars are Φ20mm steel bars. The anti-seepage pile 2 is a reinforced concrete structure of Φ950 mm, the center is a steel bar of Φ114 mm, the width of the reinforcement cage is 400 mm, and the length is 780 mm. Tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com