Patents

Literature

50results about How to "Uniform crushing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

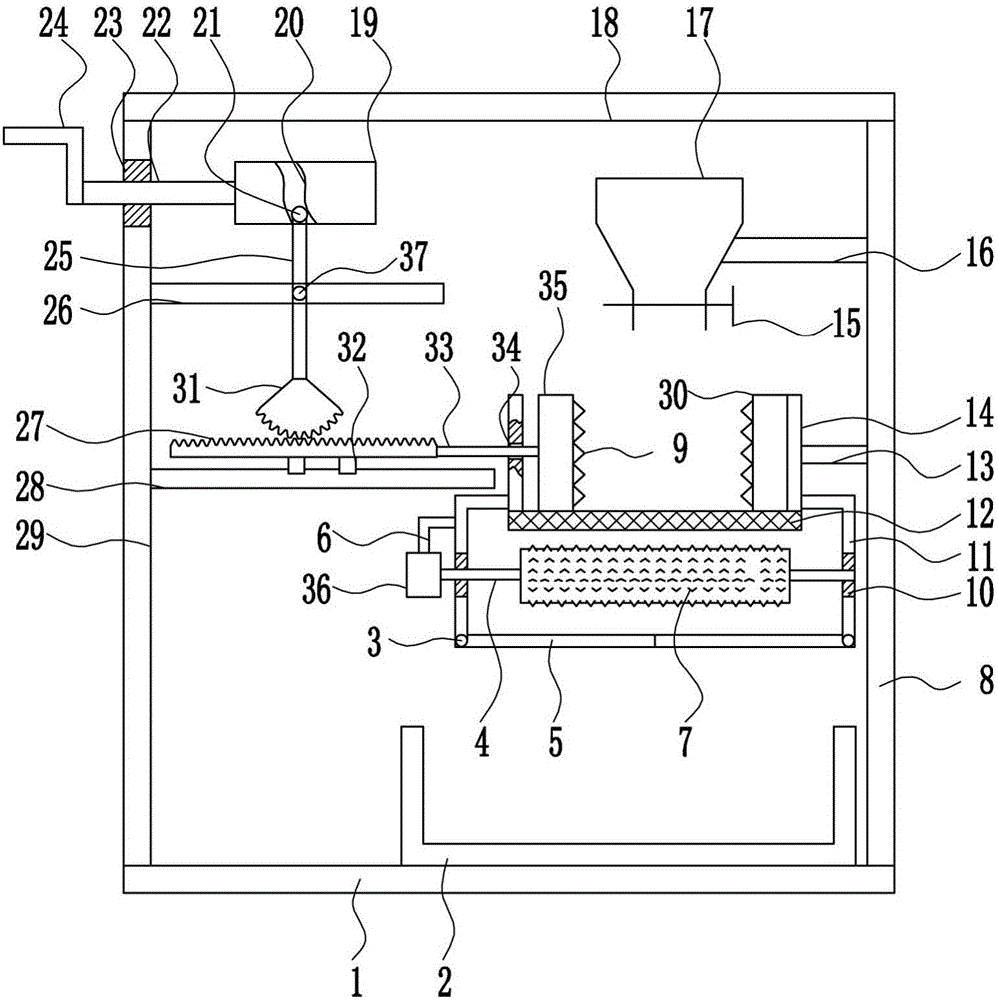

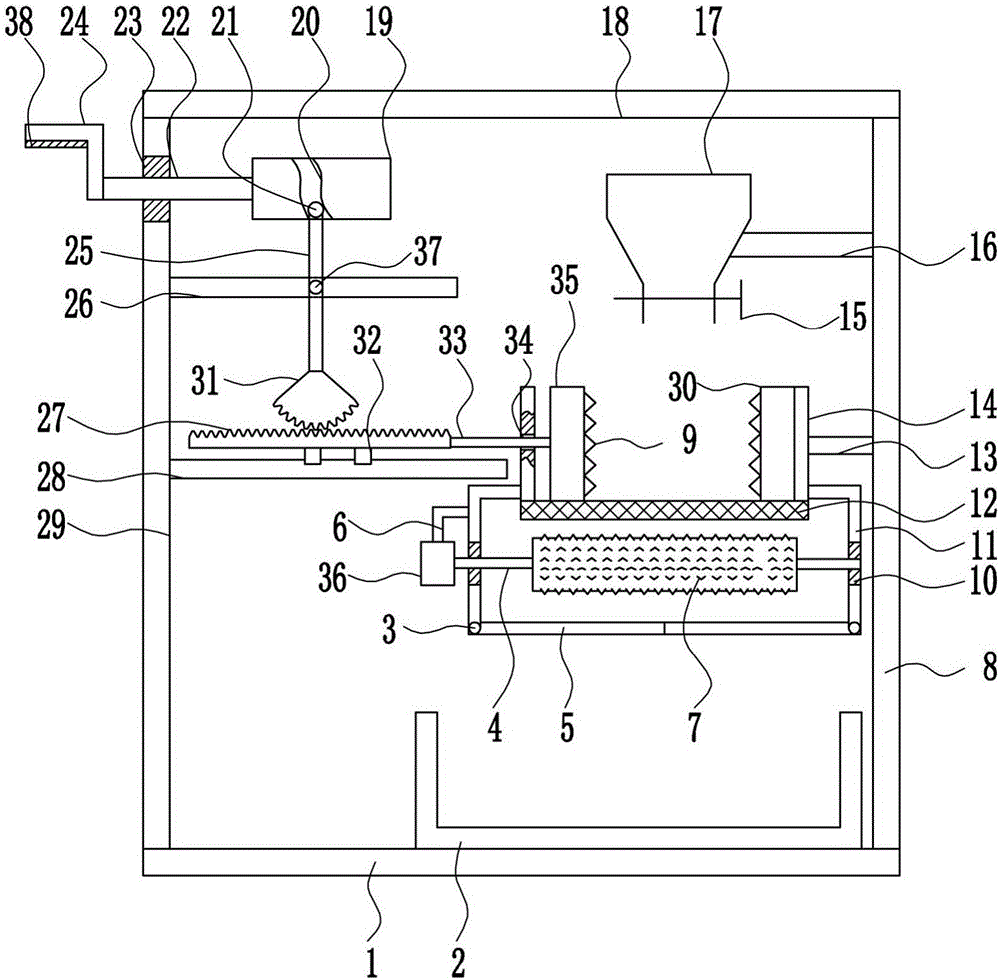

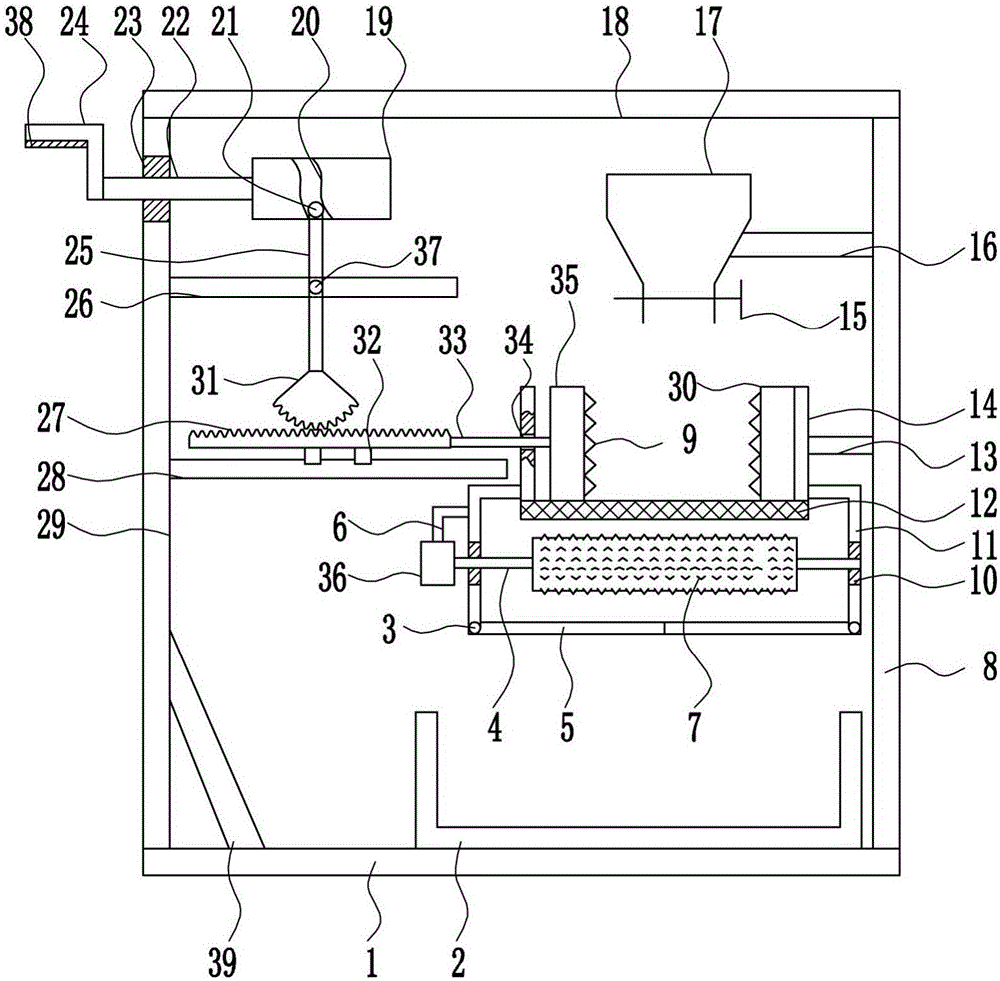

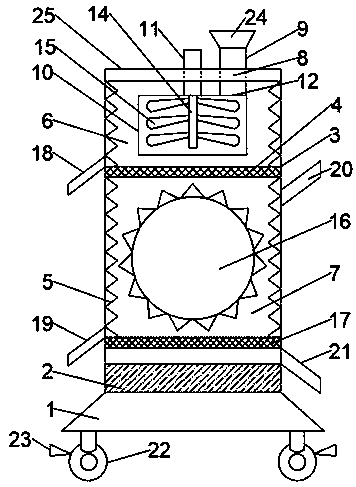

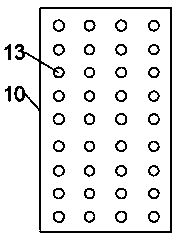

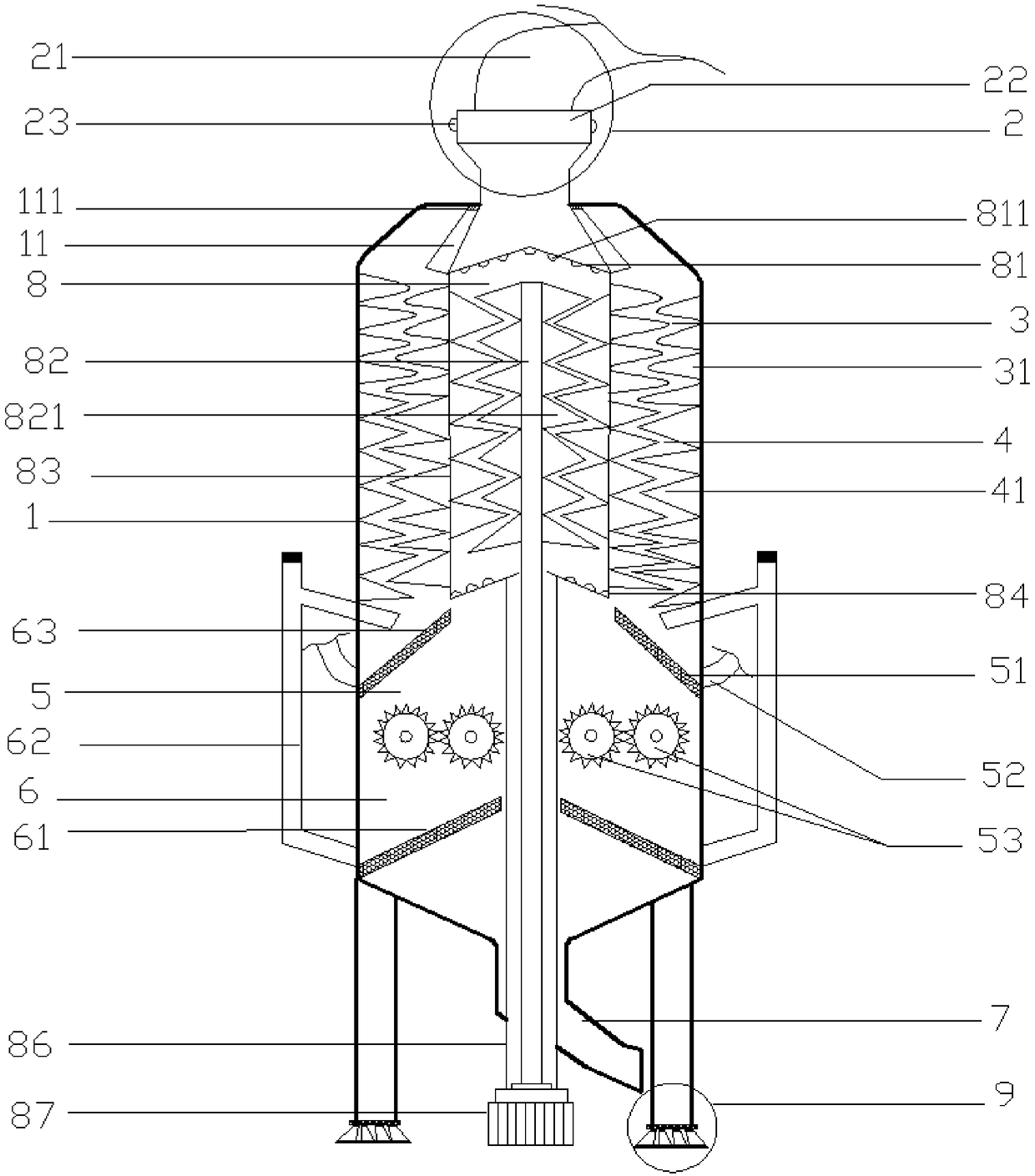

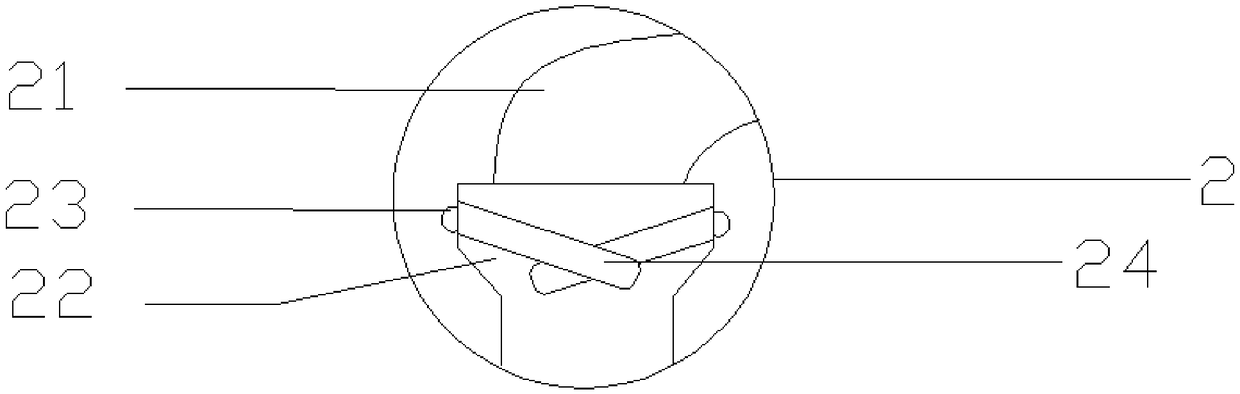

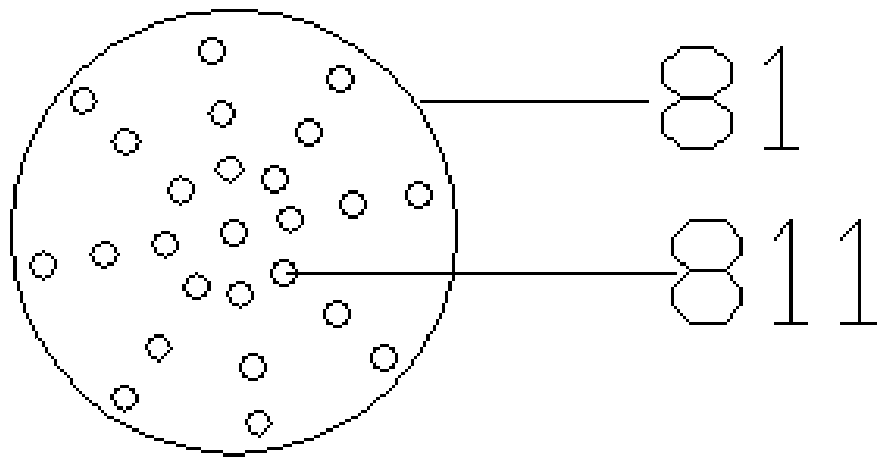

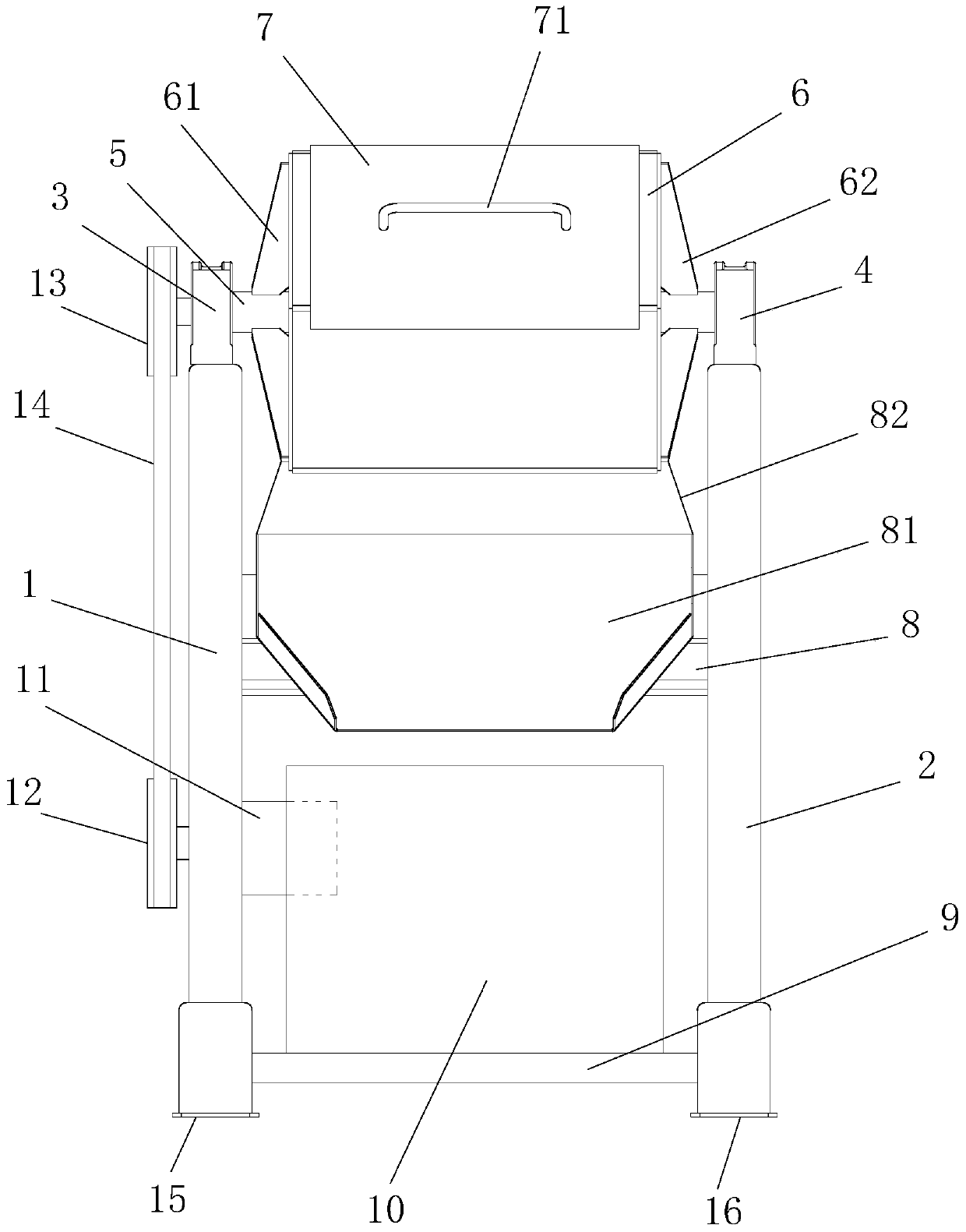

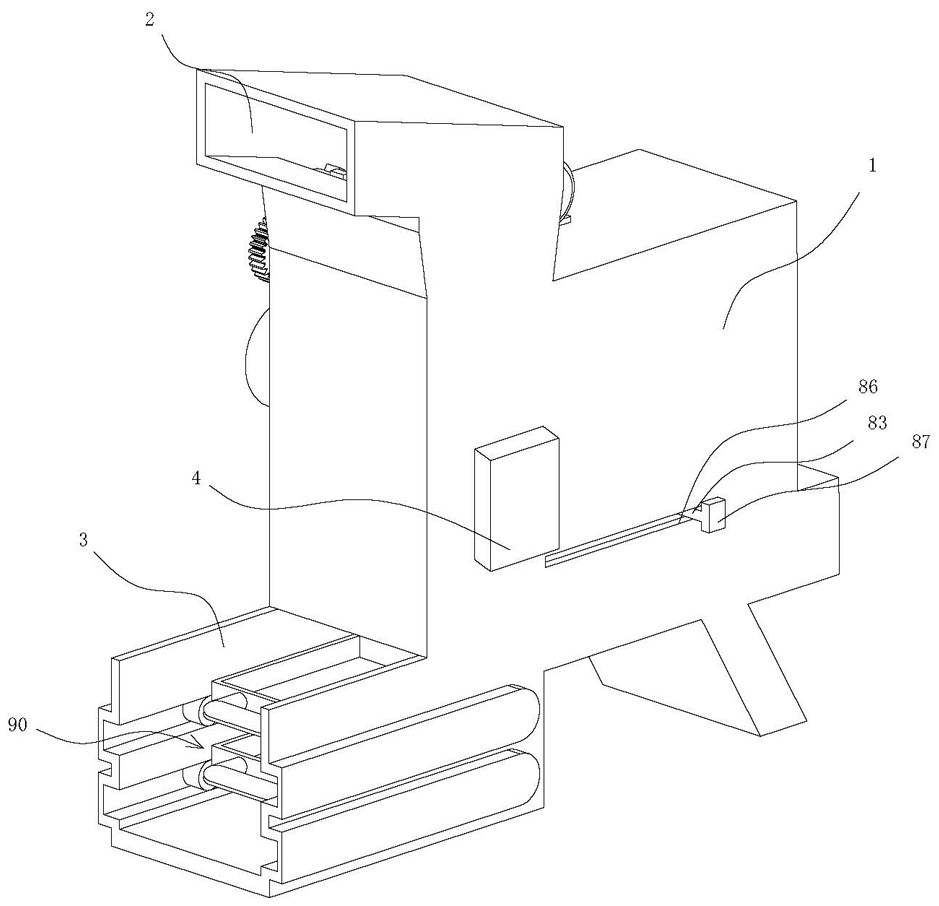

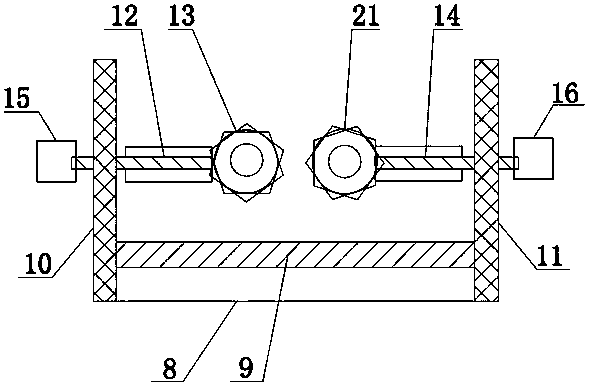

Multi-stage crushing equipment for solid veterinary drugs for livestock farm

The invention relates to veterinary drug crushing equipment, in particular to multi-stage crushing equipment for solid veterinary drugs for a livestock farm. The multi-stage crushing equipment aims at achieving the technical purposes that the crushing effect is good, crushing is uniform, and the structure is novel. To achieve the technical purposes, the multi-stage crushing equipment for the solid veterinary drugs for the livestock farm is provided. The multi-stage crushing equipment comprises a bottom plate, a collecting frame, hinges, a first rotating shaft, baffles, a second L-shaped bracket, a roller, a right frame, crushing teeth, first bearing seats, first L-shaped brackets and the like. A left frame is welded to the left end of the top of the bottom plate. A second bearing seat is connected to the upper portion of the left frame in a bolt connecting manner. A bearing in the second bearing seat is in interference fit with a second rotating shaft. The multi-stage crushing equipment has the beneficial effects of being good in crushing effect, uniform in crushing and novel in structure. The multi-stage crushing equipment plays an important role, not only has the good crushing effect, but also improves the working efficiency and has high safety.

Owner:庄永和

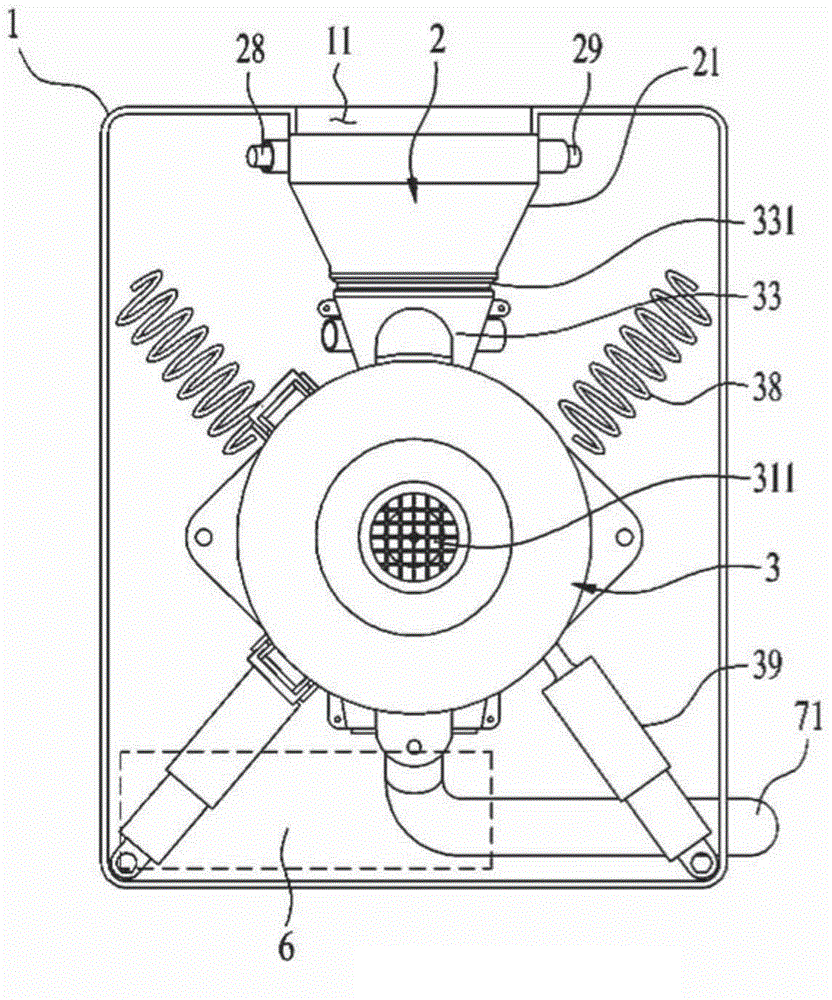

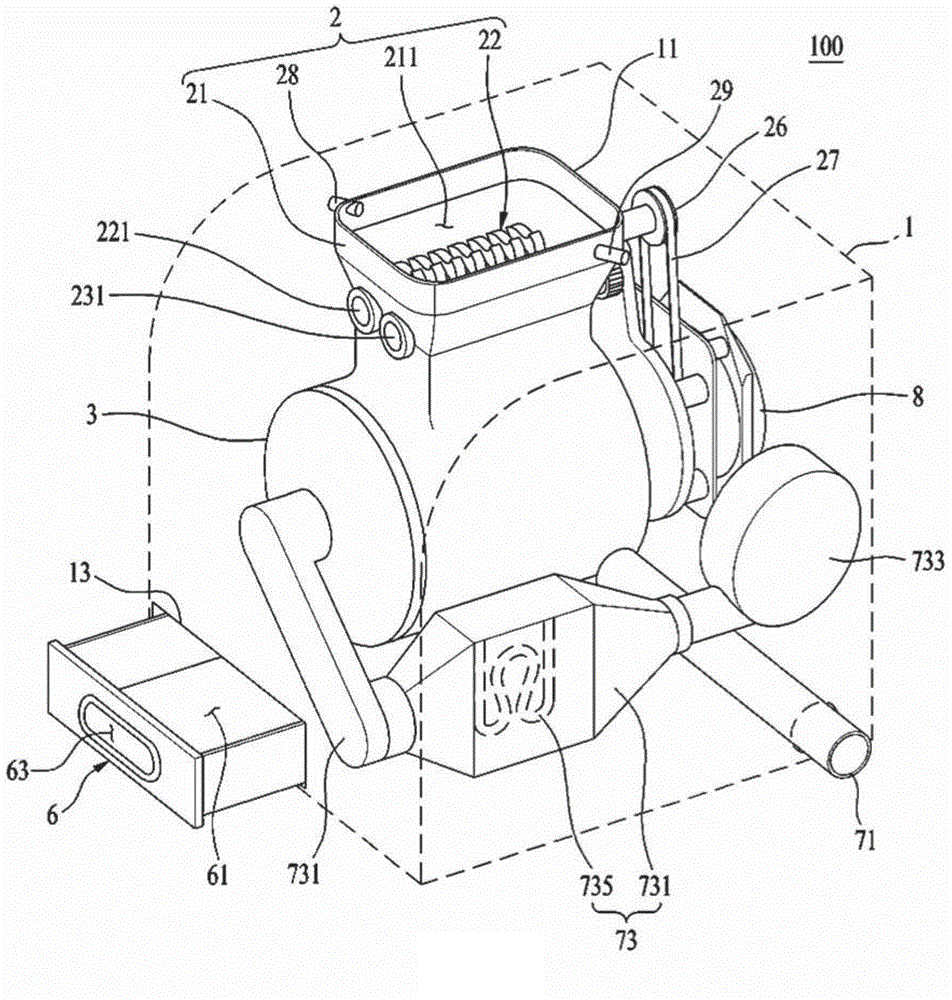

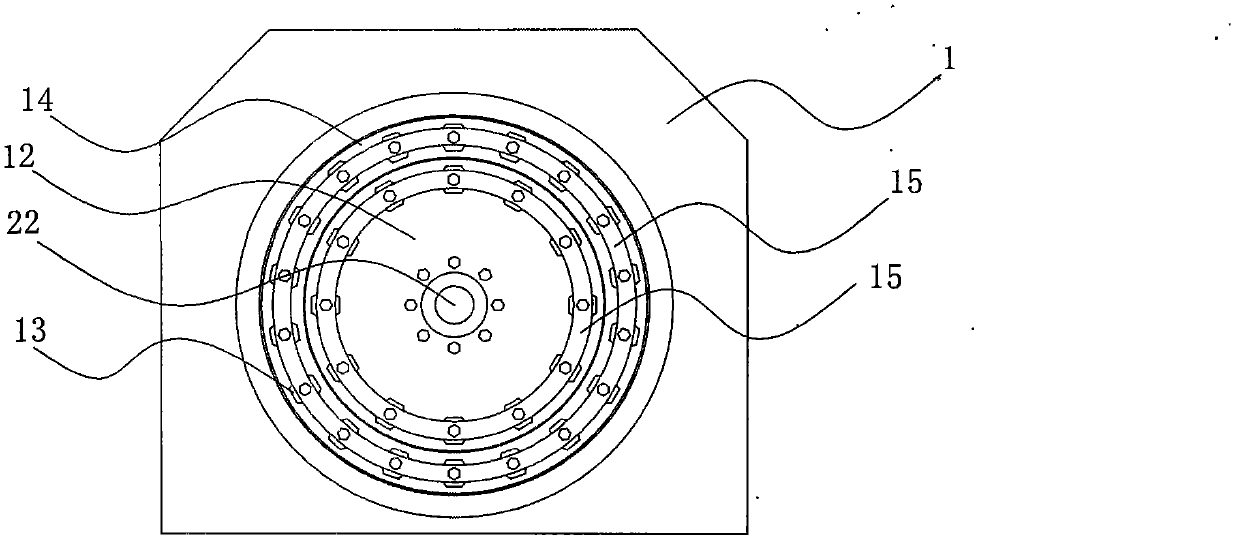

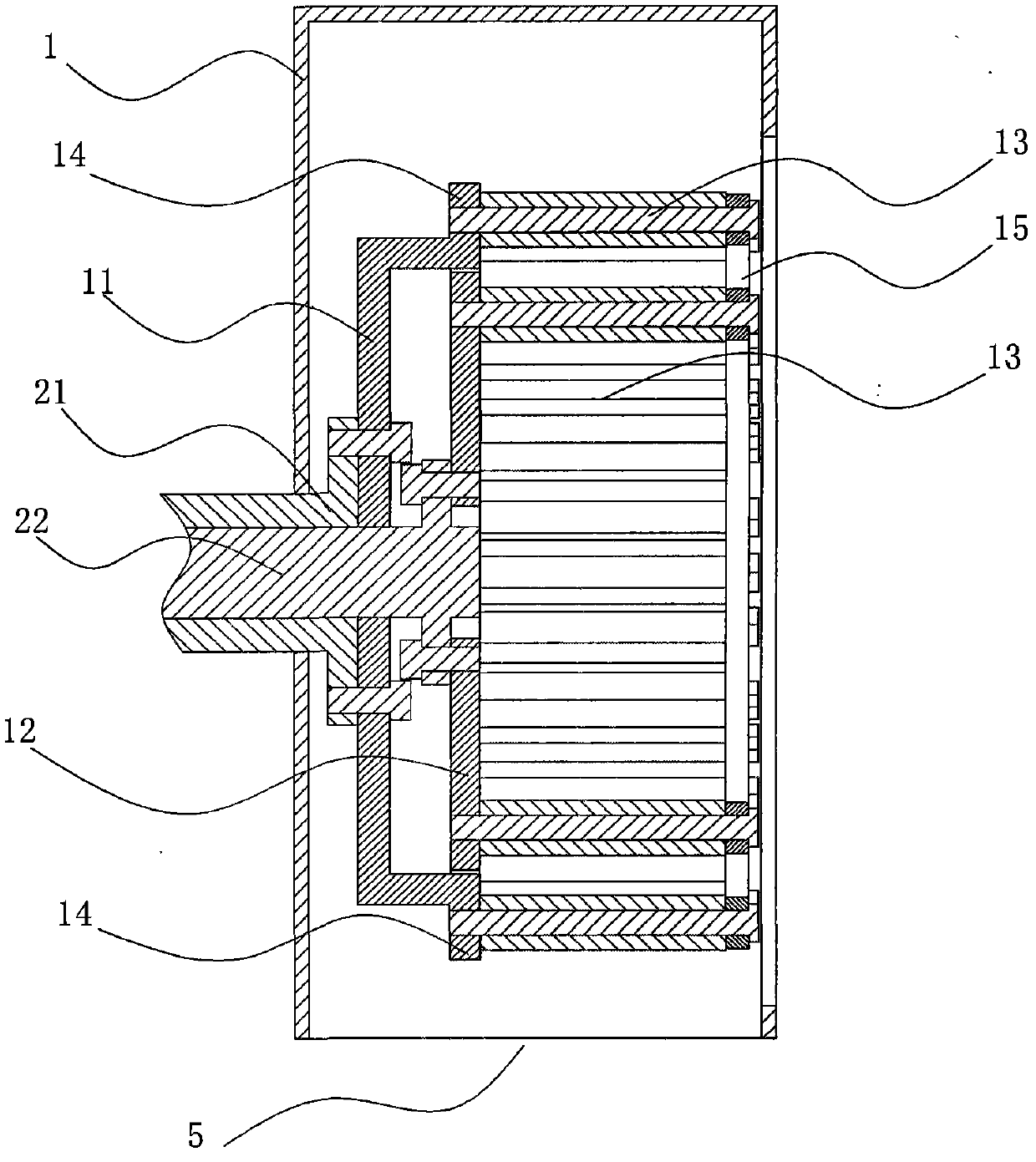

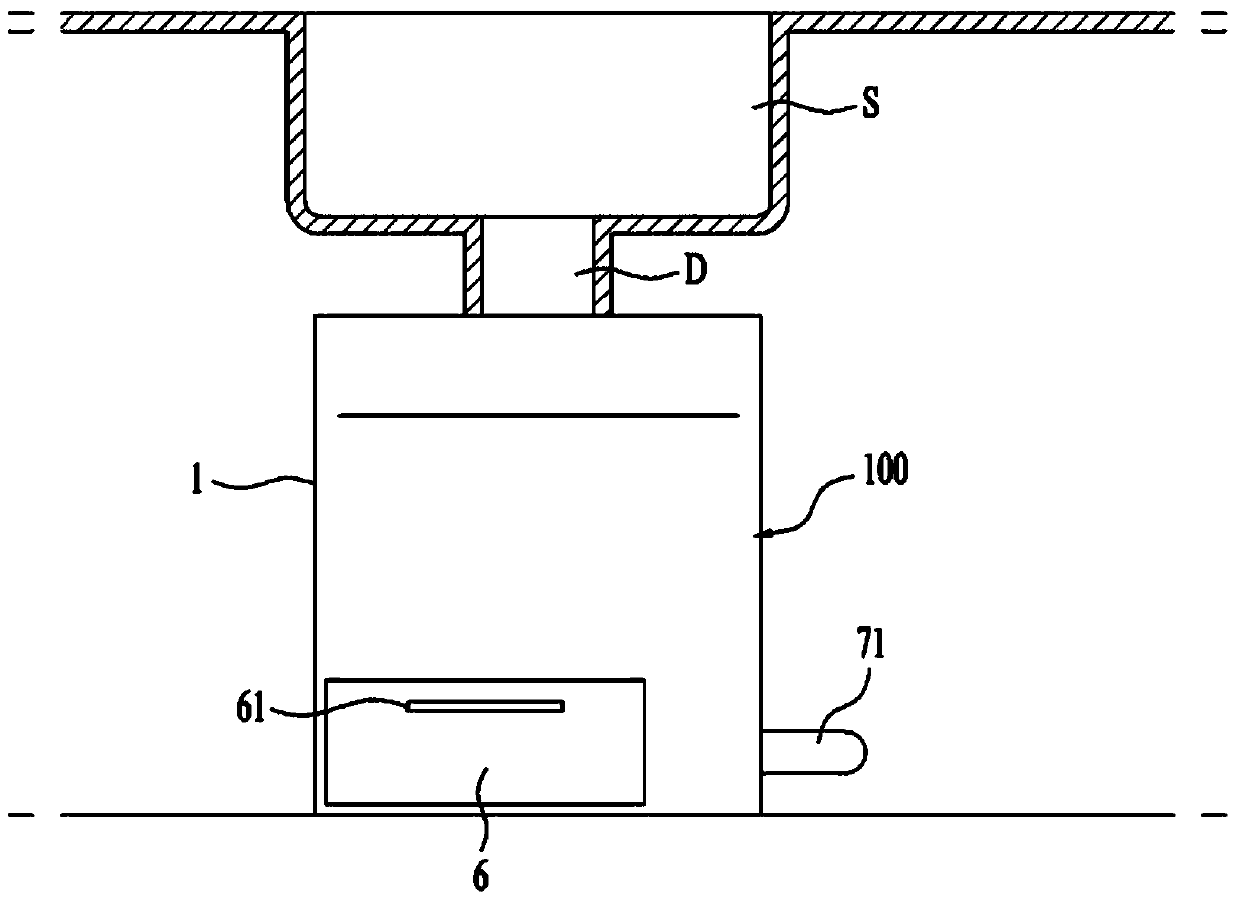

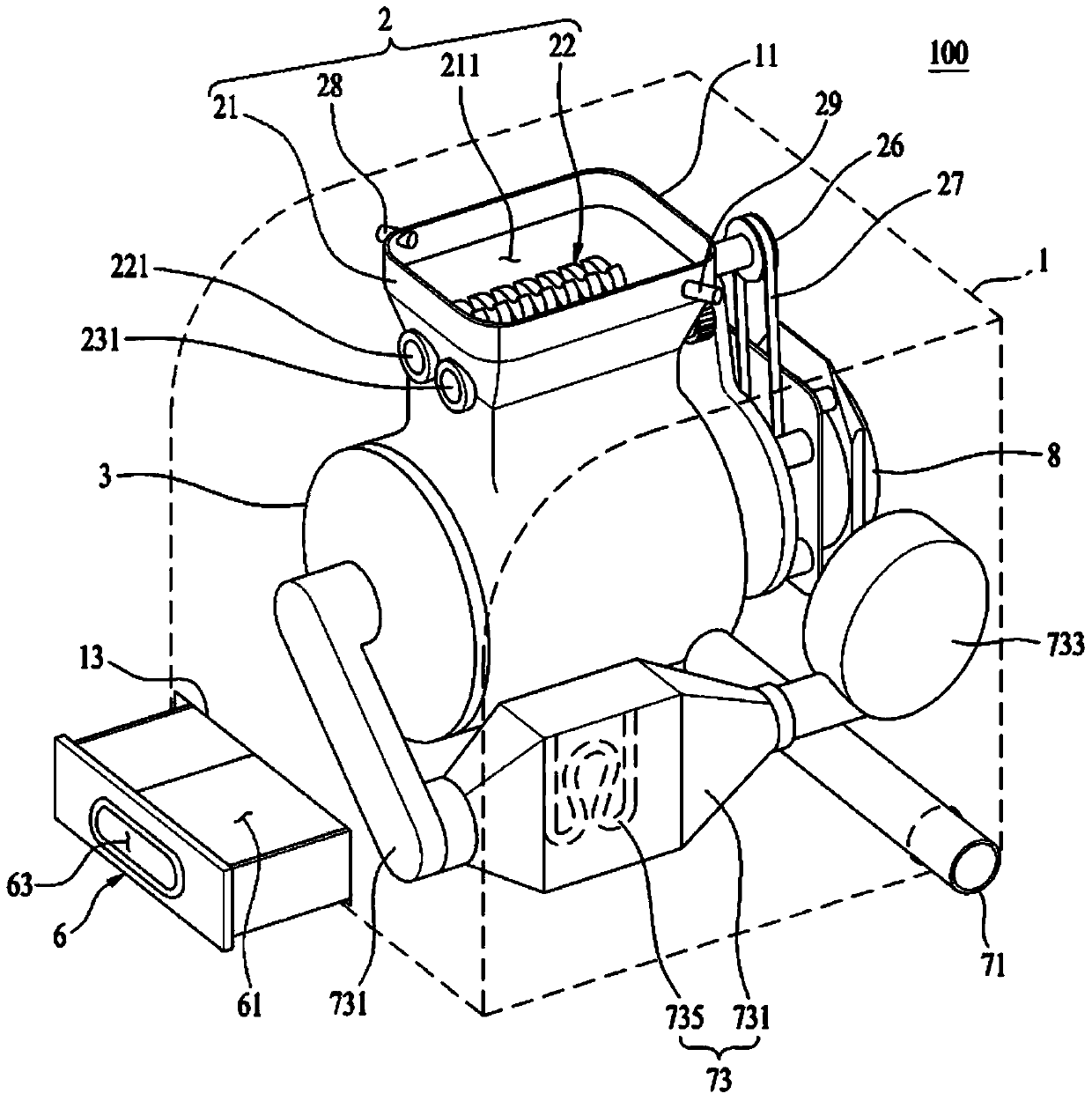

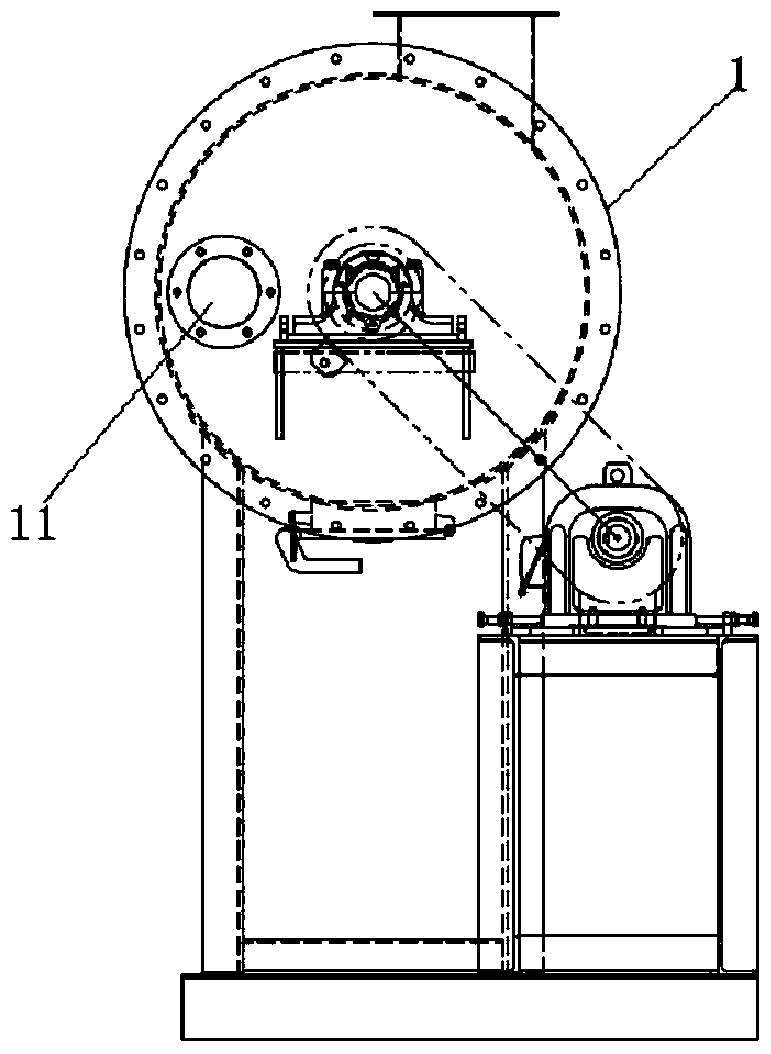

Food waste treatment apparatus

InactiveCN105312304AUniform crushing effectDrying solid materials without heatSolid waste disposalCentrifugal forceRefuse Disposals

A food waste treatment apparatus capable of pulverizing, dehydrating, and drying food waste includes a housing that defines a space that is configured to dehydrate and dry food waste, the housing having an inlet port that is configured to receive the food waste and an outlet port that is configured to discharge the food waste that has been dehydrated and dried. The apparatus includes a cylindrical dehydrator that is configured to remove water included in the food waste by spinning the food waste inside the housing, the cylindrical dehydrator having a communication hole that is configured to connect with the inlet port or the outlet port based on rotation of the cylindrical dehydrator. The apparatus includes an agitator that is located in the cylindrical dehydrator that is configured to rotate simultaneously with or independently of the dehydrator, that is configured to selectively open or close the communication hole, and that is configured to agitate and grind the food waste inside the cylindrical dehydrator based on rotation of the agitator; and a dryer that is configured to dry the food waste by supplying dry air to the housing.

Owner:LG ELECTRONICS INC

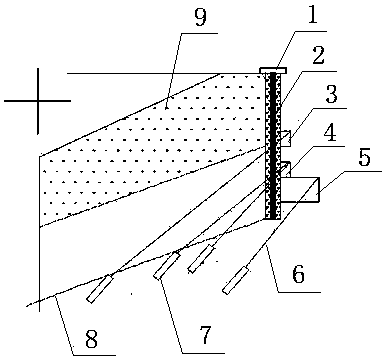

Water-coupled charging blasting demolition method for reinforced concrete beam or column

ActiveCN105571418AReduce charge resistanceCharge smoothlyBuilding repairsBlastingShock waveReinforced concrete

The invention discloses a water-coupled charging blasting demolition method for a reinforced concrete beam or column. The process that blast holes are formed along the axis of the reinforced concrete beam or column and water is poured into the blast holes is adopted, and the aims of reducing resistance of deep hole charging, achieving accurate charging, efficiently utilizing water pressure blasting energy, effectively controlling the strength and amount of vibration of blasting, blasting flyrock, air shock waves and poisonous blasting gas and reducing blasting dust are achieved. According to the method, the process is simple, operation is easy, the application range is wide, and the method is an ideal construction method for demolition of the reinforced concrete beam and column.

Owner:程大春

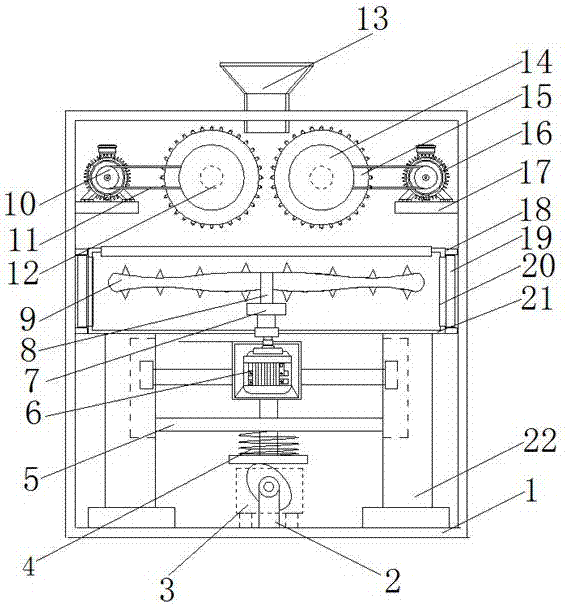

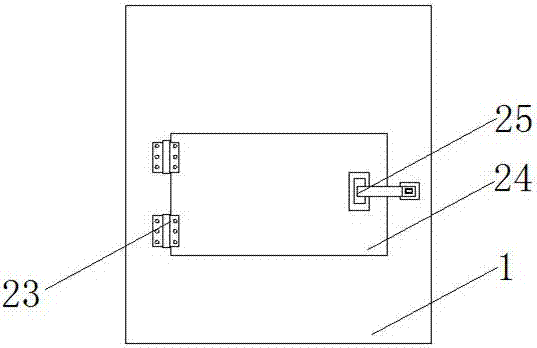

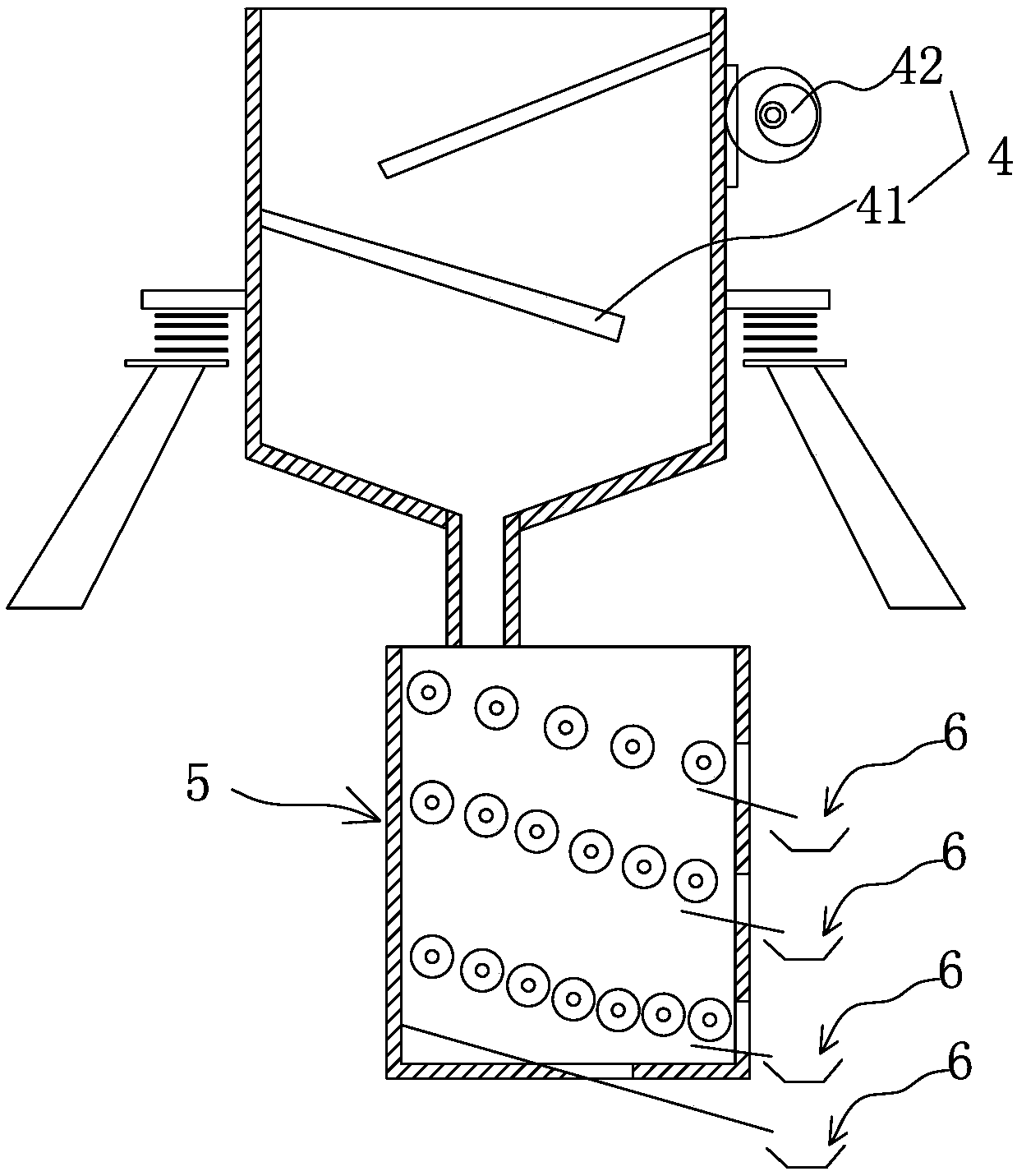

High-efficiency mushroom wood pulverizer

PendingCN107051643AAvoid damageAvoid enteringGrain treatmentsElectric machinePulp and paper industry

The invention discloses a high-efficiency mushroom wood pulverizer and relates to the technical field of edible mushroom breeding. The high-efficiency mushroom wood pulverizer comprises an outer frame. Supporting columns are fixedly connected to the two sides of the bottom of the inner wall of the outer frame, a cross plate is fixedly connected between the opposite sides of the two supporting columns, and the top ends of the supporting columns are fixedly connected with a pulverizing box. A first motor is fixedly connected to the position, located between the two supporting columns, of the bottom of the inner wall of the outer frame, and a movable device is fixedly connected to an output shaft of the first motor. The high-efficiency mushroom wood pulverizer achieves the purpose of improving the pulverizing efficiency, it is avoided that wood directly enters the pulverizing box, the pulverizing efficiency is greatly improved, the mushroom wood is more radically pulverized, and damage, caused by the fact that the wood directly enters the pulverizer, to the pulverizer is avoided; and pulverizing heads are driven by the movable device to move, the pulverizing effect is more uniform while the pulverizing efficiency is improved, and the use effect of the pulverized mushroom wood is improved.

Owner:江苏福利达农业科技有限公司

Raw material pulverizing device for preparation of traditional Chinese medicine decoction pieces

The invention discloses a raw material crushing device for the preparation of decoction pieces of traditional Chinese medicine. The filter plate divides the working room into a crushing chamber and a grinding chamber. The top of the crushing chamber is provided with a raw material inlet, and a feeding pipe is provided inside the raw material inlet. The crushing chamber is provided with a crushing barrel, and the top of the crushing barrel is provided with a rotating shaft. There is a feeding port on the barrel, a number of outlets on the side wall and bottom of the crushing barrel, a crushing shaft inside the crushing barrel, a number of crushing blades on the crushing shaft, a ball mill and a second filter plate in the grinding chamber, There is a primary discharge port on the left outer surface of the grinding chamber, a secondary discharge port on the left bottom of the grinding chamber, a return port on the right top of the grinding chamber, and a crushed material outlet on the right bottom of the grinding chamber. It is easy to operate and can realize the function of efficiently crushing raw materials in the process of preparing traditional Chinese medicine.

Owner:贵州苗立克中药科技有限公司

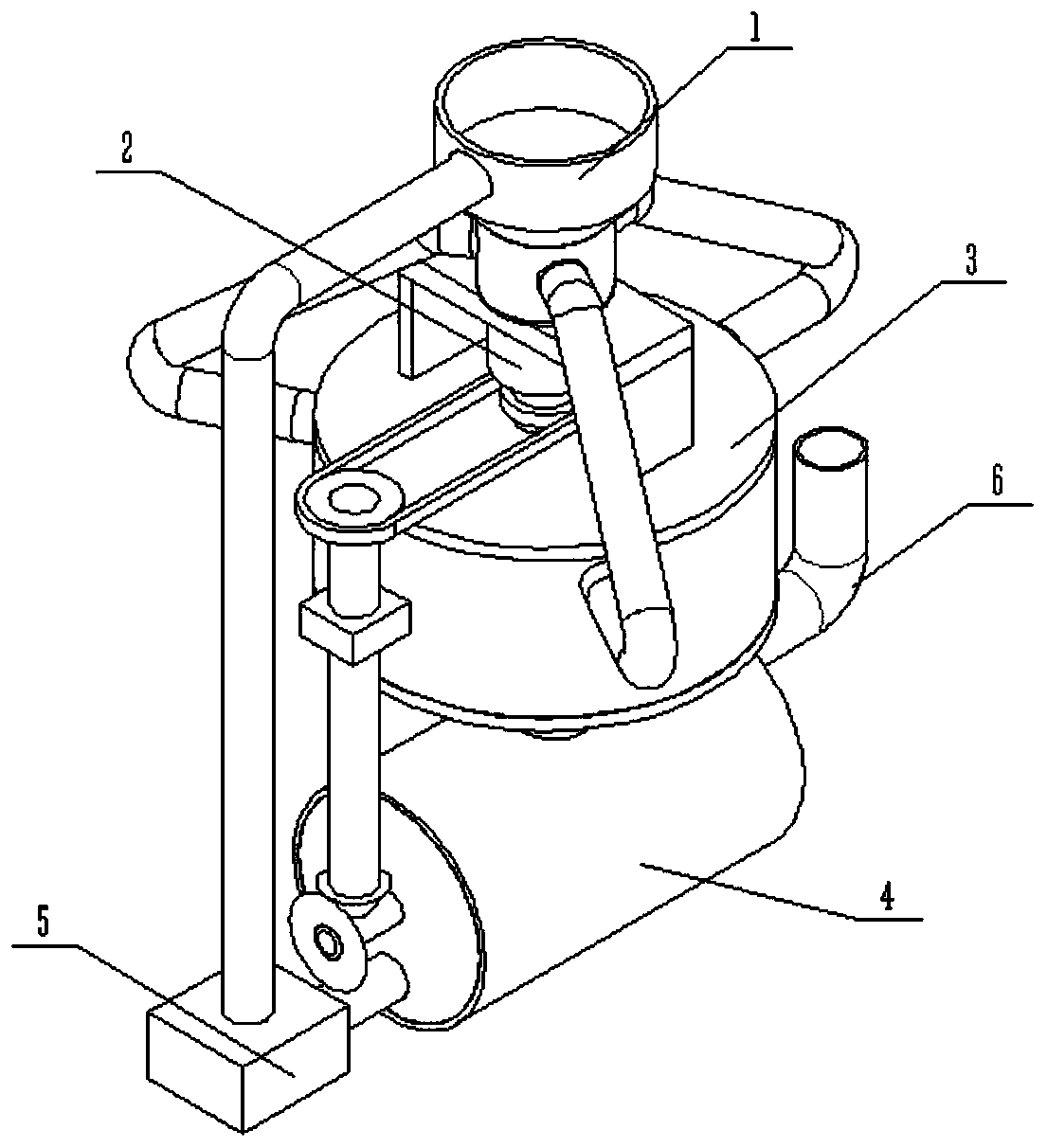

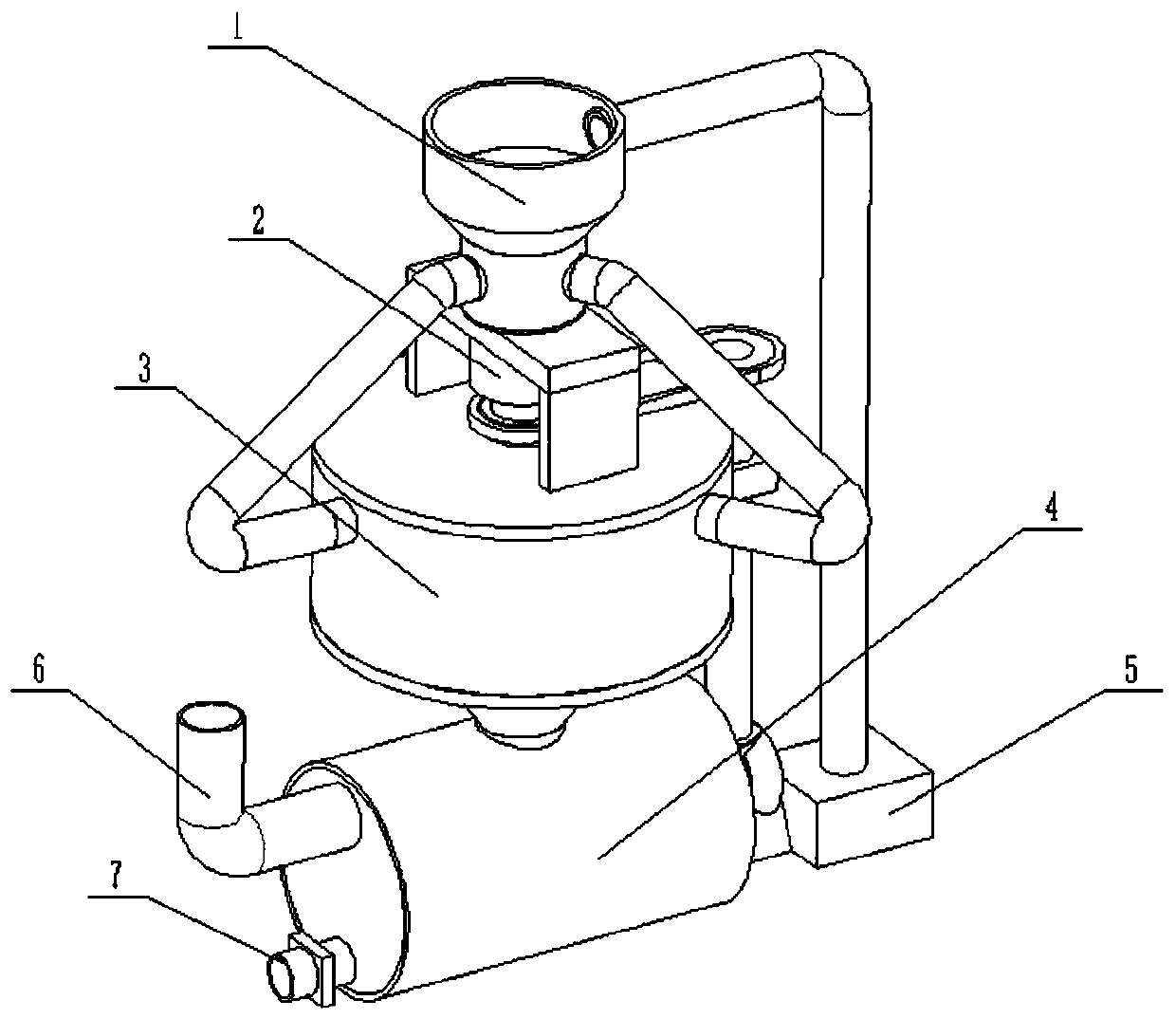

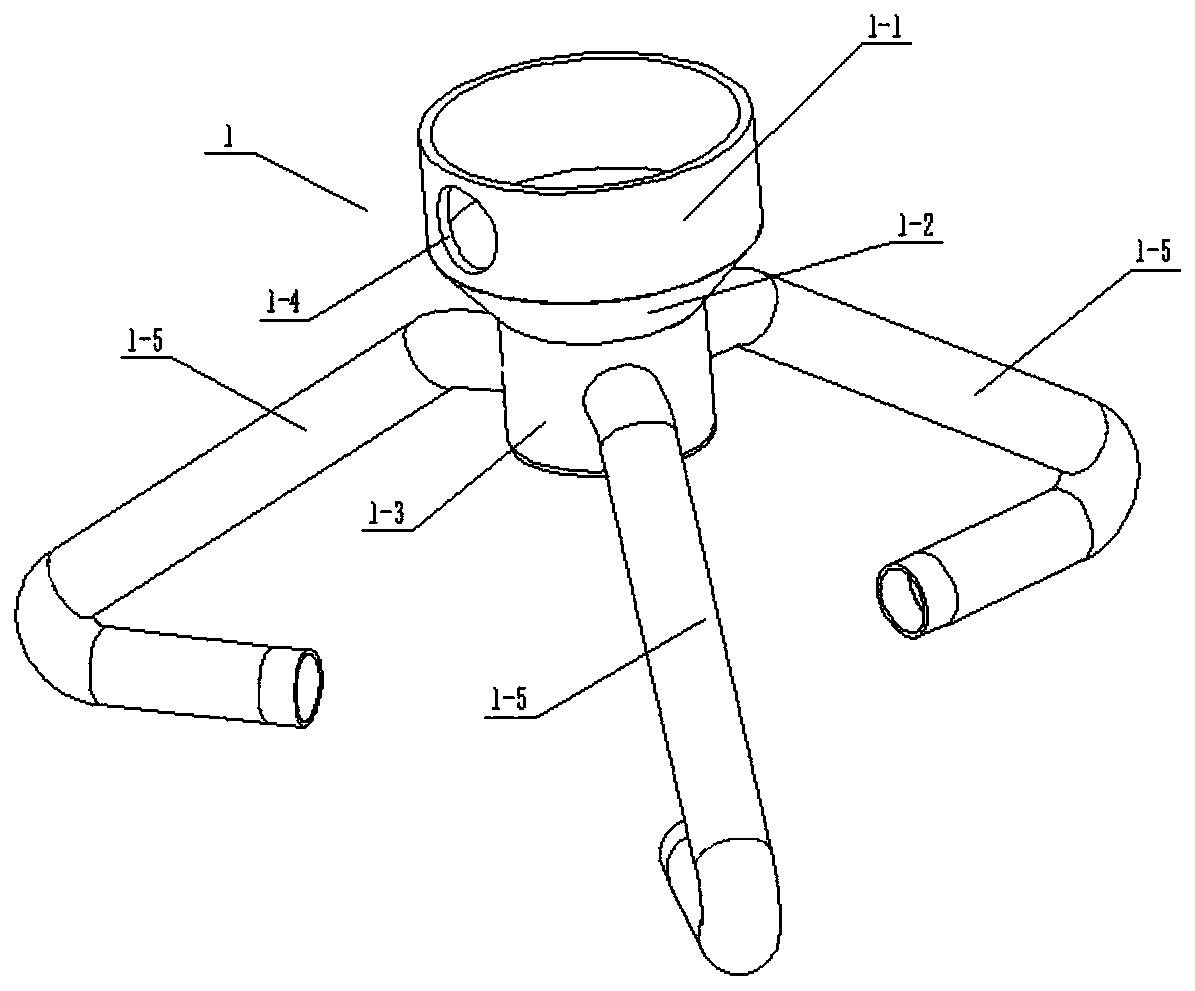

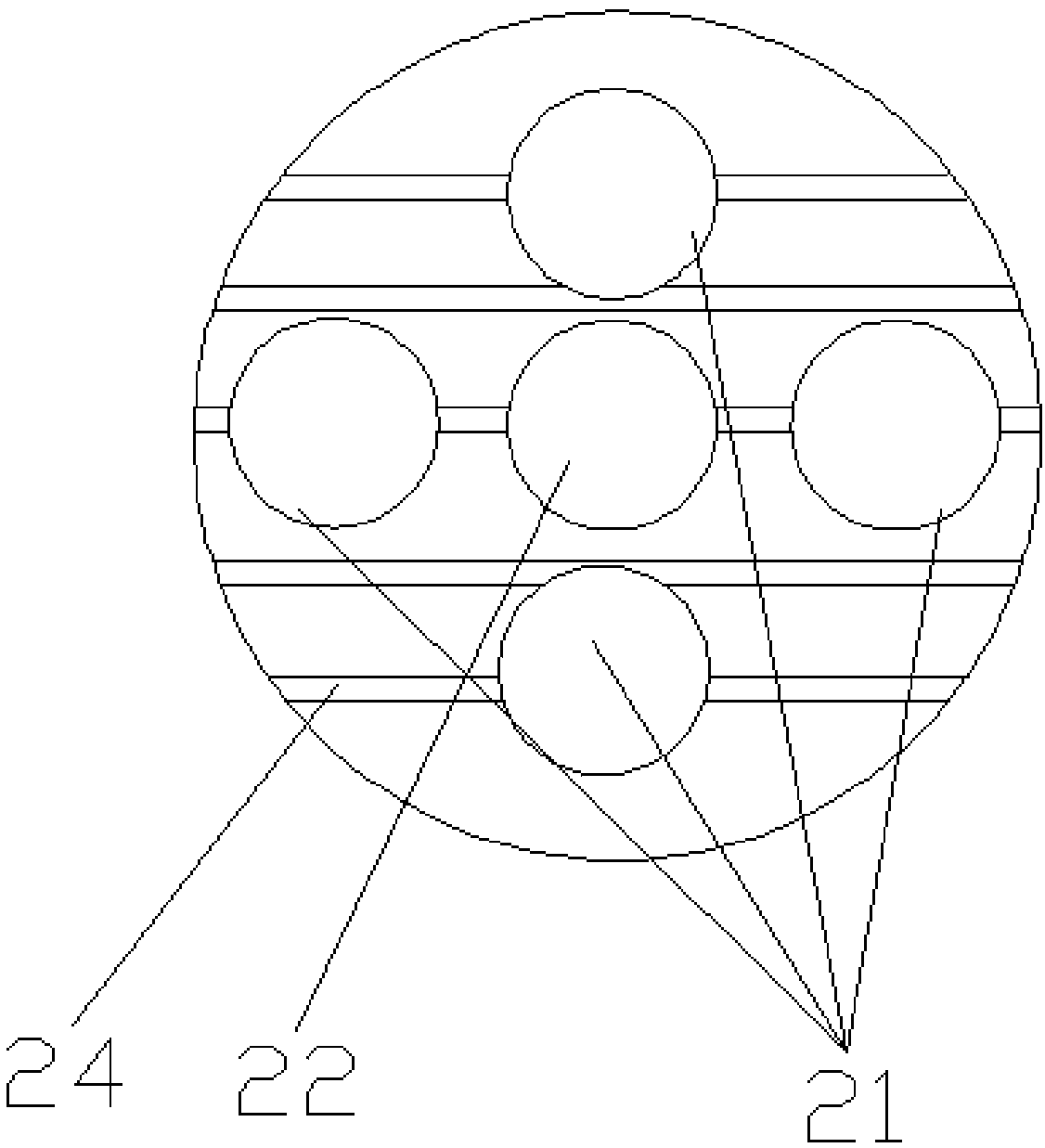

Circulation pulverizing device for device for promoting soil remediation through power ultrasounds

InactiveCN109731643AEfficient and rapid circulation stirring and crushingEven by forceMixersGrain treatmentsSoil remediationEngineering

The invention relates to the field of soil remediation, in particular to a circulation pulverizing device for a device for promoting soil remediation through power ultrasounds. The circulation pulverizing device comprises a circulation flow dividing pipe, a circulation pulverizer, a pulverization tank, a stirring tank, a circulation pump, a water inlet pipe and a recovery pipe with a valve; and the circulation flow dividing pipe comprises a circulating feeding hopper, an upper cone bucket, a flow dividing hopper, a circulating feeding hole and three flow dividing tubes, the circulating feedinghopper is fixedly connected to the upper end of the upper cone bucket, the lower end of the upper cone bucket is fixedly connected with the flow dividing hopper, and the upper cone bucket communicates with the circulating feeding hopper and the flow dividing hopper. The circulation pulverizing device has the beneficial effect that soil can be circulated, stirred and pulverized efficiently and quickly, the soil is evenly distributed into the pulverizing device, the device is even in stress, the pulverizing effect is even, and the cycle pulverizing efficiency is improved.

Owner:HEILONGJIANG LANDE ULTRASONIC TECH CO LTD

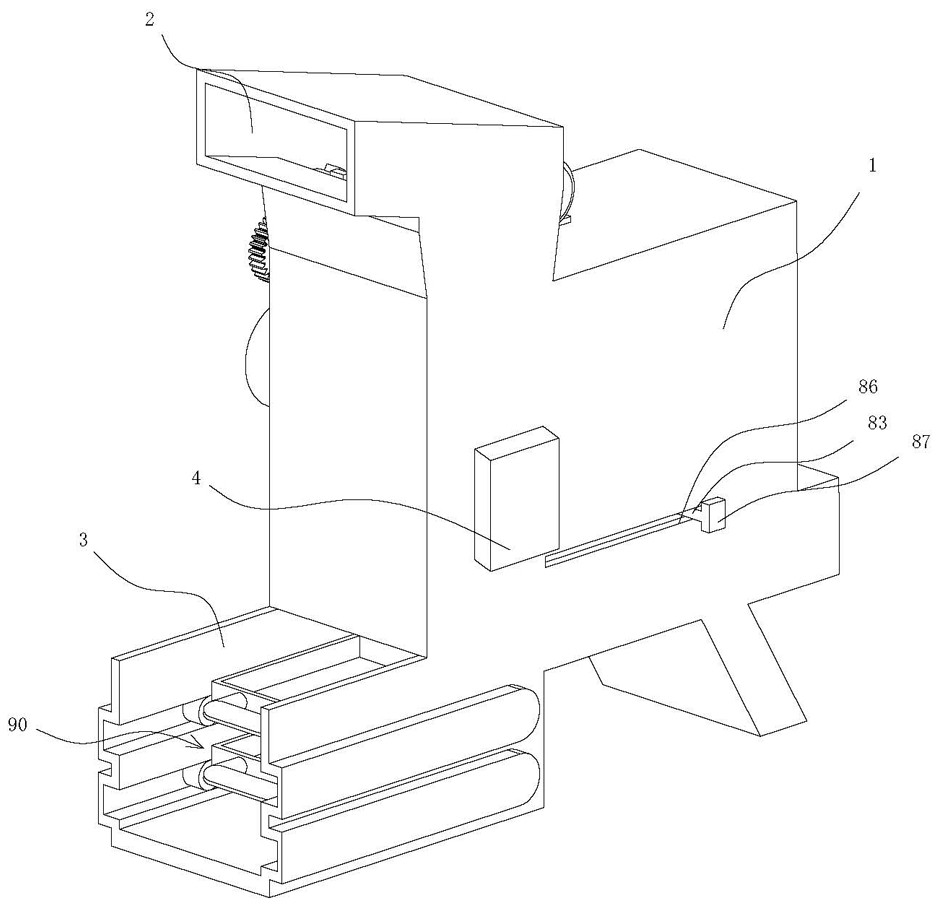

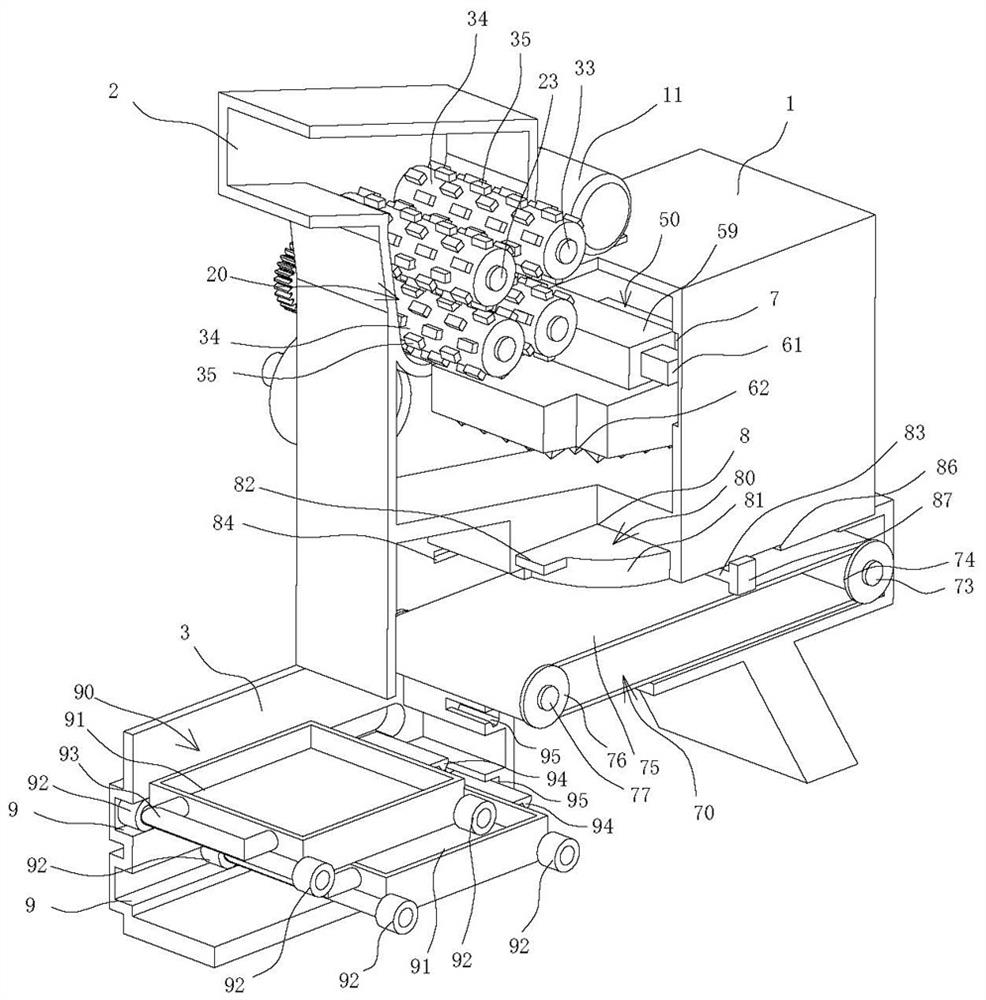

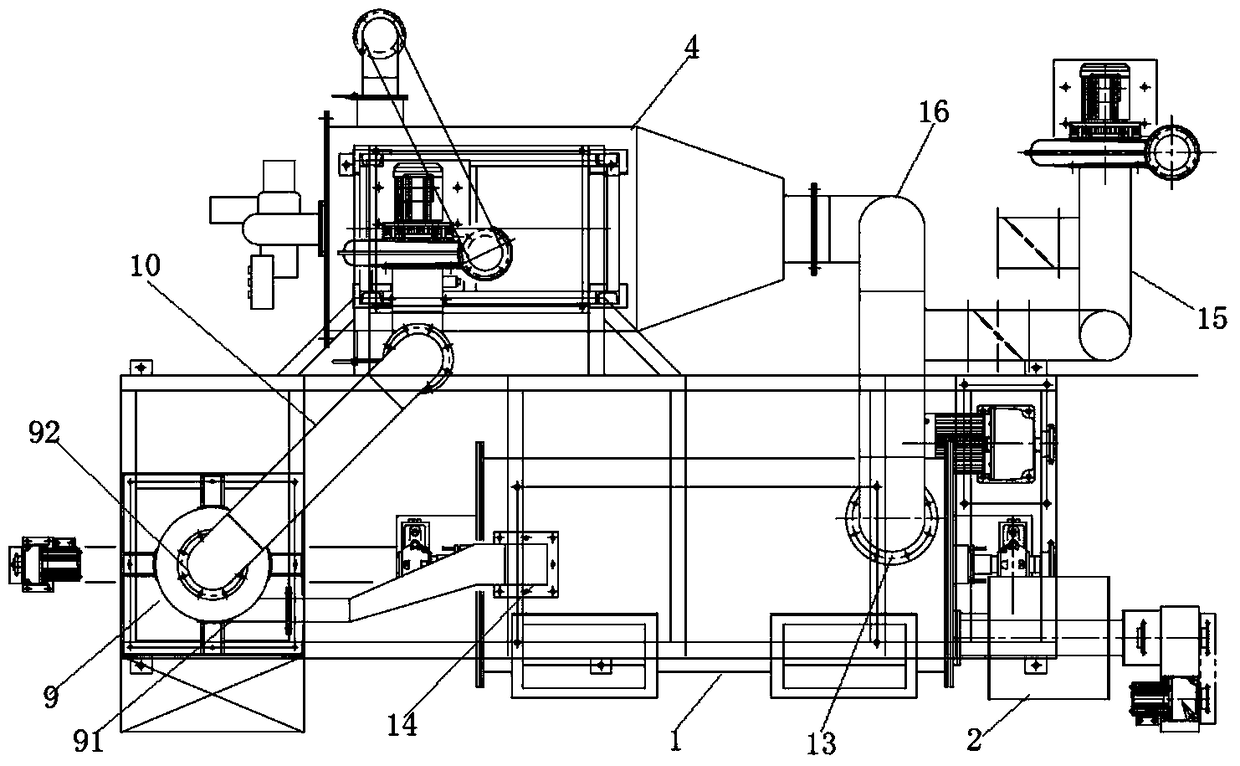

New energy automobile waste battery recovery device

ActiveCN111921673AEfficient crushingEasy to sieveWaste accumulators reclaimingCleaning using toolsNew energyBattery recycling

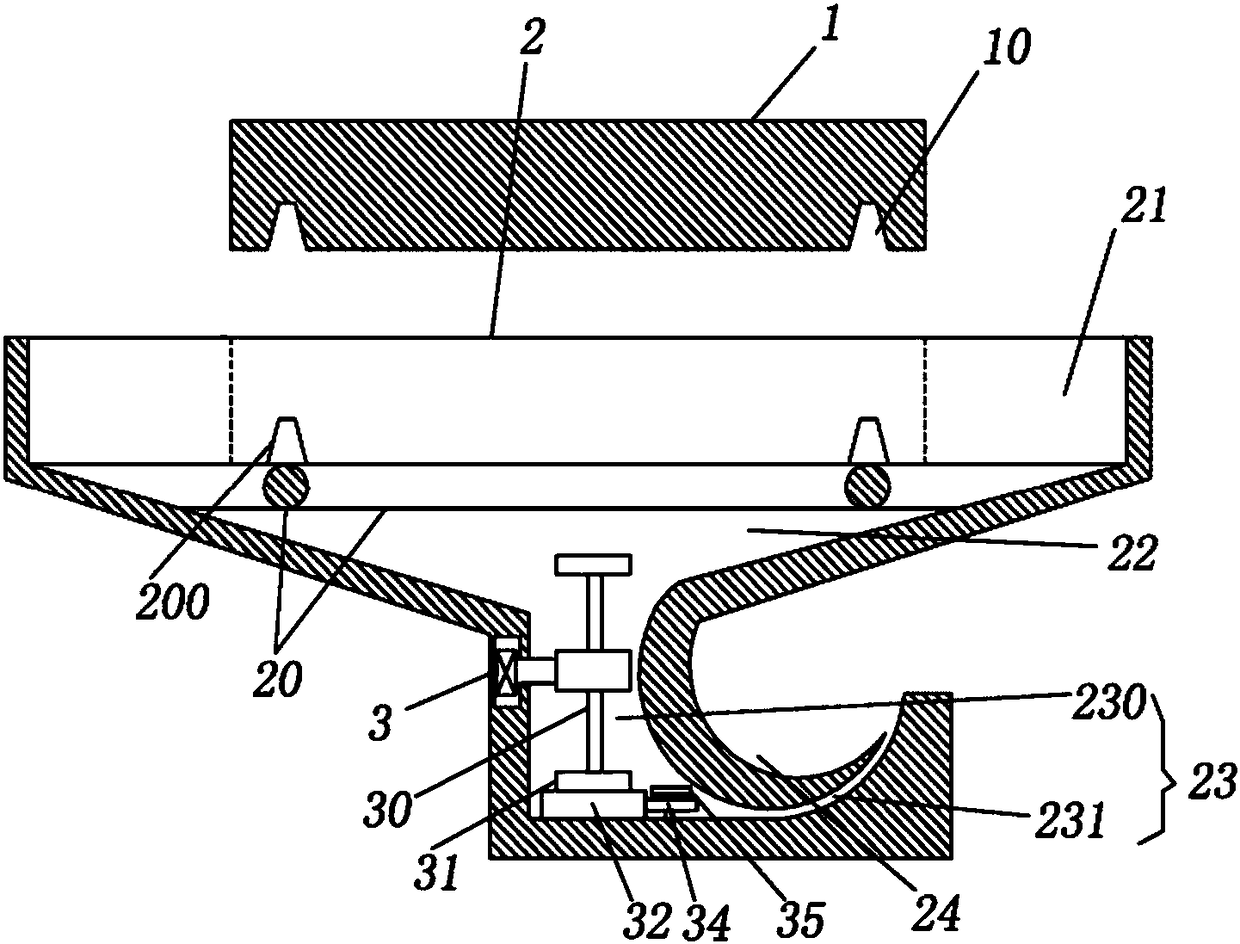

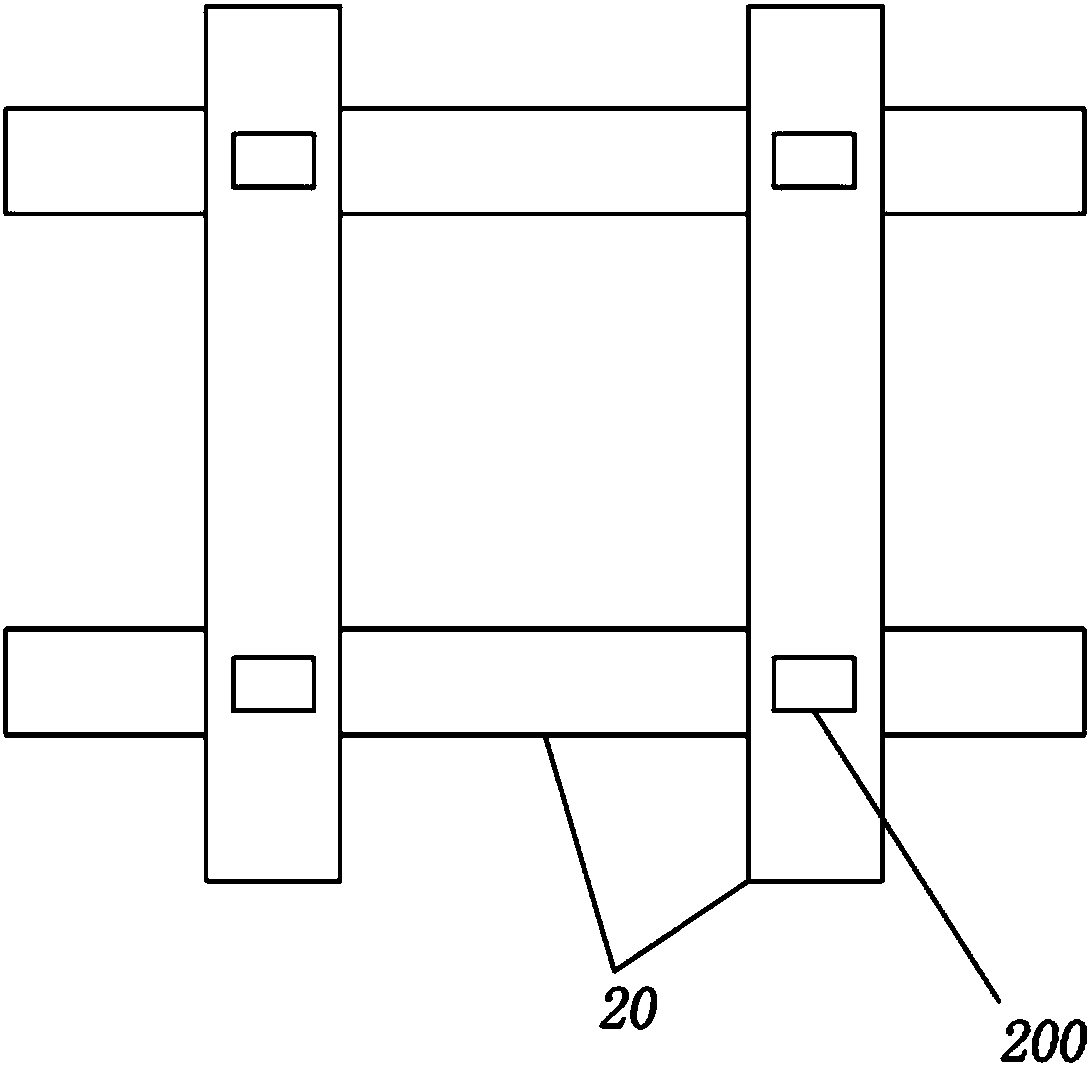

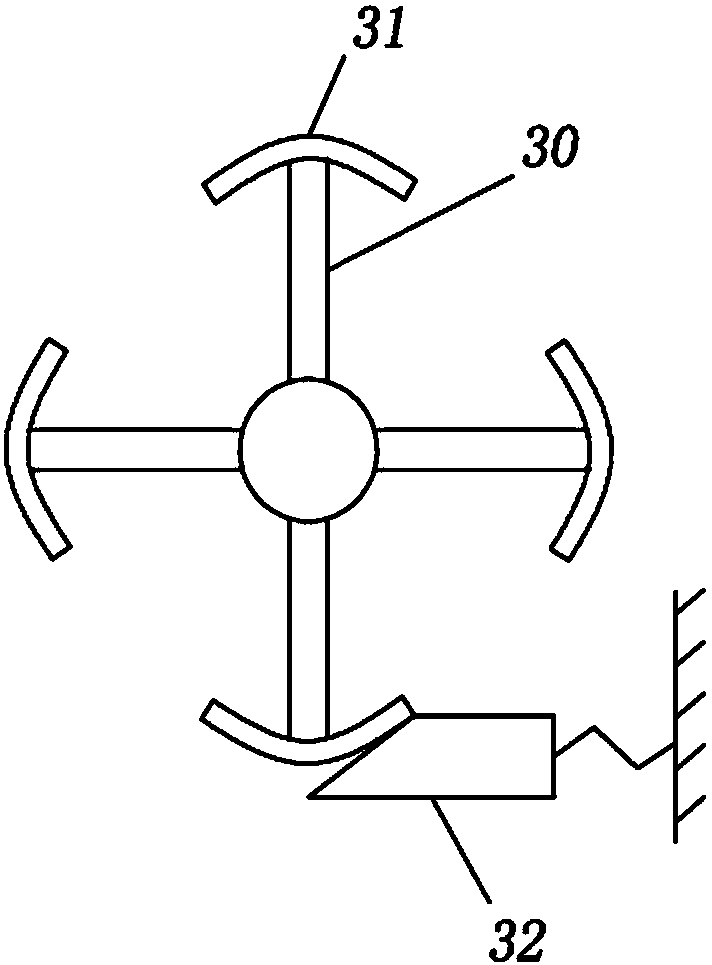

The invention discloses a new energy automobile waste battery recovery device which comprises a rack, wherein a feed inlet is formed in one end of the rack, a discharge hole is formed in the other endof the rack, and a discharge opening is formed in one side of the rack. The new energy automobile waste battery recovery device is characterized in that a power mechanism is arranged at one end of the rack, a crushing mechanism is arranged on one side of the power mechanism, an air flow screening mechanism is arranged on one side of the crushing mechanism, one end of the air flow screening mechanism is connected to the power mechanism, a smashing mechanism is arranged on one side of the air flow screening mechanism, a transfer mechanism is arranged on the other side of the power mechanism, amagnetic screening mechanism is arranged on one side of the transfer mechanism, and a storage mechanism is arranged at the discharge hole. The new energy automobile waste battery recovery device has the beneficial effects that the new energy automobile waste battery recovery device can crush and screen a waste battery periodically; primary screening can separate impurities such as diaphragm paperfragments in battery fragments effectively, and secondary screening can separate impurities such as metal materials with recovery value and crushed battery housings effectively, so that the recovery quality and the work efficiency of the new energy automobile waste battery recovery device are improved effectively.

Owner:SHAANXI RUIKAI ENVIRONMENTAL PROTECTION & TECH CO LTD

Powder coating crushing device with cooling function

The invention provides a powder coating crushing device with the cooling function. The powder coating crushing device comprises a crushing box, a feeding device, a discharging port and a supporting part at the bottom of the crushing box; the position below the feeding device is provided with a first crushing area, the first crushing area comprises a vertical shell, a material filter plate and a rotating body, a first crushing cutter is arranged on the vertical shell, the bottom of the vertical shell is connected with a rotary shaft, a second crushing cutter is arranged on the rotating body, the rotary shaft and the bottom of the rotating body are connected with a motor, a first level crushing area and a second level crushing area are formed between the inner side wall of the crushing box and the outer side wall of the vertical shell, a first crushing cavity is formed under the secondary crushing area, a funnel-shaped second crushing cavity is formed under the first crushing cavity, thefunnel-shaped second crushing cavity is connected with a discharging port, a Peltier element is attached to the outer side wall of the crushing box, a temperature detector is arranged on the rotatingbody, and the temperature detector is electrically connected with the Peltier element. The powder coating crushing device cannot only achieve multi-level crushing of the powder coating to make the powder coating reach the expected grain size quickly, but also can timely absorb the heat generated by the powder coating in the crushing and cutting process.

Owner:广东涂亿新材料科技有限公司

Blasting demolition method for reinforced concrete water retaining cofferdam

InactiveCN108132004ASafe blasting demolitionSafe useBlastingFoundation engineeringDetonationReinforced concrete

The invention relates to blasting demolition method for a reinforced concrete water retaining cofferdam, and belongs to the technical field of blasting engineering. The method includes the steps of 1)arranging, and drilling blastholes of a seepage-proofing pile, a top ring beam, a middle ring beam, a bottom ring beam and an anchor block; 2) charging; 3) arranging a blasting network and detonationmethods; 4) blasting and the like. Various detonation methods are adopted, and blasting demolition can be safely and efficiently conducted on the reinforced concrete water retaining cofferdam; various charging methods are adopted, blasting energy can be effectively utilized, crushing effects are smaller, and lumpiness is smaller; segmentation arrangement of the blastholes is adopted to reduce single-hole dose, blasting vibration, blasting flying stones and water-hammer waves are effectively controlled, and blasting dust is reduced; steps are simple, operation is easy, and the method is suitable for large-area popularization and application.

Owner:GUIZHOU XINLIAN BLAST ENG GRP

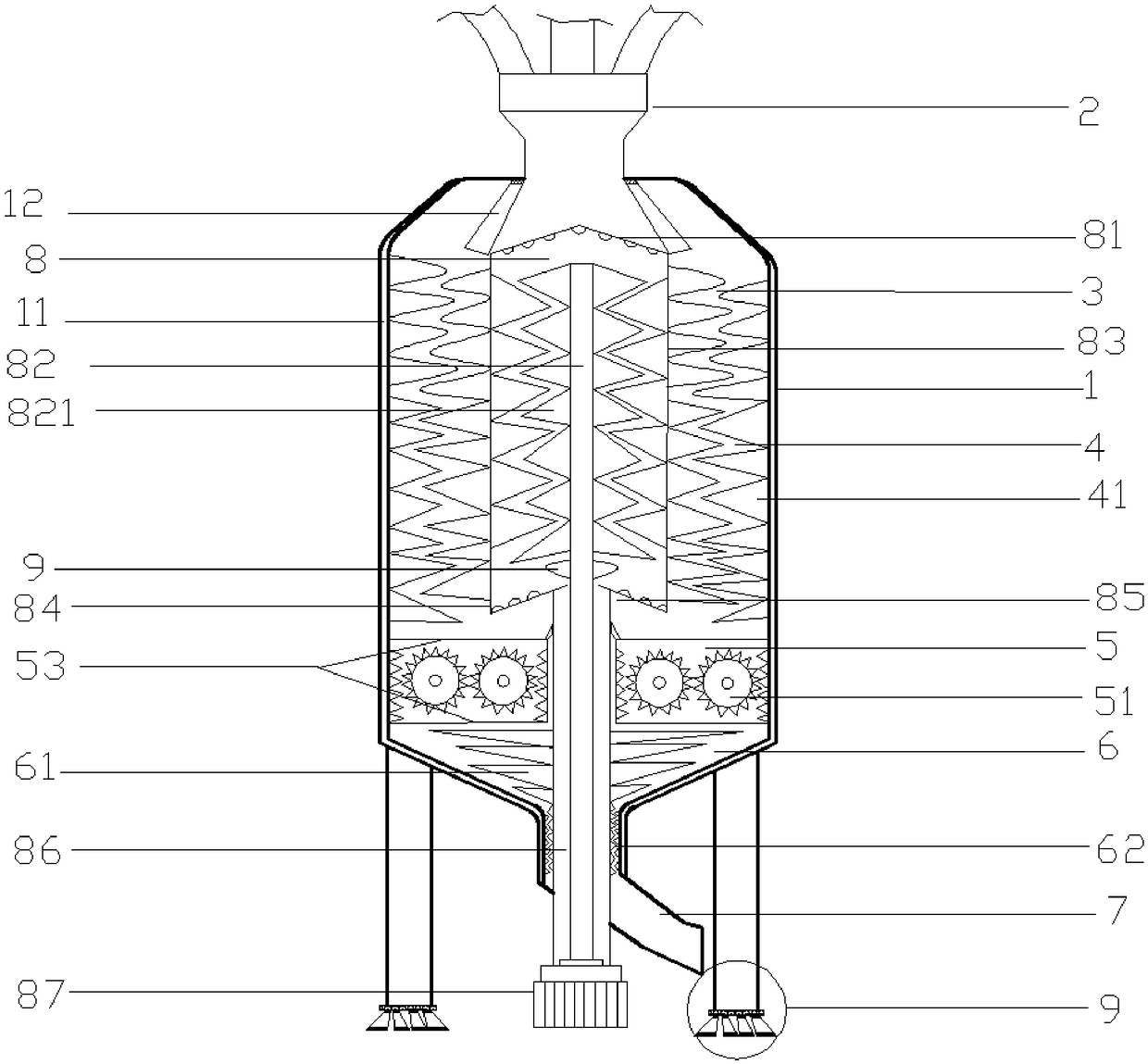

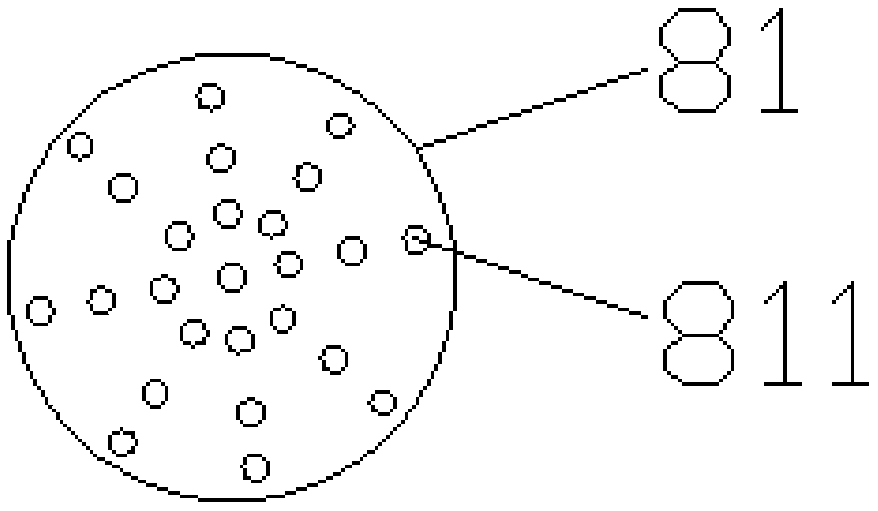

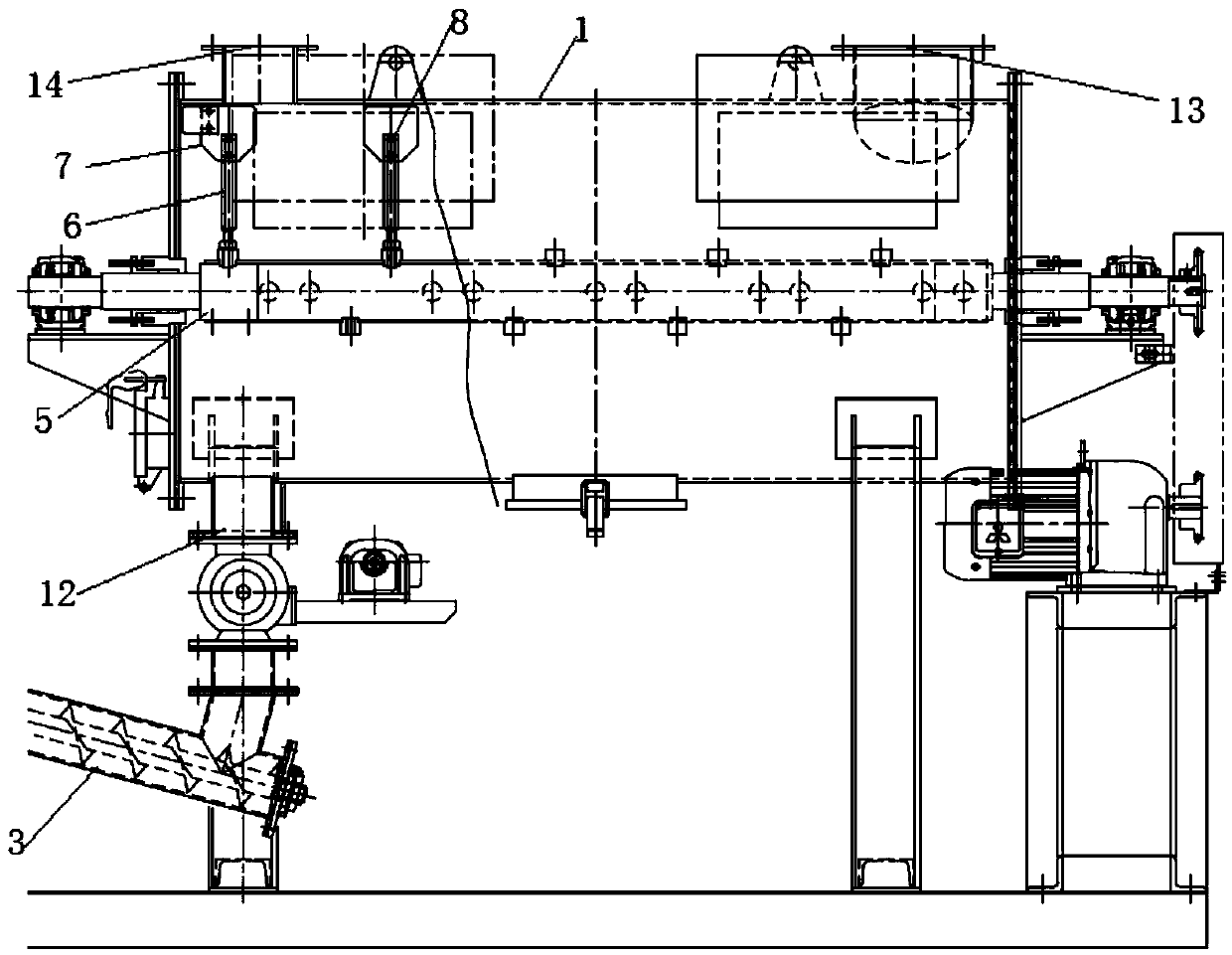

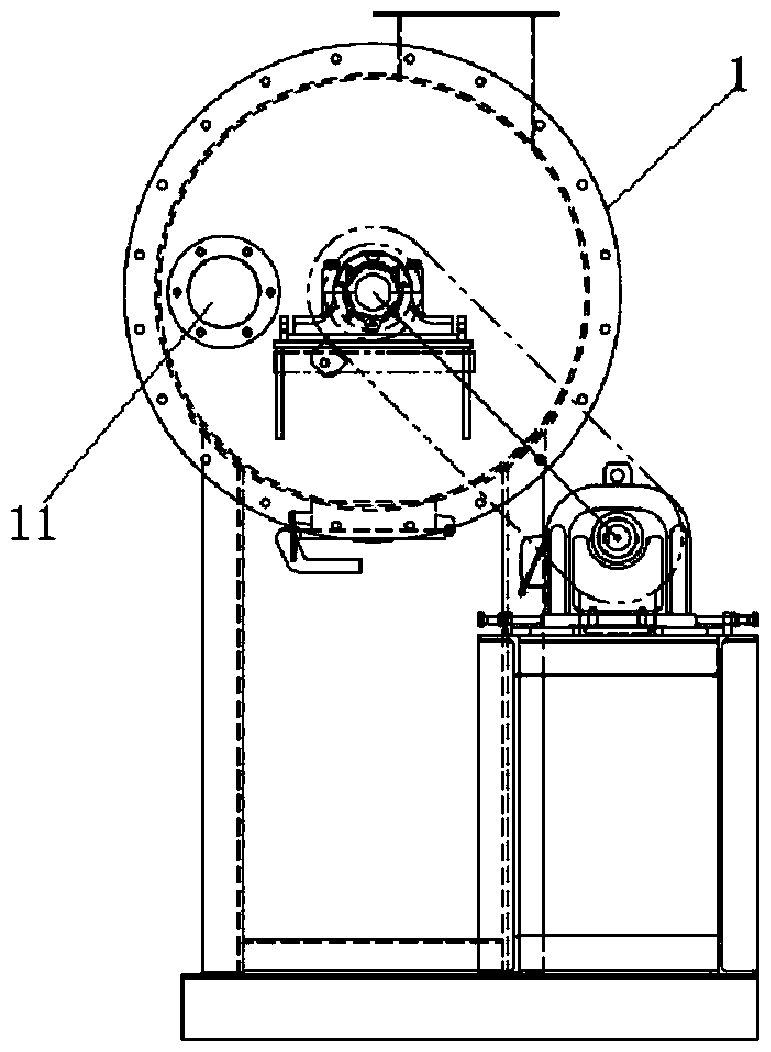

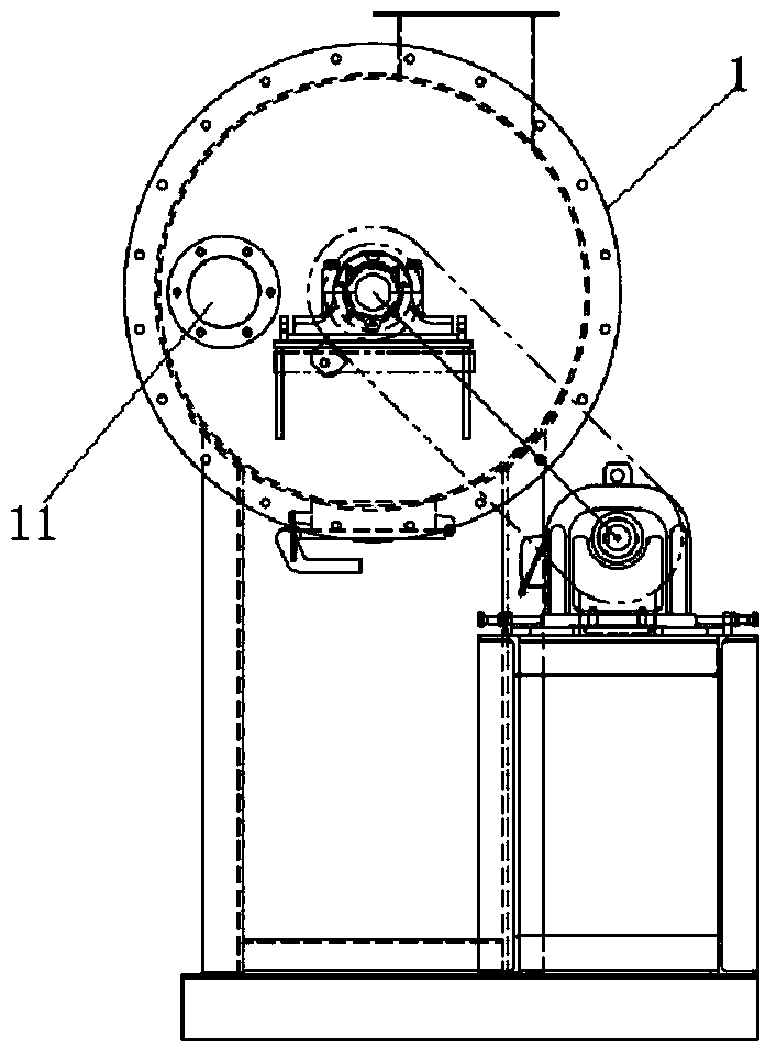

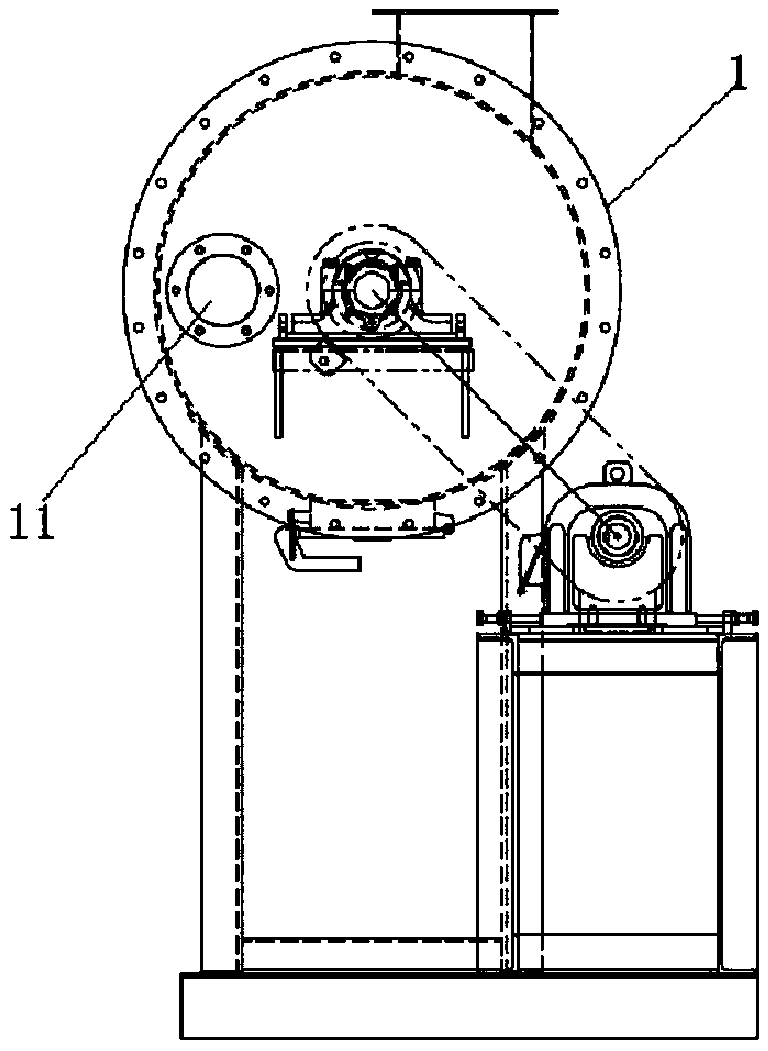

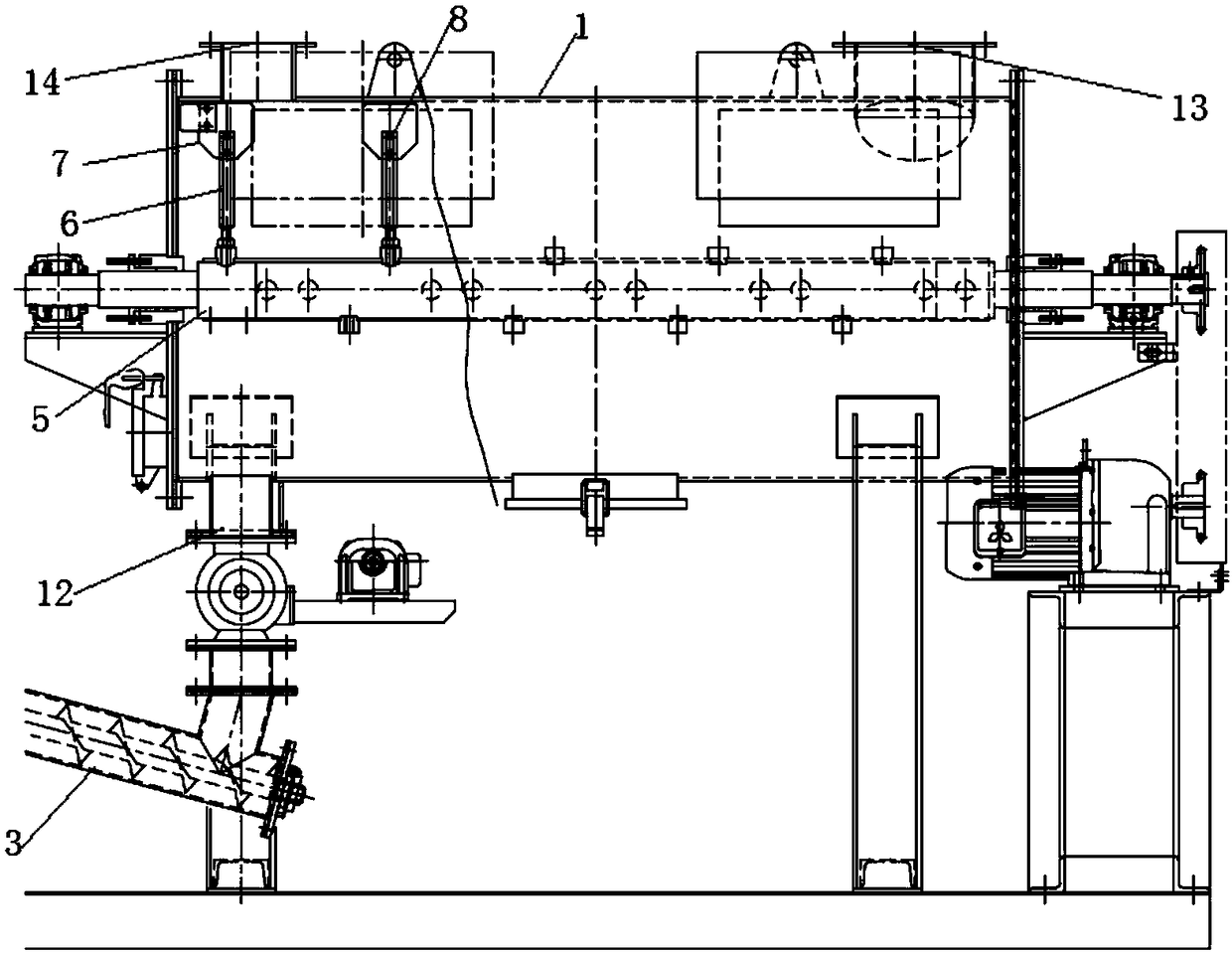

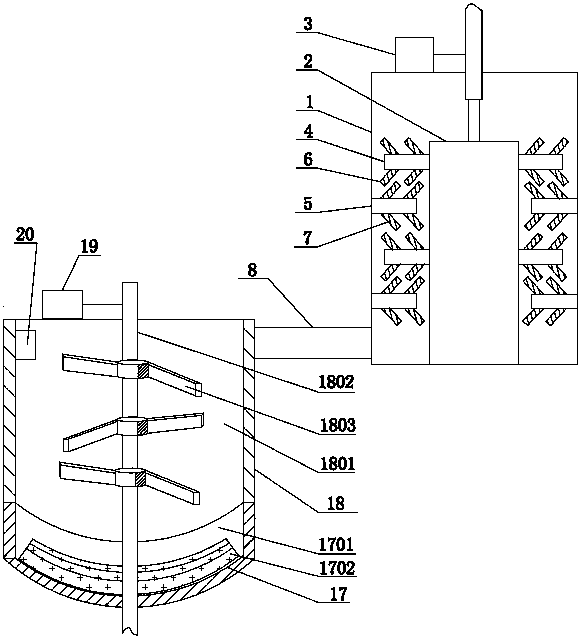

Drying device

ActiveCN105387712AKeep dryStir wellSludge treatment by de-watering/drying/thickeningSludge dryingEngineeringProduct gas

The invention discloses a drying device. The drying device comprises a furnace body, a charging device for charging a material into the furnace body, a collecting device for collecting a dried material in the furnace body, an air supply device for inducing external hot gas into the furnace body by a first gas inlet, and a stirring device for stirring and pulverizing the material, wherein the stirring device comprises a rotary shaft which penetrates through a cavity of the furnace body, the rotary shaft is provided with a venting cavity provided with a plurality of gas nozzles, the gas spraying direction of the gas nozzles is misaligned and not parallel with the stirring direction of the stirring device and the stirring direction of blades, during material drying, the hot gas is induced into the cavity of the furnace body by the first gas inlet, and the rotary shaft rotates to drive a stirring assembly on the rotary shaft to continuously stir the material along the axial direction and radial direction of the rotary shaft, so that the material is turned over in the furnace body along the axial direction and radial direction of the rotary shaft, the stirring time of the material is prolonged, and a convection heat exchange area between the material and the hot gas is increased. In addition, the stirring assembly can pulverize the material to form a material of smaller particles, thus further increasing the convection heat exchange area between the material and the hot gas and improving the drying efficiency and drying effect of the material.

Owner:汪振朴

Sludge treatment system

ActiveCN105502881ASmoothly fall intoImprove space utilizationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningEngineeringTreatment system

The invention relates to a sludge treatment system which comprises a conveying device, a water removal structure and a drying device. The drying device comprises a furnace body, a feed device used for adding materials into the furnace body, a material collection device used for collecting the dried materials in the furnace body, an air supply device used for leading external hot air into the furnace body through a first air inlet, and a stirring device used for stirring and smashing the materials. When the materials are dried, hot air is led into a cavity of the furnace body through the first air inlet, a second rotating shaft rotates and drives a stirring assembly on the second rotating shaft to unceasingly stir the materials in the radial direction and the axial direction of the second rotating shaft, and therefore the materials can roll in the axial direction and the radical direction of the second rotating shaft in the furnace body, the time during which the materials are stirred is prolonged, and the convective heat exchange area of the materials and hot air is enlarged. In addition, the materials can be smashed through the stirring assembly, materials with smaller particles can be formed, the convective heat exchange area of the materials and hot air is further enlarged, and the material drying efficiency and effect are improved.

Owner:GUYUAN XINYUE HALAL FOOD +1

Multi-stage crushing device of powder coating

The invention provides a multi-stage crushing device of powder coating. The multi-stage crushing device includes a crushing box, a feeding device, a discharging port and a supporting part of the bottom of the crushing box, a first crushing zone is arranged on the lower part of the feeding device, the first crushing zone includes a vertical shell, a filter plate and a rotating body, the vertical shell is provided with a first crushing cutter, and the bottom of the vertical shell is connected with a rotating shaft; the rotating body is provided with a second crushing cutter, the bottoms of the rotating shaft and the rotating body are connected with a motor, and a first-stage crushing zone and a second-stage crushing zone are formed between the inner side wall of the crushing box and the outer side wall of the vertical shell; and a first screening zone is arranged on the lower part of the second-stage crushing zone, a crushing wheel is arranged on the lower part of the first screening zone, and a second screening zone is arranged under the crushing wheel. According to the multi-stage crushing device of powder coating, by arranging two screening zones, the crushing process is efficientand targeted, powder coating with different particle sizes can be crushed more fully and evenly, and the customer need of powder coating with the small particle size can be met.

Owner:佛山市涂亿装饰材料科技有限公司

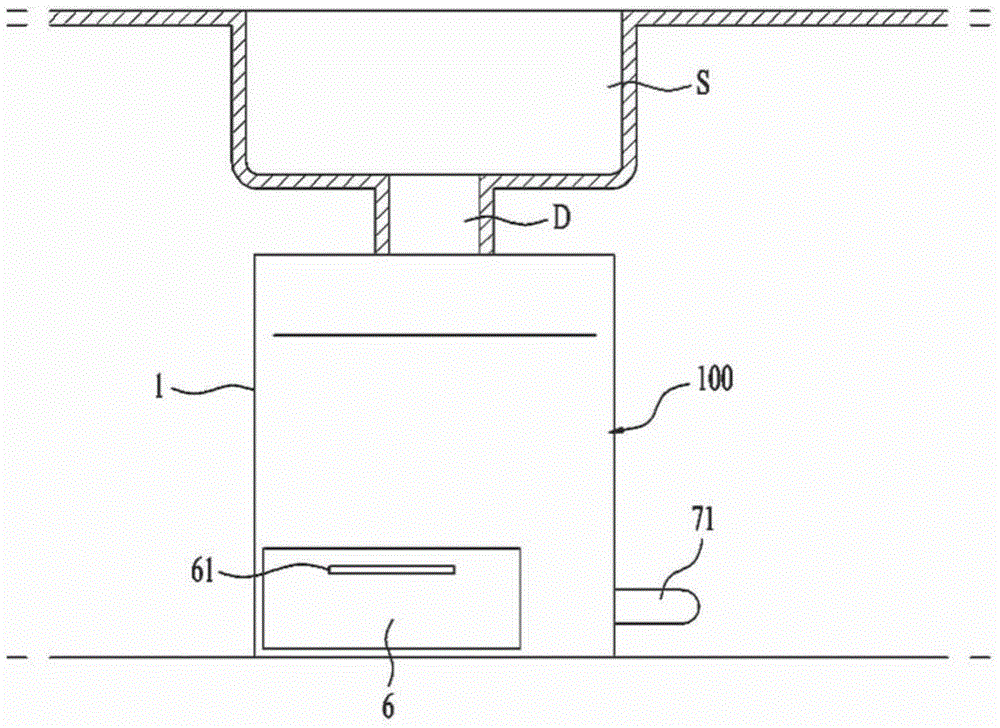

Traditional Chinese medicine crushing machine

InactiveCN110918218AUniform crushing effectEasy to operateGrain treatmentsKnife bladesIndustrial engineering

The invention discloses a traditional Chinese medicine crushing machine. The crushing machine comprises a first adjusting frame and a second adjusting frame, a first bearing block is mounted at the top end of the first adjusting frame, a second bearing block is mounted at the top end of the second adjusting frame, a crushing shaft is mounted between the first bearing block and the second bearing block, a crushing blade is mounted outside the crushing shaft, the crushing blade is located in a crushing chamber of the crushing machine body, and a machine cover is hinged to the outer part of the crushing machine body. A handle is mounted on the machine cover, a leaking groove is formed in the bottom of the crushing machine body, and the leaking groove is manually opened and closed by using a sealing plate. A supporting frame is installed in the middle position between the first adjusting frame and the second adjusting frame, an inclined transition funnel is installed on the supporting frame, a material baffle is installed between the leaking groove and the inclined transition funnel, a supporting plate is installed at the bottom between the first adjusting frame and the second adjusting frame, a traditional Chinese medicine storage box is installed at the upper end of the supporting plate, and a material leakage hole of the inclined transition funnel is aligned with the opening part of the traditional Chinese medicine storage box.

Owner:泗县玖知和科技信息咨询有限公司

Agricultural planting fertilization device

PendingCN110809928AAvoid cakingUniform crushing effectSpadesPloughsRotational axisAgricultural engineering

The invention discloses an agricultural planting fertilization device which comprises a box. A first bin and a second bin are formed in the box from top to bottom, the first bin is communicated with the second bin, a first driving motor is fixed at the top of the box through a bolt, a rotating shaft is rotatably arranged at the output end of the first driving motor, a crushing rod is welded at oneend of the rotating shaft in the first bin, a connecting rod is welded on the outer wall of the rotating shaft, the other end of the connecting rod is welded with the crushing rod, and spiral vanes are welded on the outer wall of the rotating shaft. According to the device, fertilizers can be crushed by the crushing rod, caking of the fertilizers is avoided, the fertilizers can be uniformly distributed and discharged by a distributing disk and are uniformly spread by rotating a spreading disk, a soil turning rod can be moved in soil, so that the fertilizers can enter the soil, a user screws two threaded sleeves, the height of a screw can be adjusted, and soil turning depth is adjusted.

Owner:肖尚元

A new energy vehicle waste battery recycling device

ActiveCN111921673BEfficient crushingEasy to sieveWaste accumulators reclaimingCleaning using toolsElectrical batteryNew energy

The invention discloses a waste battery recovery device for new energy vehicles, which comprises a frame, one end of the frame is provided with a material inlet, the other end of the frame is provided with a discharge port, and one side of the frame is provided with a discharge port, which is characterized in that : One end of the frame is equipped with a power mechanism, one side of the power mechanism is equipped with a crushing mechanism, one side of the crushing mechanism is equipped with an airflow sieving mechanism, one end of the airflow sieving mechanism is connected with the power mechanism, and one side of the airflow sieving mechanism is equipped with a crushing mechanism. The other side of the power mechanism is provided with a transmission mechanism, one side of the transmission mechanism is provided with a magnetic sieving mechanism, and a material storage mechanism is provided at the discharge port. Sieve treatment, primary sieving can effectively separate impurities such as diaphragm paper fragments in battery debris, and secondary sieving can effectively separate metal materials with recycling value from broken battery casings and other impurities, effectively improving The recovery quality and working efficiency of the present invention.

Owner:SHAANXI RUIKAI ENVIRONMENTAL PROTECTION & TECH CO LTD

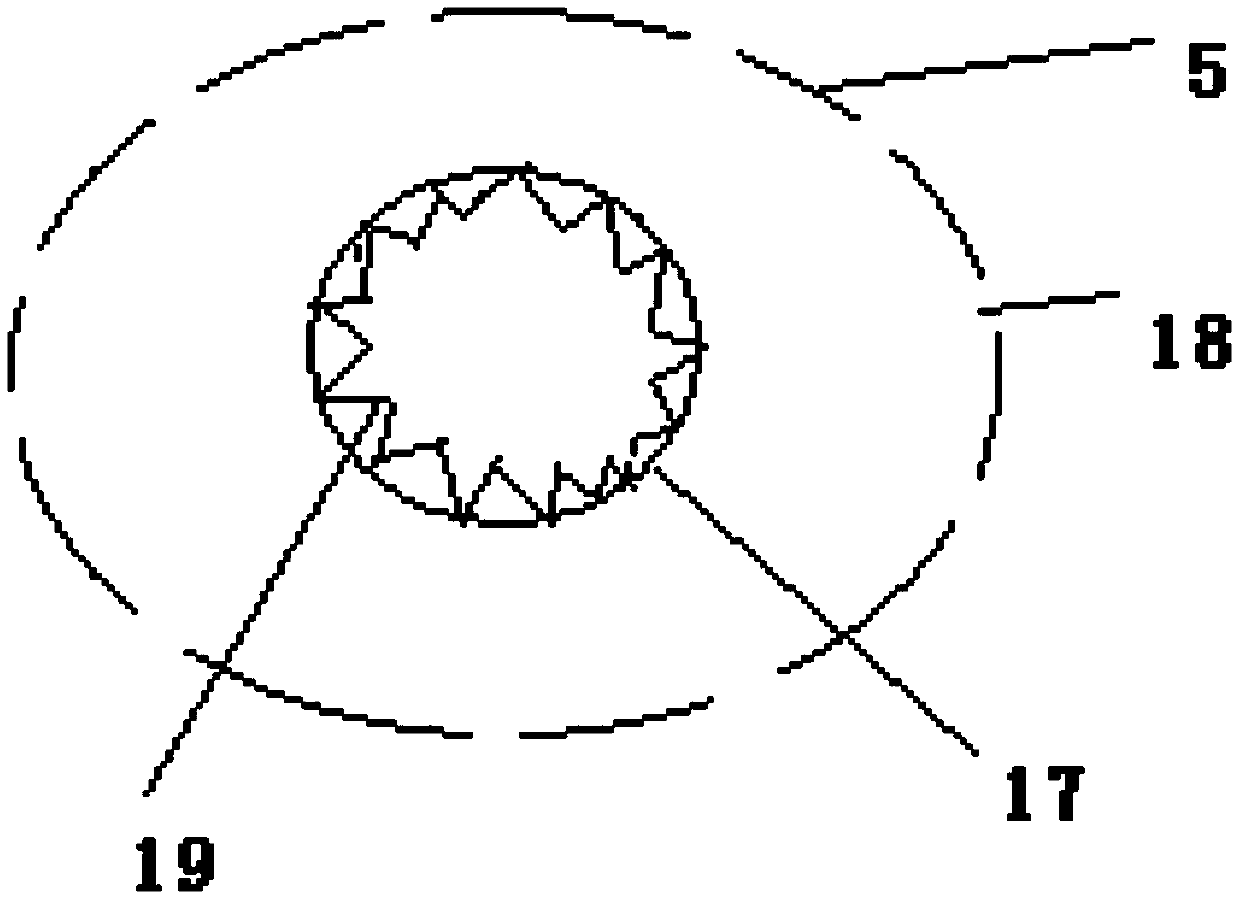

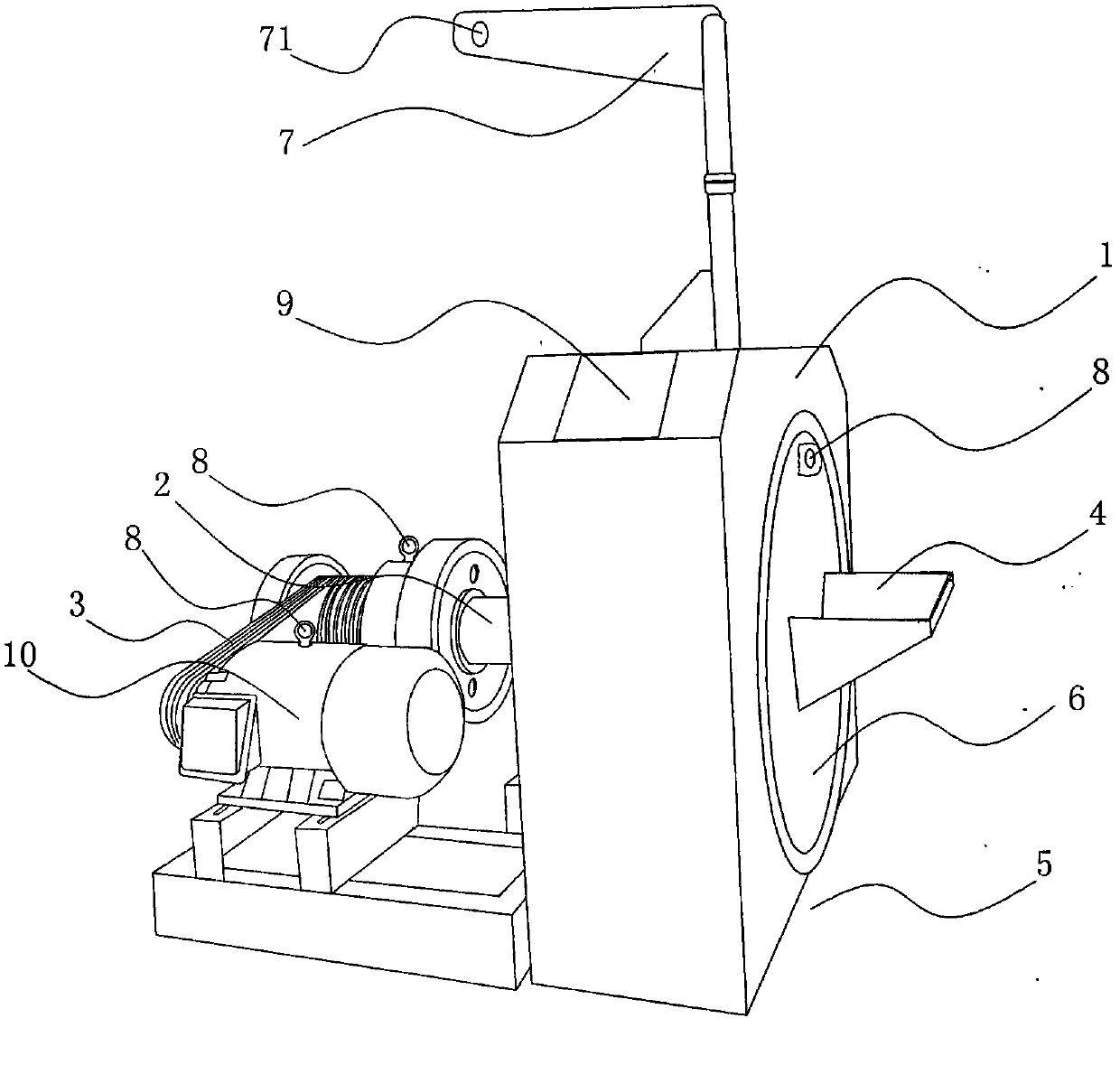

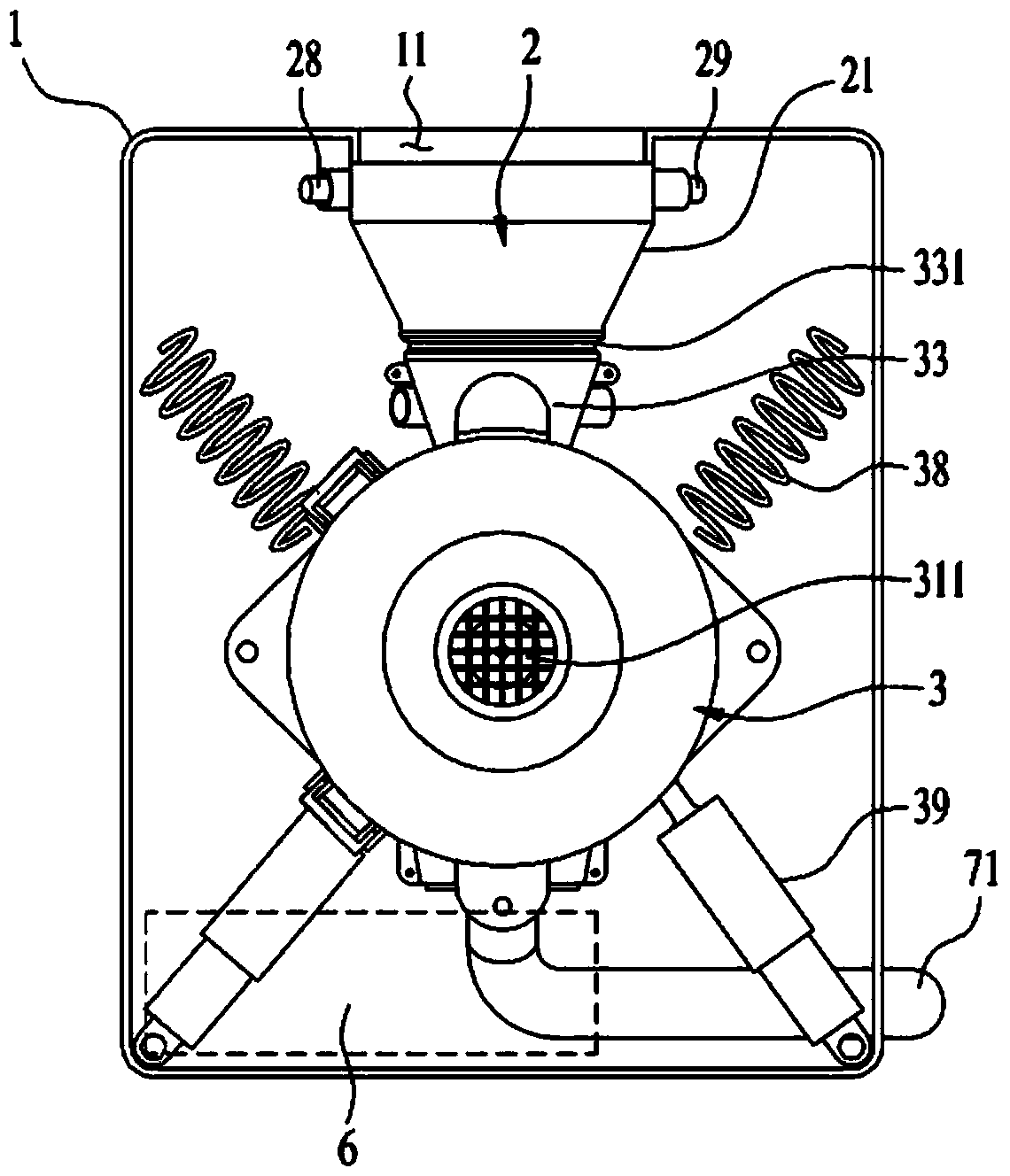

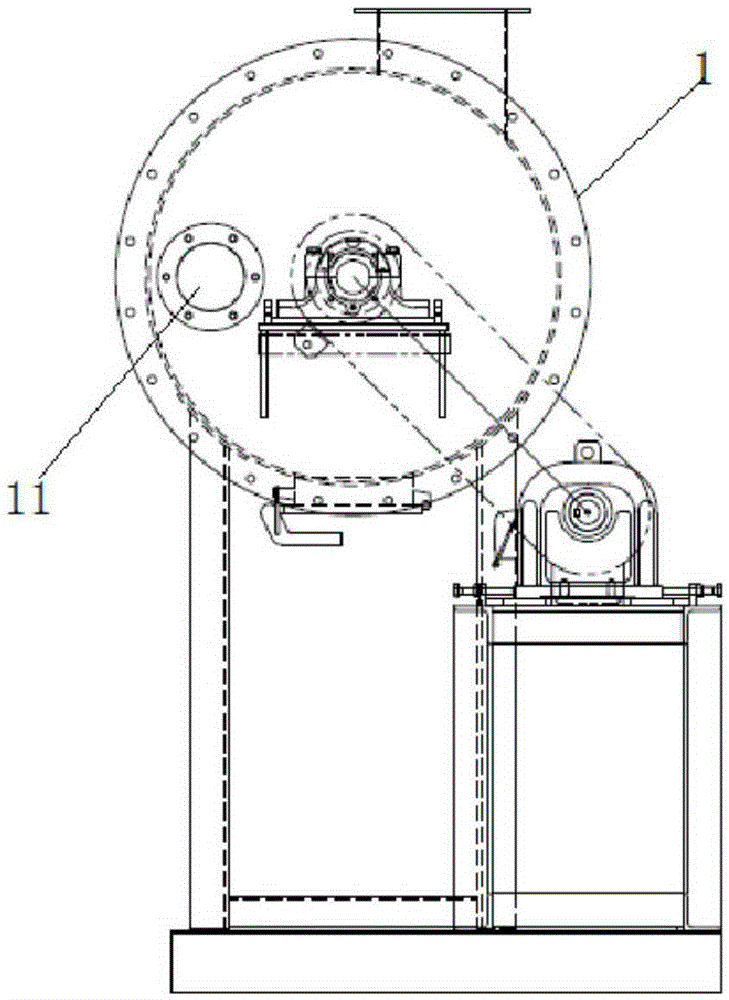

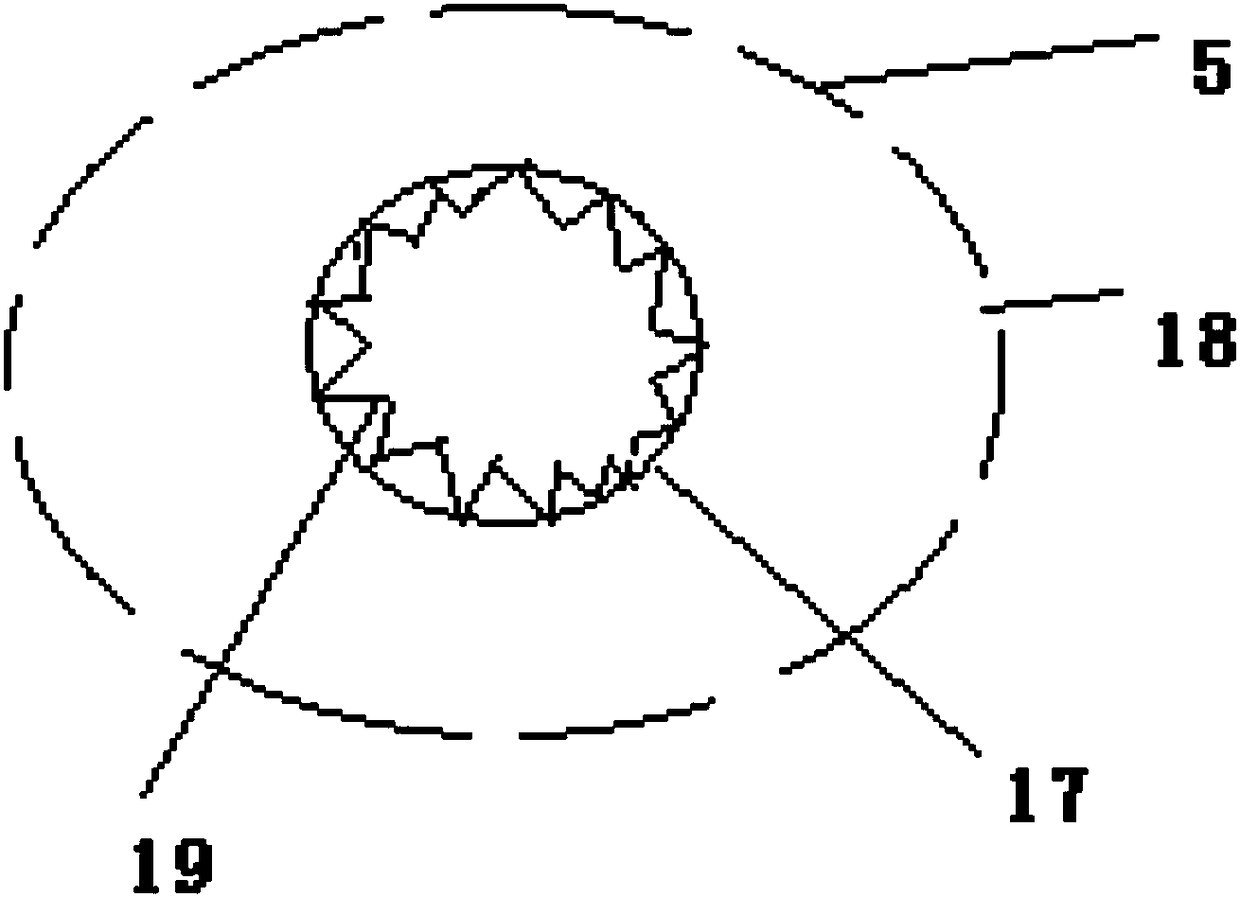

Grinder

InactiveCN103372491ANot easy to wearFierce collisionGrain treatmentsEngineeringMechanical engineering

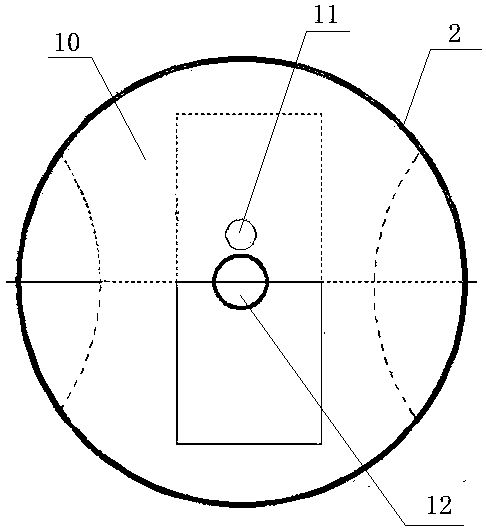

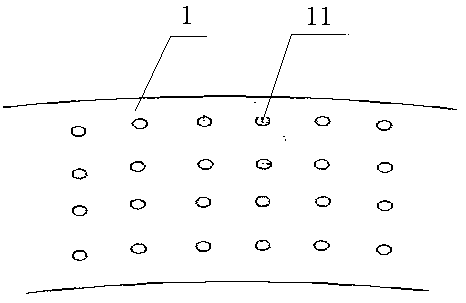

The invention discloses a grinder which is particularly suitable for grinding shale and coal gangues. An existing grinder can perform grinding in a manner of knocking by a mechanical part and the uniform grinding is difficultly guaranteed by the knocking manner; the mechanical part is very easy to abrade. The grinder comprises an enclosure and rotary shafts; the rotary shafts stretch into the enclosure; the enclosure is internally provided with a rotary table I and a rotary table II; two rotary shafts are arranged and respectively comprise a rotary shaft I and a rotary shaft II; the rotary table I and the rotary table II are respectively connected with the rotary shaft I and the rotary shaft II; the edges of the rotary table I and the rotary table II are provided with a plurality of rollers. The rollers are rotated to further drive raw materials entering the enclosure to rotate so that the raw materials are collided and grinded with one another; not only can the grinding effect be uniform, but also the mechanical part is hard to abrade.

Owner:徐正才

Food waste treatment device

InactiveCN105312304BUniform crushing effectSolid waste disposalDrying solid materials without heatEngineeringEnvironmental engineering

The invention provides a food waste processing device that can crush, dehydrate and dry food waste, including: a cover, which forms a space for dehydration and drying of food waste, and forms an inlet and outlet for inputting food waste. A discharge port for dehydrated and dried food waste; a cylindrical dehydration part inside the cover, which uses centrifugal force to dehydrate the water contained in the food waste, and has a function that communicates with the inlet or the discharge port as it rotates The communication hole; the stirring part, inside the dehydration part, rotates simultaneously with the rotation of the dehydration part or rotates independently, and with the rotation, selectively opens and closes the communication hole, and at the same time stirs the food waste inside the dehydration part. and crushing; and a drying part that supplies dry air to the cover to dry the food waste.

Owner:LG ELECTRONICS INC

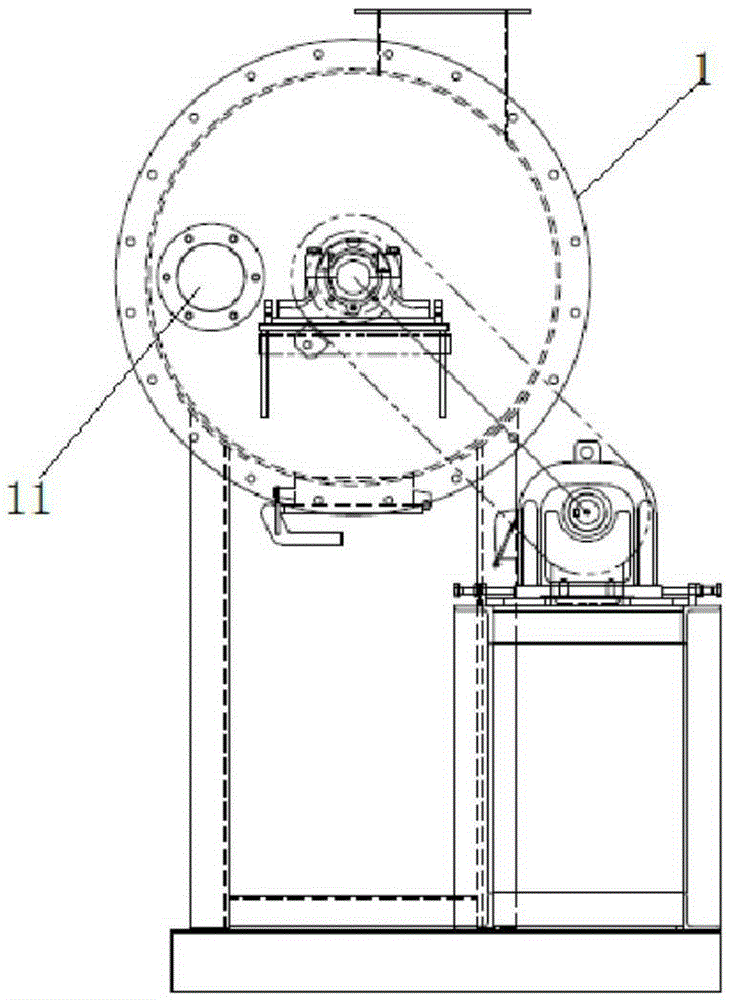

Drying machine

ActiveCN105333706AIncrease the areaImprove heat transfer efficiencyDrying machines with non-progressive movementsDrying solid materialsSmall particleMechanical engineering

The invention discloses a drying machine. The drying machine comprises a furnace body, rotating shafts, and stirring components, wherein the furnace body is arranged in the horizontal direction; the furnace body is provided with a feed opening through which materials are added and a discharge opening through which the materials are taken out; the rotating shafts are arranged in the cavity of the furnace body in a penetrating manner; the stirring components are arranged on the rotating shafts; the stirring components are used for stirring and crushing the materials in the axial directions of the rotating shafts and in the radial directions of the rotating shafts. According to the drying machine disclosed by the invention, when the materials are dried, under the driving of the rotating shafts, the stirring components can stir the materials in the axial directions of the rotating shafts and in the radial directions of the rotating shafts, so that the materials can be rolled in the furnace body in the axial directions of the rotating shafts and in the radial directions of the rotating shafts; besides, when the materials are stirred, the materials can also be crushed to form the materials with smaller particles, so that the area of heat convection between the materials and external environment is increased, the drying efficiency of the materials is improved, and the drying effect of the materials is improved.

Owner:江苏碧诺环保科技有限公司

A high-efficiency solid-liquid mixture treatment system

ActiveCN105605892BTake full advantage of the squeezeAffect the degree of loosenessDrying machines with non-progressive movementsHeating arrangementEngineeringGas supply

The invention relates to a high-efficiency solid-liquid mixture processing system, which includes a transmission device, a water removal structure and a drying device. The material receiving device, the air supply device that introduces the external hot gas into the furnace body through the first air inlet, and the stirring device for stirring and crushing the materials. Wherein, the stirring device includes a second rotating shaft, which is installed in the cavity of the furnace body. The second rotating shaft has a ventilating cavity, and several air jets are arranged on the venting cavity. The stirring direction of the stirring shaft and the stirring direction of the blades do not overlap and are not parallel; when drying the material, the hot gas is introduced into the cavity of the furnace body through the first air inlet, and the rotation of the second rotating shaft drives the gas on the second rotating shaft. The stirring assembly continuously stirs the materials along the radial and axial directions of the second rotating shaft.

Owner:王良源

Sludge Treatment System

ActiveCN105439416BAffect the degree of loosenessIncrease the convective heat transfer areaSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesMechanical engineeringTreatment system

Owner:淮安中顺环保科技有限公司

A drying system integrating heating and drying

ActiveCN105546957BAffect the degree of loosenessIncrease the convective heat transfer areaSludge treatment by de-watering/drying/thickeningDrying gas arrangementsEngineeringConvection

The invention discloses a drying system integrating heating with drying. The drying system comprises a furnace body, a feeding device used for adding materials into the furnace body, a material collecting device used for collecting dried materials in the furnace body, an air feeding device used for introducing outside hot gas into the furnace body through a first gas inlet, and a stirring device used for stirring and crushing the materials, wherein the stirring device comprises a second rotary shaft; the second rotary shaft is arranged in a cavity of the furnace body in a penetration mode, and is provided with a gas ventilating cavity; a plurality of gas vents are formed in the gas ventilating cavity; the gas spraying direction of the gas vents is not superposed with and is not parallel to the stirring direction of the stirring shaft and the stirring direction of blades; during material drying, the hot gas is introduced into the cavity of the furnace body through the first gas vents; the second rotary shaft drives a stirring assembly on the second rotary shaft to continuously stir materials in a radial direction and in an axial direction of the second rotary shaft, so that the materials can turn over in the axial direction and in the radial direction of the second rotary shaft in the furnace body, and therefore, the convection and heat exchange area of the materials and the hot gas is increased.

Owner:JUYE ZHONGHAI CHEM

Car shell model manufacturing tool

ActiveCN108295958AImprove reuse efficiencyImprove work efficiencyGrain treatmentsPressesEngineeringMechanical engineering

The invention belongs to the technical field of car design and particularly relates to a car shell model manufacturing tool. The car shell model manufacturing tool comprises a working table and further comprises a recovery box which is designed to be hollow. An opening is formed in the top of the recovery box, and a receiving cavity is formed in the middle of the recovery box. A returning cavity is formed in the bottom of the recovery box, and a supporting frame used for supporting the working table is arranged at the top of the receiving cavity. Falling cavities communicating with the top ofthe receiving cavity are formed in the tops of the working table and the recovery box, and the cross sectional area of the receiving cavity is decreased gradually from the top of the recovery box to the bottom of the recovery box. The returning cavity comprises a crushing cavity and a forming cavity used for extruding oil sludge into a piece shape. The crushing cavity communicates with the bottomof the receiving cavity, and a crushing mechanism is arranged in the crushing cavity and comprises a driving part and a plurality of crushing rods driven to rotate by the driving part. The ends of thecrushing rods are provided with extruding parts for extruding the oil sludge in the crushing cavity into the forming cavity. According to the scheme, the reutilization efficiency of the oil sludge can be improved.

Owner:重庆中壹迪工业设计有限公司

Improved solid-liquid mixture treatment system

InactiveCN108800755ASmoothly fall intoTake full advantage of the squeezeSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermodynamicsEngineering

The invention discloses an improved solid-liquid mixture treatment system. The system comprises a transmission device, a dewatering structure and a drying device, wherein the drying device comprises afurnace body, a feeding device, a material receiving device, an air supply device and a stirring device, wherein the feeding device is used for feeding materials into a furnace body, the material receiving device is used for collecting the materials dried in the furnace body, the air supply device is used for introducing external hot air into the furnace body through a first air inlet, and the stirring device is used for stirring and crushing the materials; and the stirring device comprises a second rotating shaft, the second rotating shaft penetrates a cavity of the furnace body, the secondrotating shaft is provided with a ventilation cavity, a plurality of air jet holes are formed in the ventilation cavity, the air injection directions of the air jet holes are misalign and are not parallel to the stirring directions of stirring shafts and the stirring directions of blades; and when the materials are dried, the hot air is introduced into the cavity of the furnace body through the first air inlet, the materials can roll in the furnace body in the axial direction and the radial direction of the second rotating shaft, the time for stirring the materials is increased, and the area of convective heat exchange between the materials and the hot air is increased.

Owner:王良源

Sludge treatment system

InactiveCN108821537AAffect the degree of loosenessIncrease the convective heat transfer areaSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeProcess engineering

The invention relates to a sludge treatment system which comprises a conveying device, a water removal structure and a drying device. The drying device comprises a furnace body, a feeding device for adding materials to the furnace body, a receiving device for collecting the materials dried in the furnace body, an air supply device for introducing external hot gas into the furnace body through a first air inlet, and a stirring device for stirring and pulverizing the materials. The stirring device comprises a second rotating shaft arranged in the cavity of the furnace body in a penetrating manner, the second rotating shaft is provided with a ventilation cavity, and the ventilation cavity is provided with a plurality of air jet holes, the air jet direction of the air jet holes is not coincident with or parallel to the stirring direction of the stirring shaft and the stirring direction of blades, the time of stirring material and the area of convective heat transfer between the material and the hot gas are increased.

Owner:王良源

A sludge treatment system

ActiveCN105502881BSmoothly fall intoAffect the degree of loosenessSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningMechanical engineeringTreatment system

Owner:GUYUAN XINYUE HALAL FOOD +1

An improved solid-liquid mixture processing system

ActiveCN105585237BSmoothly fall intoTake full advantage of the squeezeSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningMixed materialsMechanical engineering

The invention relates to an improved solid-liquid mixture treatment system, which includes a transmission device, a water removal structure and a drying device. The drying device includes a furnace body, a feeding device for adding materials to the furnace body, and a collection device for collecting The material receiving device for the dried material, the air supply device that introduces the external hot gas into the furnace body through the first air inlet, and the stirring device for stirring and crushing the material. Wherein, the stirring device includes a second rotating shaft, which is installed in the cavity of the furnace body. The second rotating shaft has a ventilating cavity, and several air jets are arranged on the venting cavity. The stirring direction of the stirring shaft and the stirring direction of the blades do not overlap and are not parallel; when drying the material, the hot gas is introduced into the cavity of the furnace body through the first air inlet, and the rotation of the second rotating shaft drives the gas on the second rotating shaft. The stirring assembly continuously stirs the materials along the radial and axial directions of the second rotating shaft.

Owner:王良源

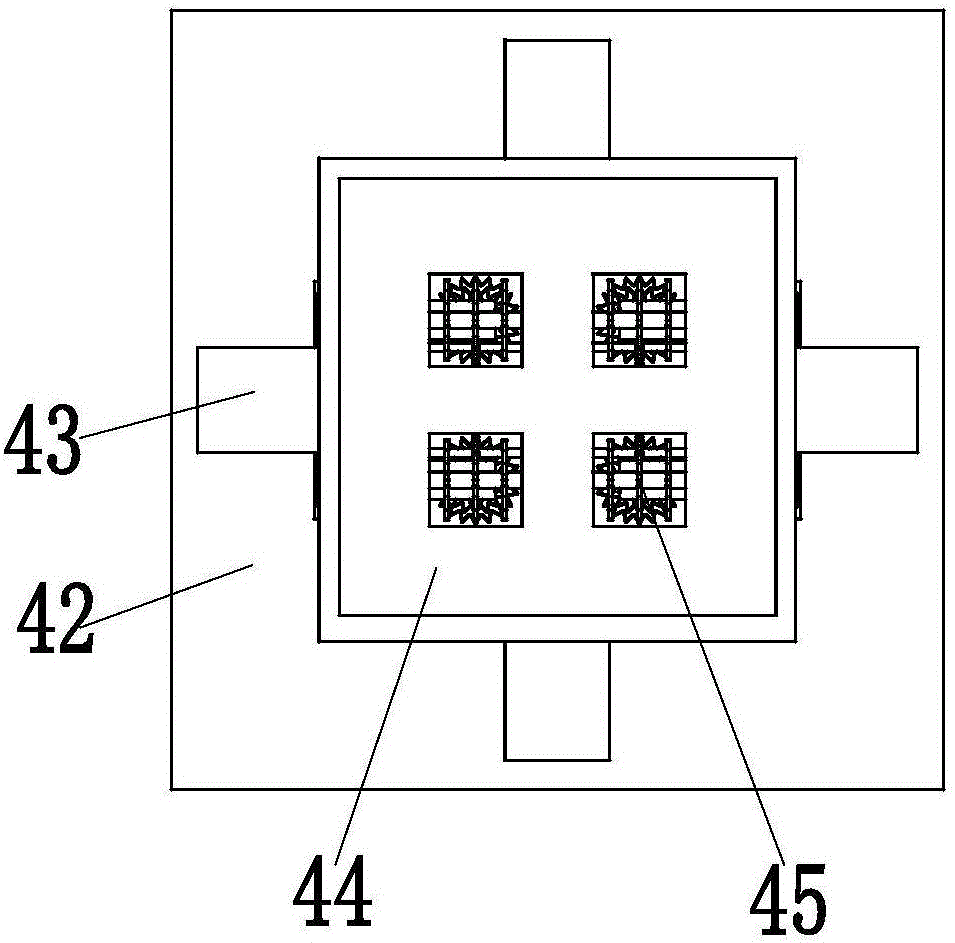

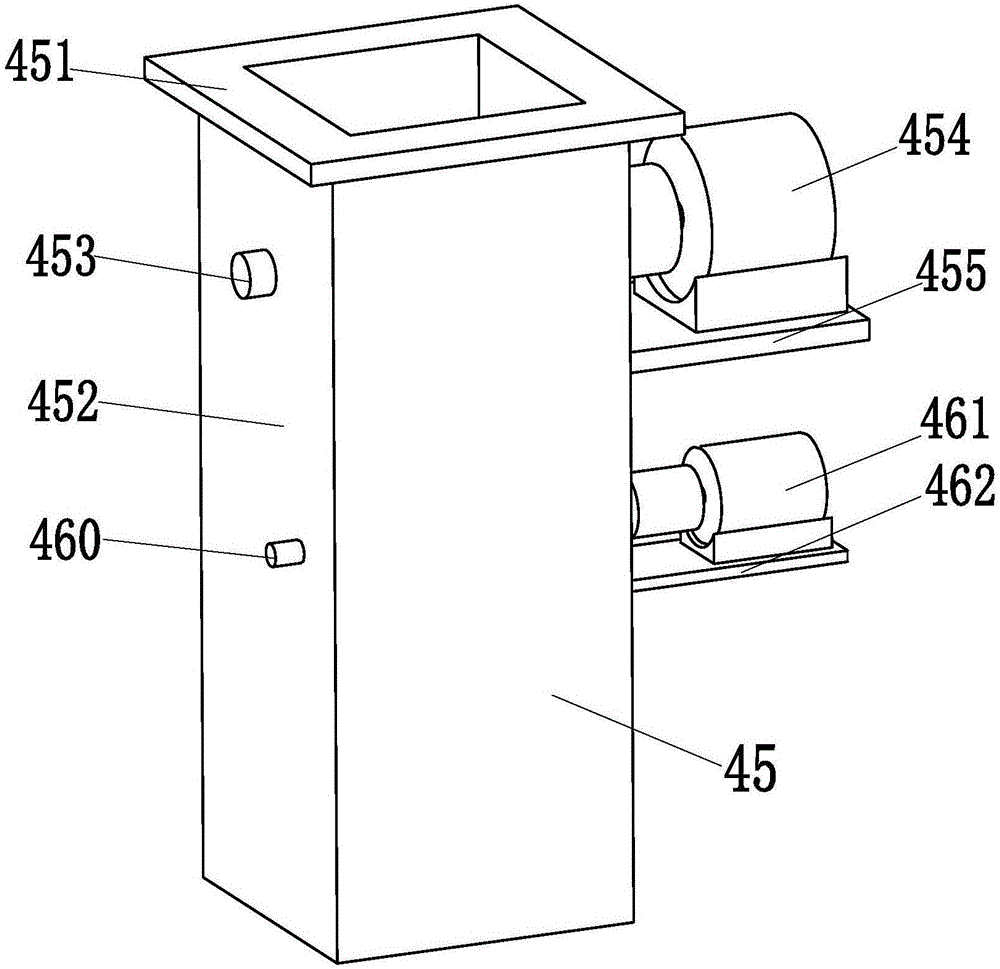

Glue material smashing machine

InactiveCN106269103AUniform and complete crushing functionEvenly arranged vertical rotary slices can evenly and completely pulverize the rubber materialGrain treatmentsEngineeringMaterial recovery

The invention relates to a glue material smashing machine which comprises four first supporting legs. A fixed plate is installed at the upper ends of the four first supporting legs. The four first supporting legs have an effect for uniformly supporting the fixed plate. Four L-shaped supporting rods are symmetrically installed on the upper end face of the fixed plate. A discharge box is installed among the four L-shaped supporting rods. The four L-shaped supporting rods have an effect of powerfully fixing the discharge box. Four discharge ports are symmetrically formed in the bottom of the discharge box. Four complete smashing mechanisms are installed on the four discharge ports of the discharge box respectively. Existing glue materials enter the four complete smashing mechanisms through the four discharge ports of the discharge box respectively to be completely smashed. The problems that an existing glue material recovery device is poor in smashing effect, not uniform in smashing, low in work efficiency and the like can be solved, the complete smashing function of the glue materials can be achieved, and the glue material smashing machine has the advantages of being good in smashing effect, uniform in smashing, high in work efficiency and the like.

Owner:安徽永大胶业科技发展有限公司

A solid-liquid mixture processing system

ActiveCN105565641BAffect the degree of loosenessIncrease the convective heat transfer areaSludge treatment by de-watering/drying/thickeningDrying solid materialsThermodynamicsEngineering

The invention relates to a solid-liquid mixture treatment system, which includes a transmission device, a water removal structure and a drying device. The drying device includes a furnace body, a feeding device for adding materials to the furnace body, and a collection of dried materials in the furnace body. The material receiving device, the air supply device that introduces the external hot gas into the furnace body through the first air inlet, and the stirring device for stirring and pulverizing the materials. Wherein, the stirring device includes a second rotating shaft, which is installed in the cavity of the furnace body. The second rotating shaft has a ventilating cavity, and several air jets are arranged on the venting cavity. The stirring direction of the stirring shaft and the stirring direction of the blades do not overlap and are not parallel; when drying the material, the hot gas is introduced into the cavity of the furnace body through the first air inlet, and the rotation of the second rotating shaft drives the gas on the second rotating shaft. The stirring assembly continuously stirs the materials along the radial and axial directions of the second rotating shaft.

Owner:王良源

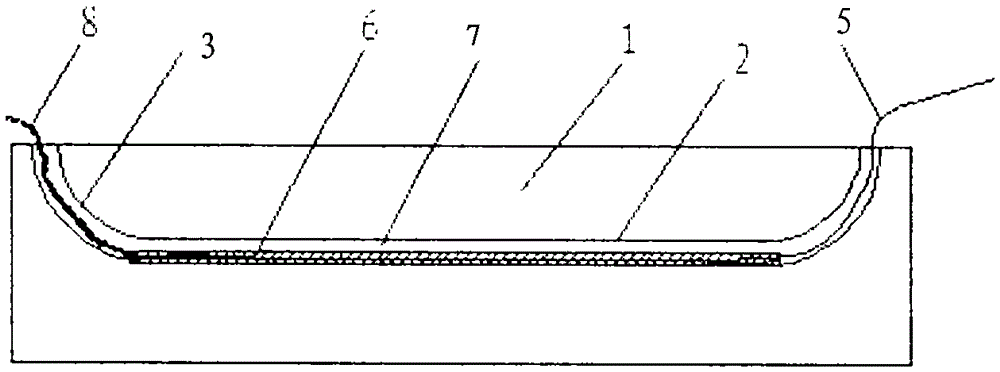

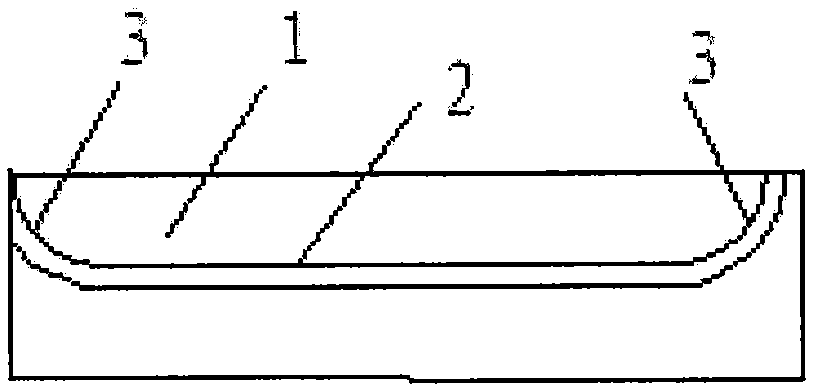

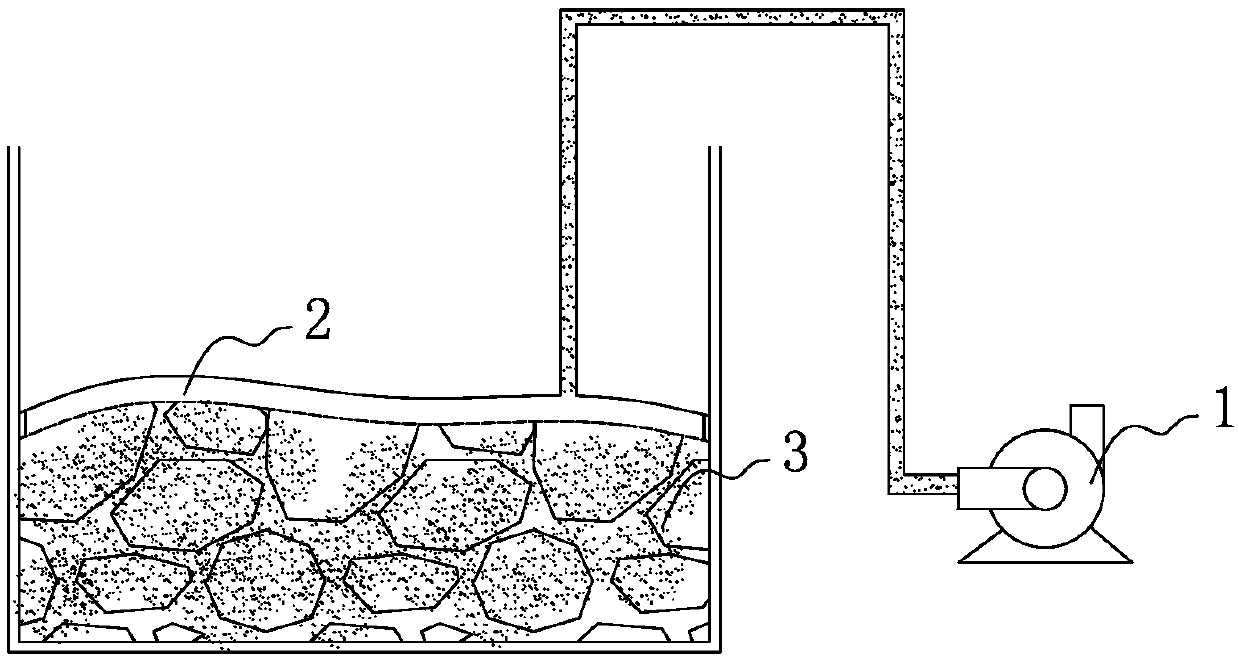

Static nondestructive granulation method for waste asphalt mixture

PendingCN109550573AAchieve the purpose of breakingWon't breakGrain treatmentsSolid waste managementScrapMoisture

The invention discloses a static nondestructive granulation method for a waste asphalt mixture, which is used for recycling the waste asphalt. The method comprises the following steps that step 1, proportioning the slurry, mixing a high-alumina furnace slag with a titanium gypsum according to the ratio of 3: 2 and adding water to form mixed slurry, and the mixed slurry submerges the materials in the container; step 2, absorbing water from the mixed slurry, a water absorption pad completely covers the surface of the mixed slurry in the container, the vacuum water suction machine is started after the container is connected with the vacuum water suction machine, the excessive moisture in the container is absorbed by the water absorption pad and is discharged by the vacuum water suction machine; step 3, standing and maintaining; step 4, carrying out vibration cracking and vibration screening on the cured materials. According to the method, the raw materials are titanium dioxide productionwaste and another waste high-aluminum slag, so that waste materials can be changed into wealth, resources can be recycled, the generated calcium-alum-stone expansion body has no pollution to the environment, the whole process is environment-friendly, and the development of the industry is facilitated.

Owner:SHANDONG JIAOTONG UNIV

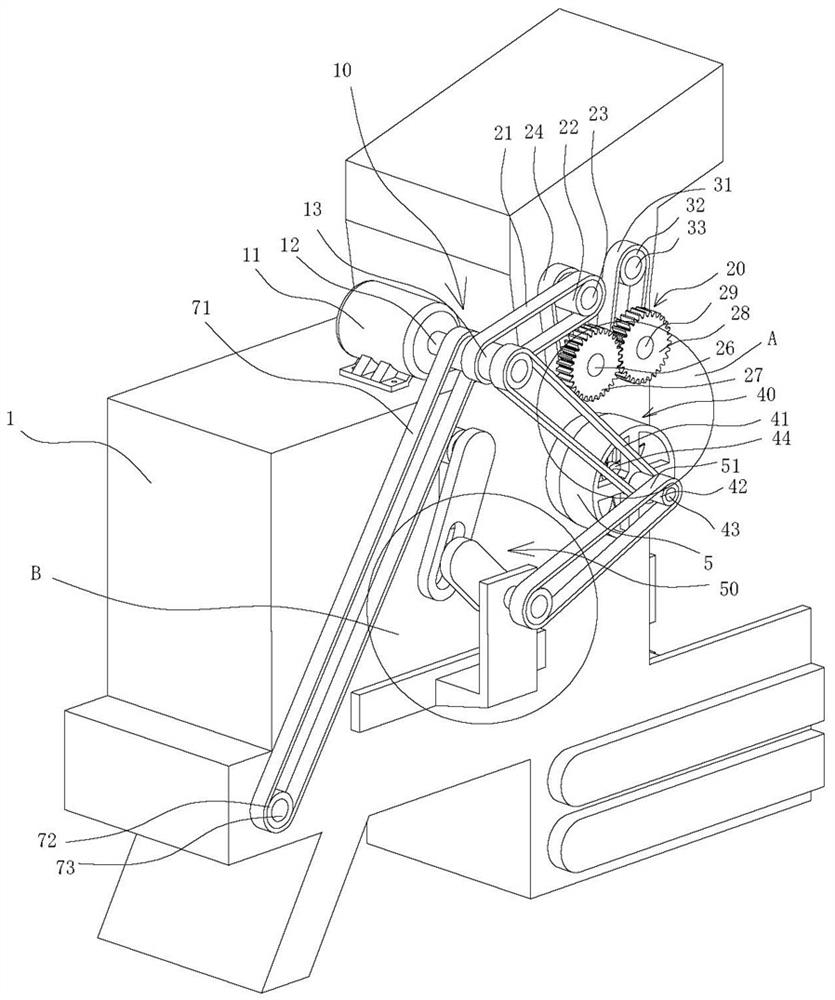

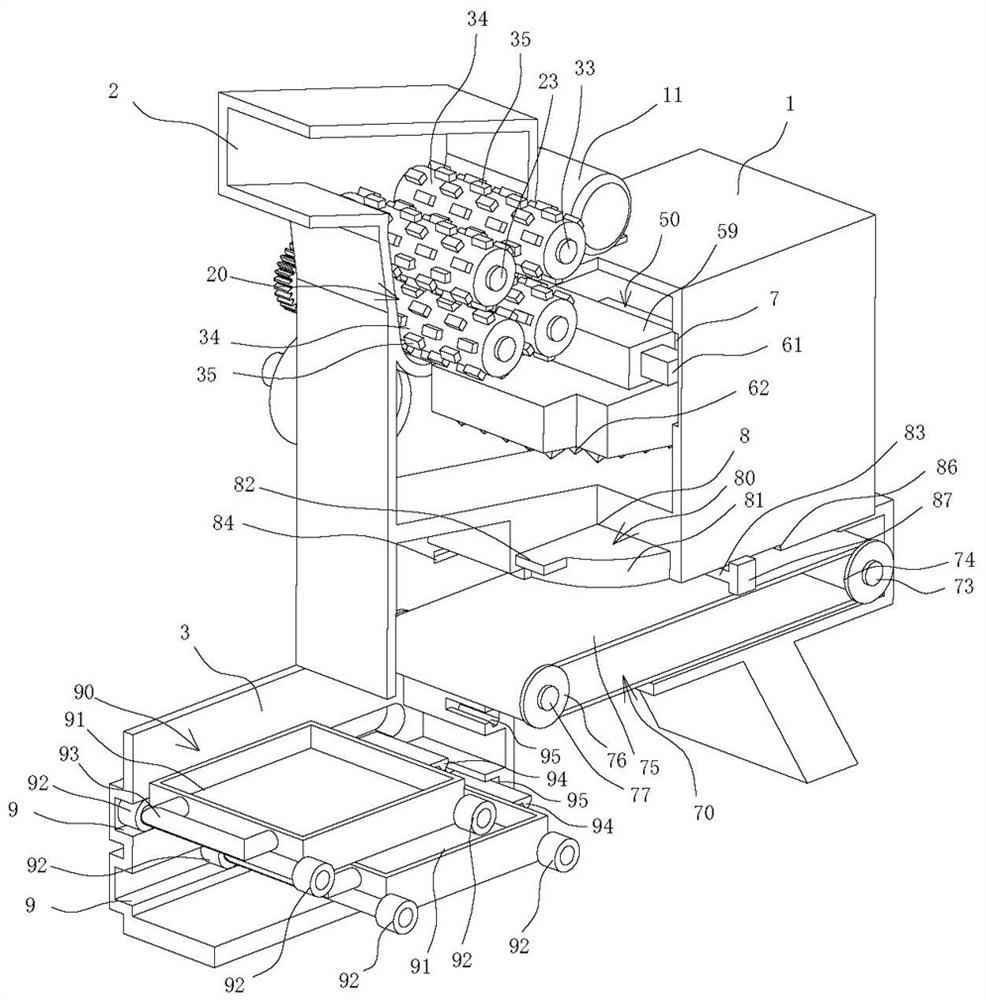

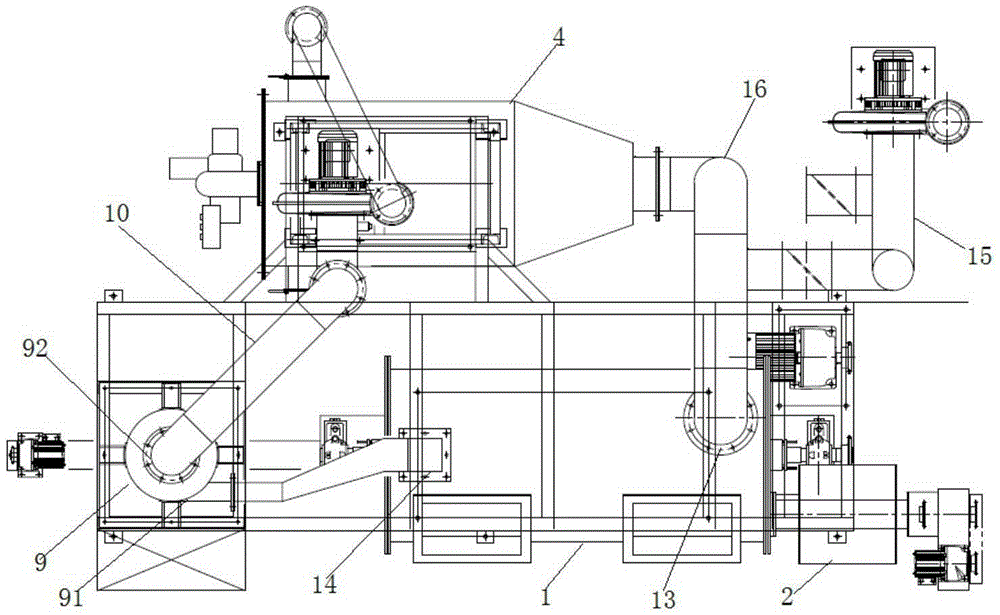

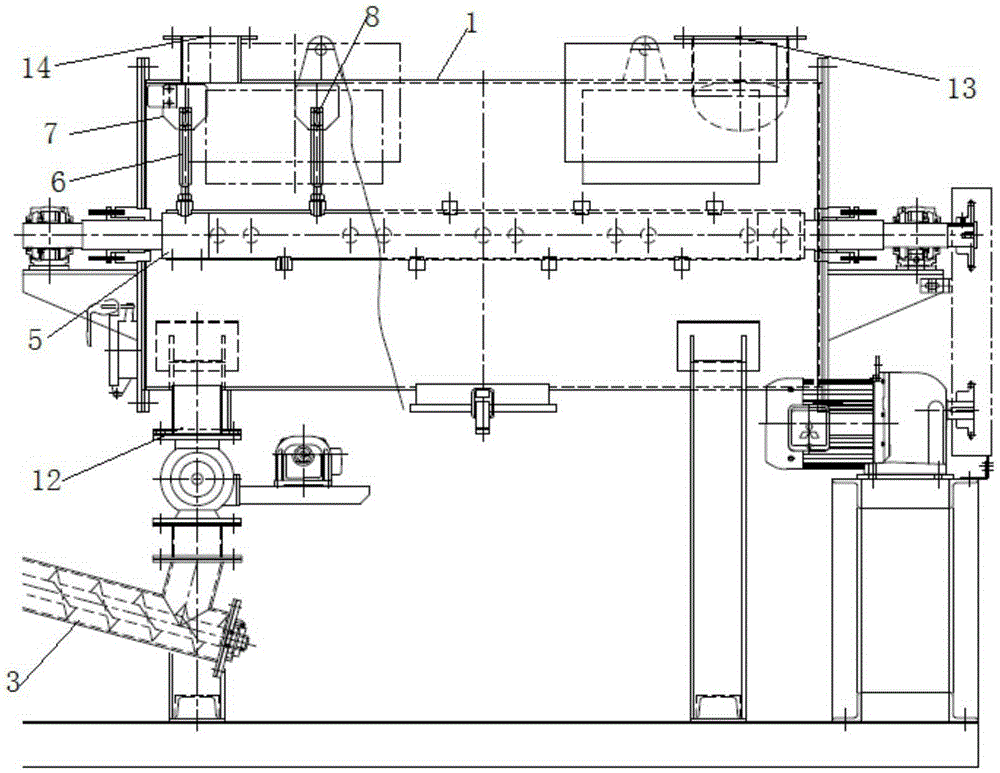

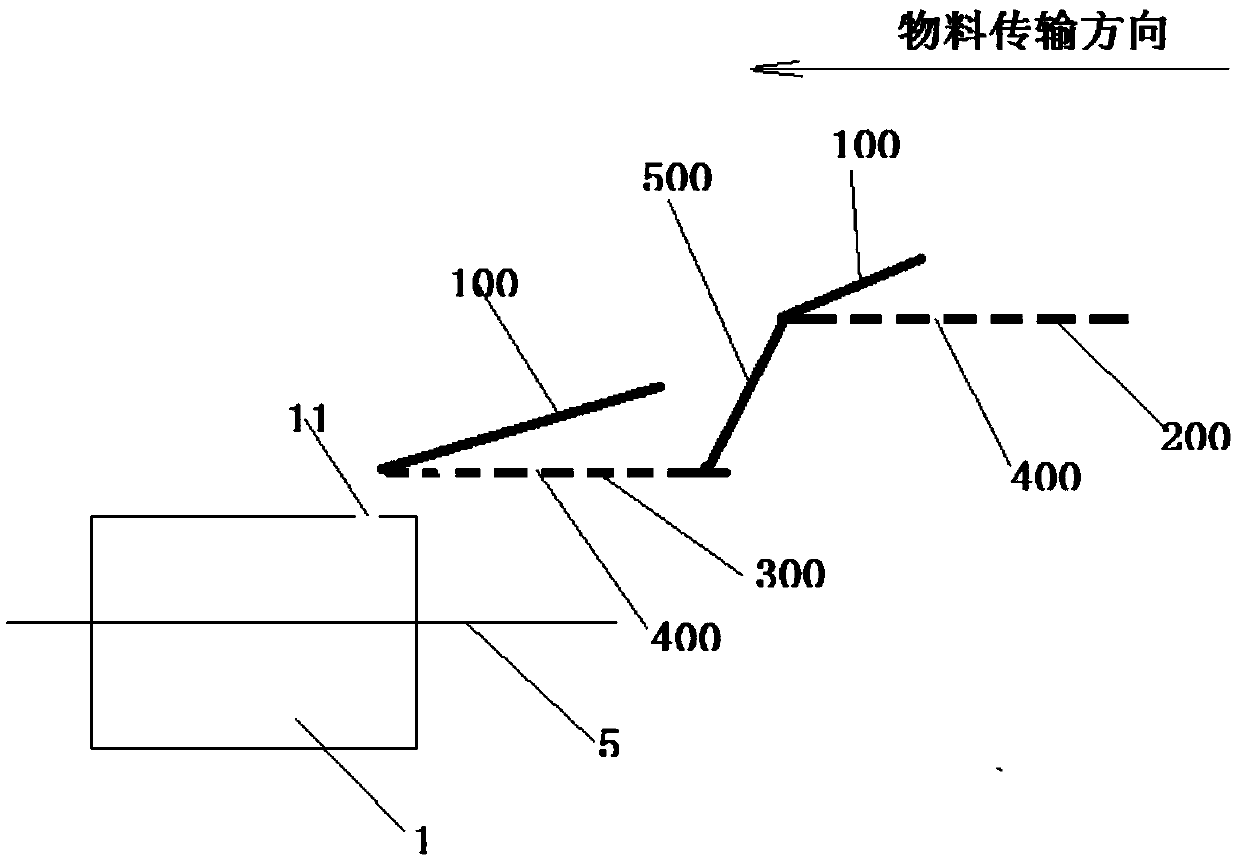

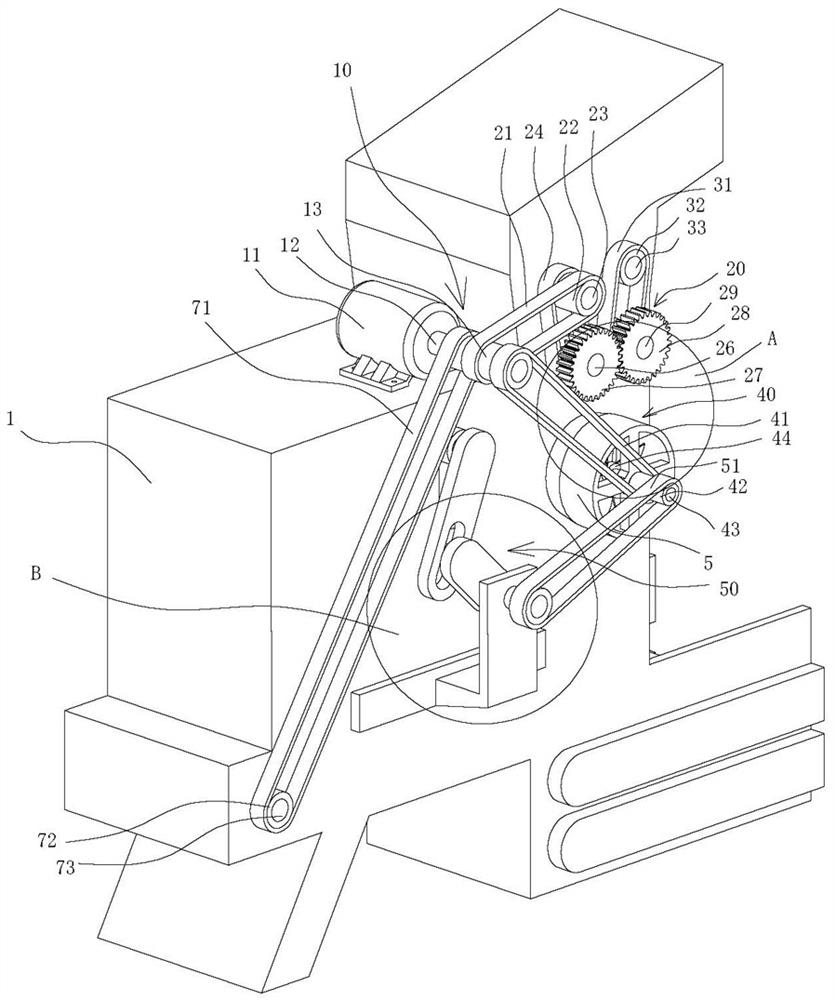

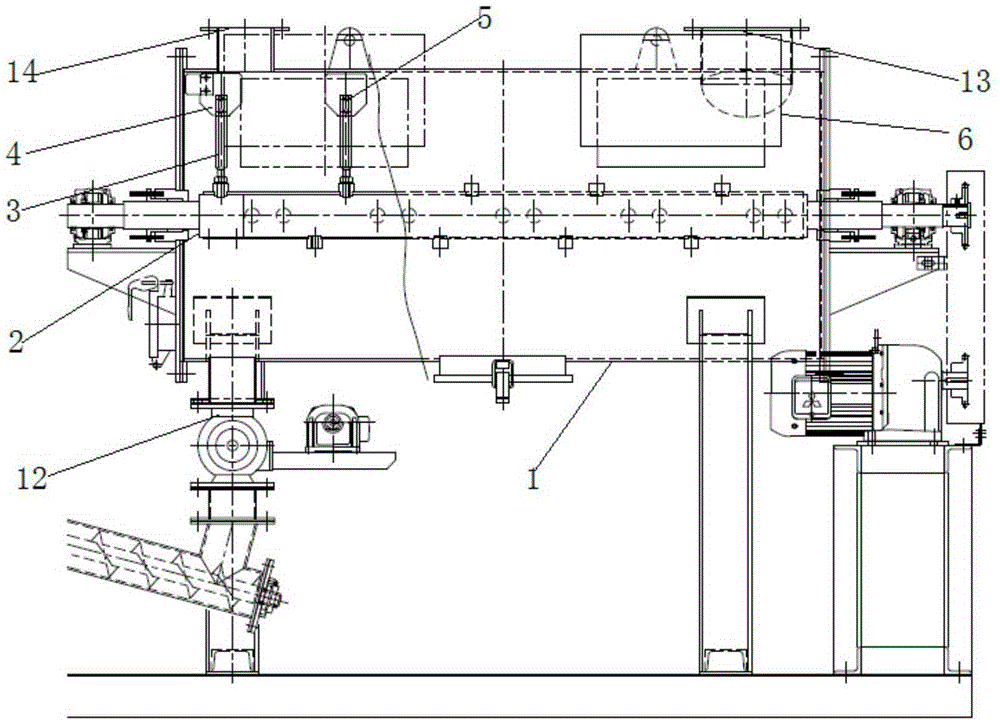

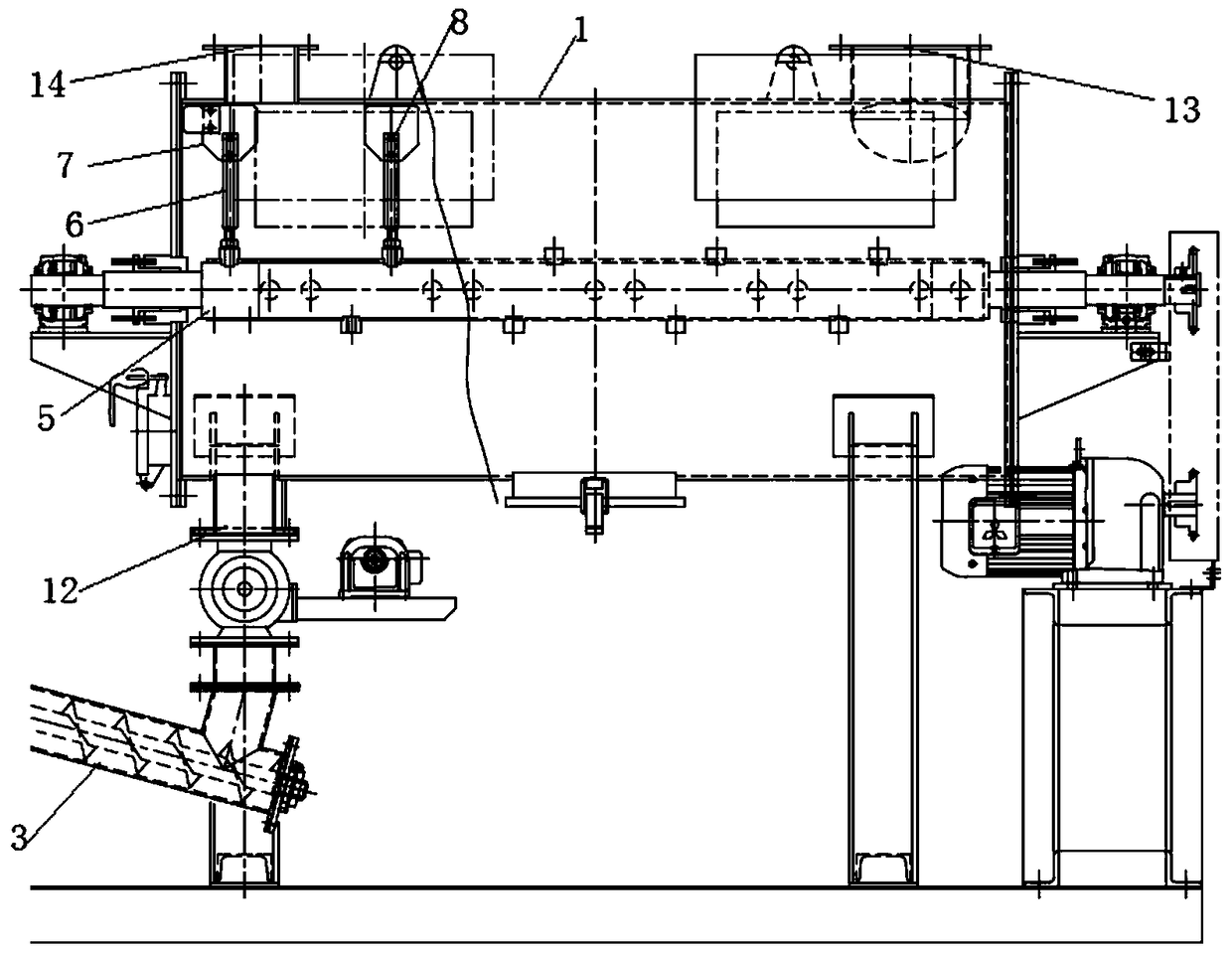

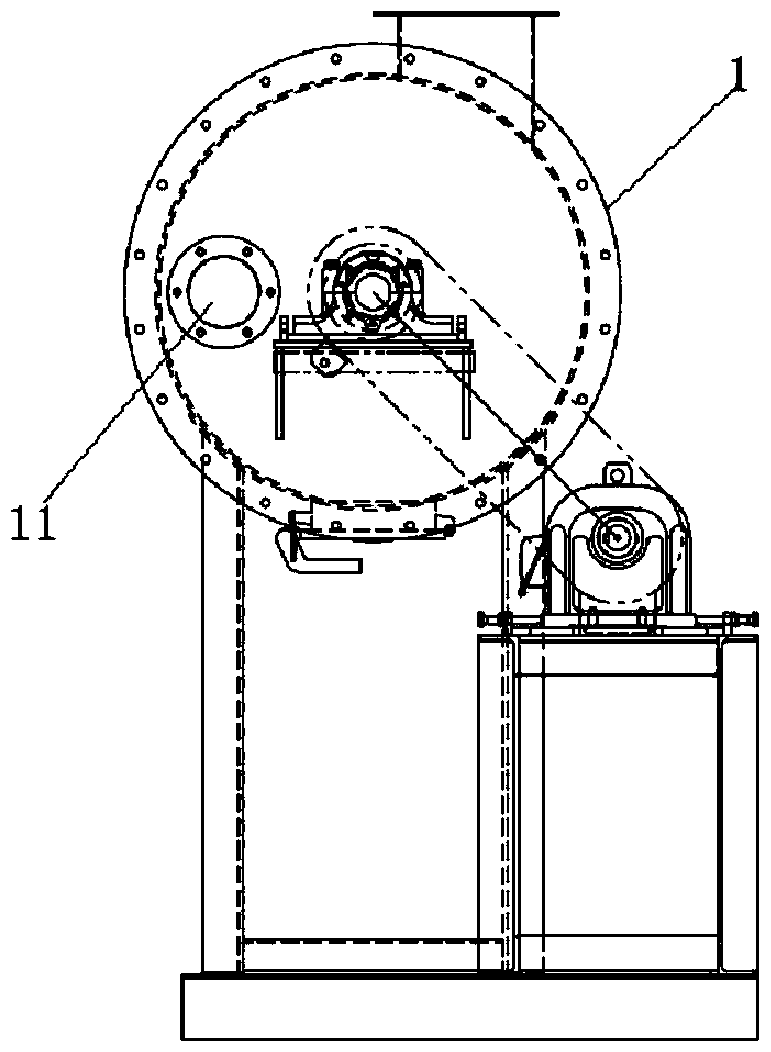

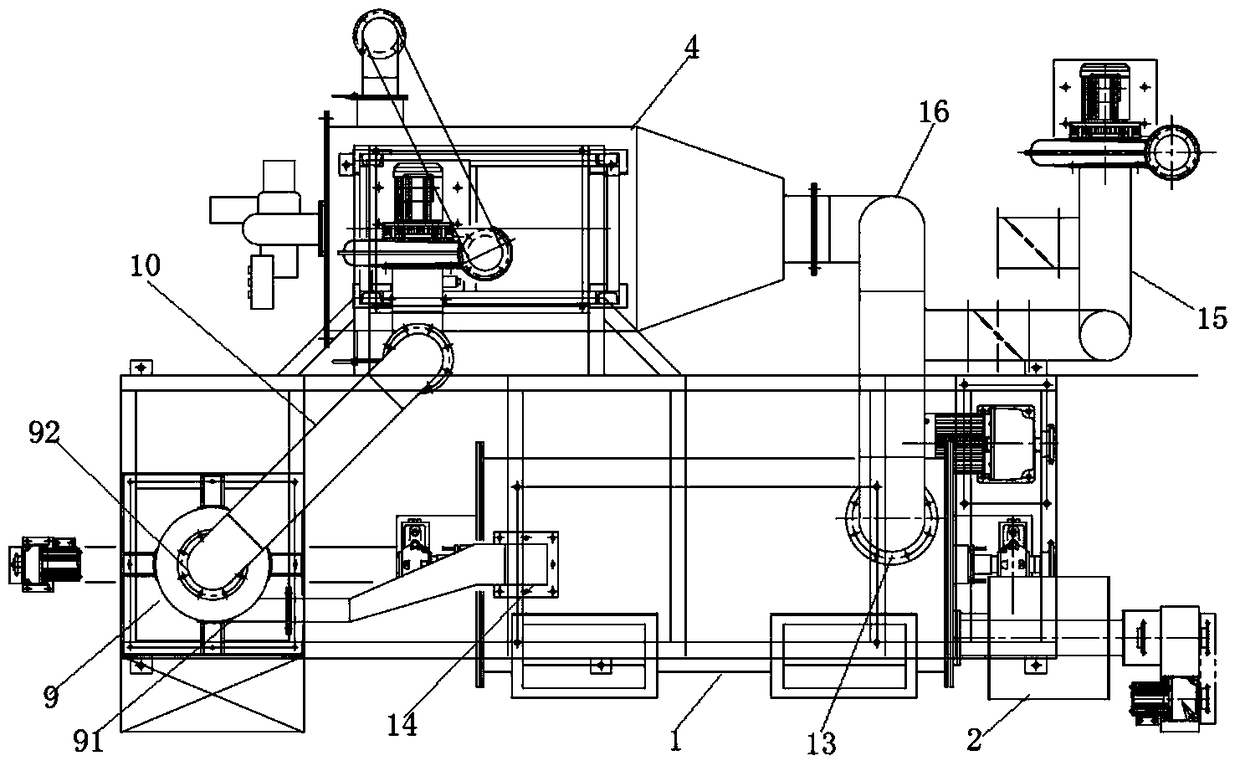

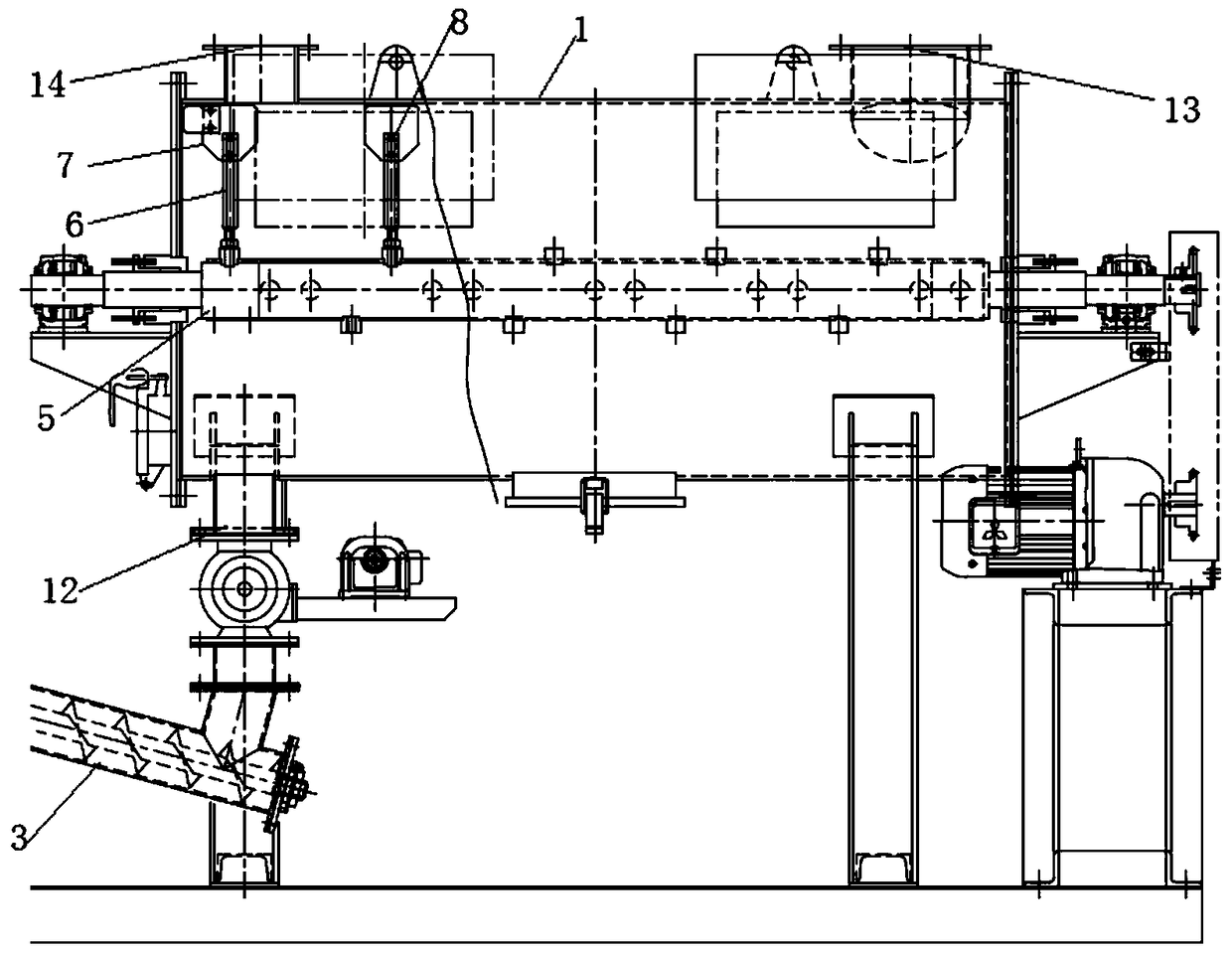

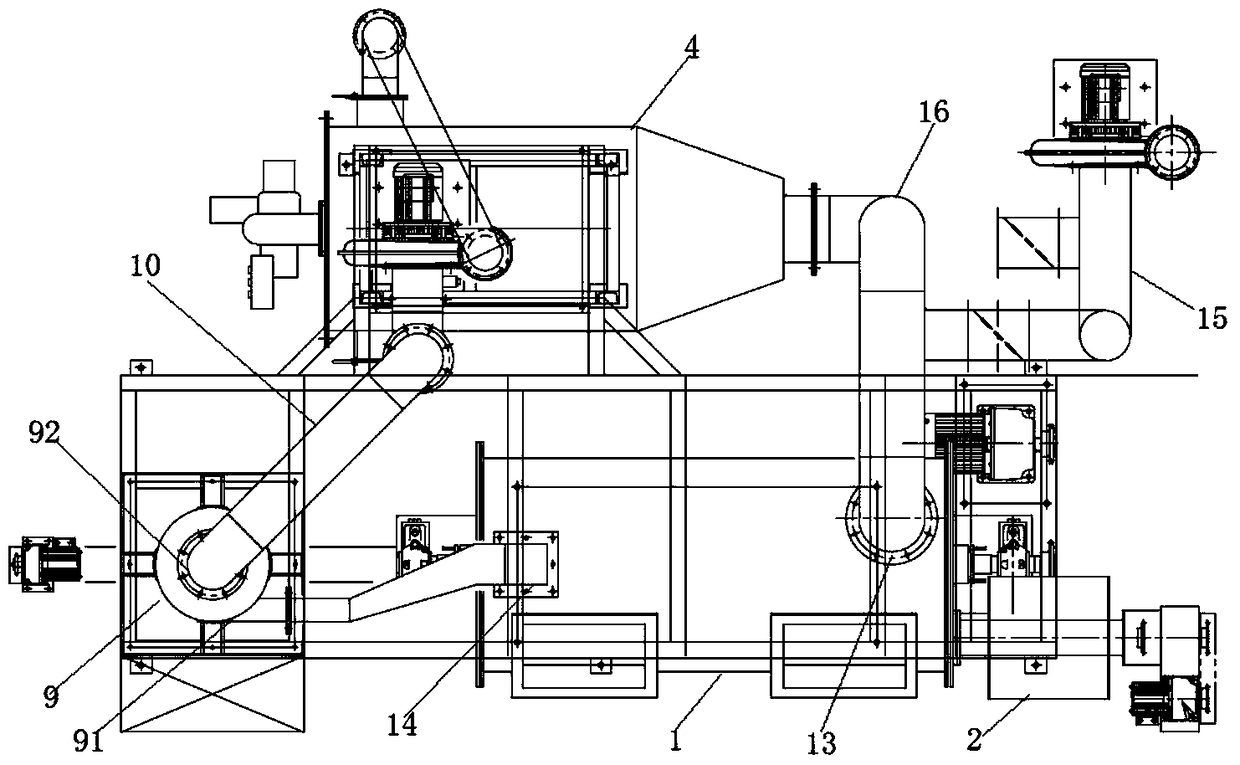

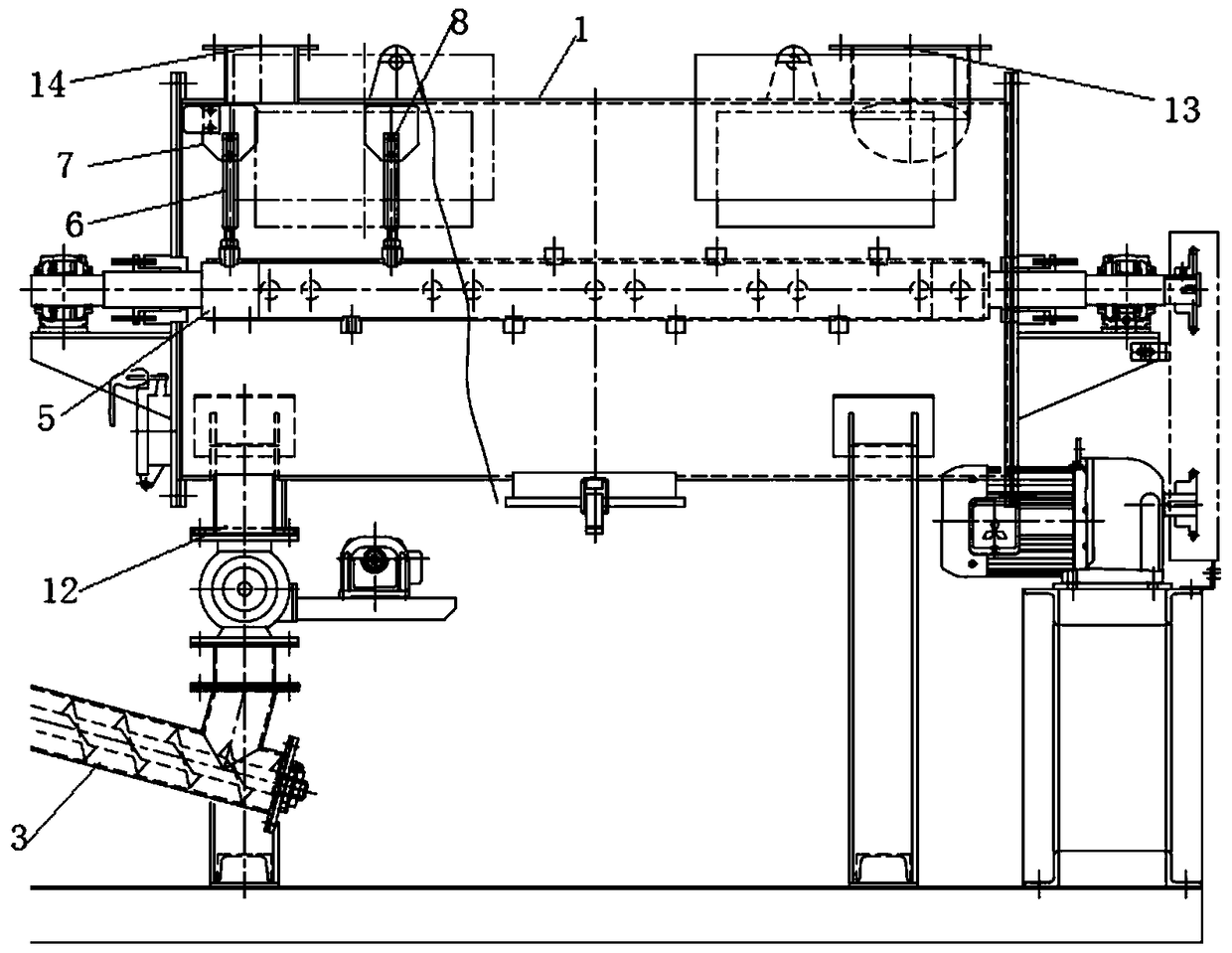

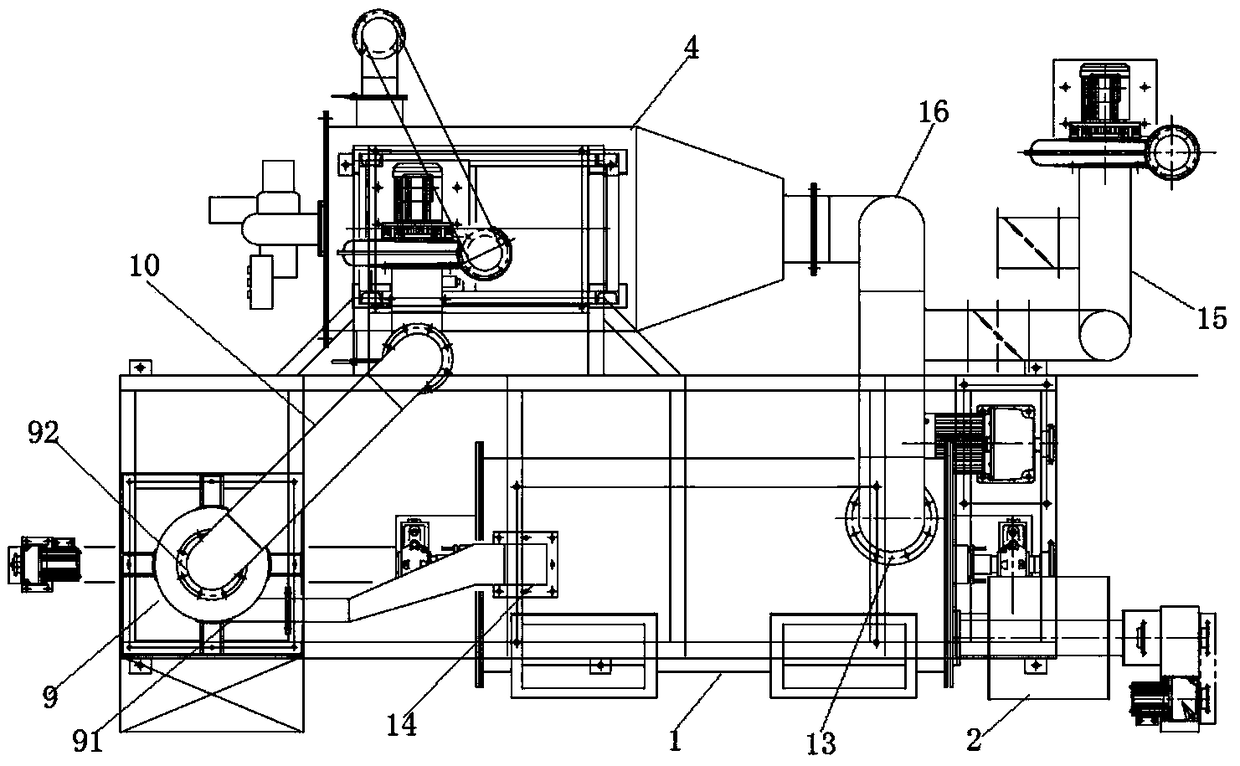

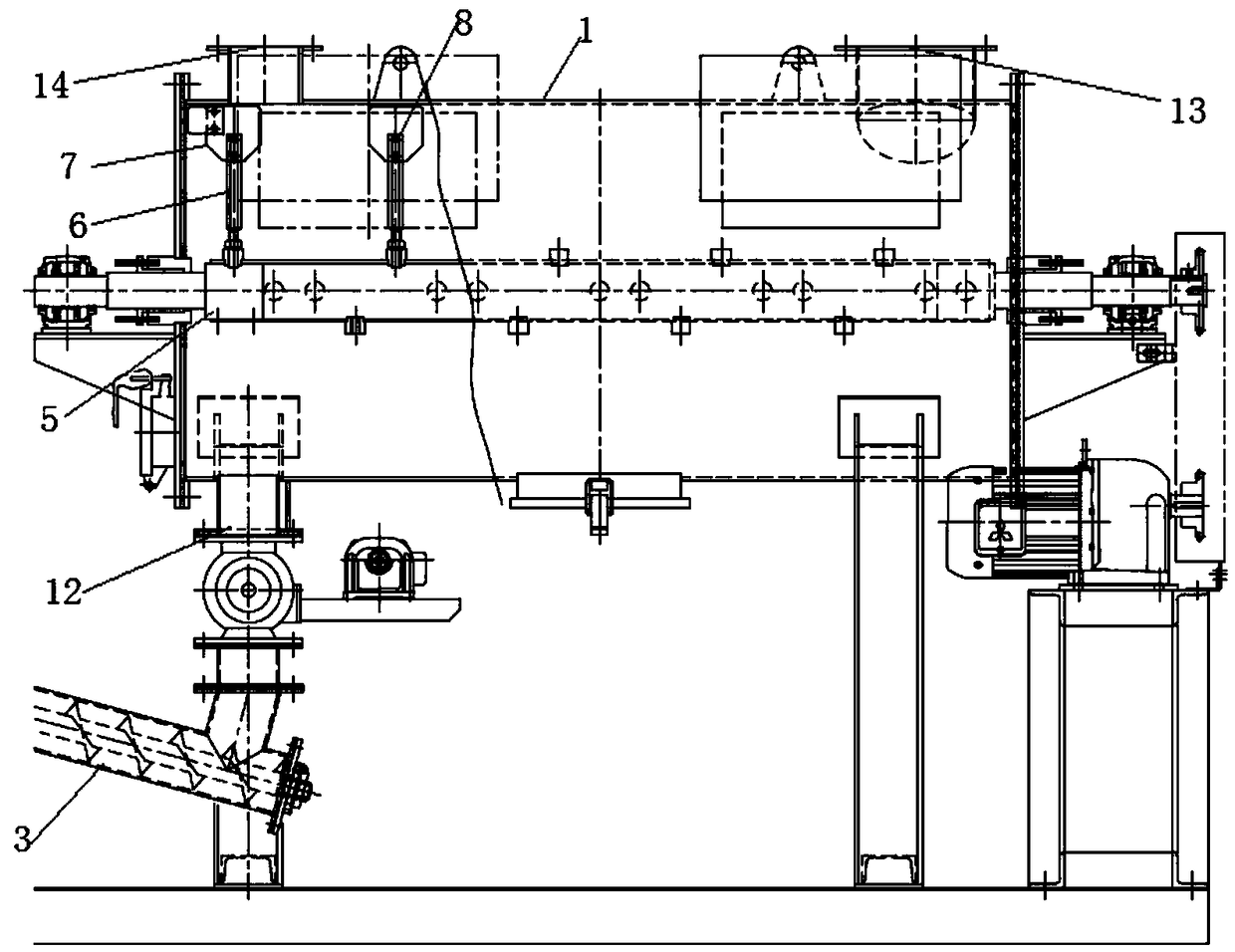

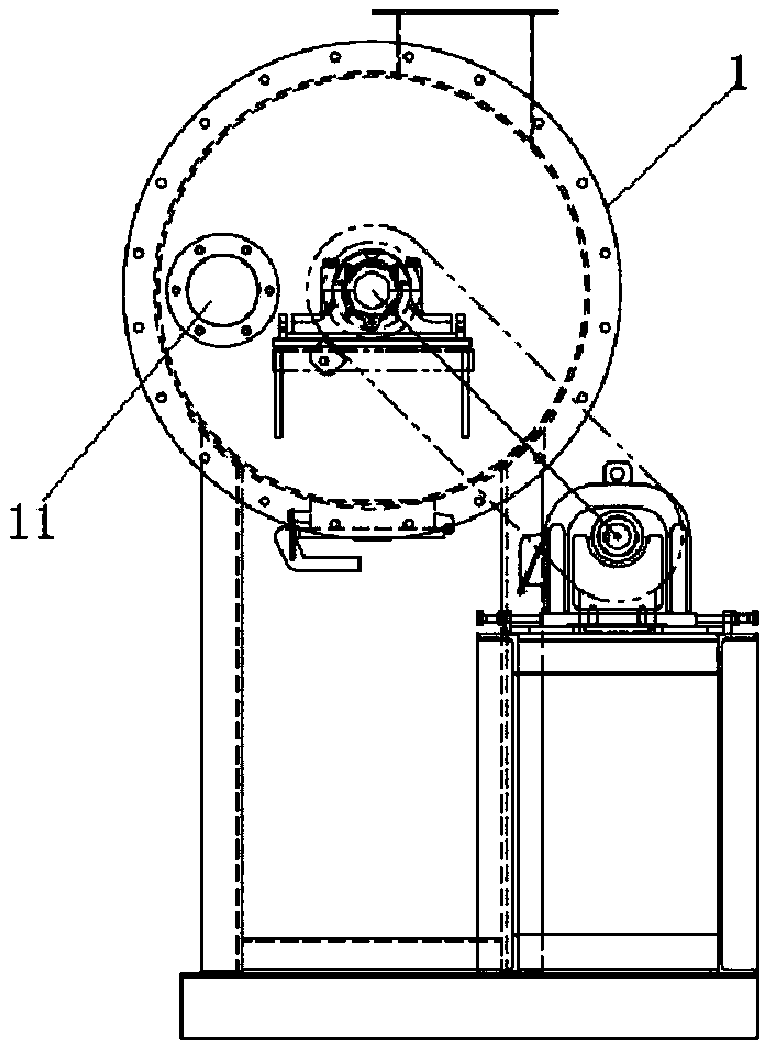

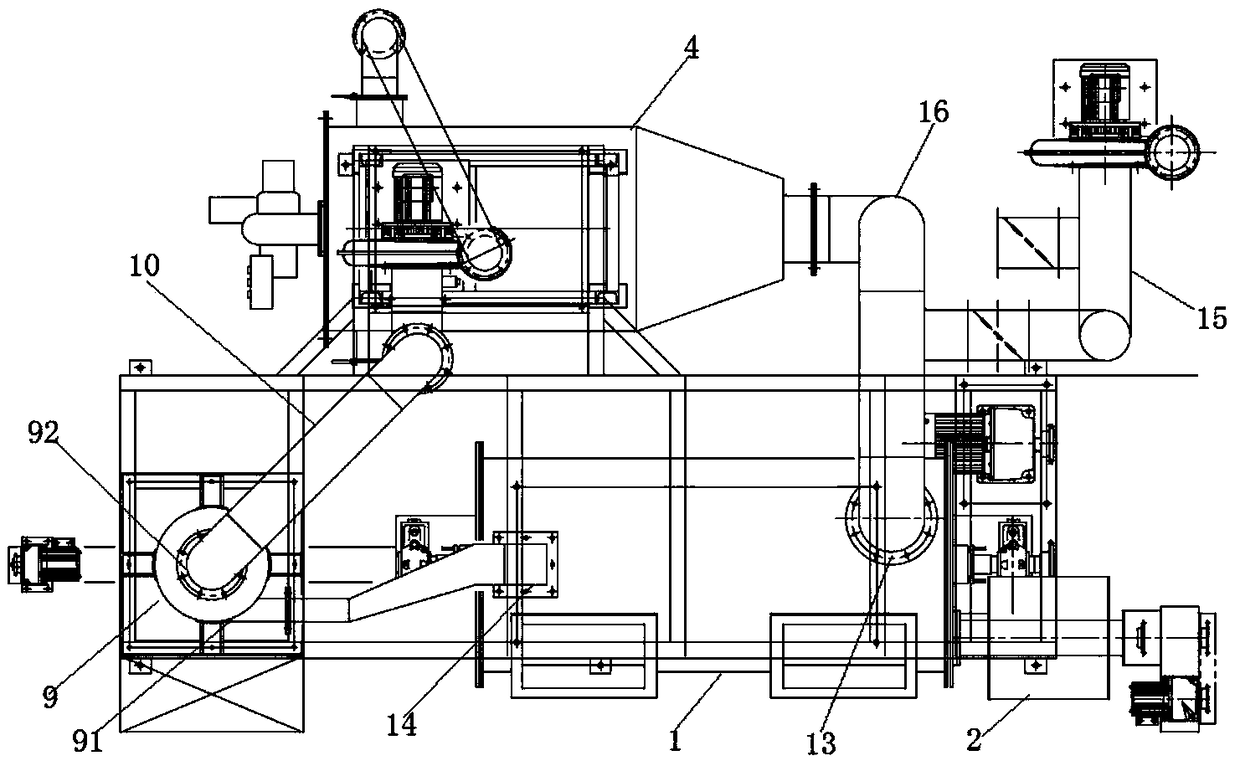

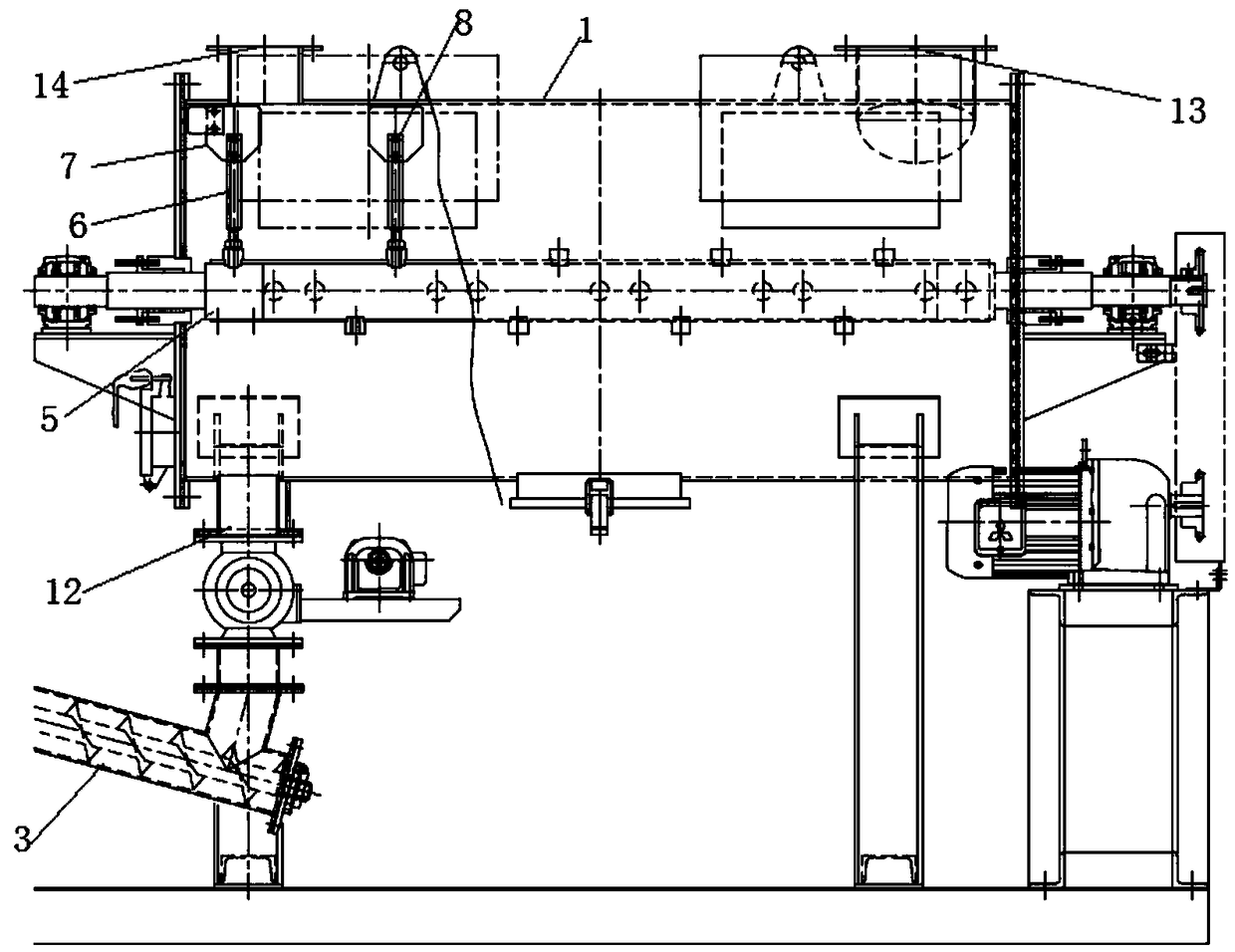

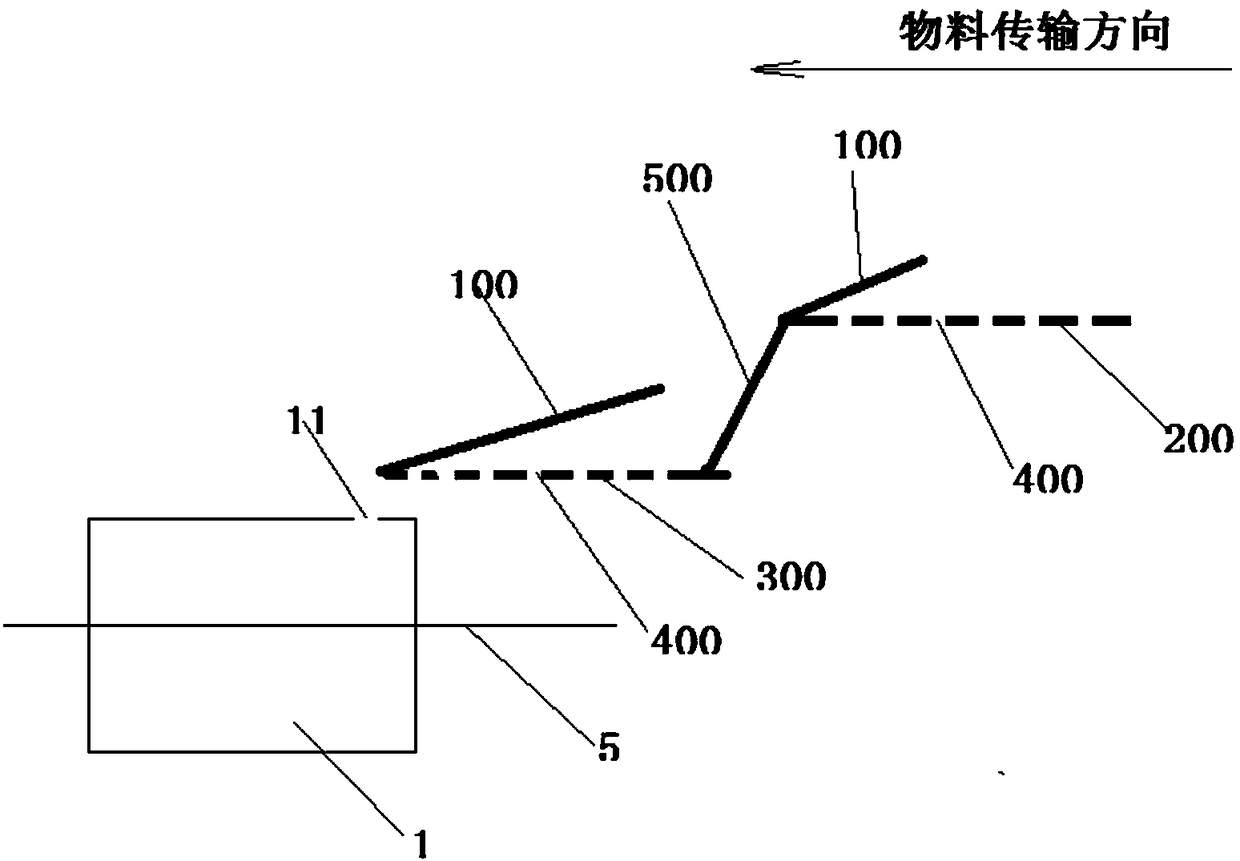

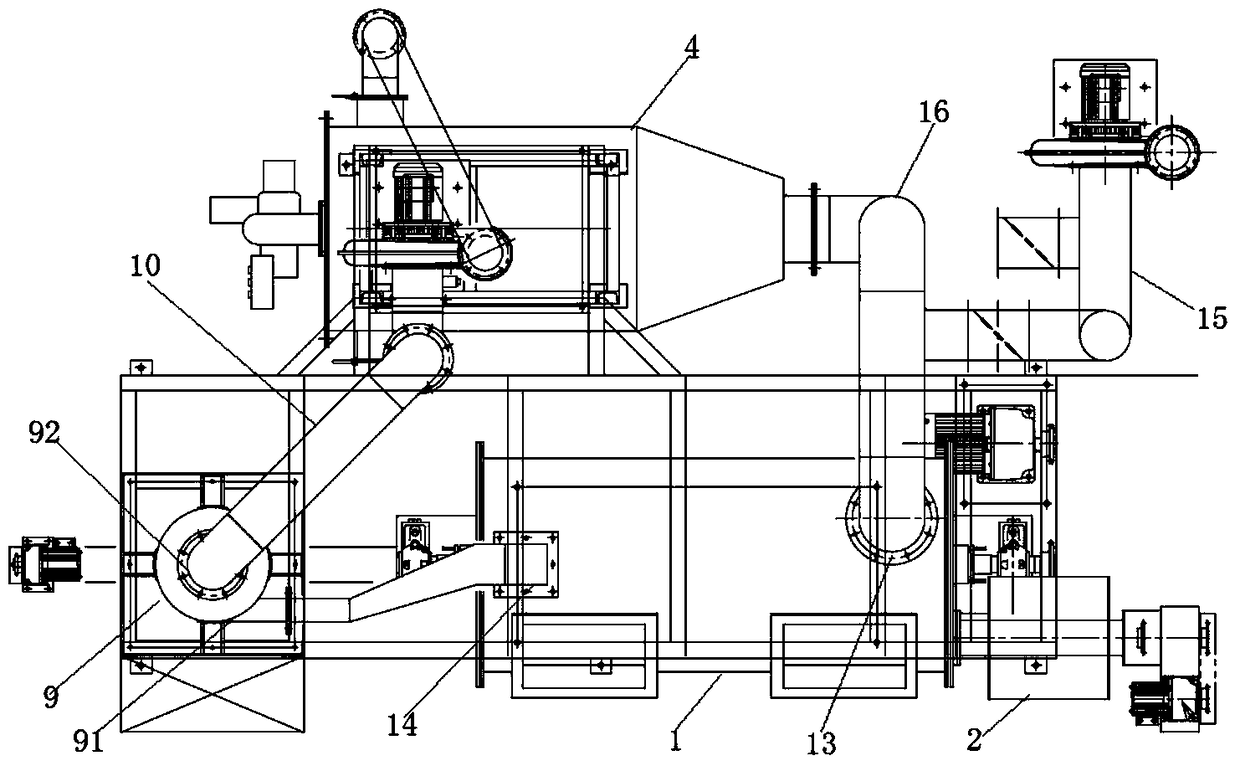

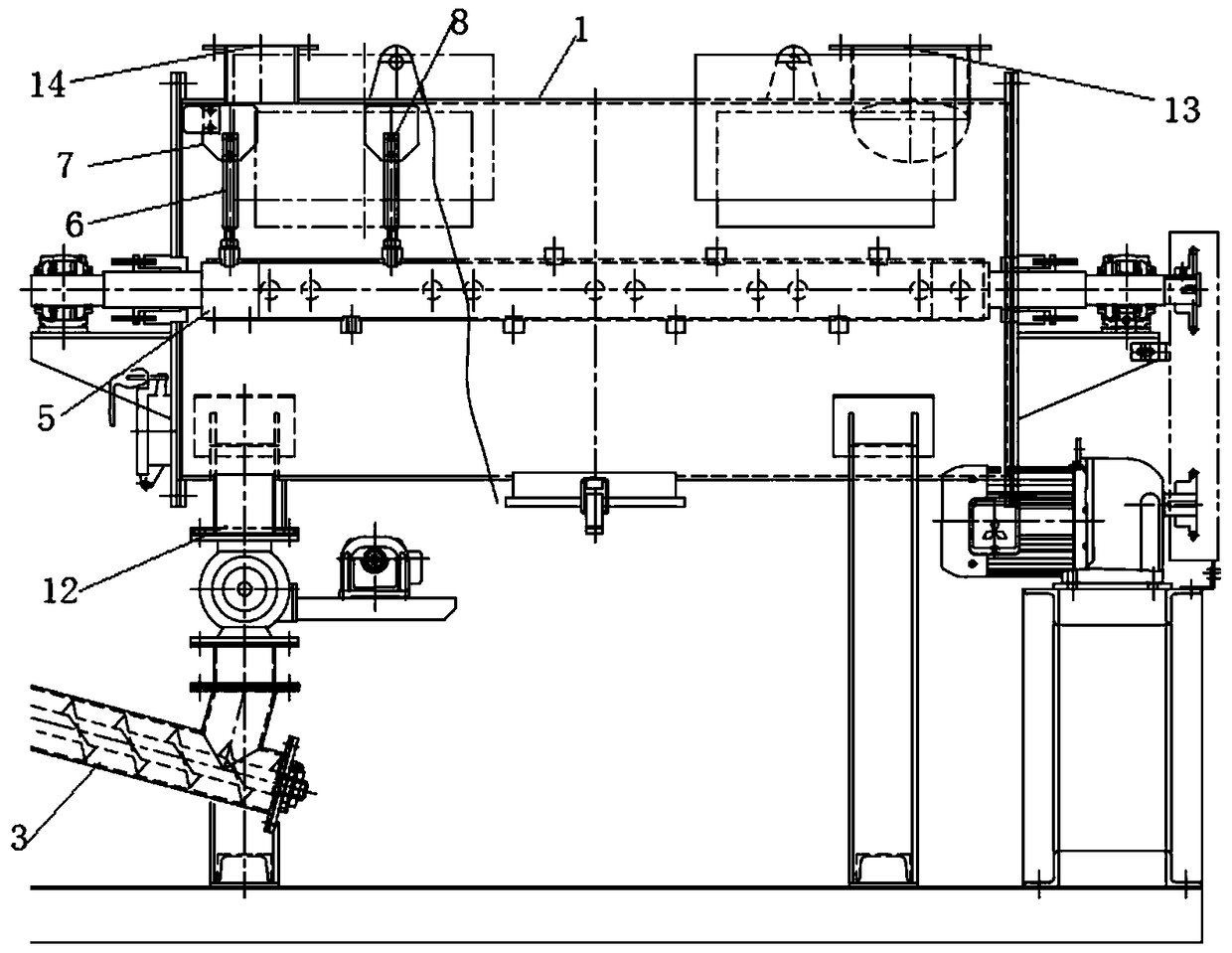

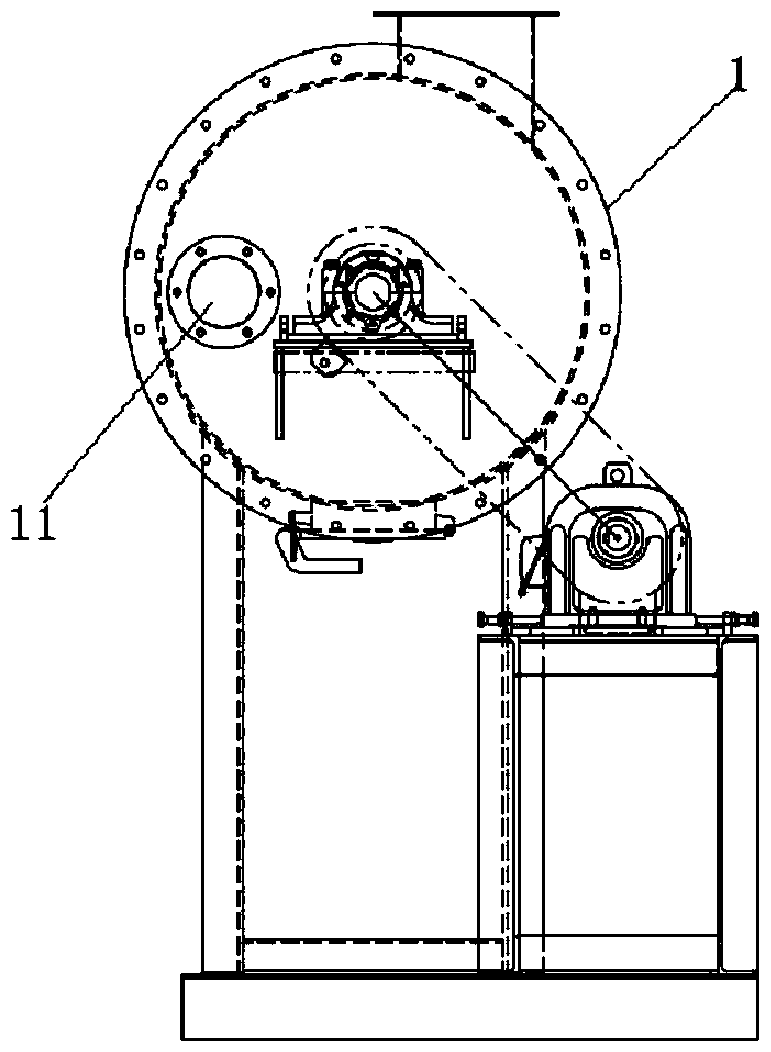

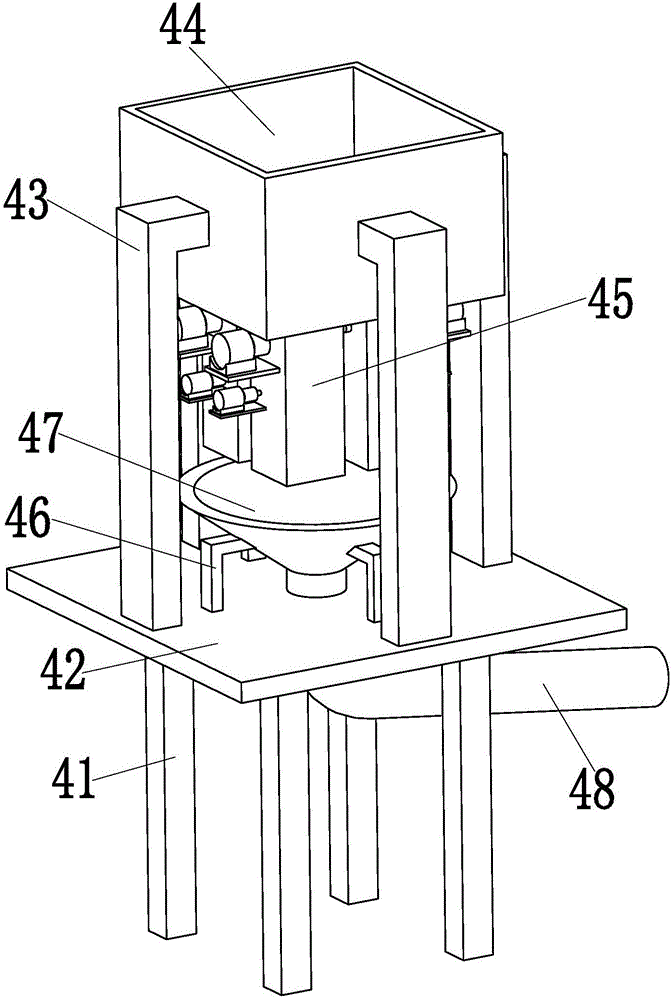

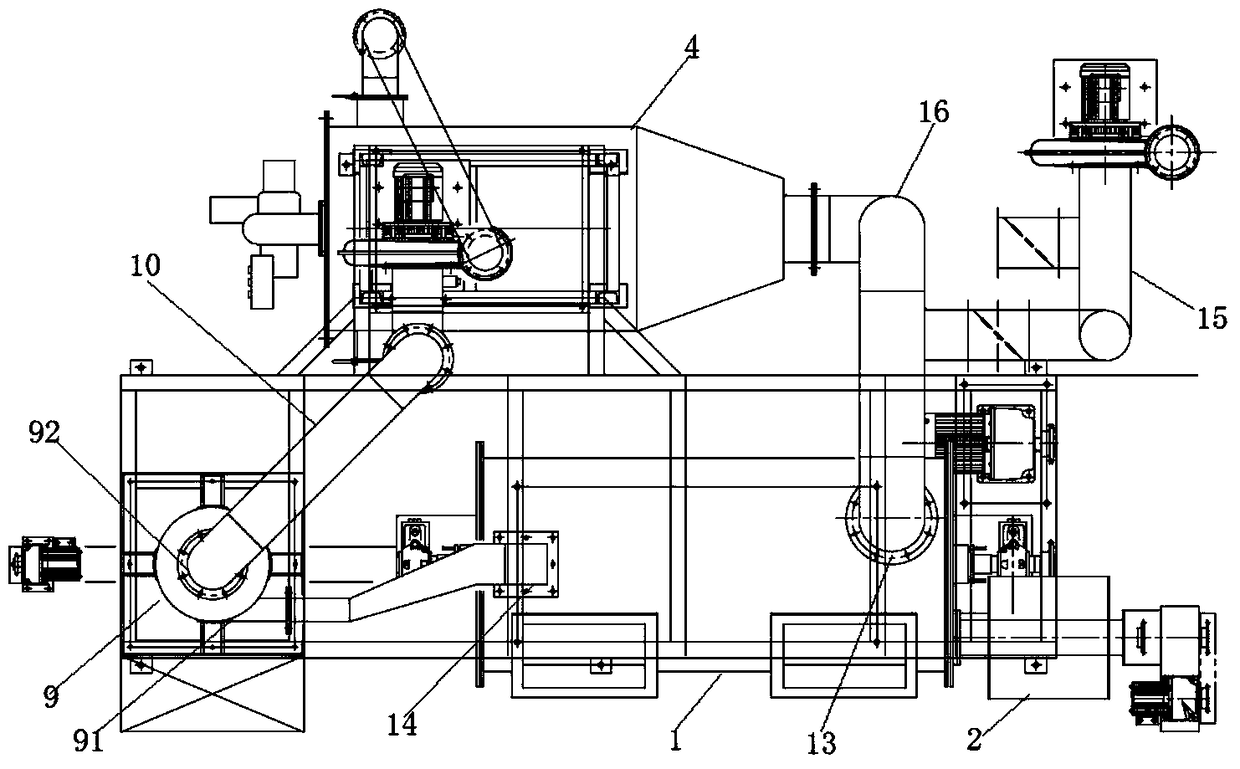

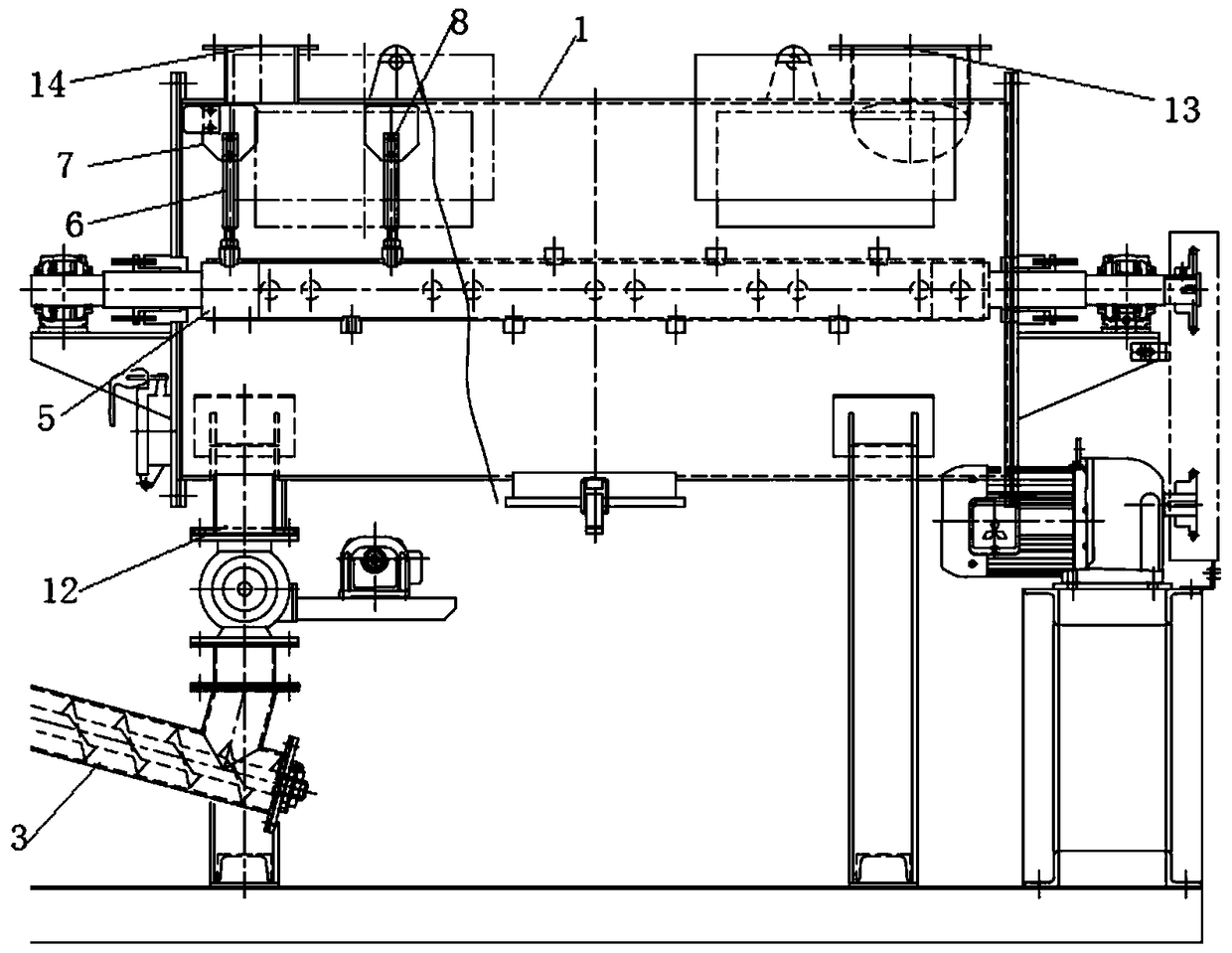

Household garbage pollution-free treatment system capable of accelerating fermentation

InactiveCN108380647ASpeed up space movementImprove crushing efficiencySolid waste disposalTransportation and packagingEnvironmental engineeringIntegrated design

The invention discloses a household garbage pollution-free treatment system capable of accelerating fermentation. The household garbage pollution-free treatment system comprises a primary treatment device, a secondary treatment device and a middle conveying device which is arranged between the primary treatment device and the secondary treatment device. The household garbage pollution-free treatment system is novel in integrated design, simple in structure, comprehensive in function, and convenient and efficient to operate; through primary treatment, middle conveying and secondary treatment, household garbage is subjected to multiple stages of breaking, stirring and treatment, so that the breaking effect is good, the automation degree is high, and the treatment efficiency is improved greatly; and the household garbage pollution-free treatment system is safe, reliable, energy-saving and environmentally friendly.

Owner:惠畅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com