Static nondestructive granulation method for waste asphalt mixture

A technology for waste asphalt and mixture, applied in the direction of grain processing, etc., can solve the problems of insignificant effect of asphalt viscosity, inability to meet grading requirements, and low degree of crushing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

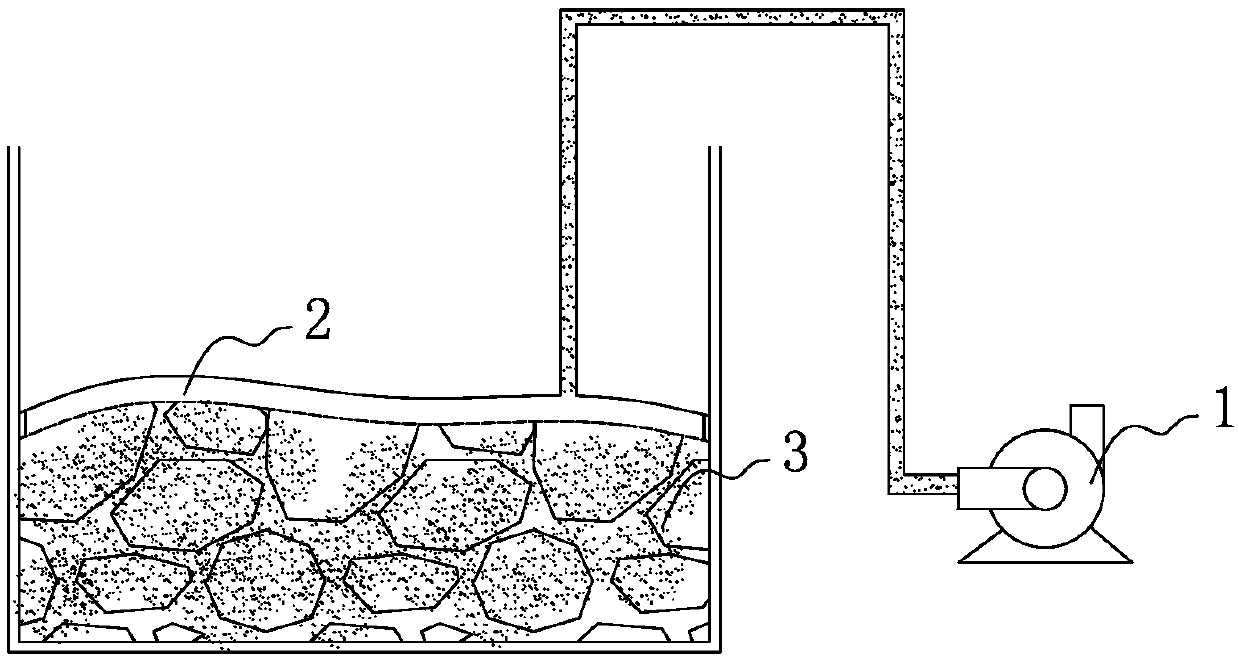

[0071] refer to figure 1 , in this embodiment, the material bin 3 should be in a cylindrical shape, because the circular water-absorbing pad can be combined with the cylinder gap and has a larger space, and more RAP materials that need to be broken can be placed. If it is a square or rectangular material The fit of the gap is the same as that of the round bin, but this shape has four right-angled corners. If it is not handled properly, the sealing effect will be greatly reduced; if it is an oval bin, the sealing effect is considerable, but the storage space is limited. , so the circular silo is the best choice.

[0072] Pour an appropriate amount of RAP material into the material bin 3 in advance. Usually, the amount of RAP material occupies no more than two-thirds of the volume in the material bin, so as to reserve enough grouting space. The physical size range of the usual RAP material as follows:

[0073] Step 1, the ratio of the slurry, according to the best experimental...

Embodiment 2

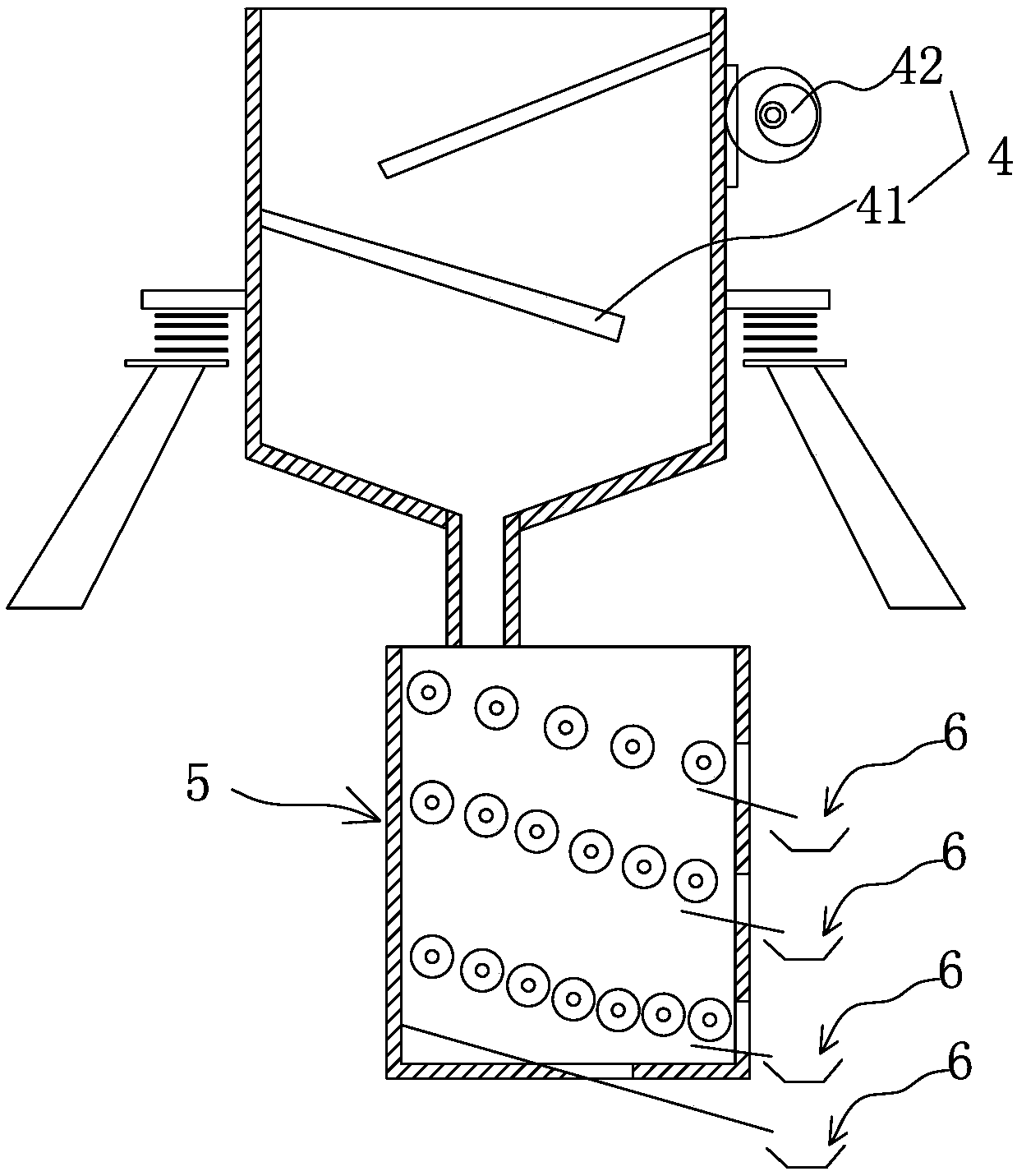

[0087] This embodiment is to improve the crushing scheme and provide a reliable crushing scheme, that is, to replace the vibration cracking machine in step 4, refer to Figure 9 , the rotary crusher 7 is a drum-shaped tank as a whole, and a rotating disk is arranged inside the tank. The top of the tank is a feed inlet 71, the feed inlet is funnel-shaped, and the bottom is a discharge outlet. 72. The discharge port is designed to be funnel-shaped and directly facing the vibrating screening machine below. The inner wall of the tank body is inlaid with a cast iron wear-resistant plate 73. When the central rotating disk 74 rotates at high speed, the asphalt material is thrown out at high speed and hits the outer cast iron wear-resistant plate 73. The above-mentioned rotating disk 74 It is driven by the speed-regulating and variable-frequency motor 75 located below, that is to say, the speed of the rotating disc body is adjustable and controllable. The mechanical installation struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com