Patents

Literature

34results about How to "Affect the degree of looseness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drying device

ActiveCN105387712AKeep dryStir wellSludge treatment by de-watering/drying/thickeningSludge dryingEngineeringProduct gas

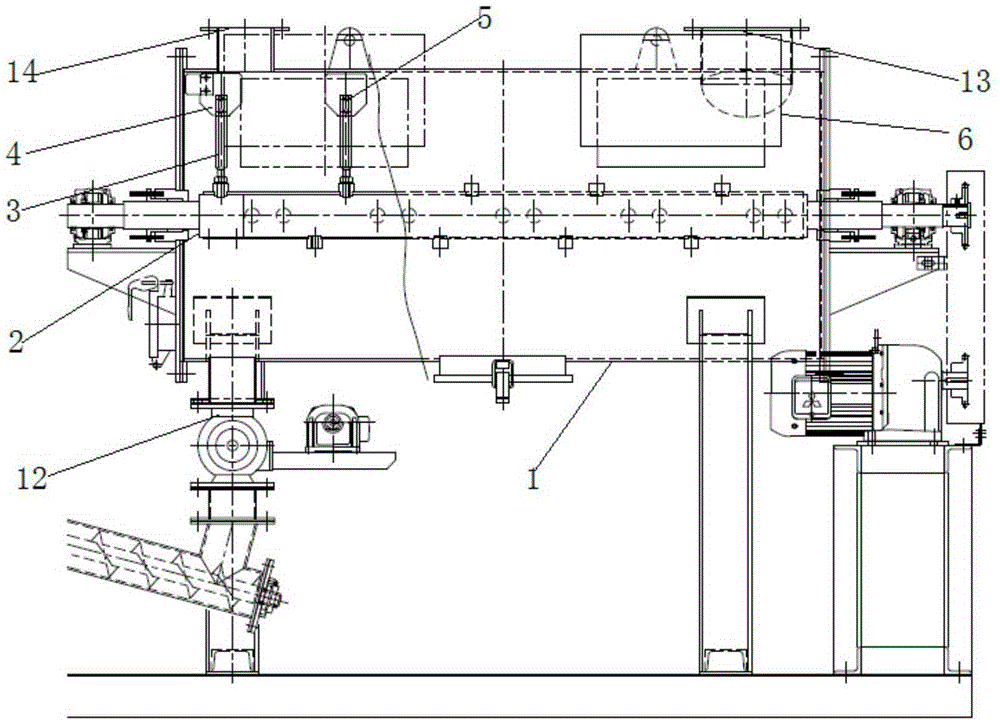

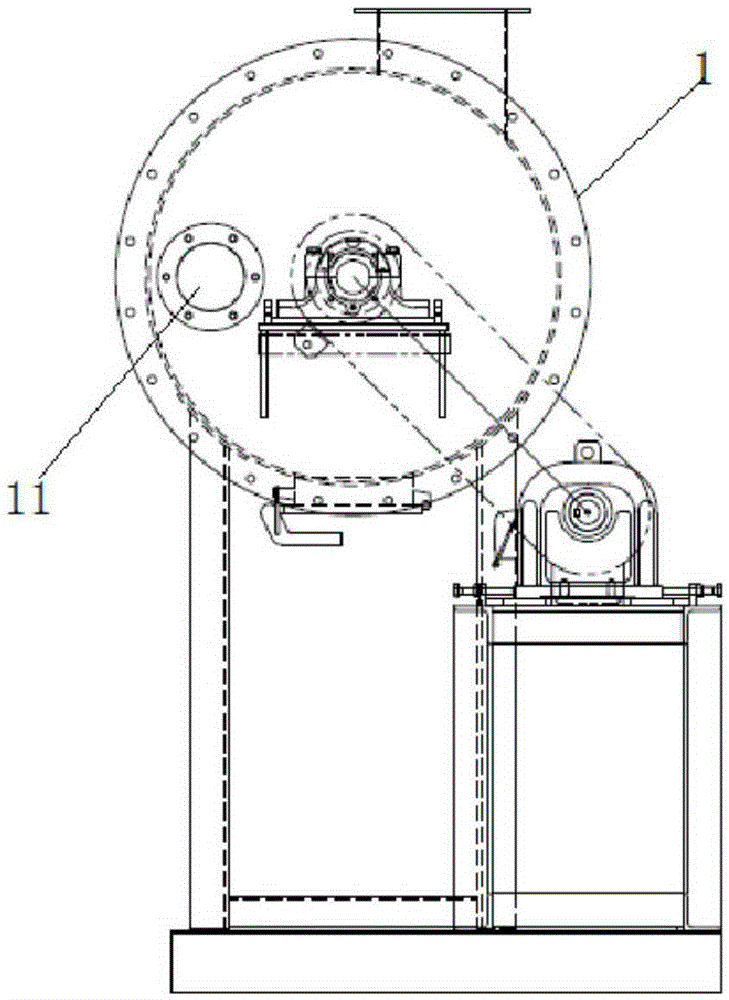

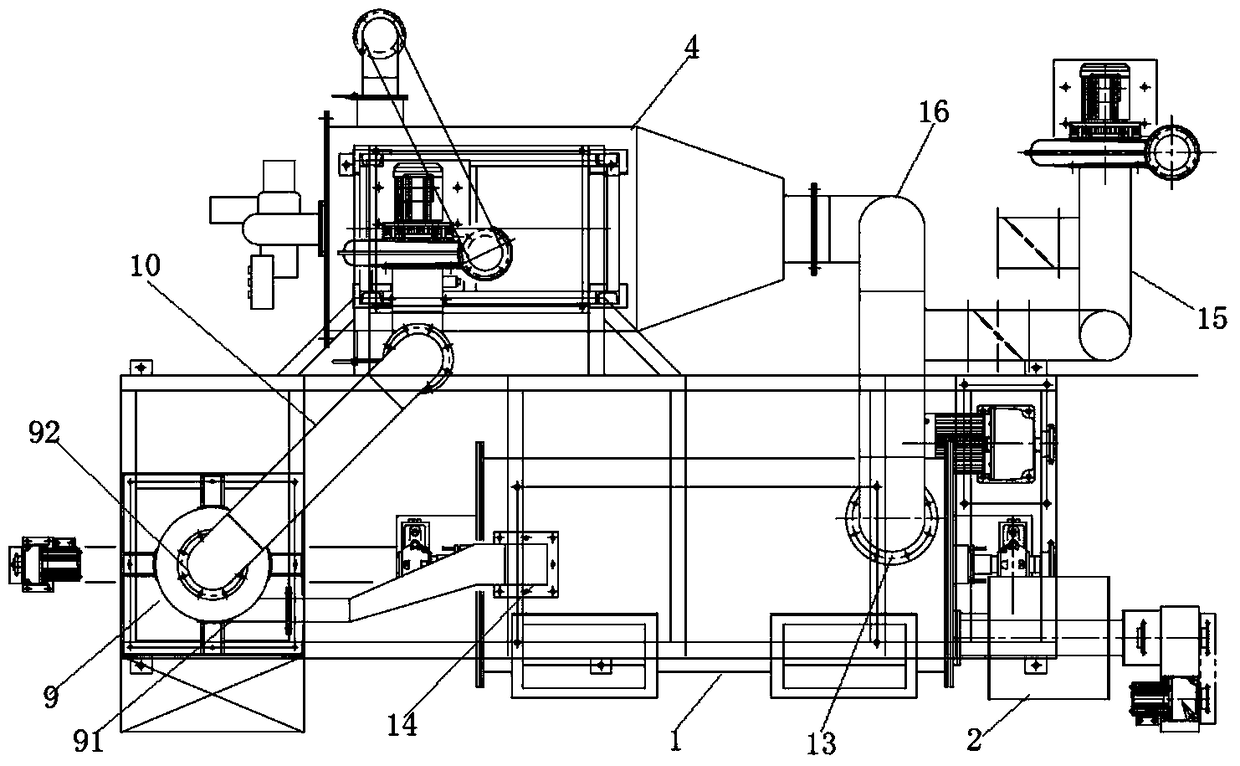

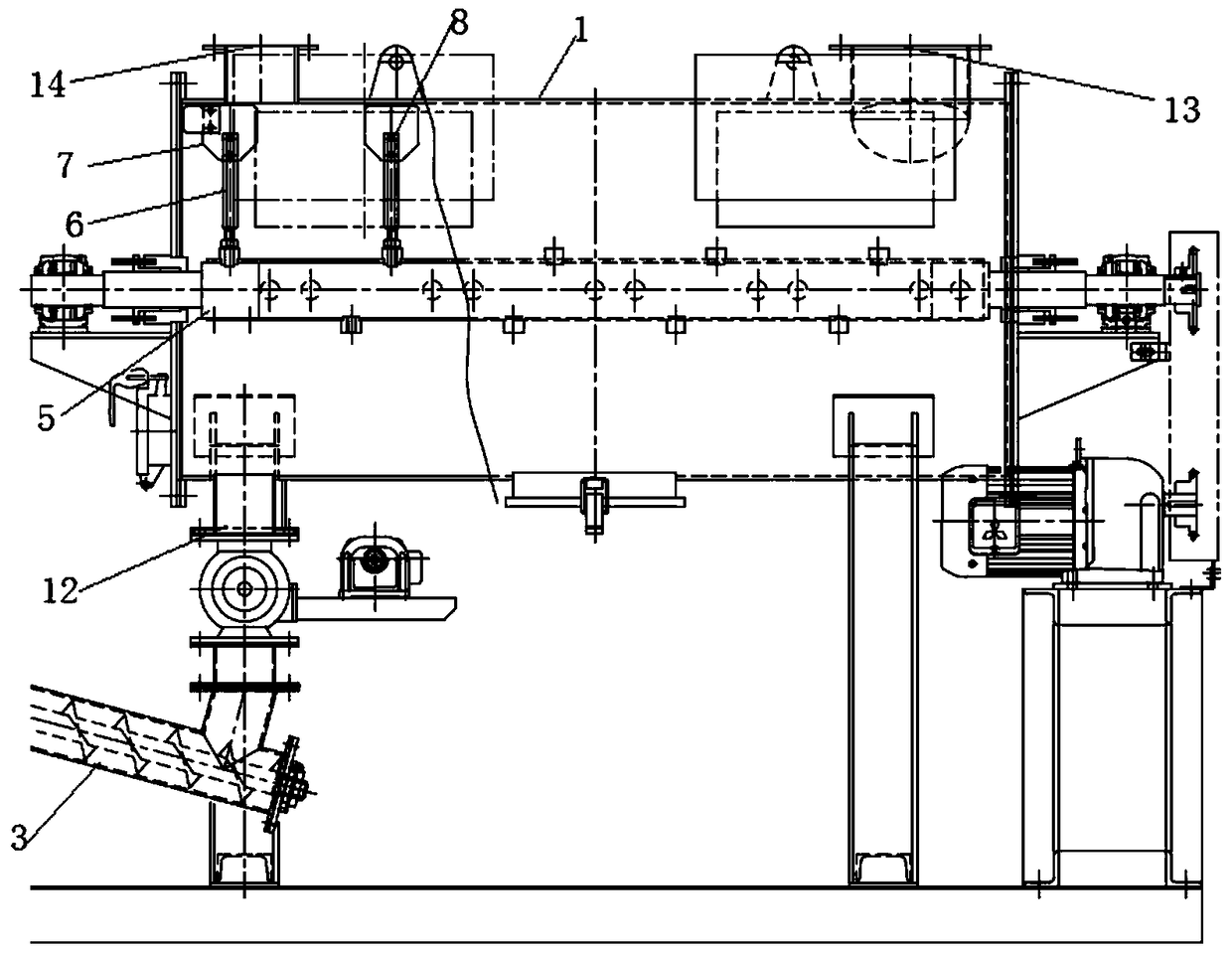

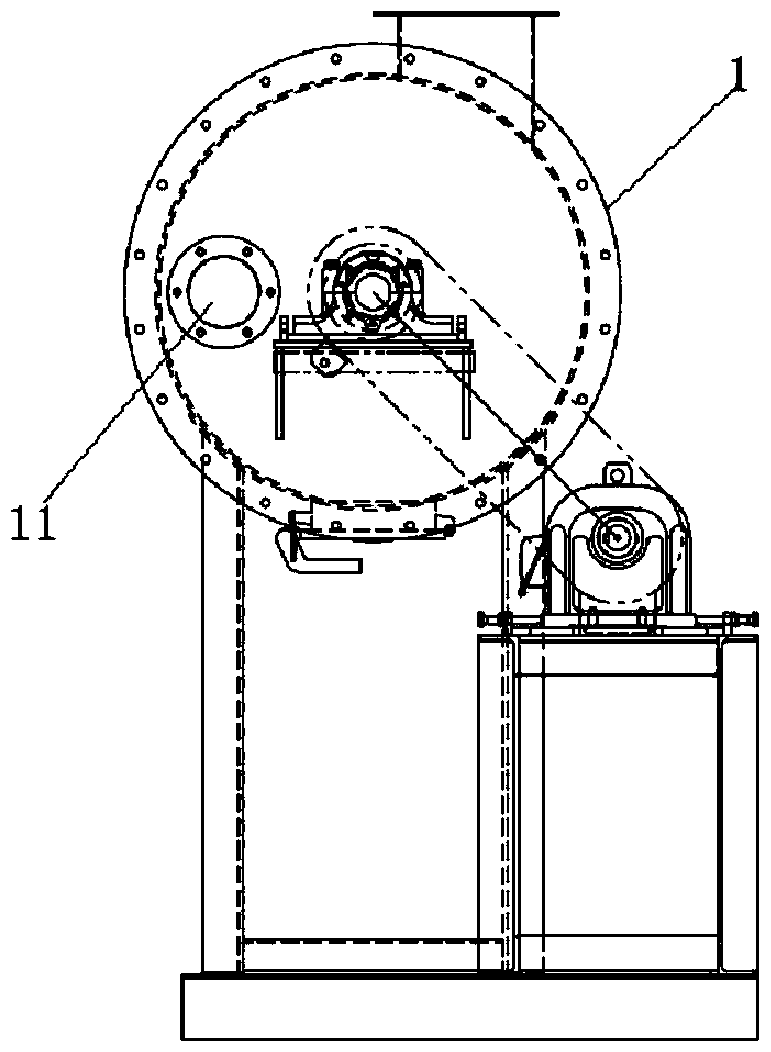

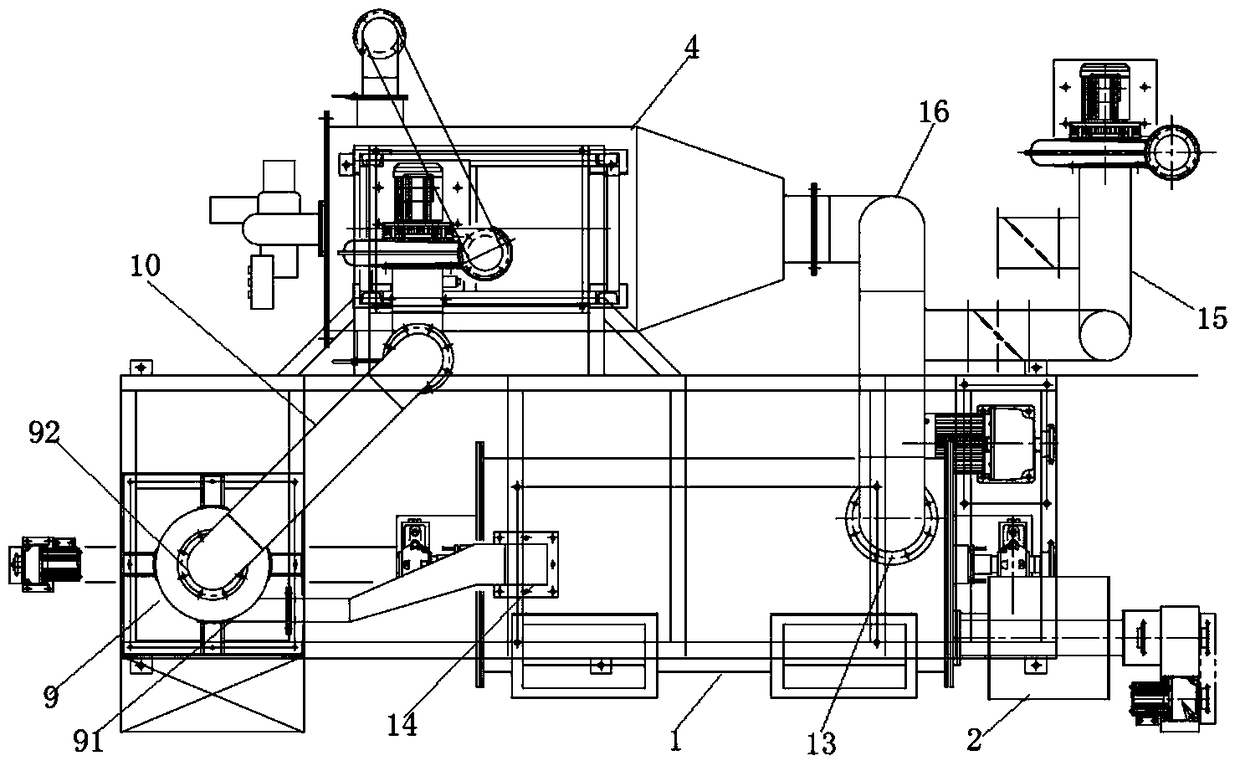

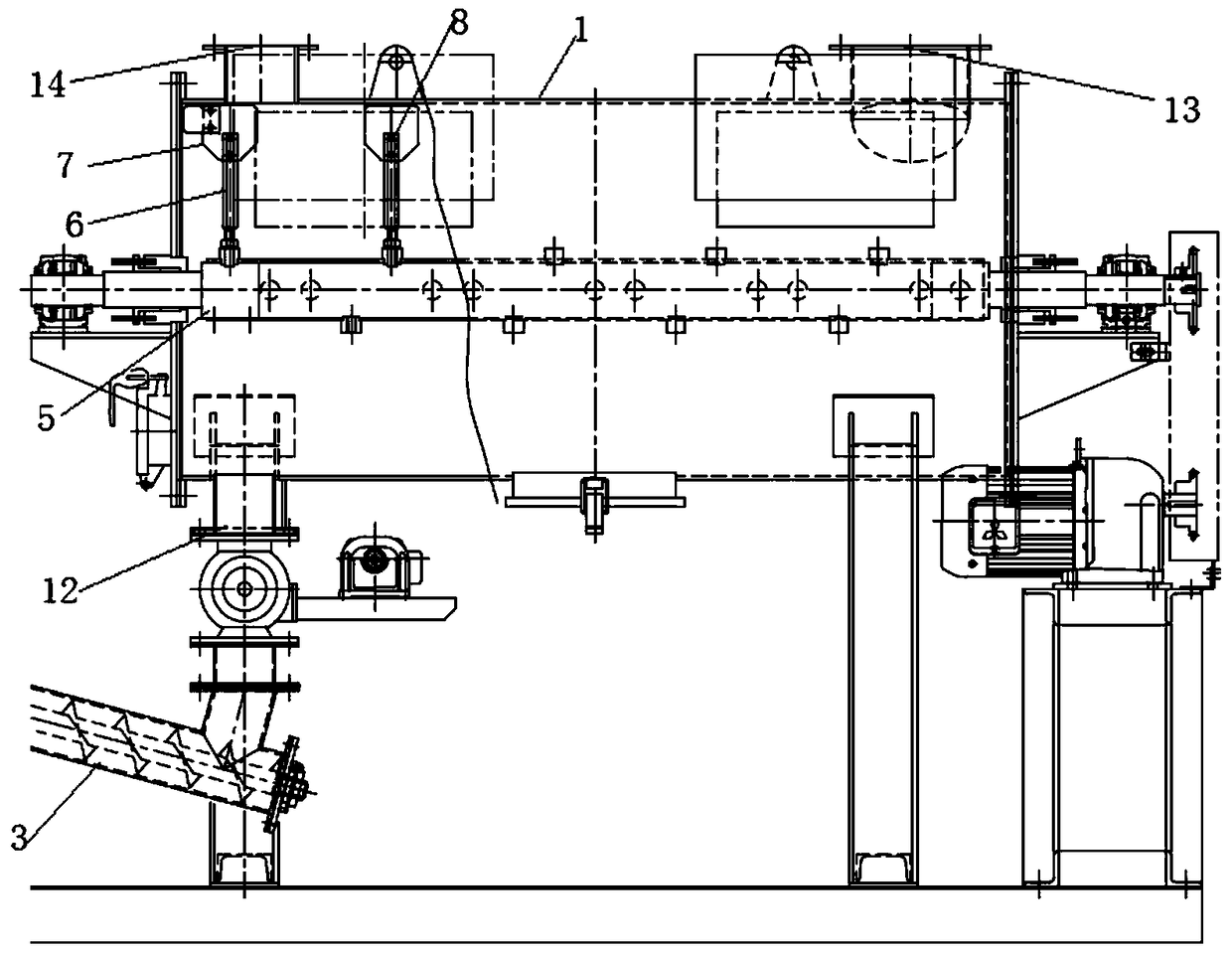

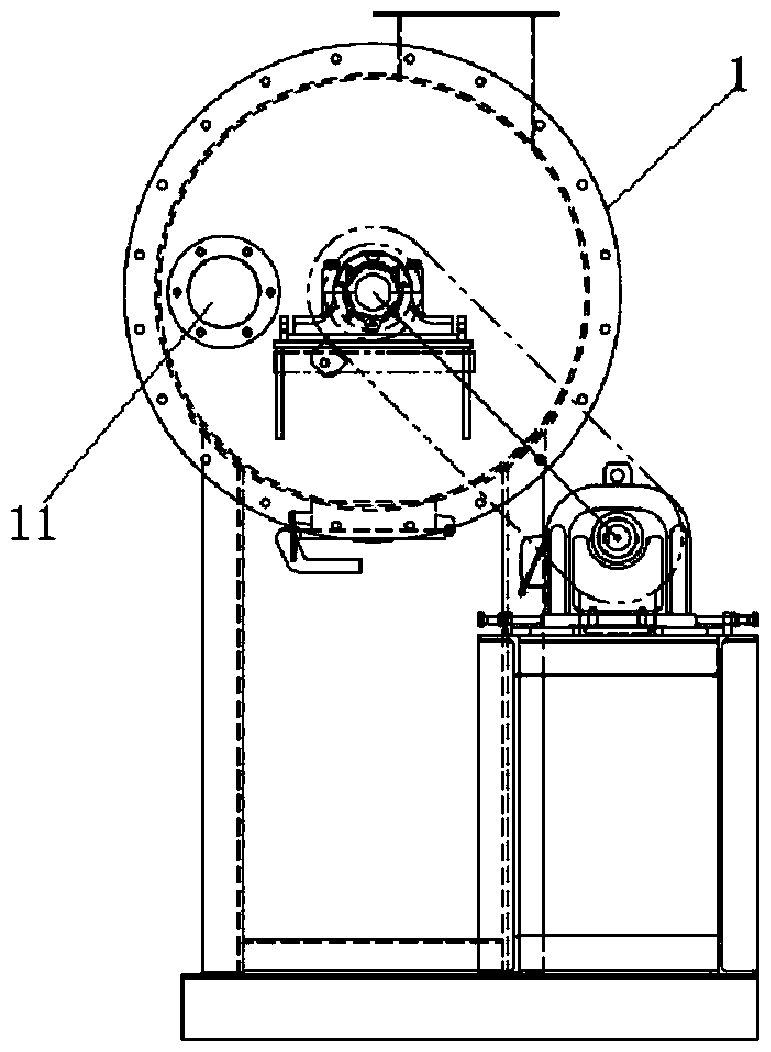

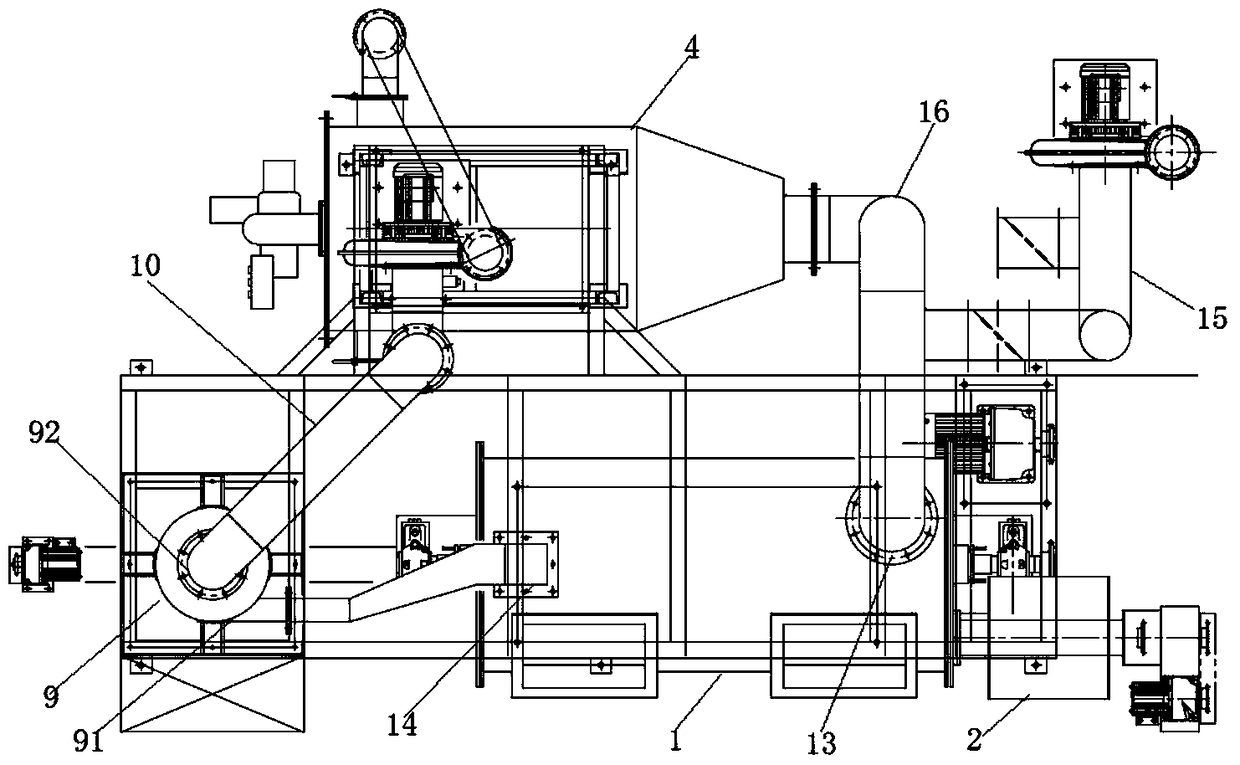

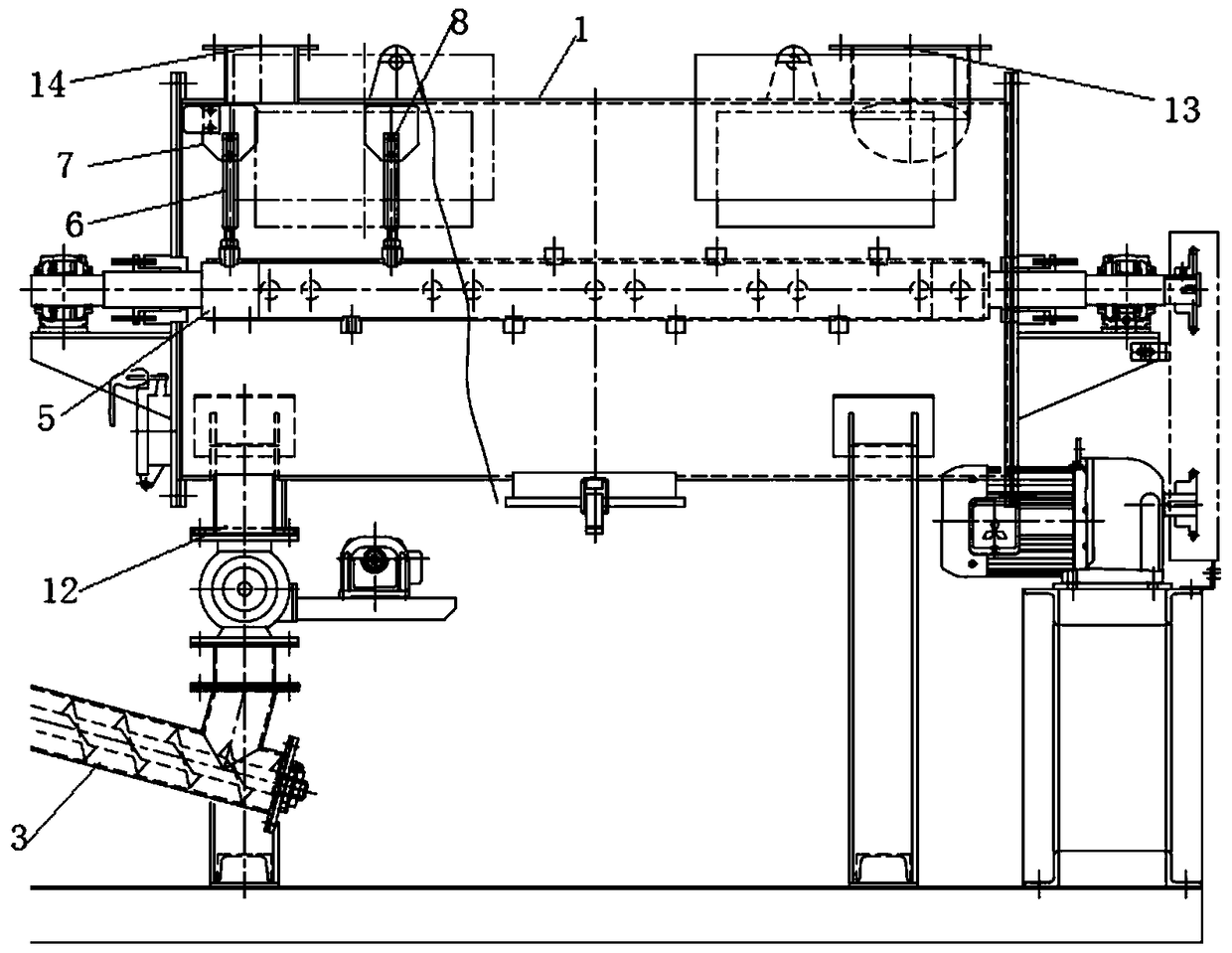

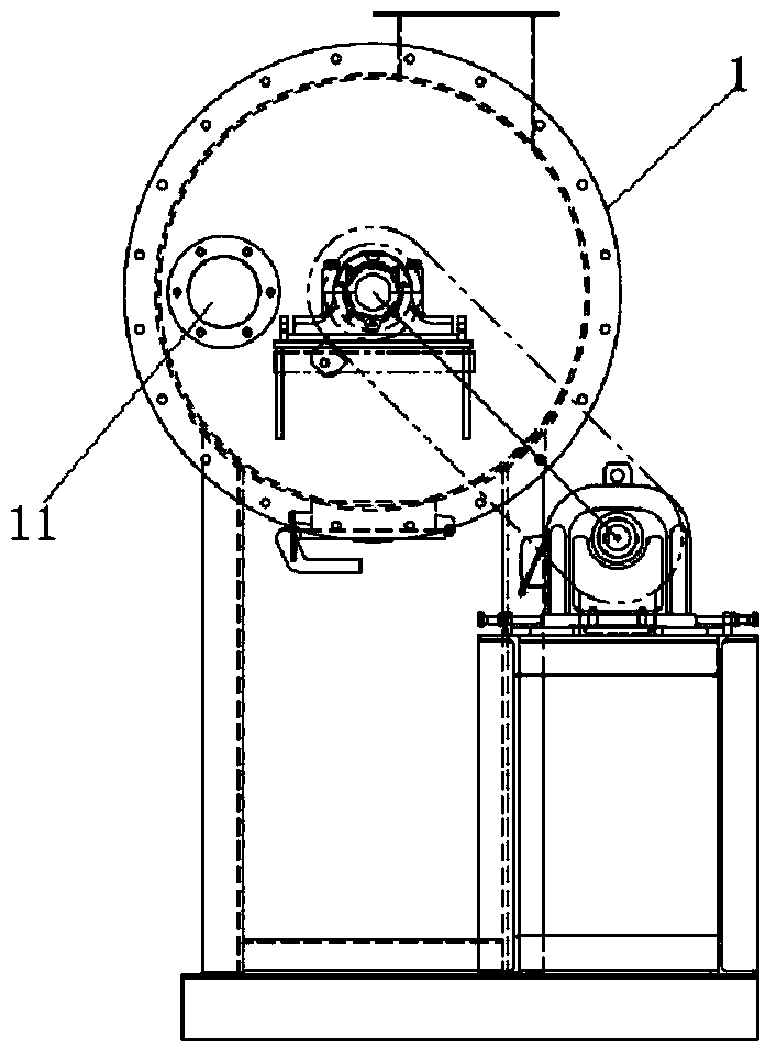

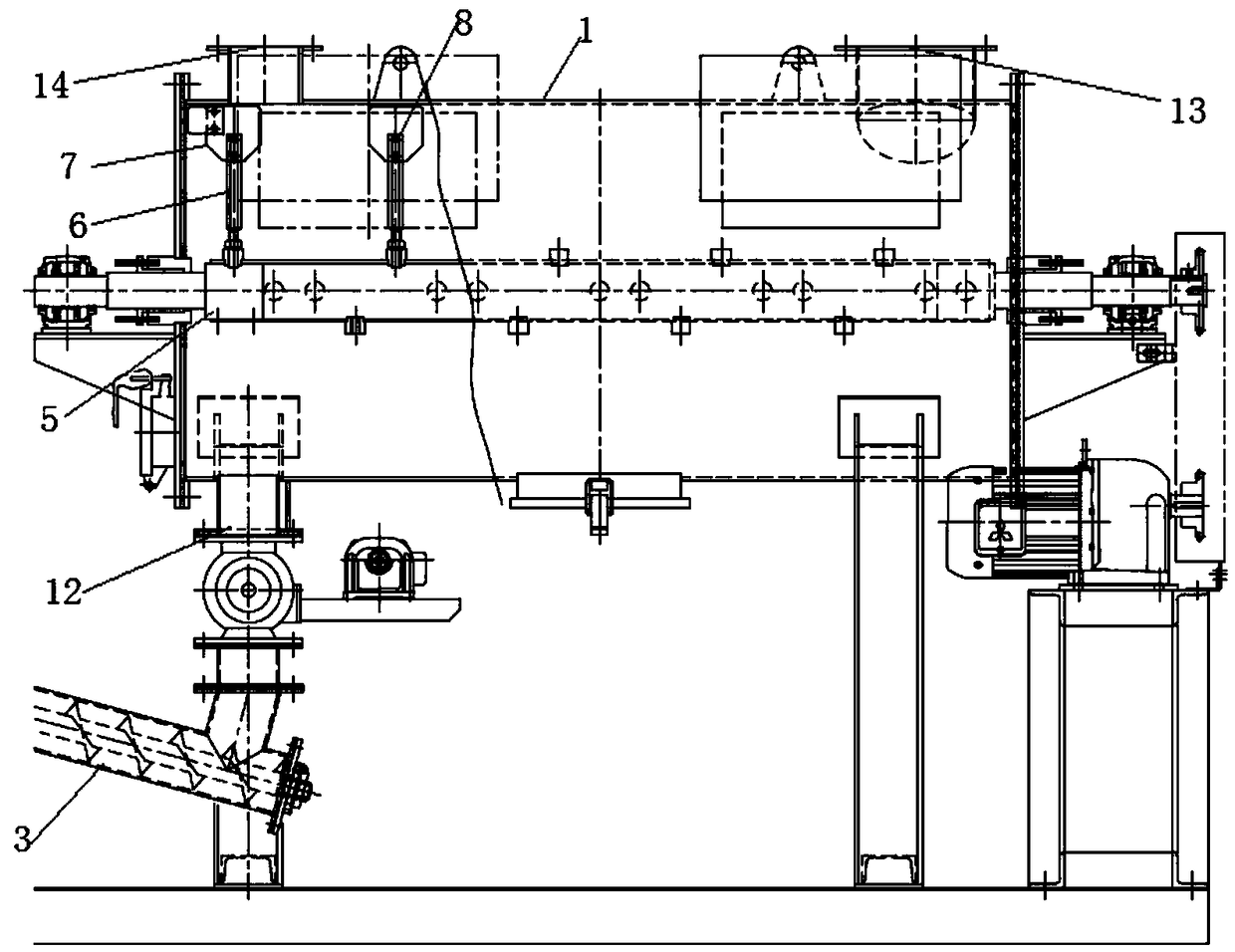

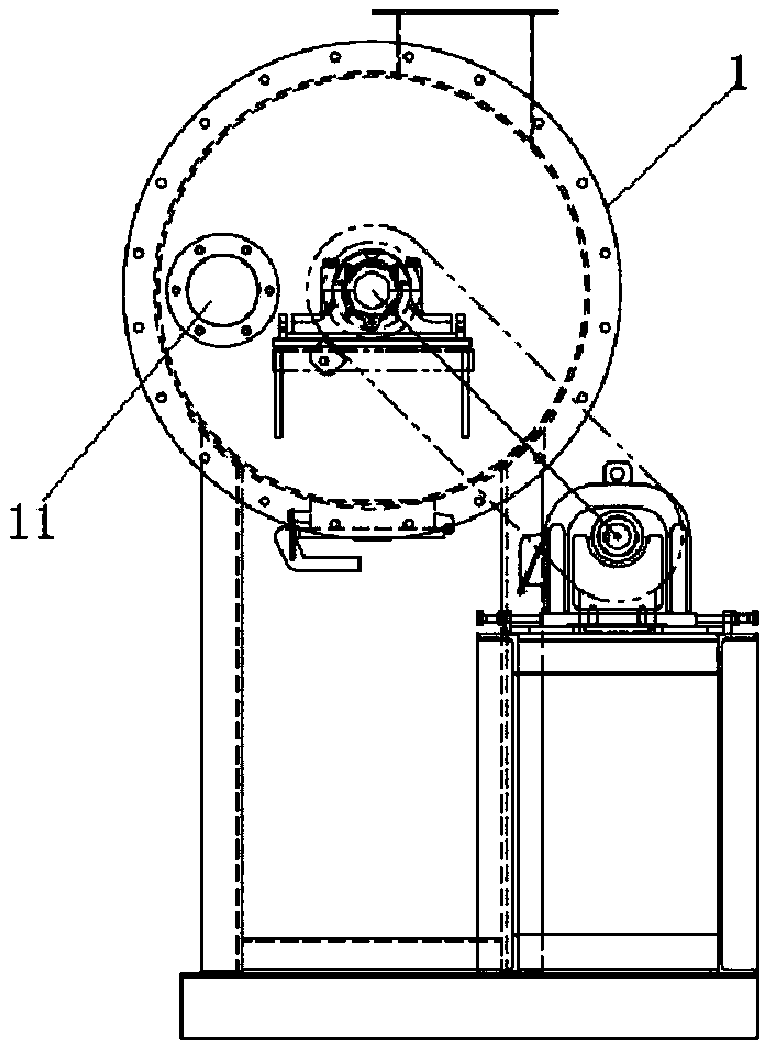

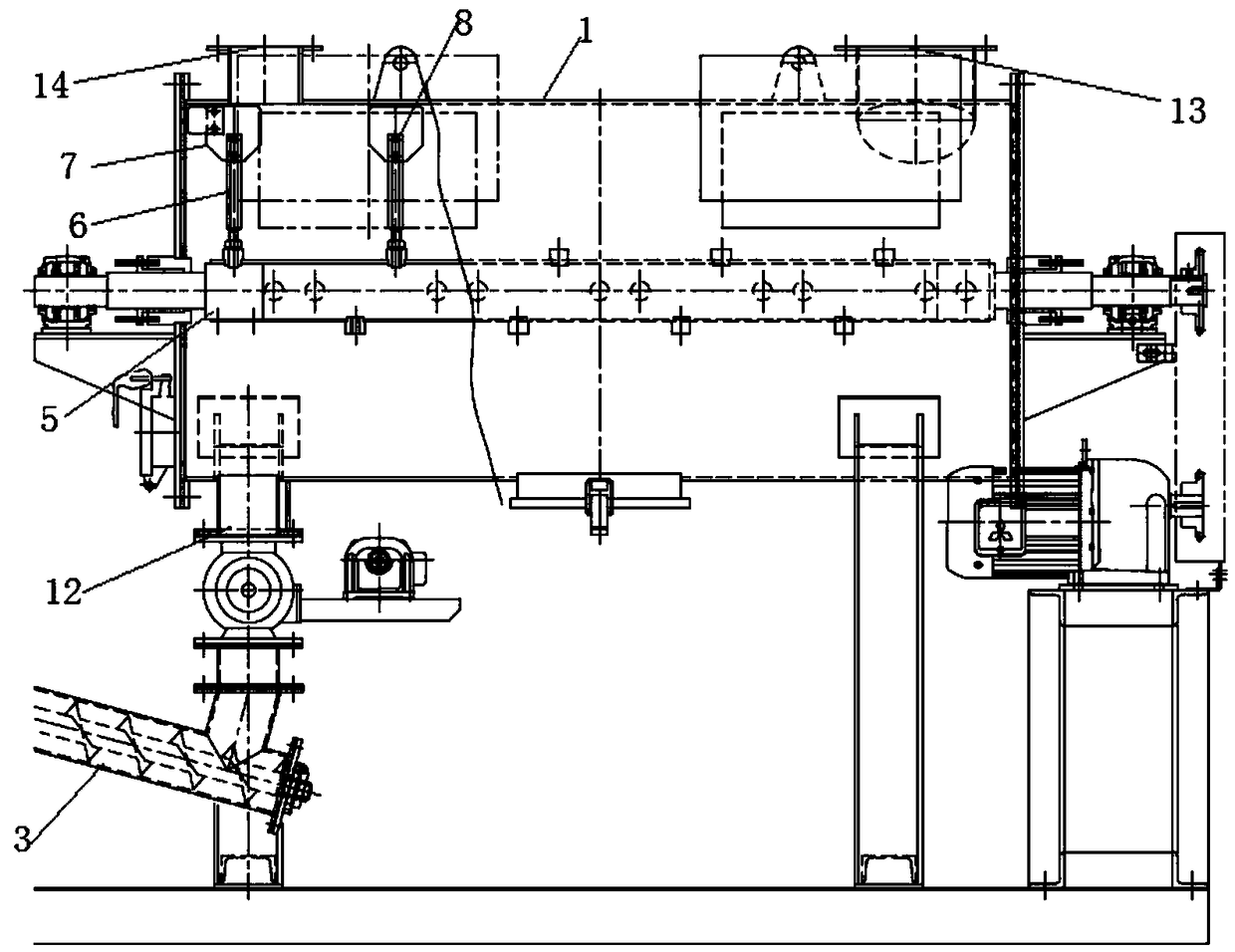

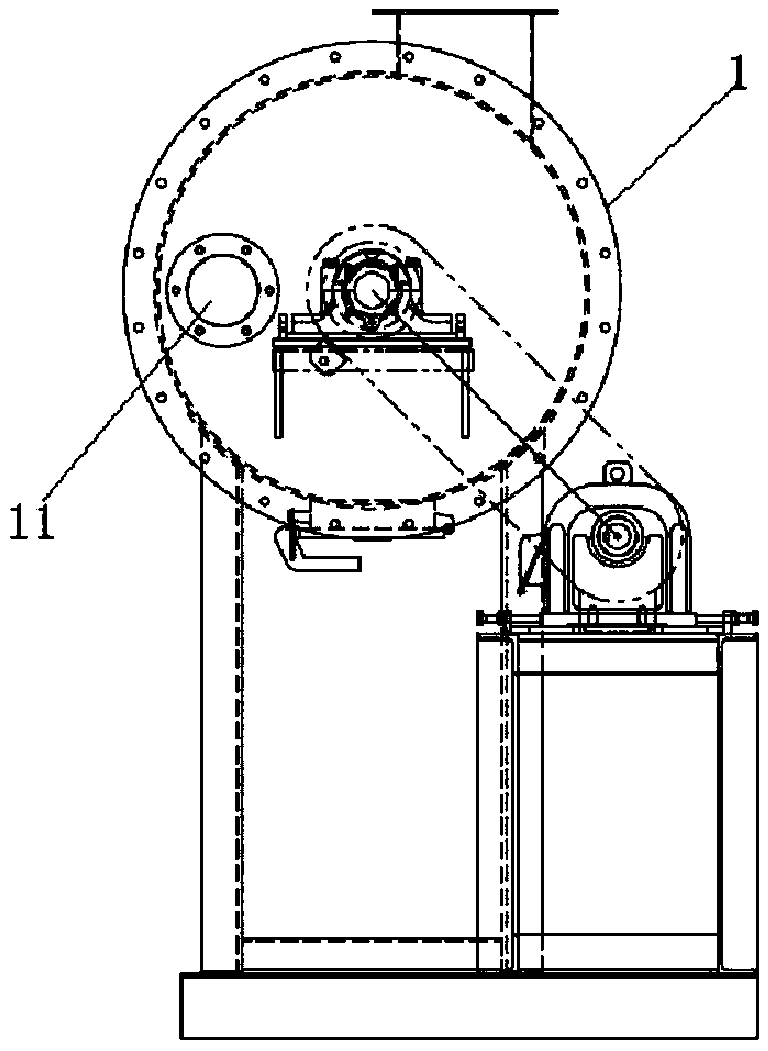

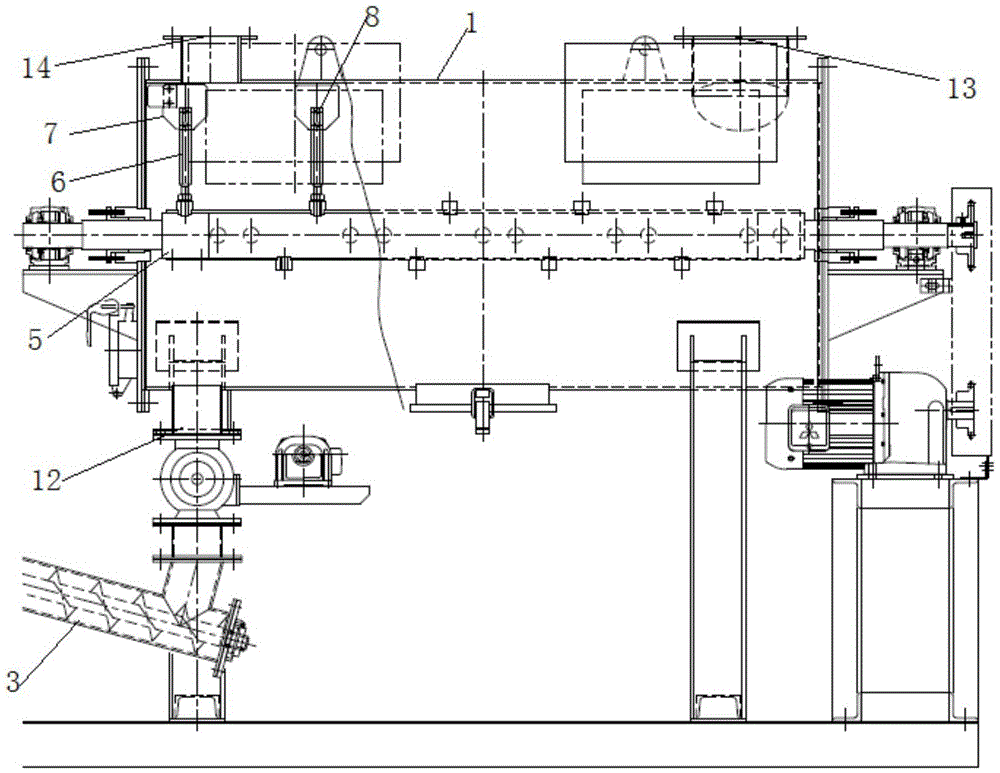

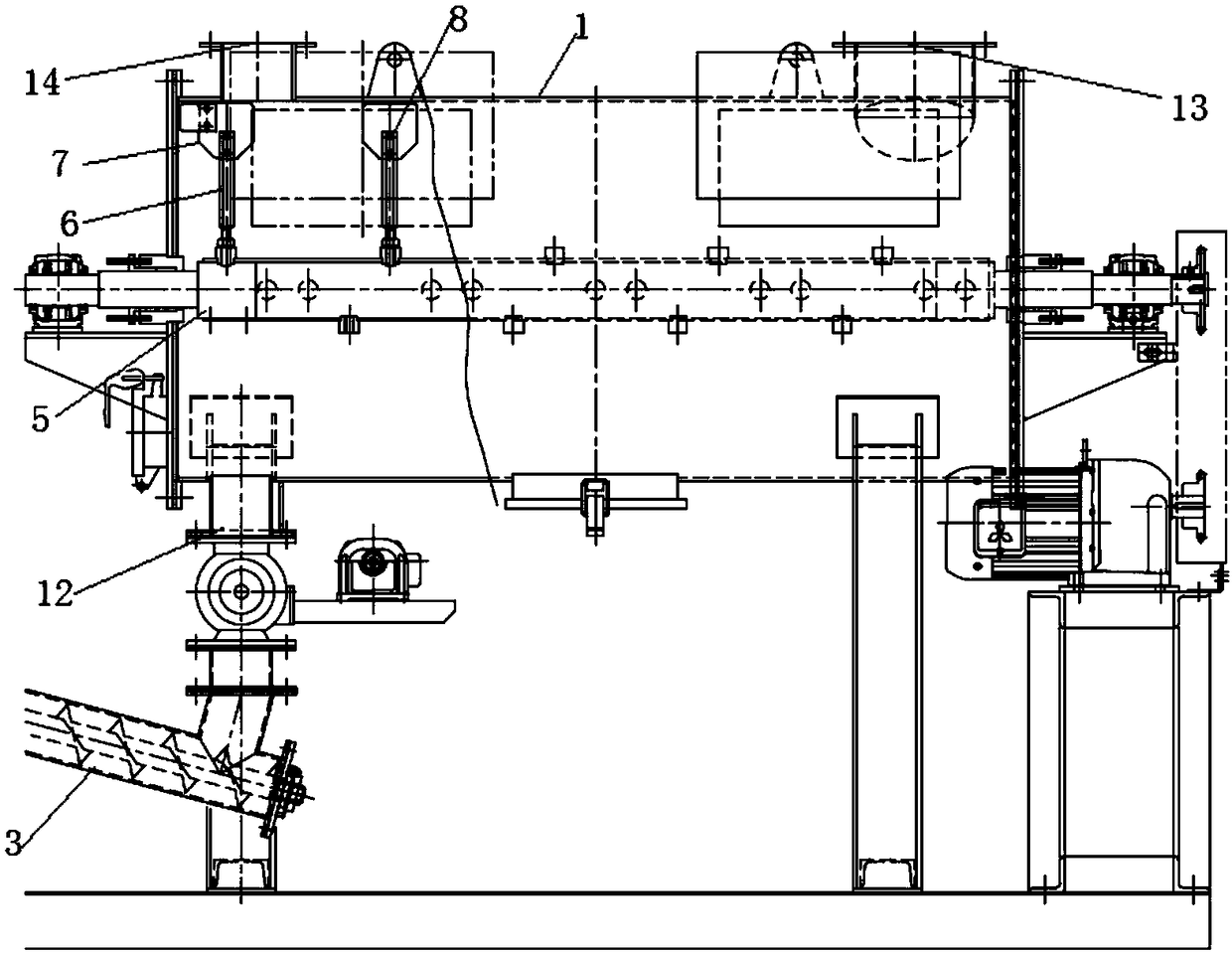

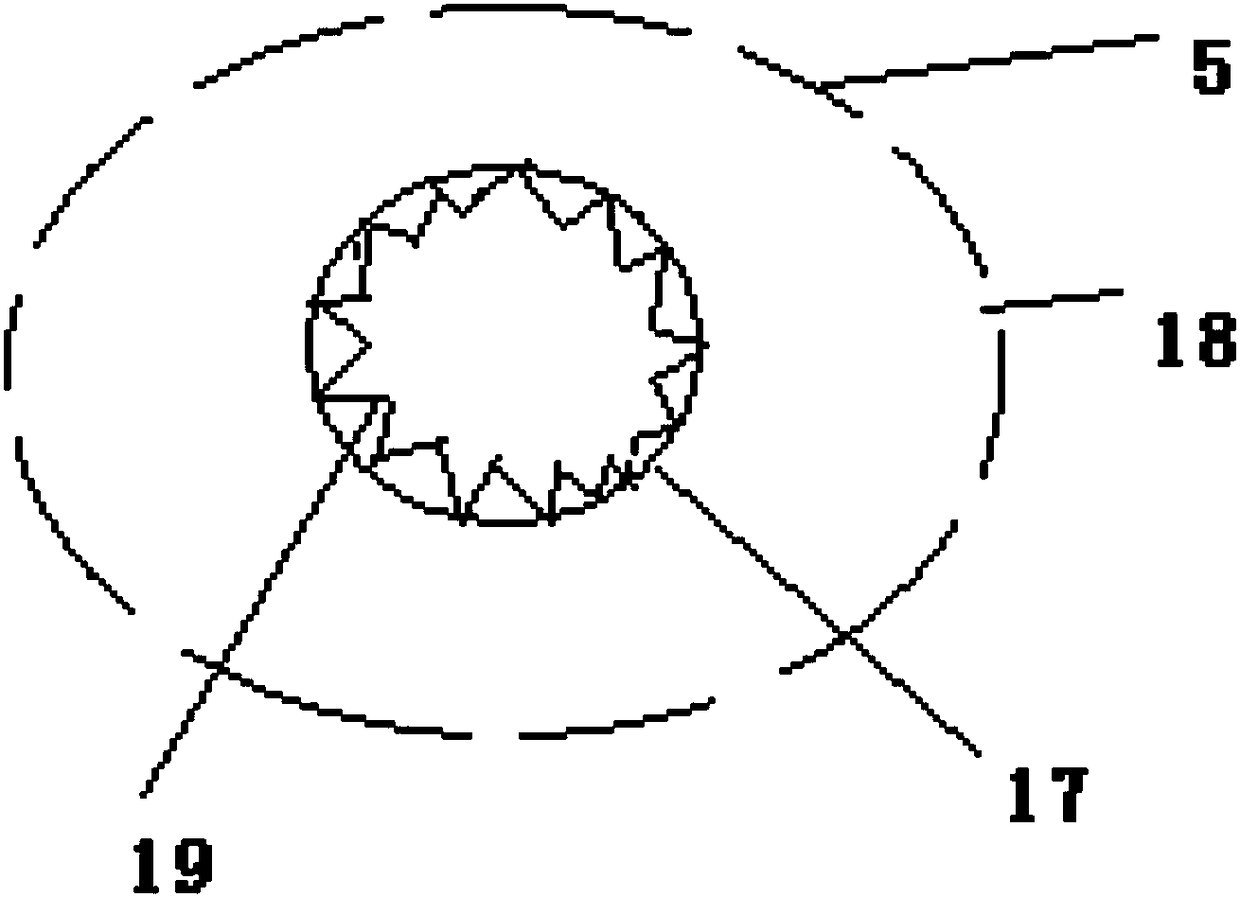

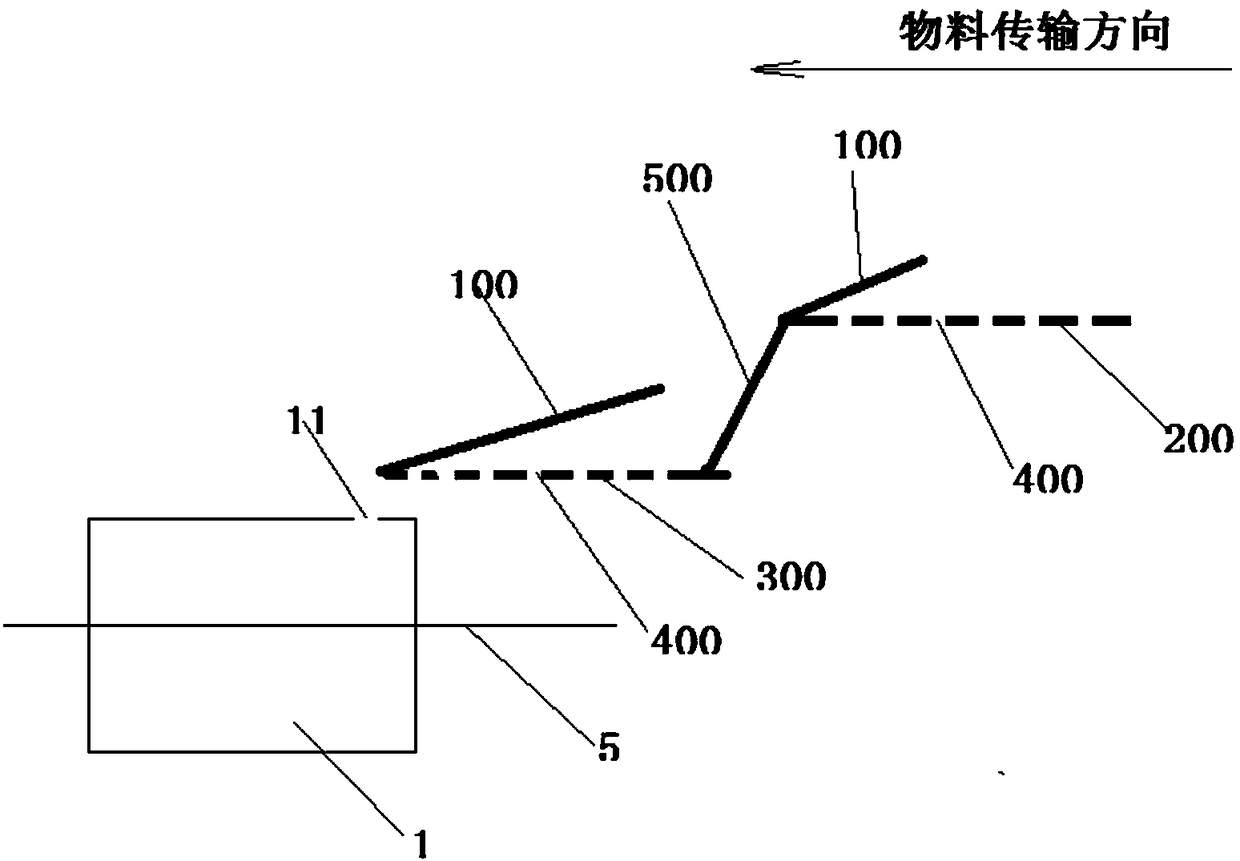

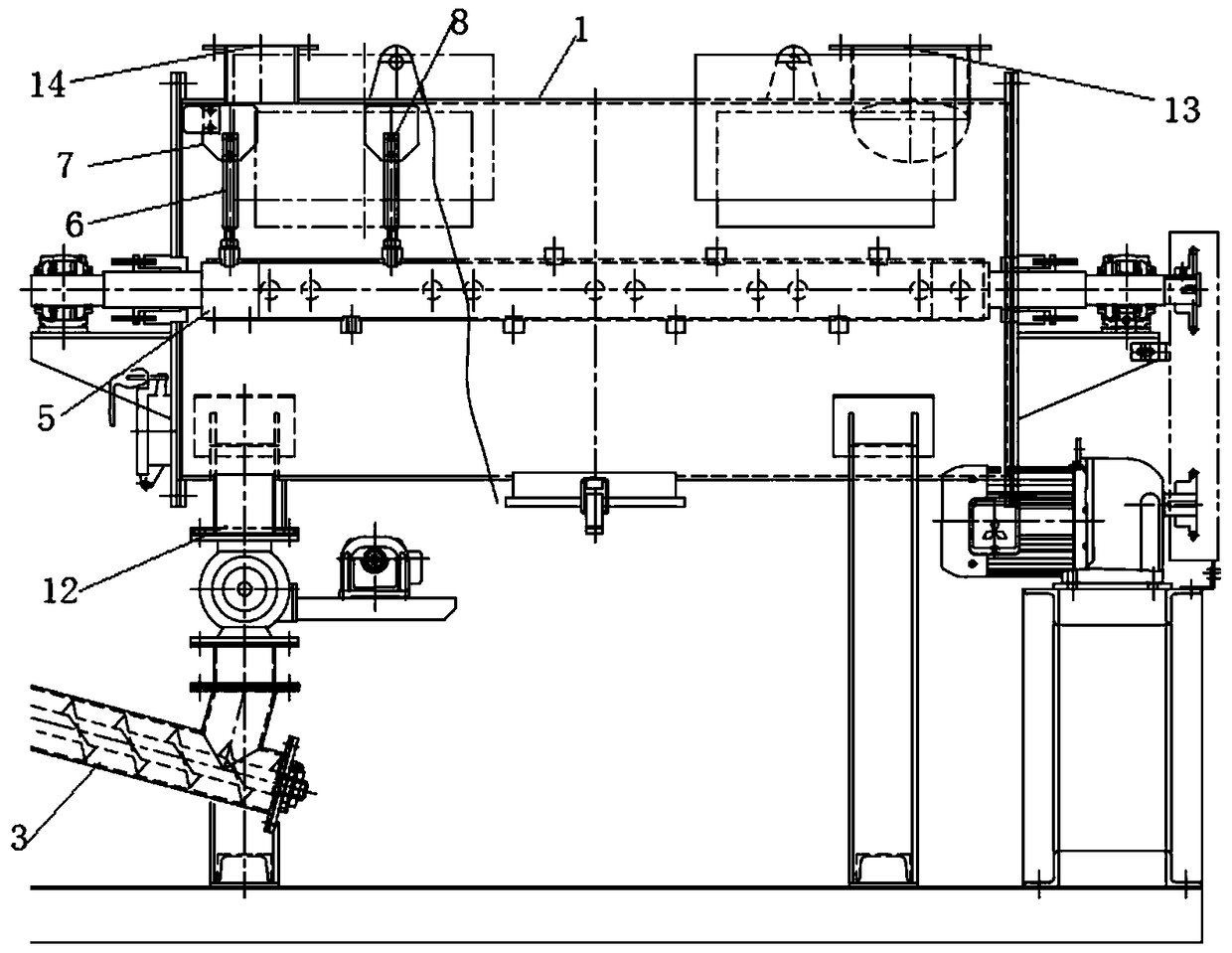

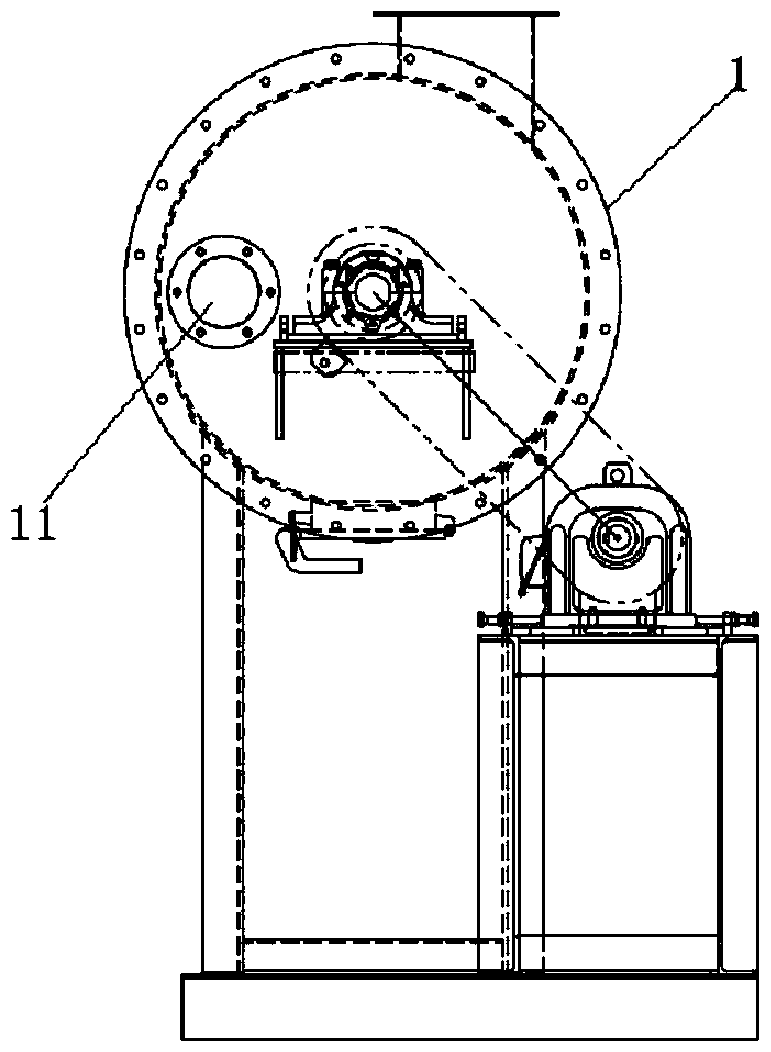

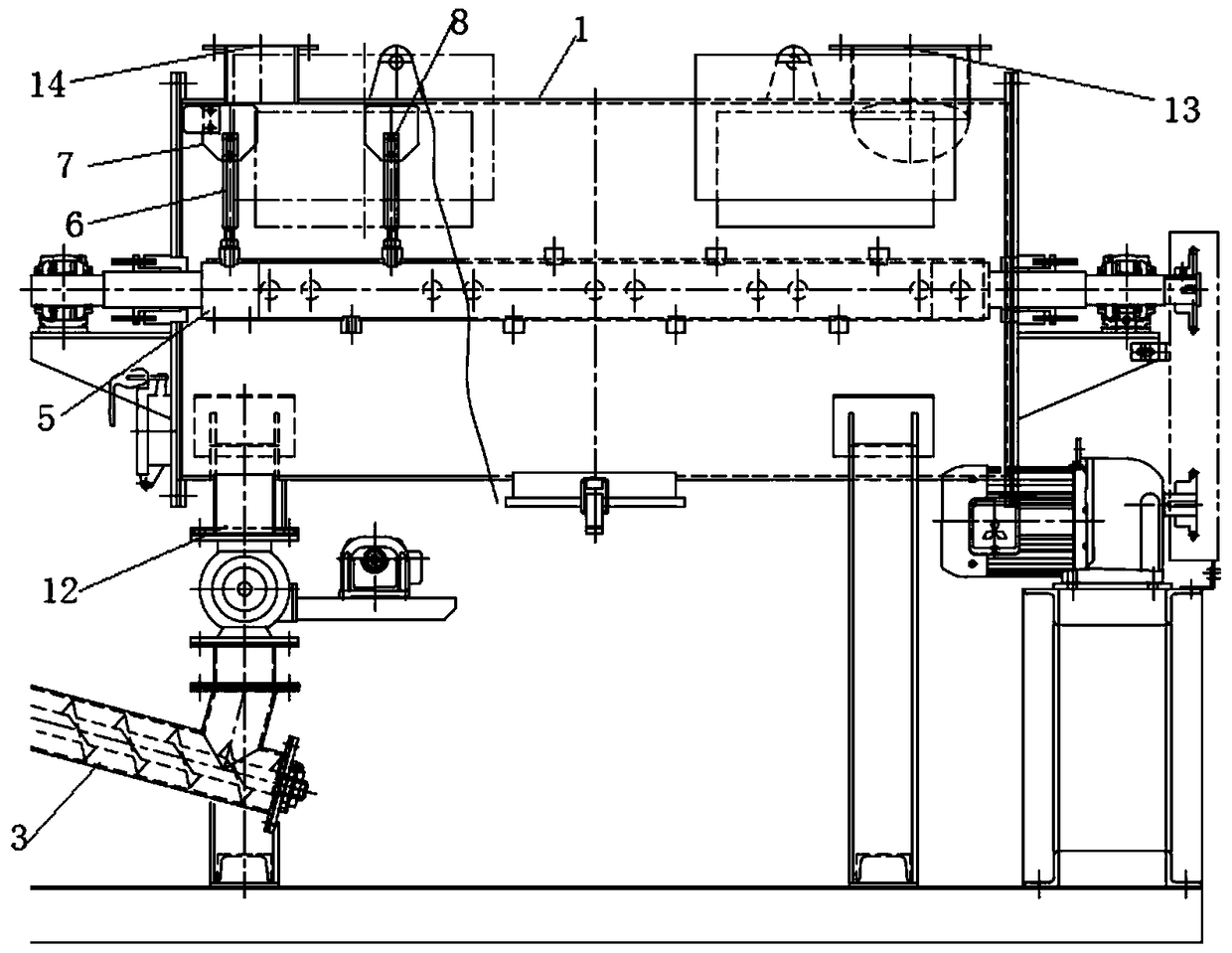

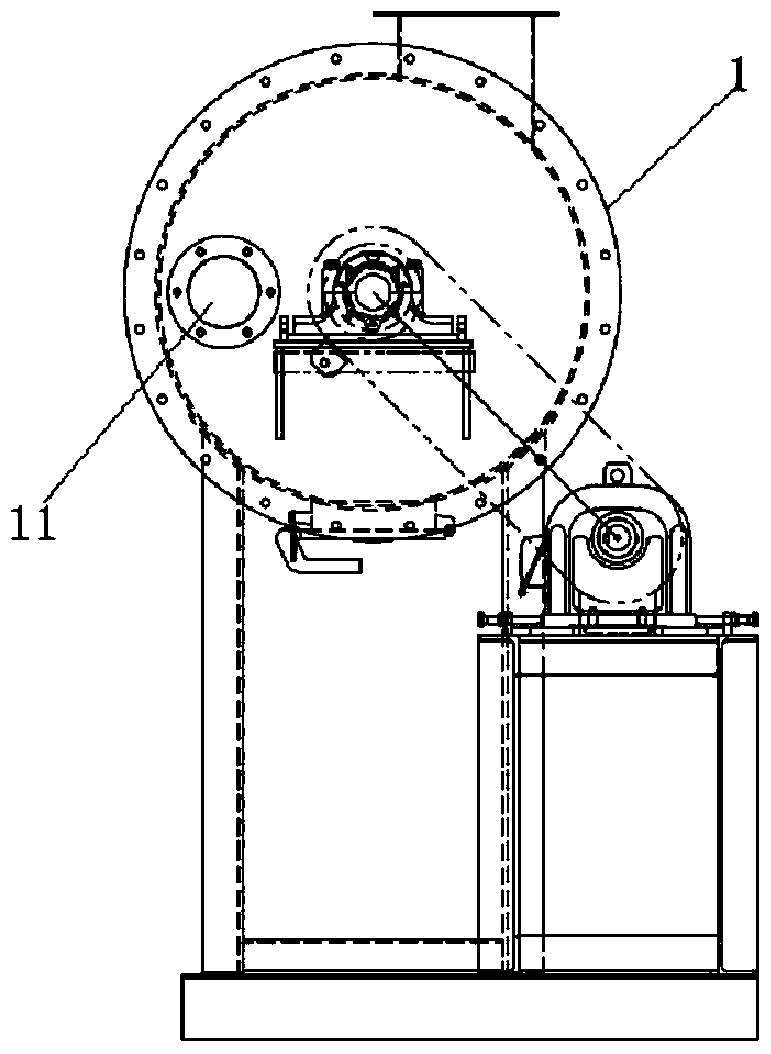

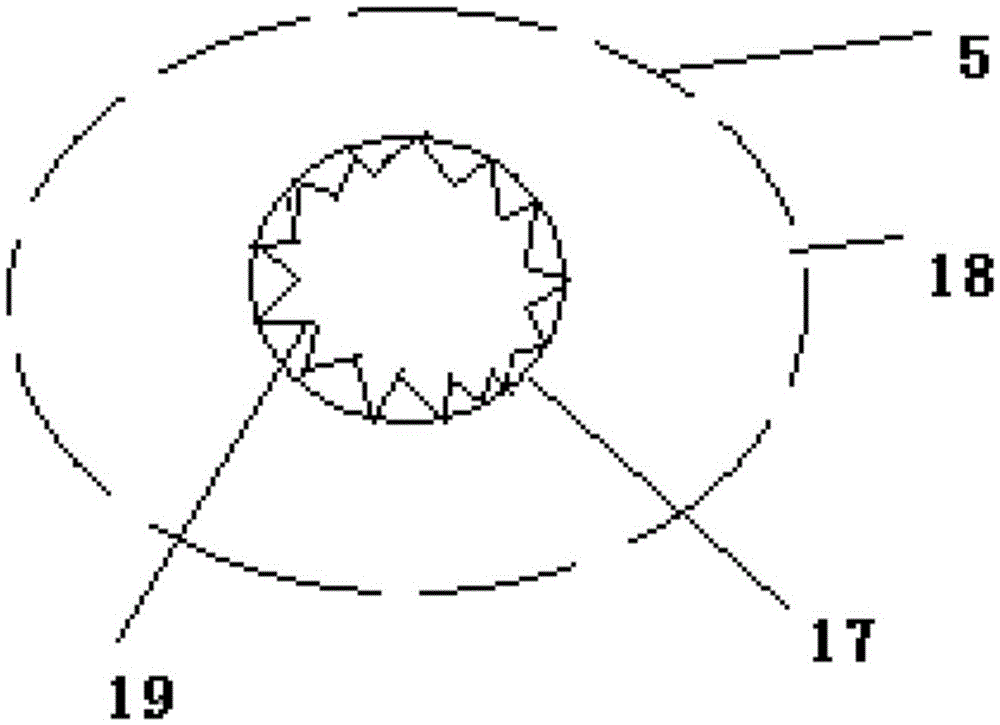

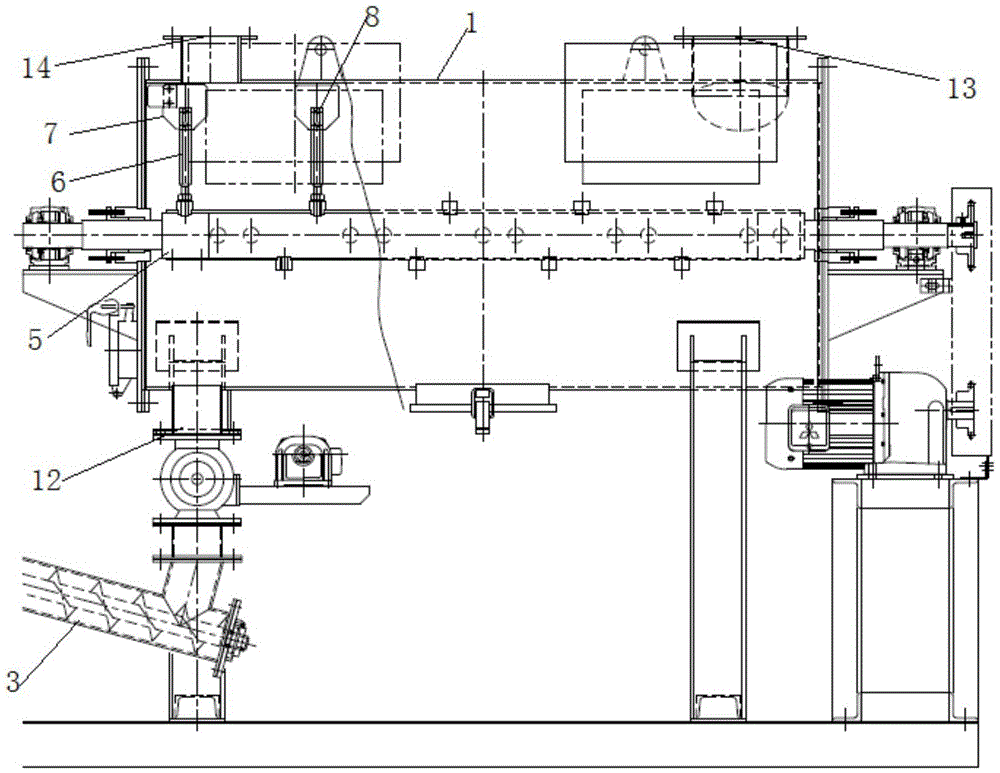

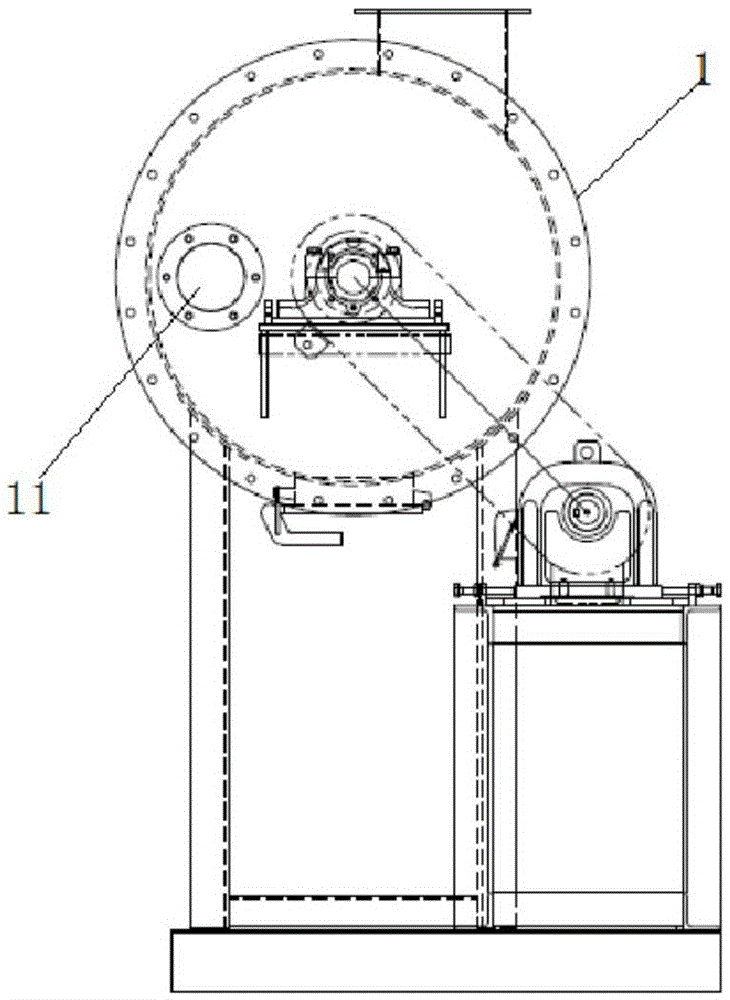

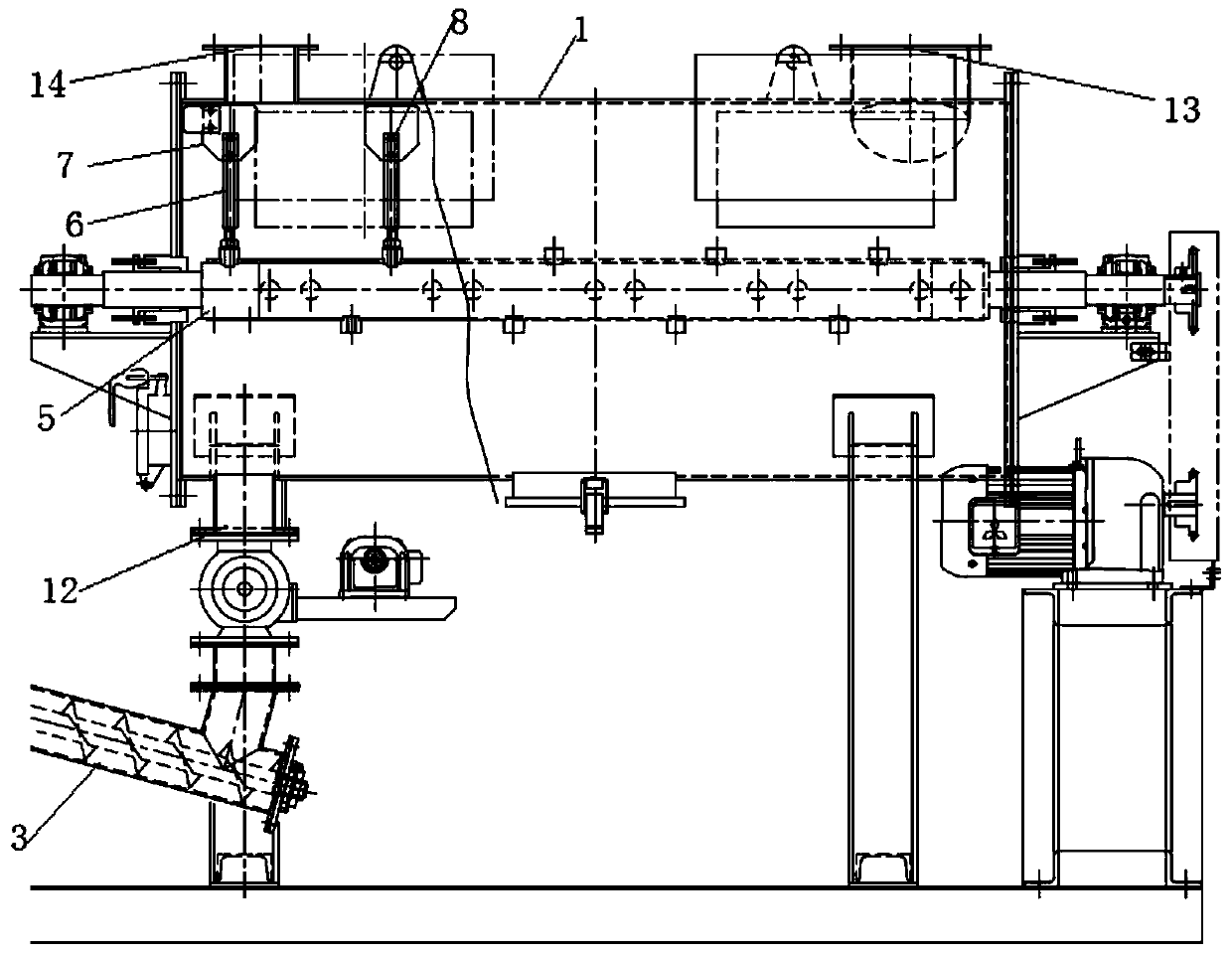

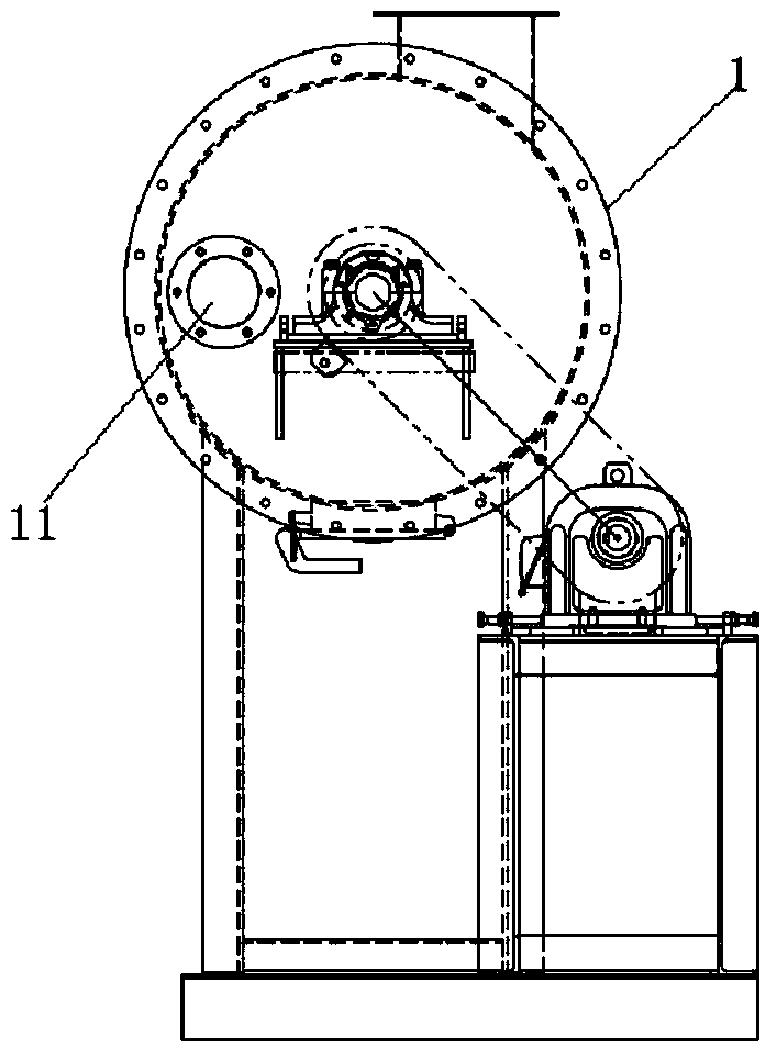

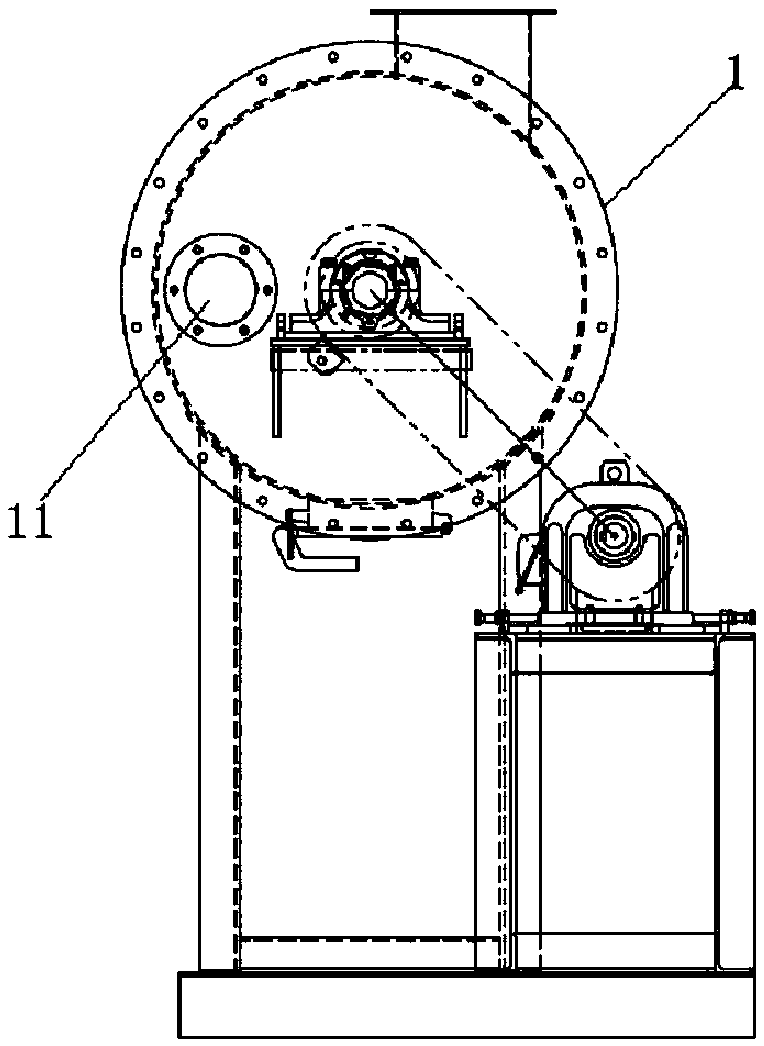

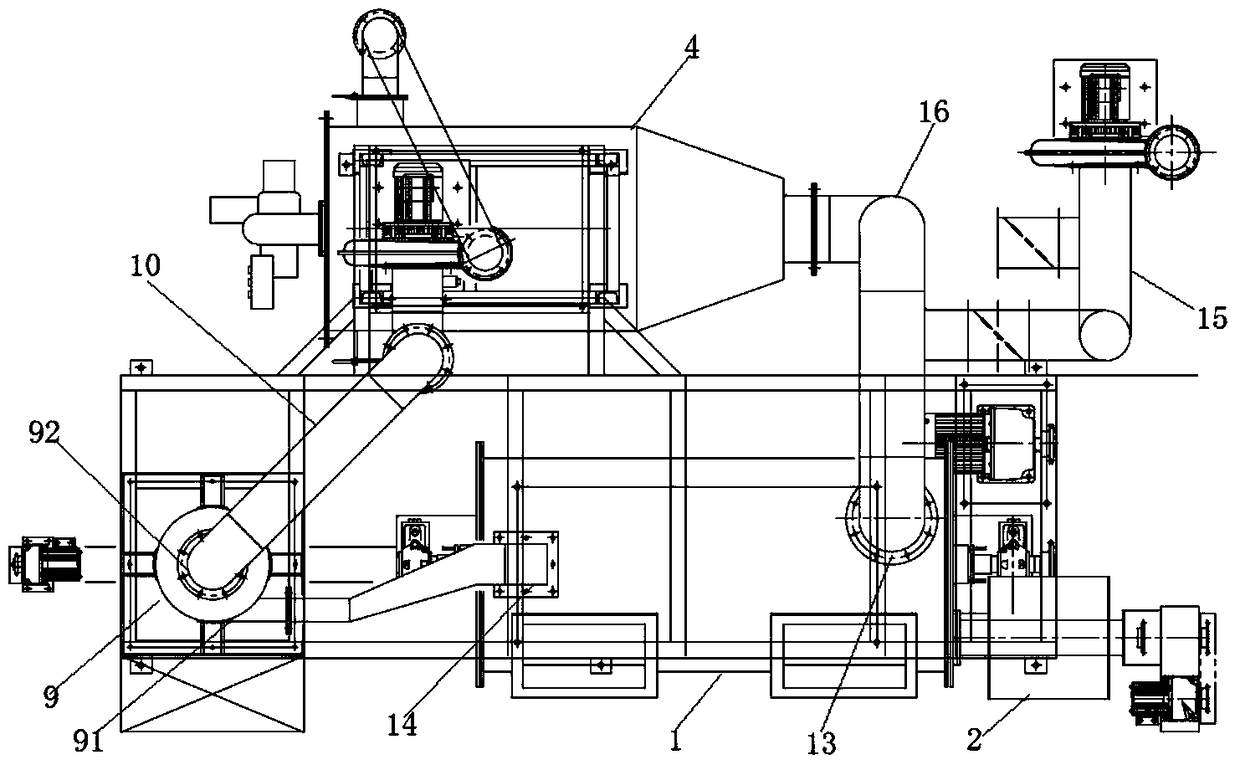

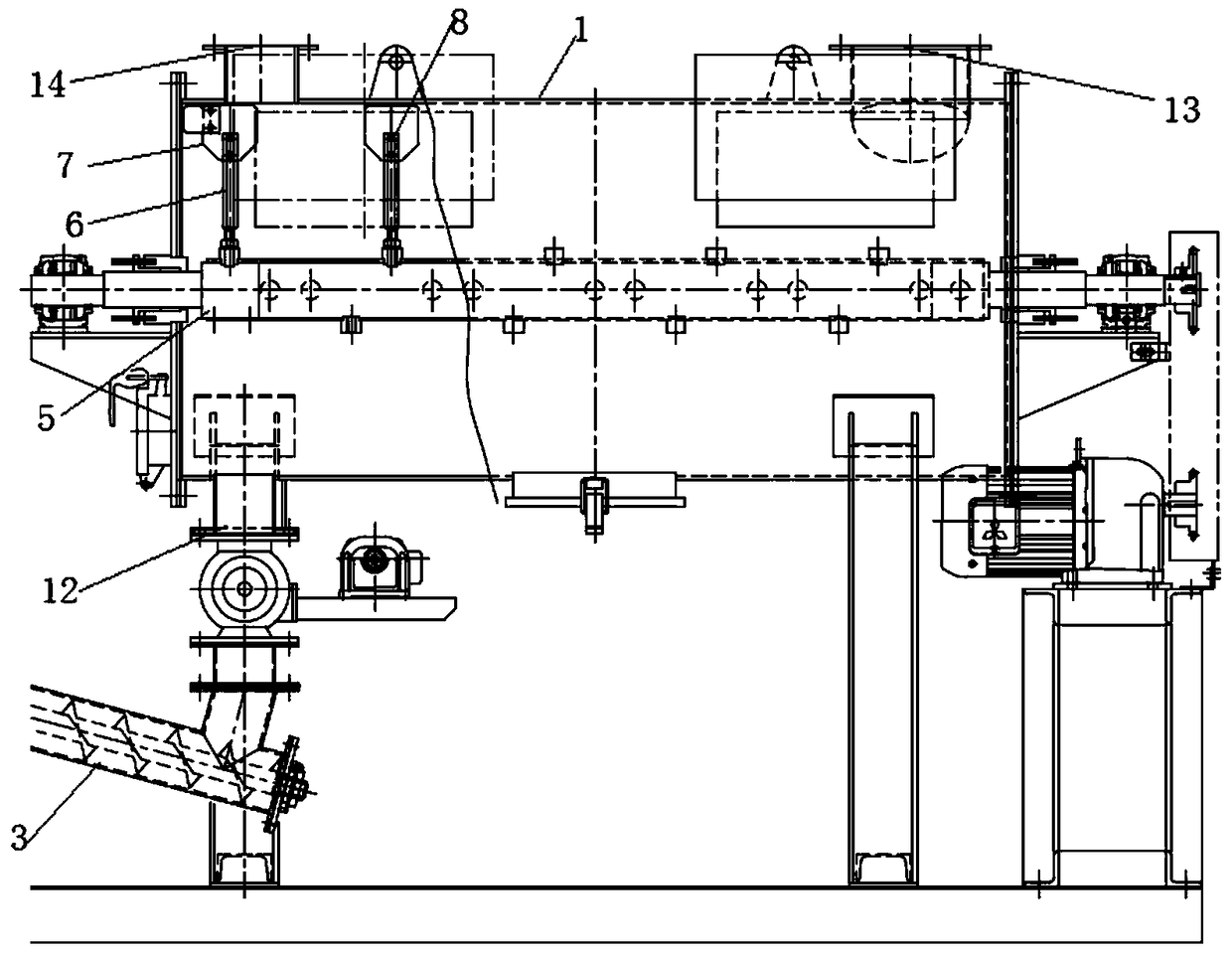

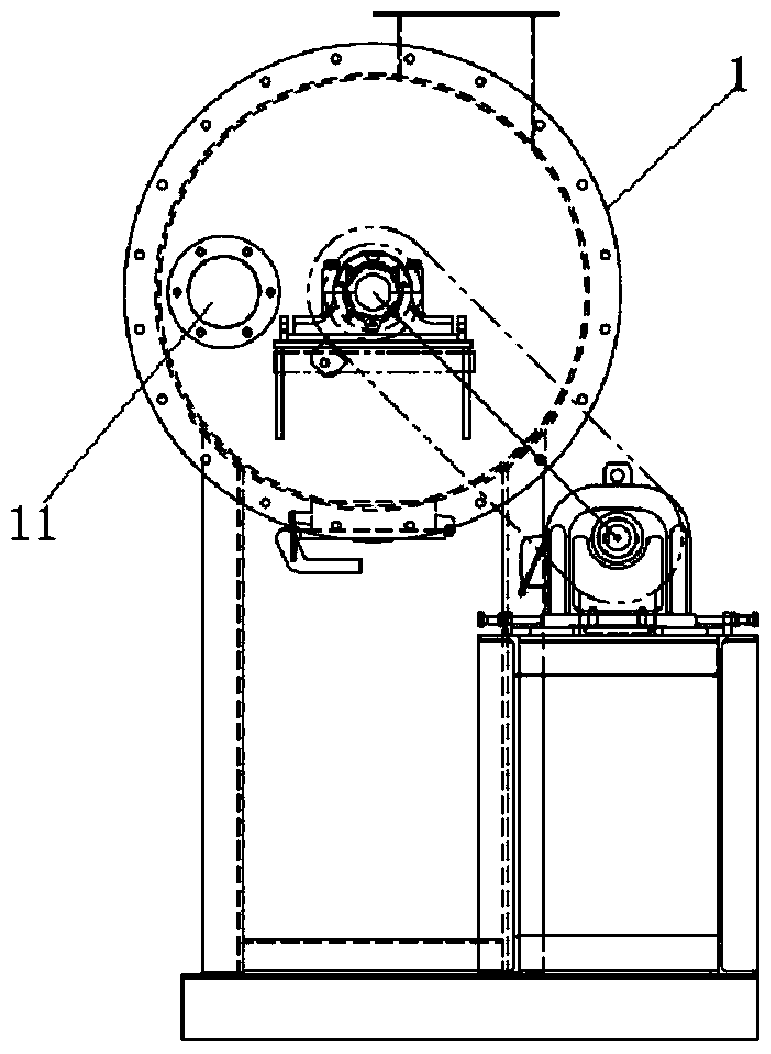

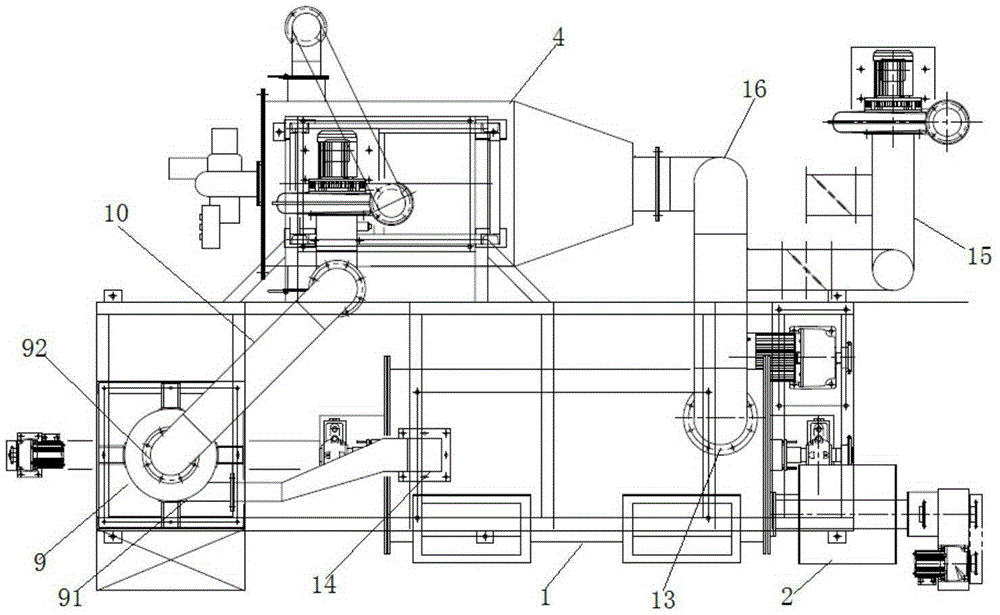

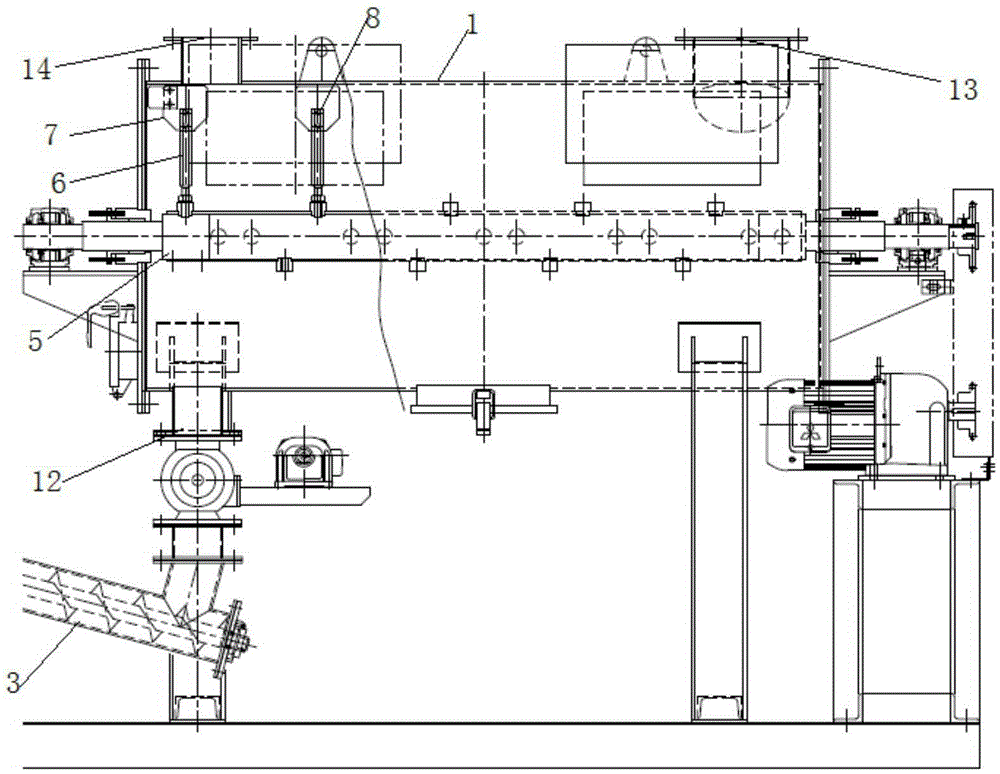

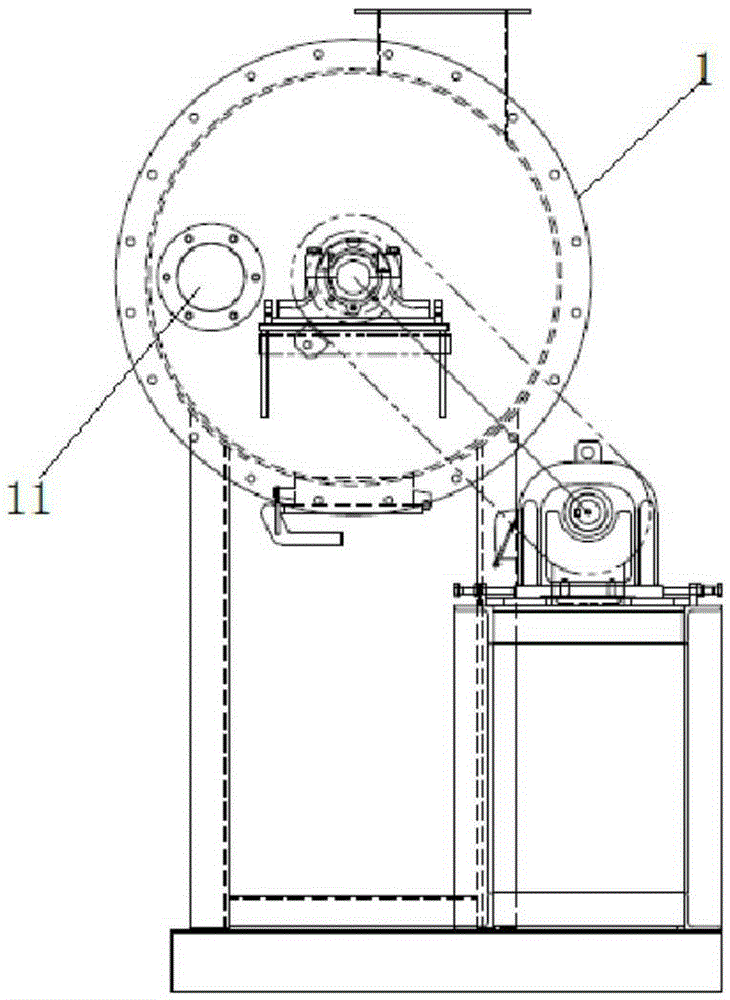

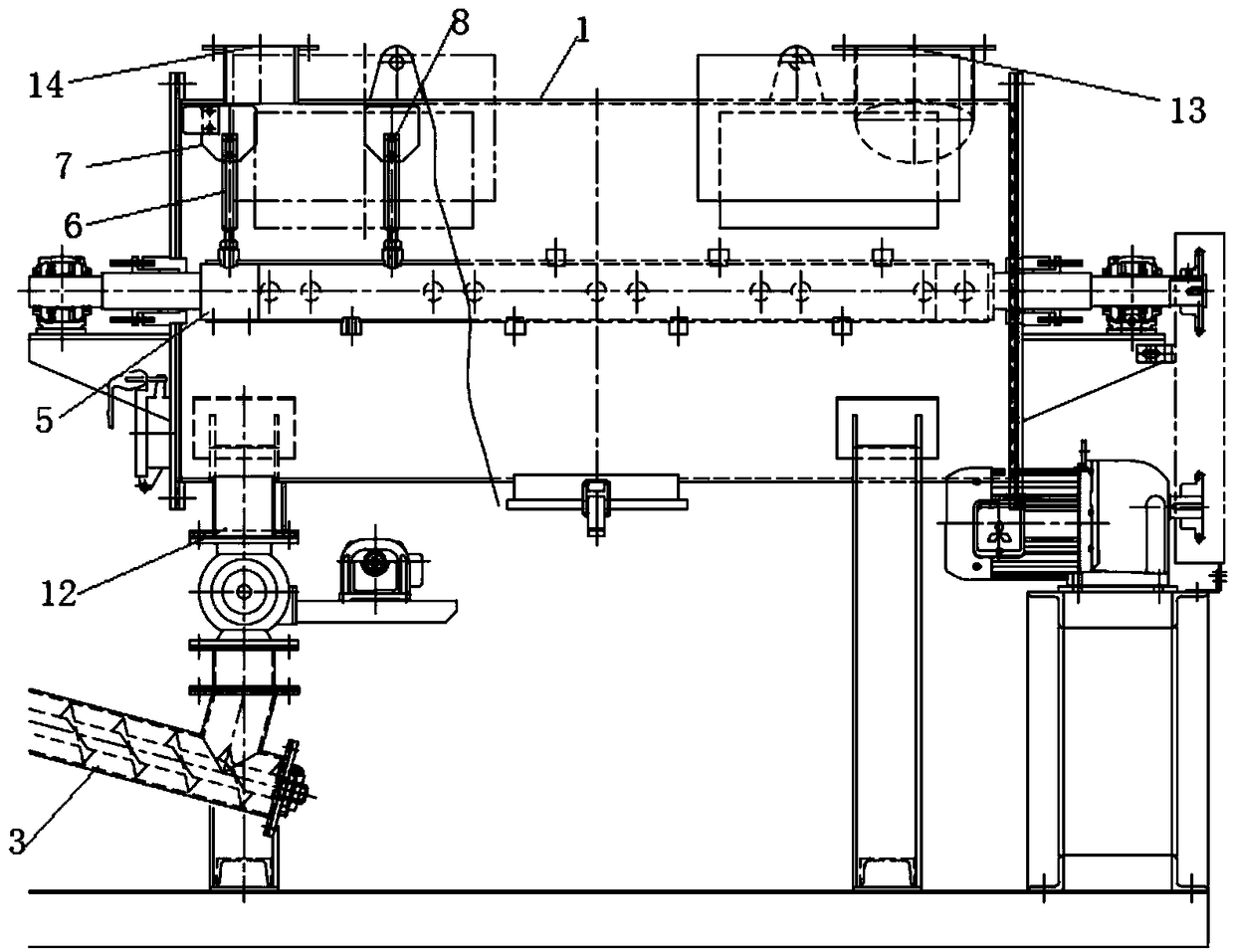

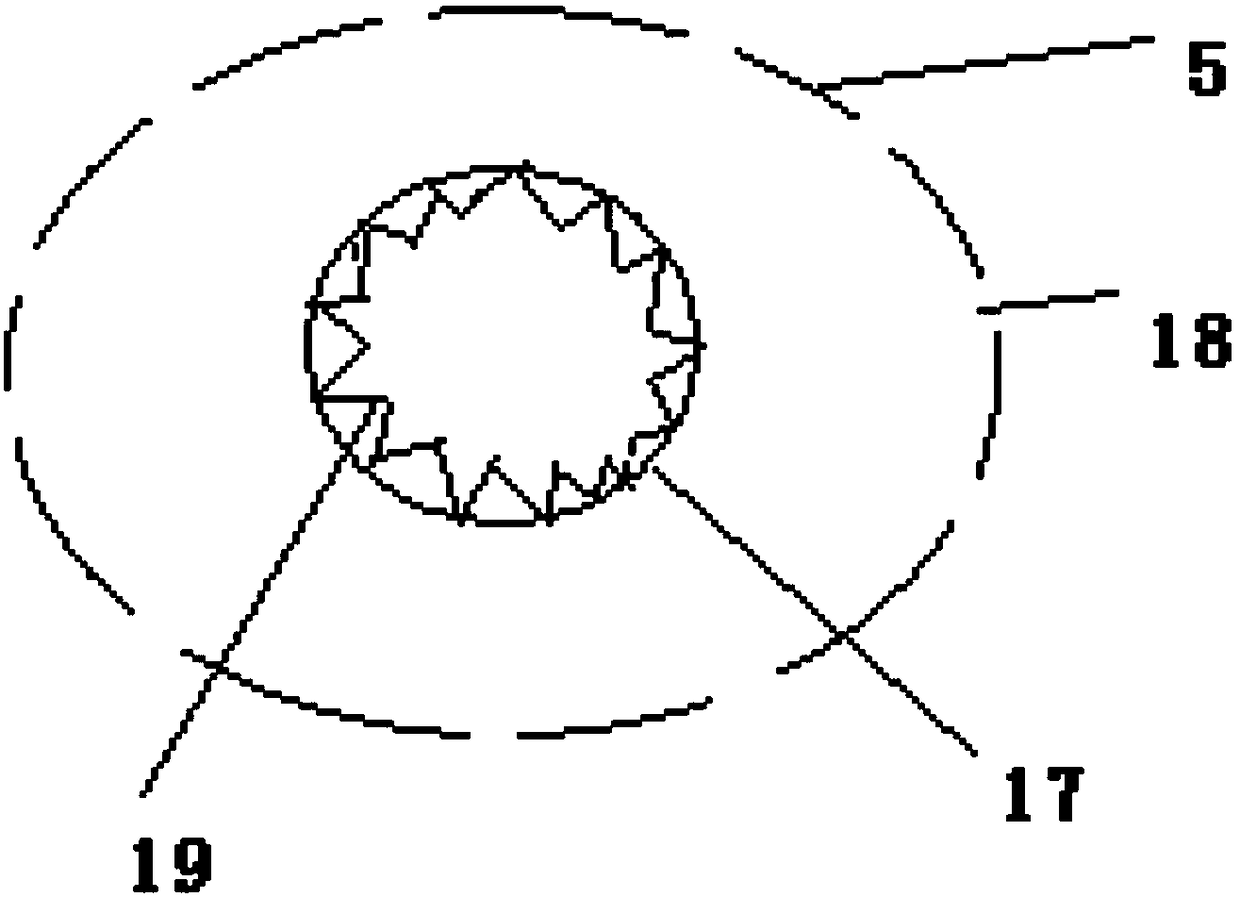

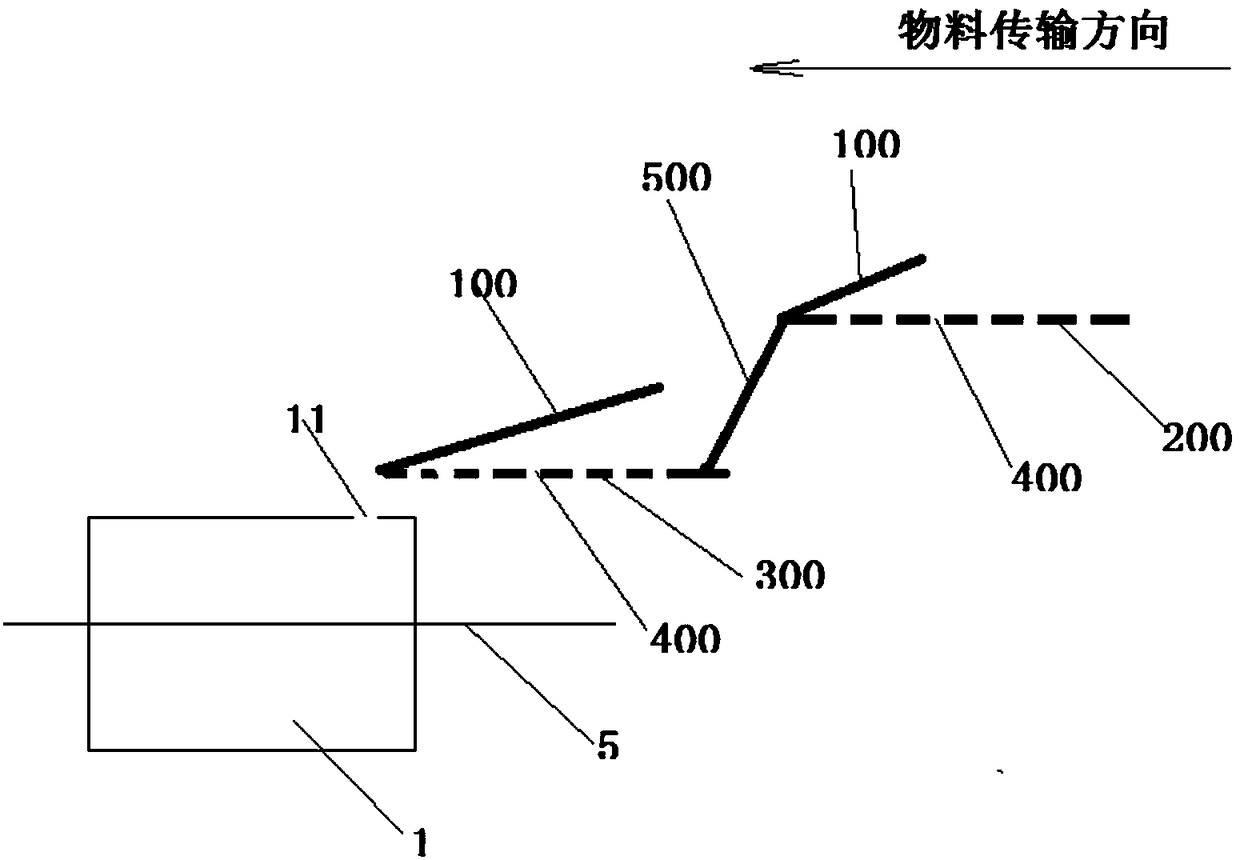

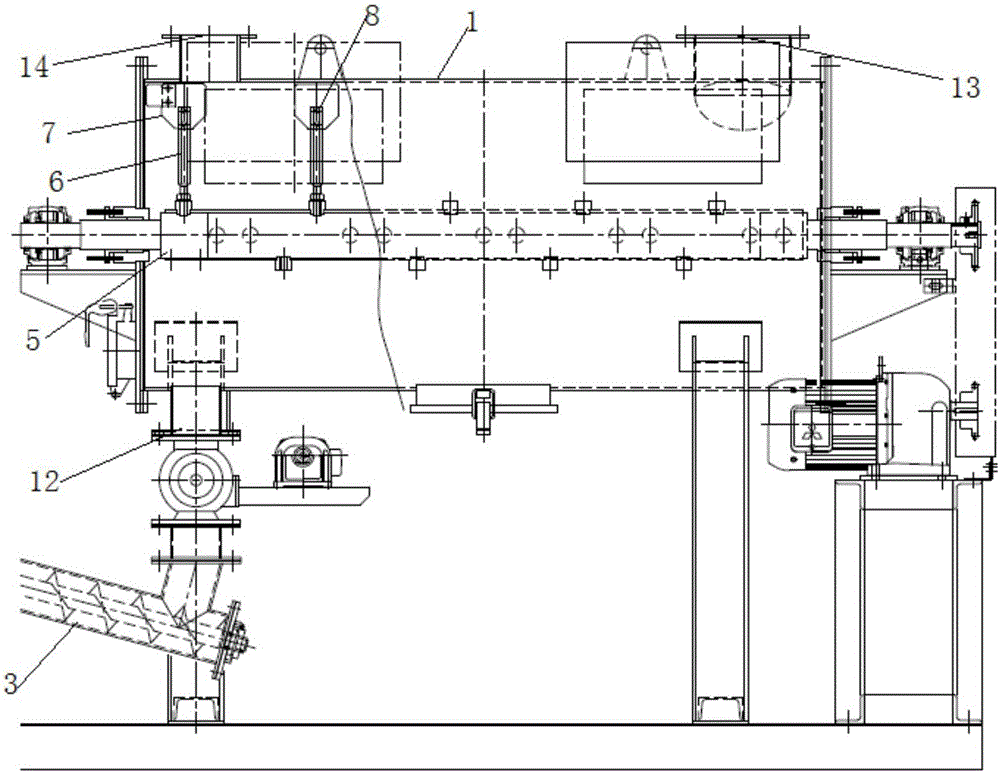

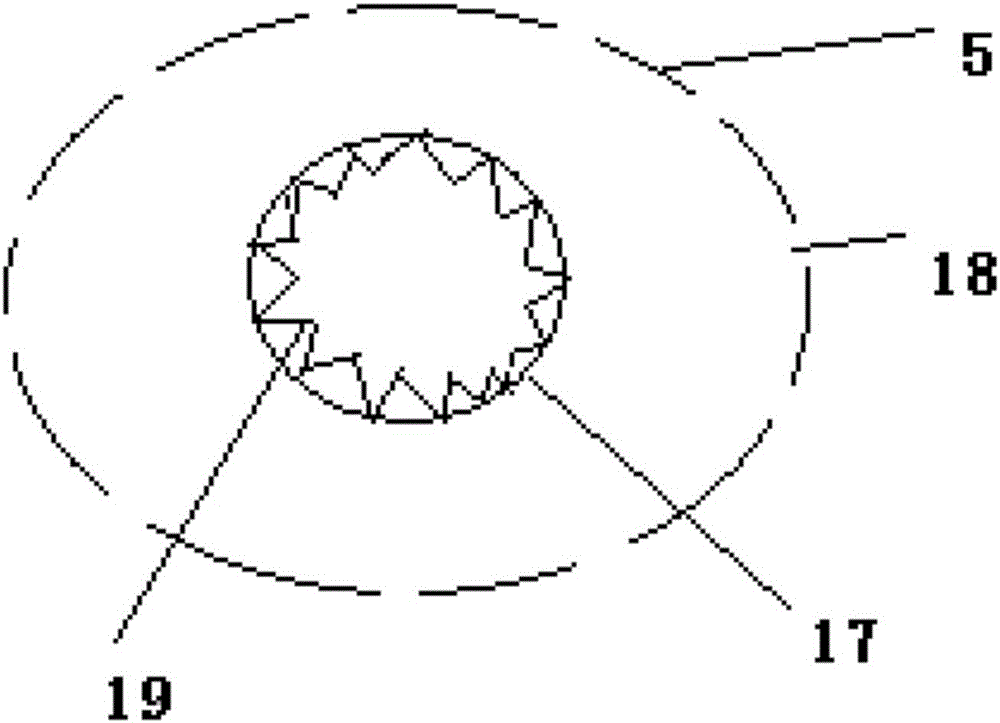

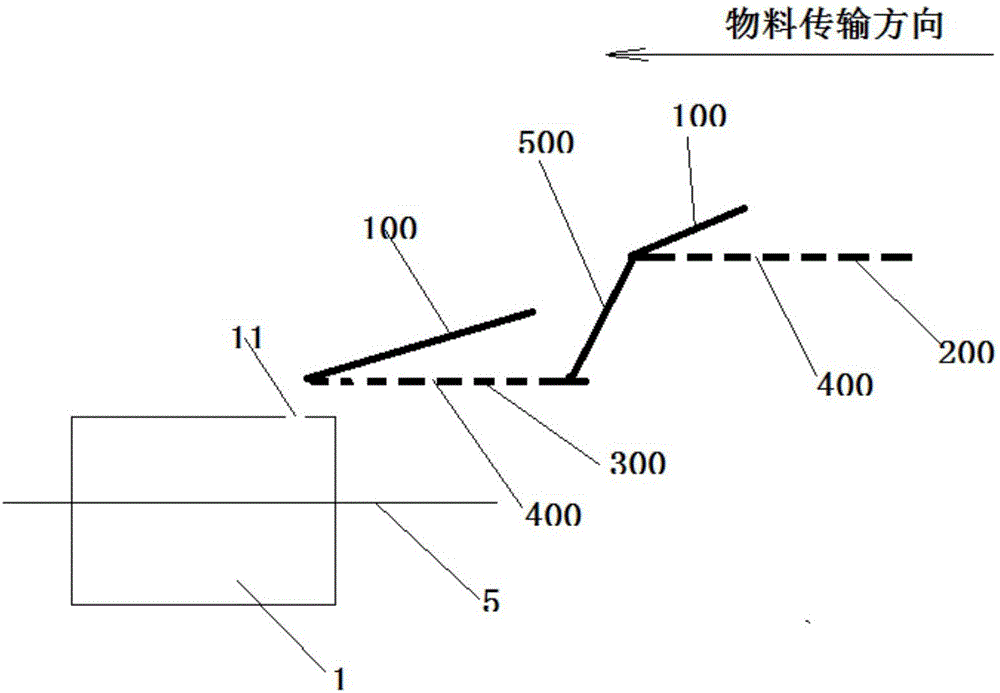

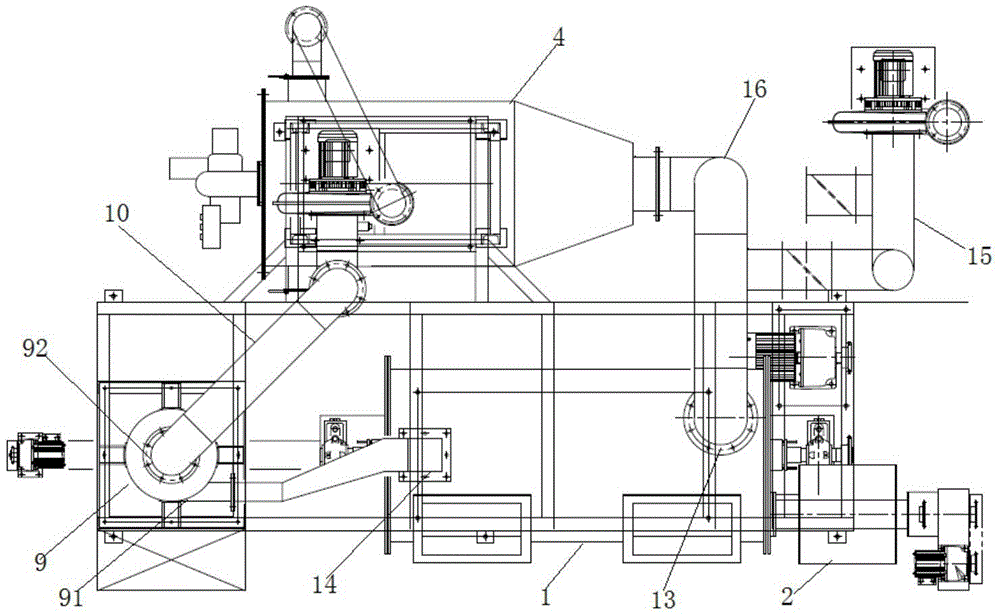

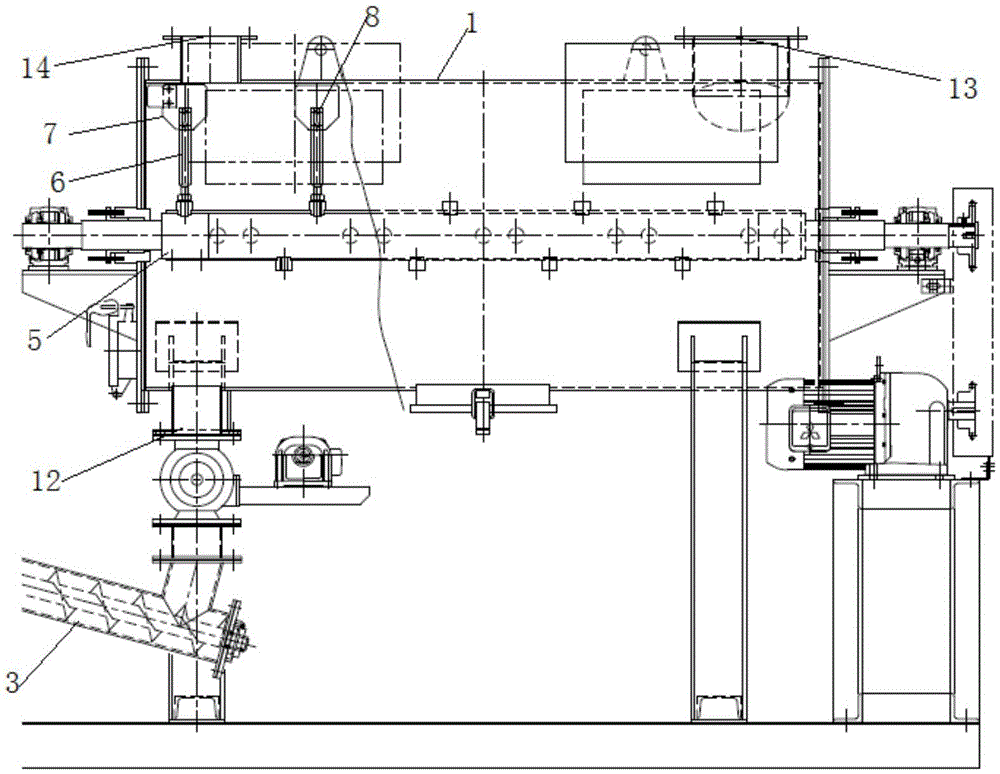

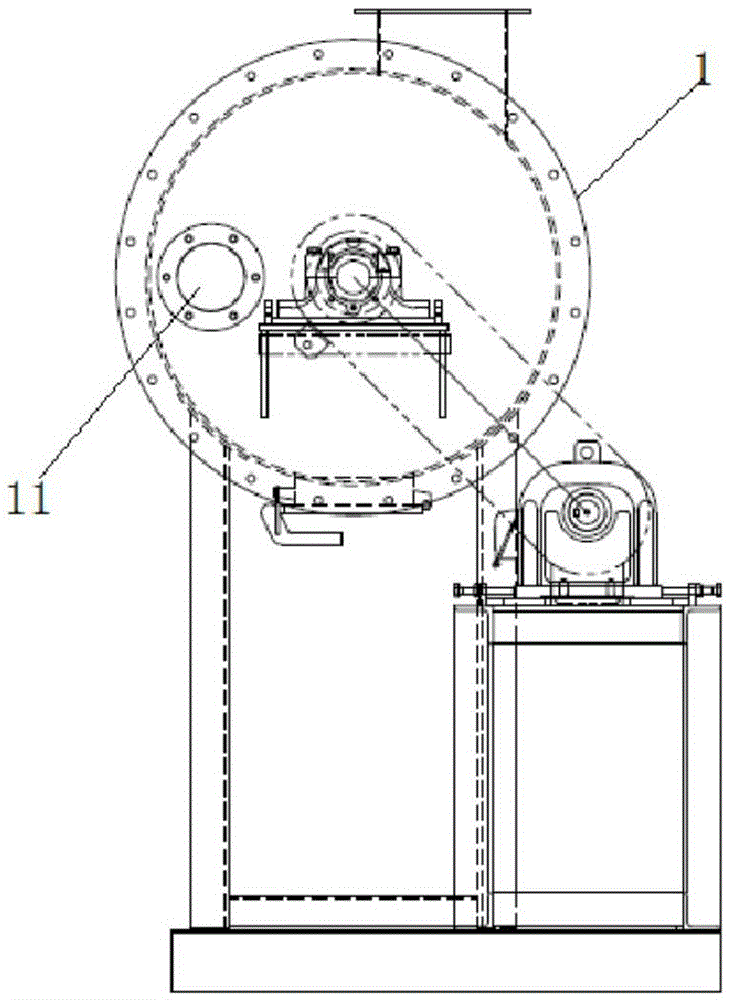

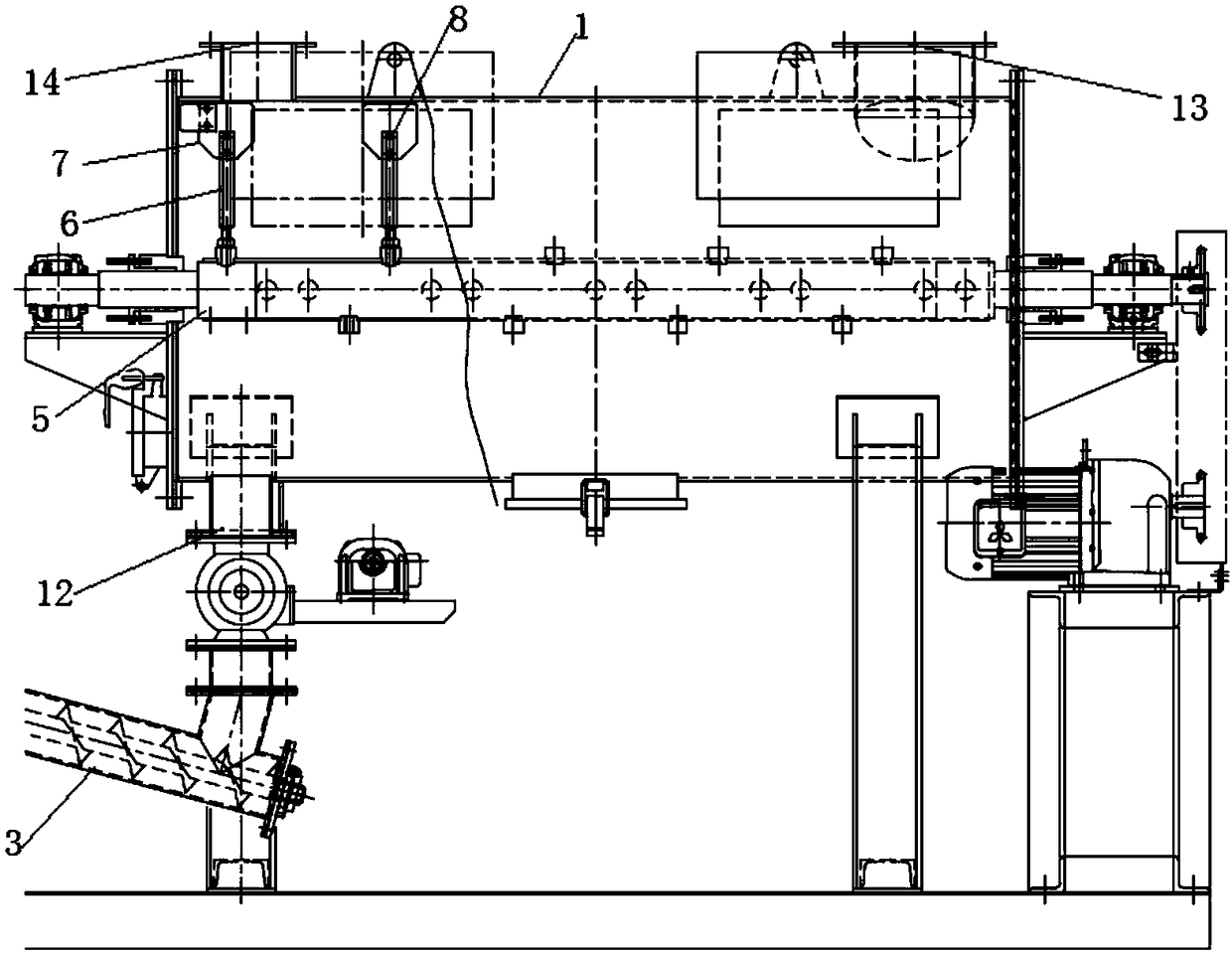

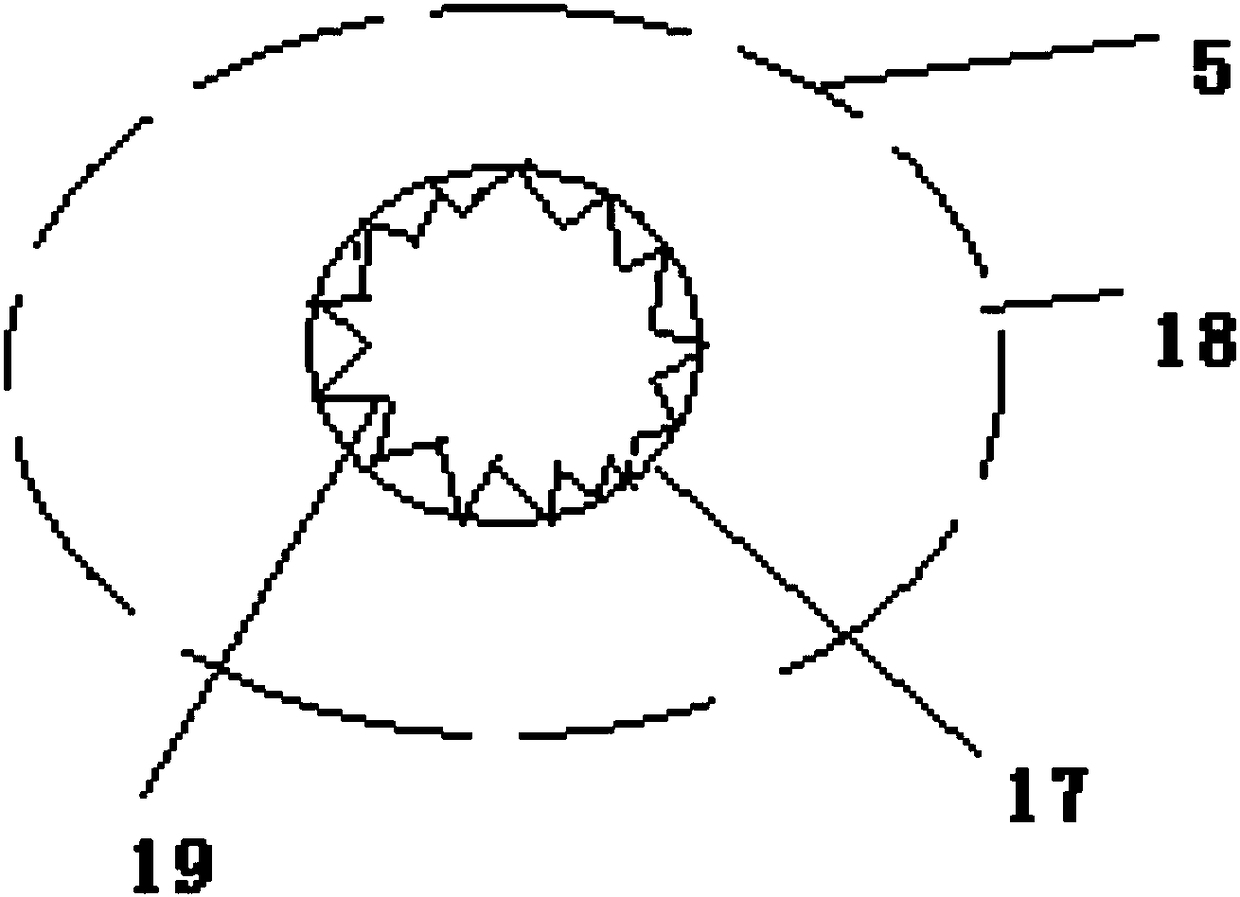

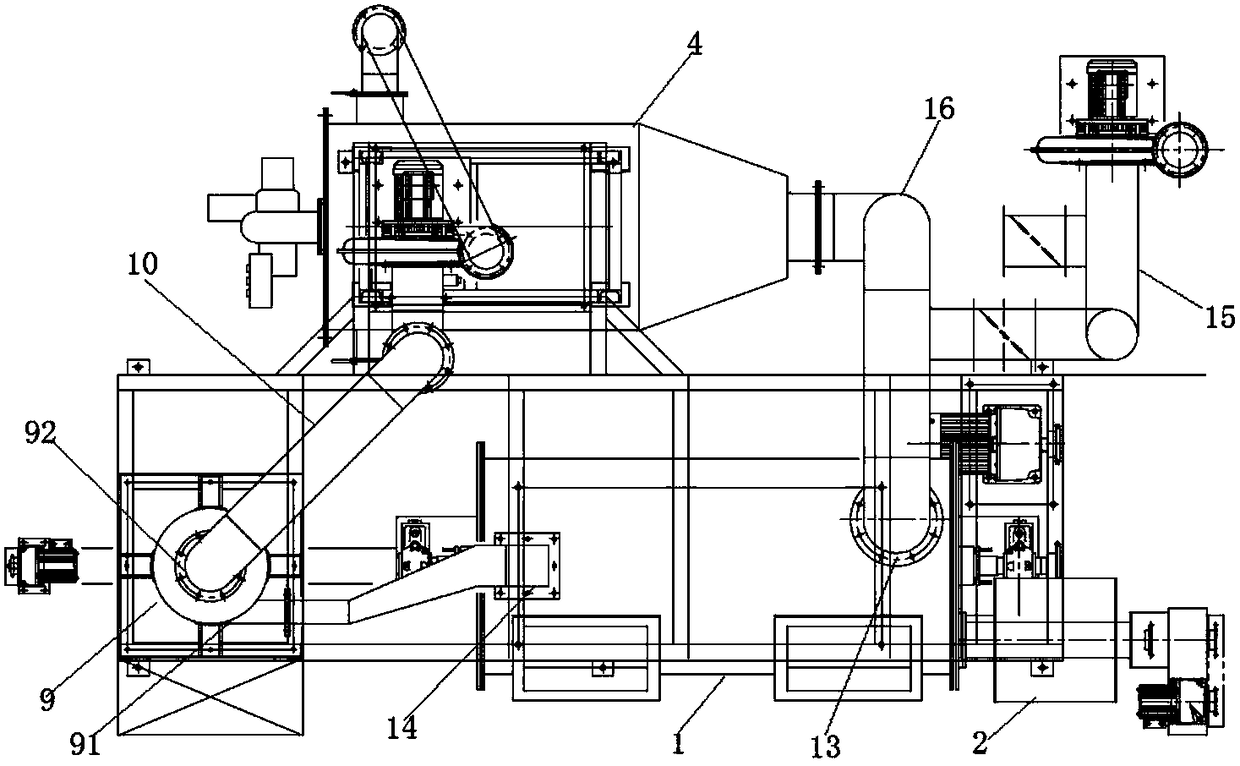

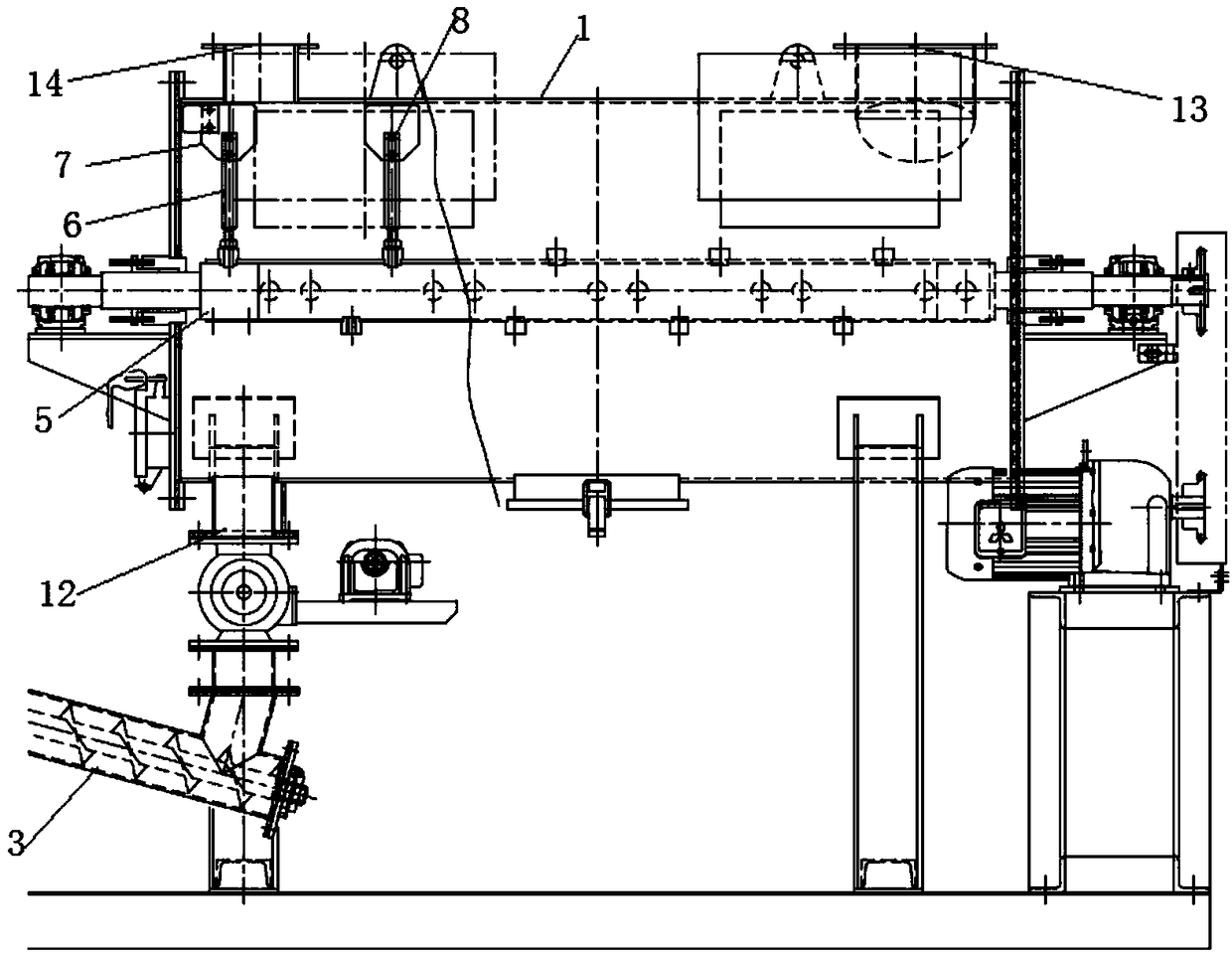

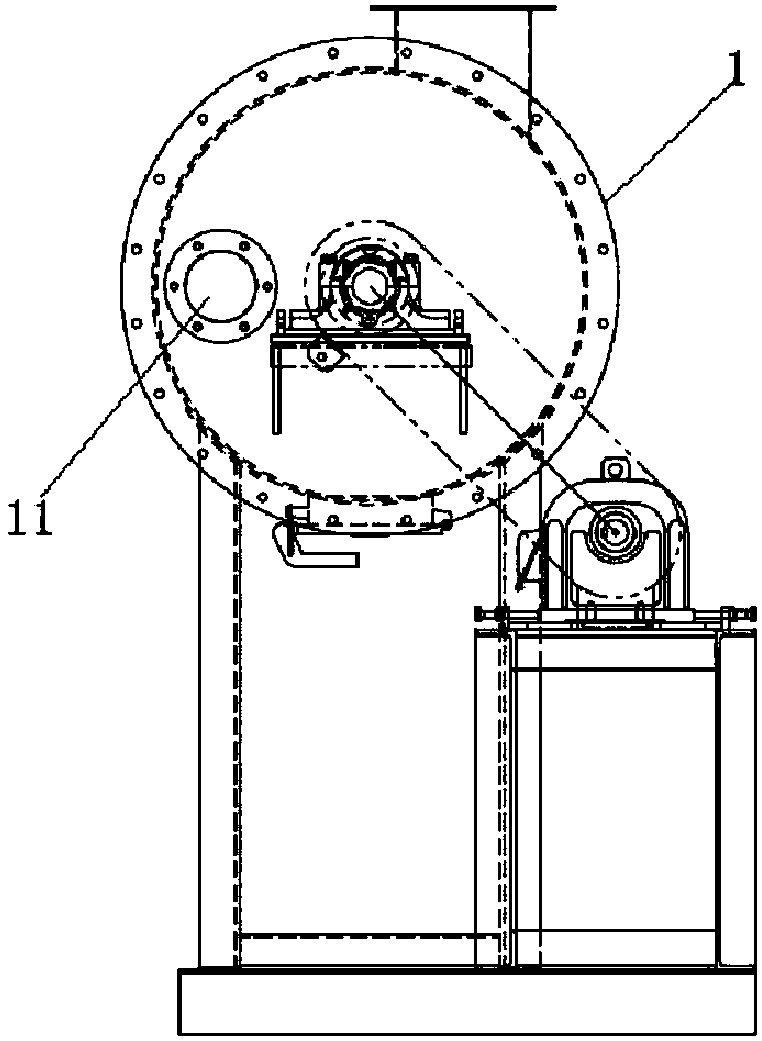

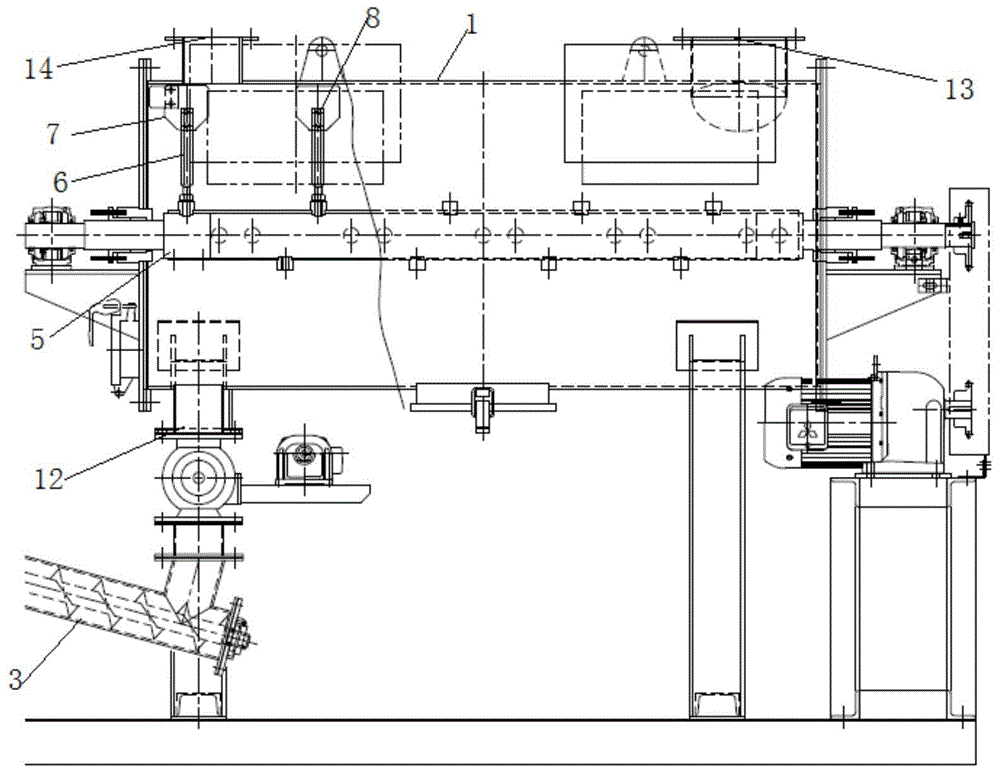

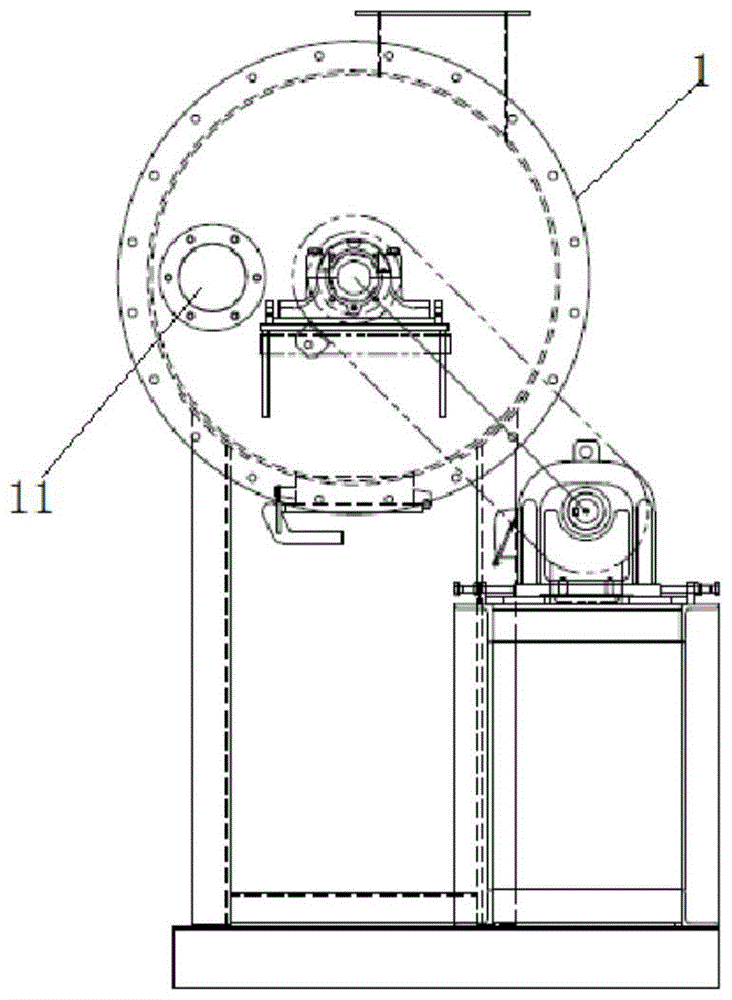

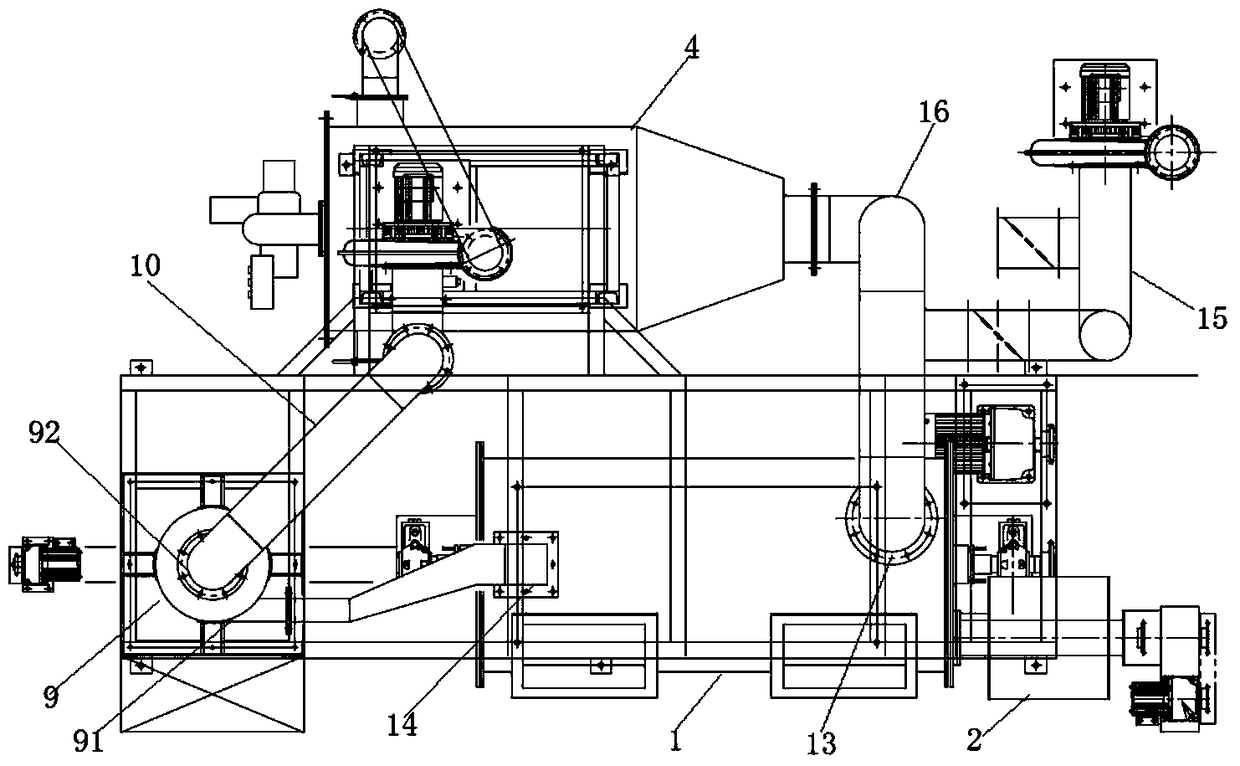

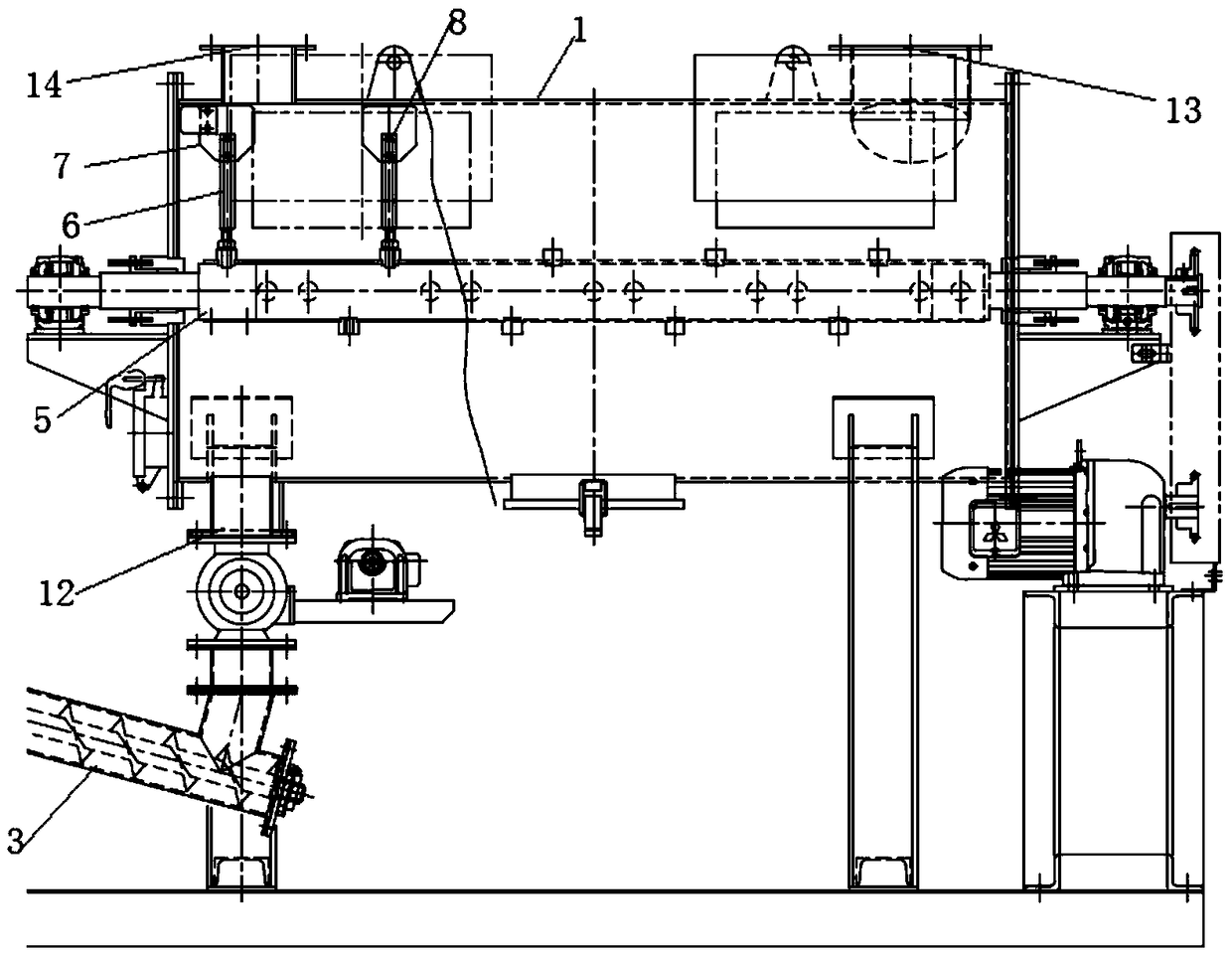

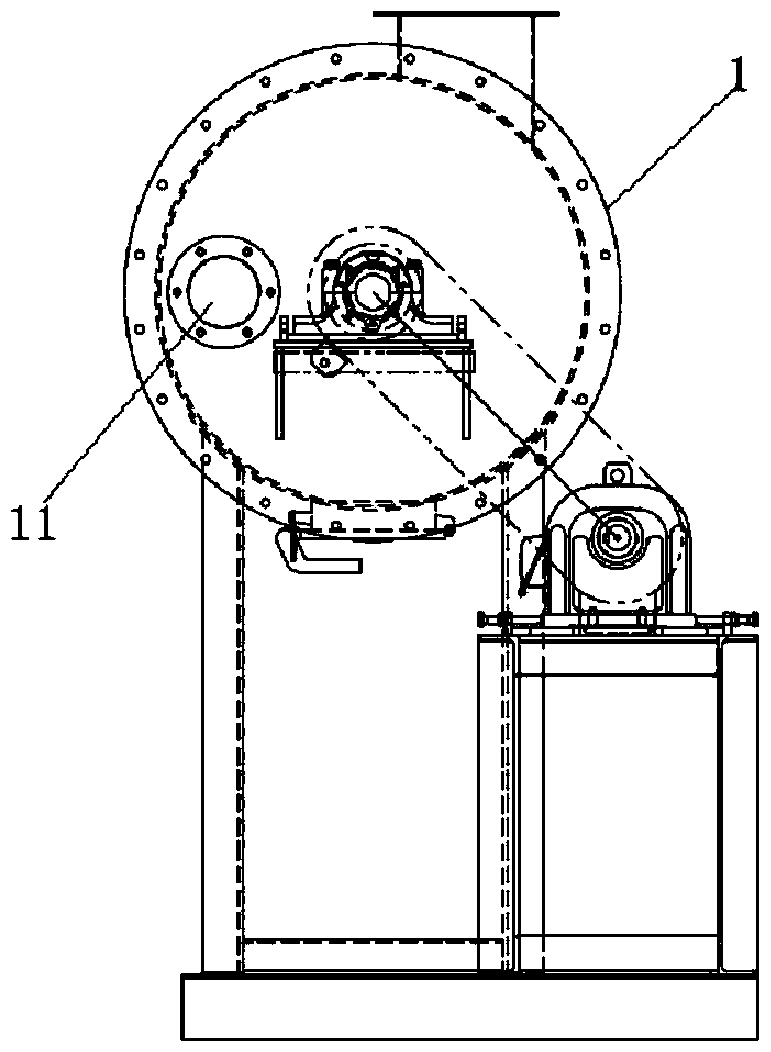

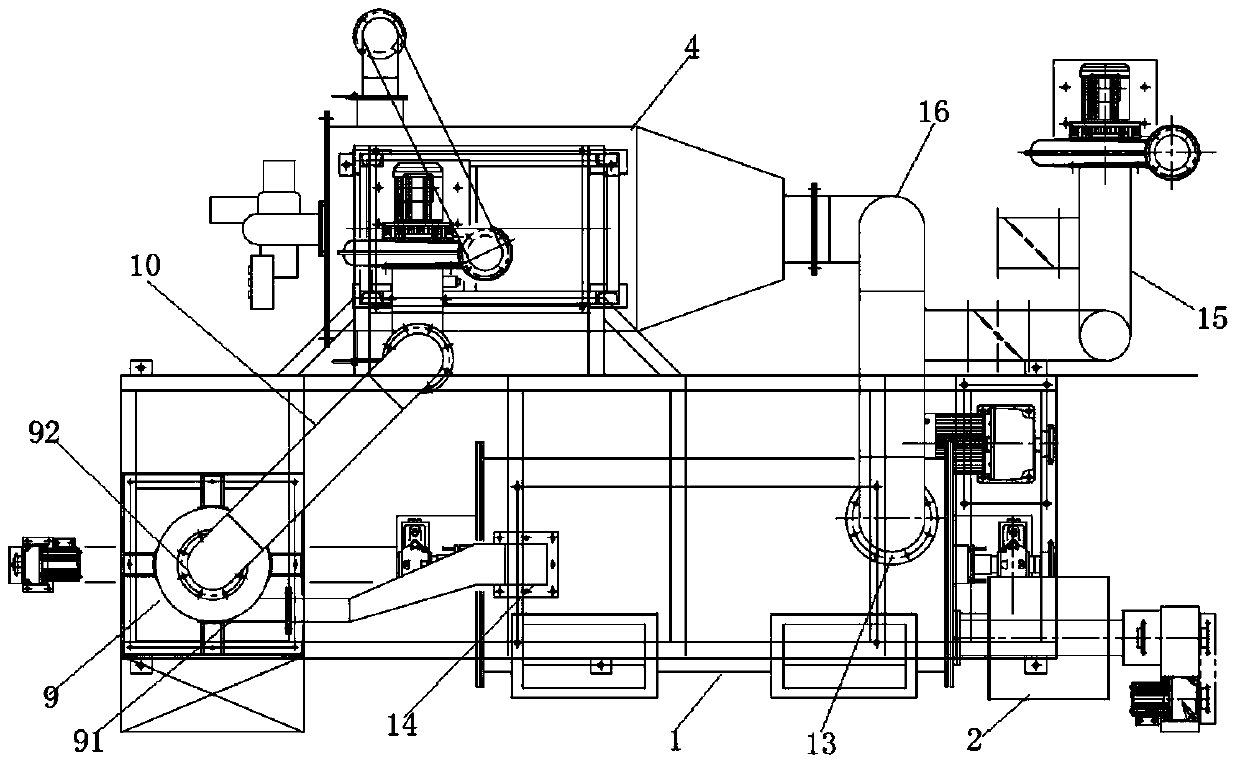

The invention discloses a drying device. The drying device comprises a furnace body, a charging device for charging a material into the furnace body, a collecting device for collecting a dried material in the furnace body, an air supply device for inducing external hot gas into the furnace body by a first gas inlet, and a stirring device for stirring and pulverizing the material, wherein the stirring device comprises a rotary shaft which penetrates through a cavity of the furnace body, the rotary shaft is provided with a venting cavity provided with a plurality of gas nozzles, the gas spraying direction of the gas nozzles is misaligned and not parallel with the stirring direction of the stirring device and the stirring direction of blades, during material drying, the hot gas is induced into the cavity of the furnace body by the first gas inlet, and the rotary shaft rotates to drive a stirring assembly on the rotary shaft to continuously stir the material along the axial direction and radial direction of the rotary shaft, so that the material is turned over in the furnace body along the axial direction and radial direction of the rotary shaft, the stirring time of the material is prolonged, and a convection heat exchange area between the material and the hot gas is increased. In addition, the stirring assembly can pulverize the material to form a material of smaller particles, thus further increasing the convection heat exchange area between the material and the hot gas and improving the drying efficiency and drying effect of the material.

Owner:汪振朴

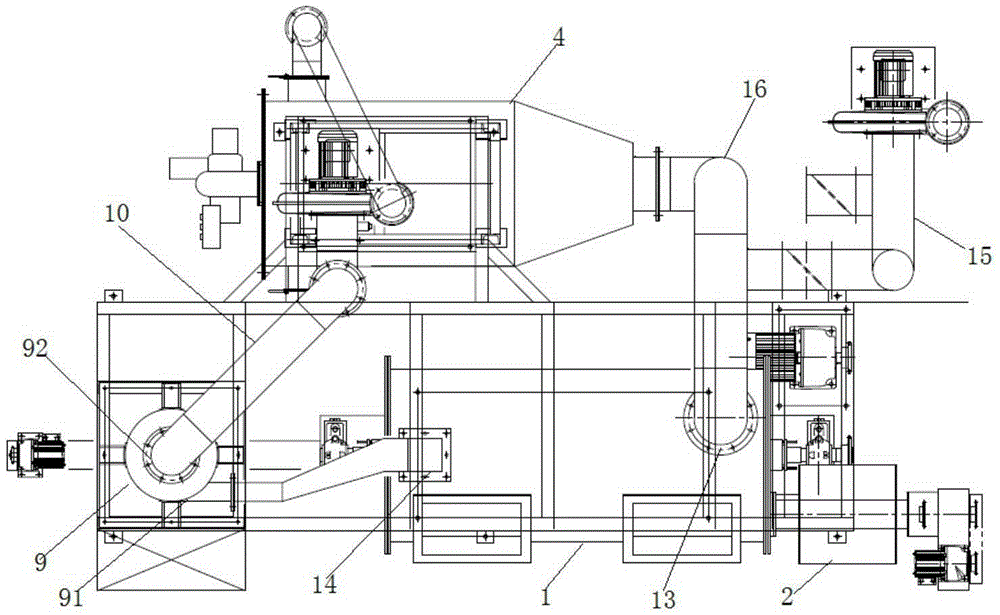

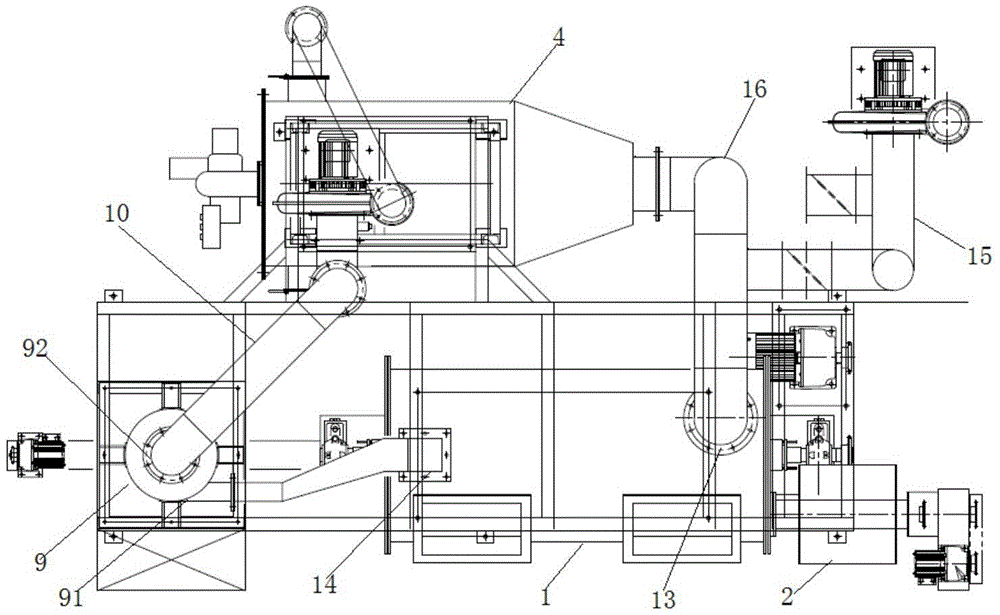

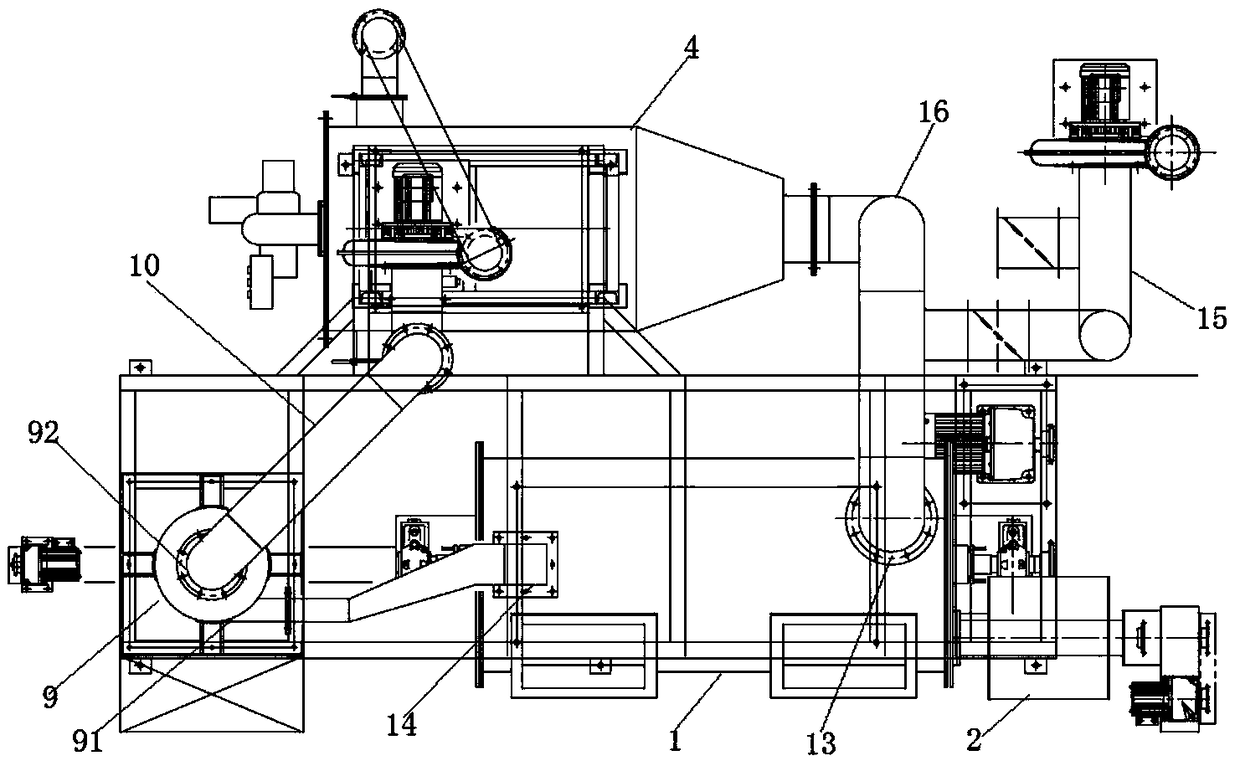

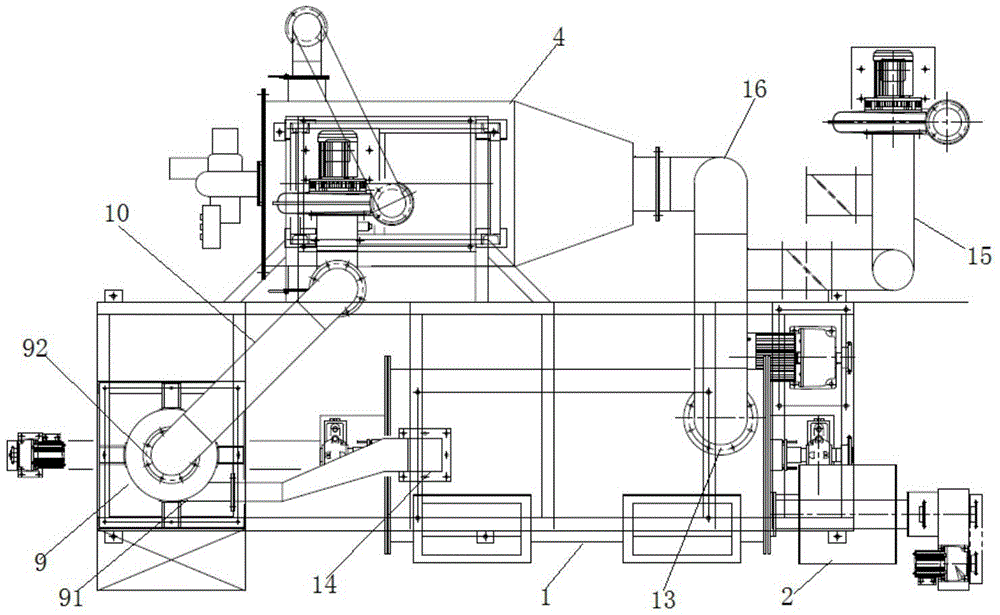

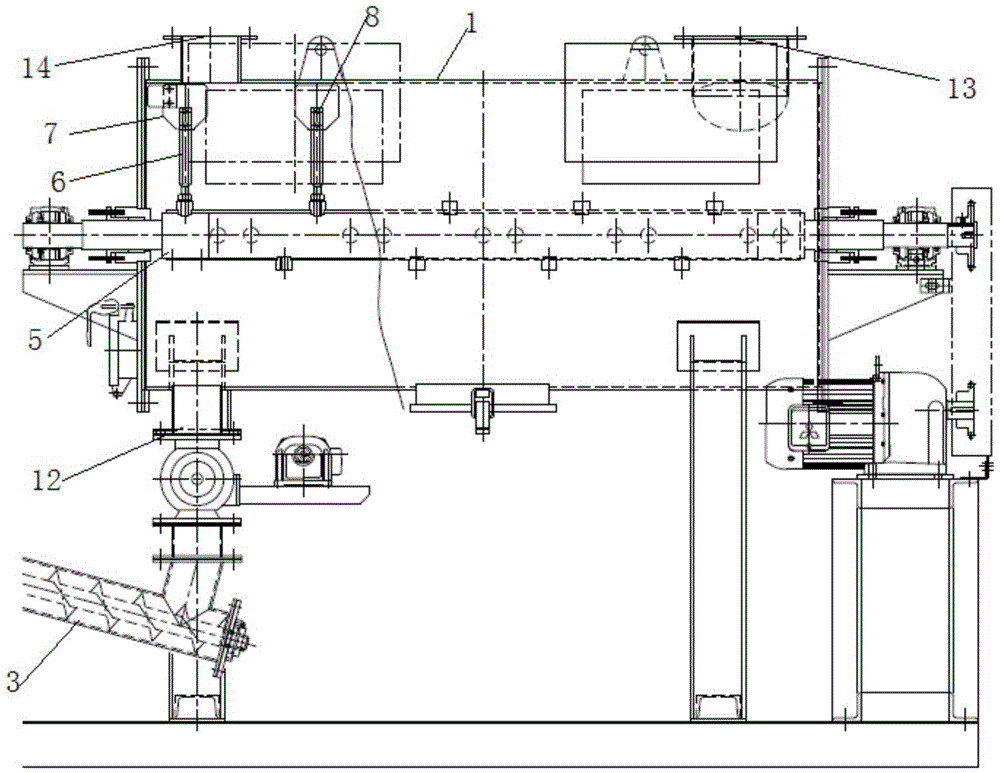

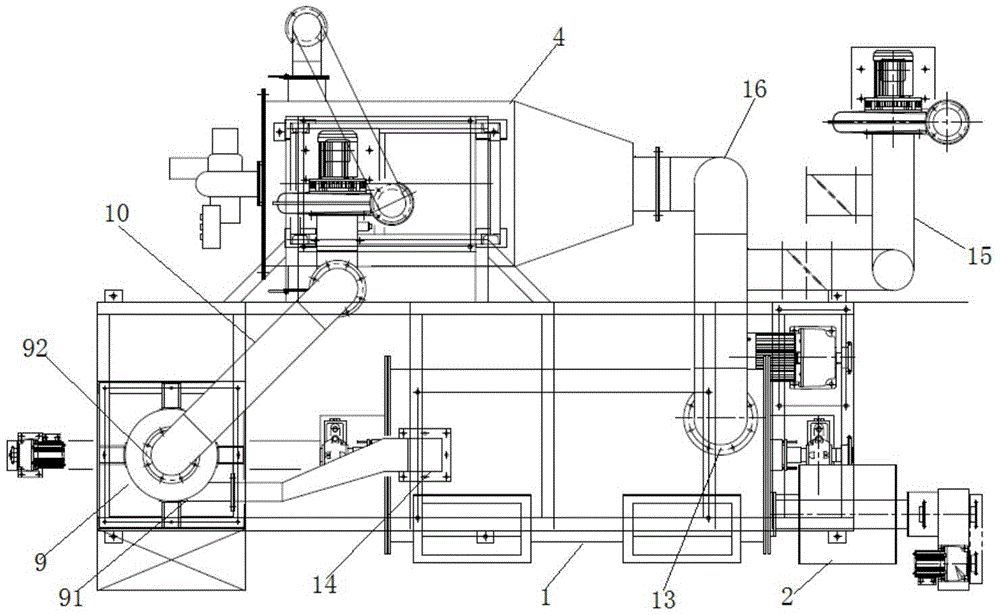

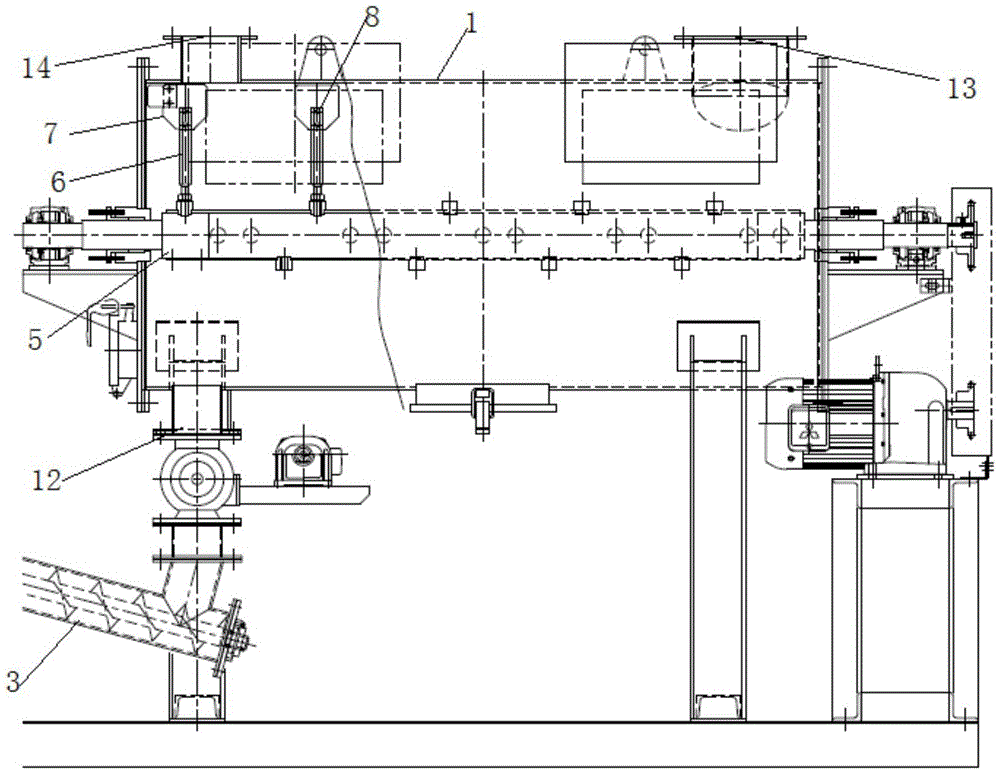

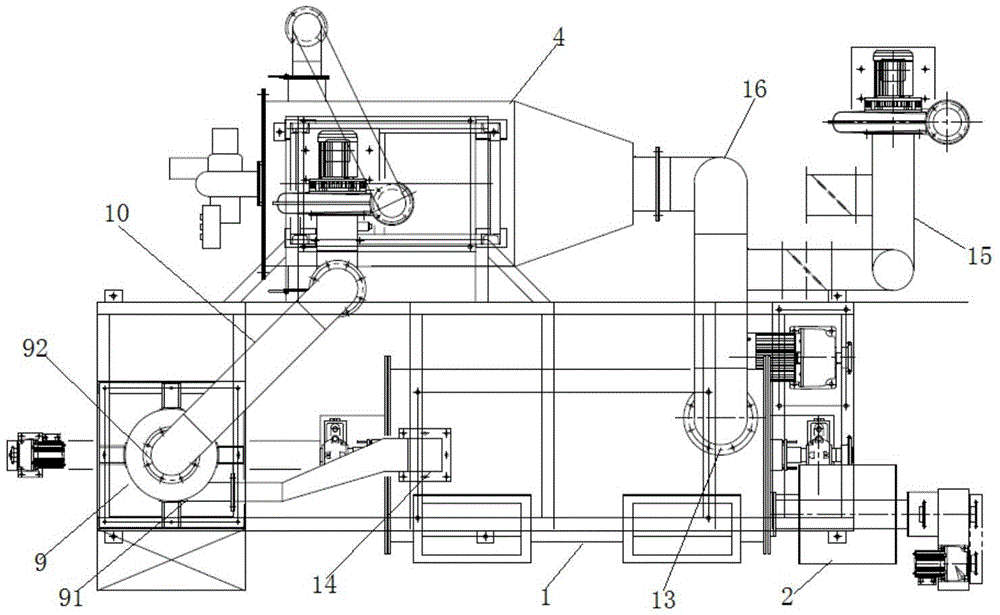

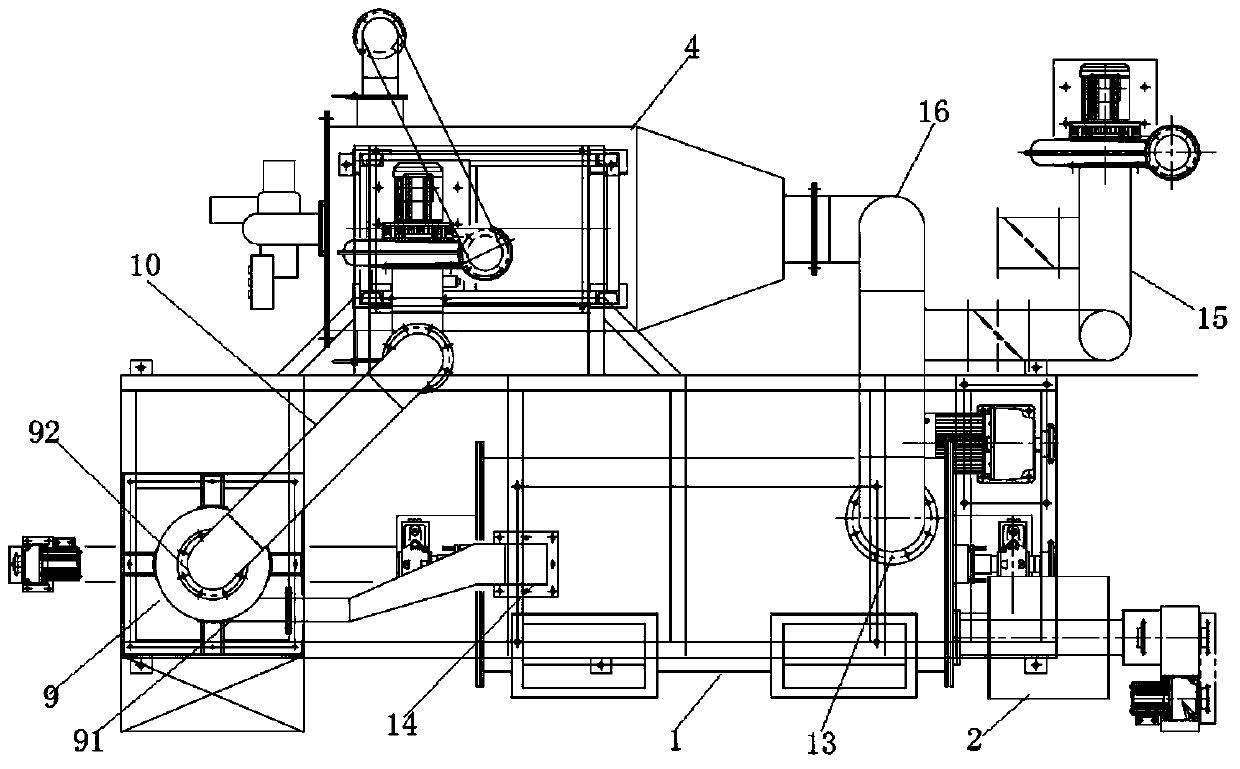

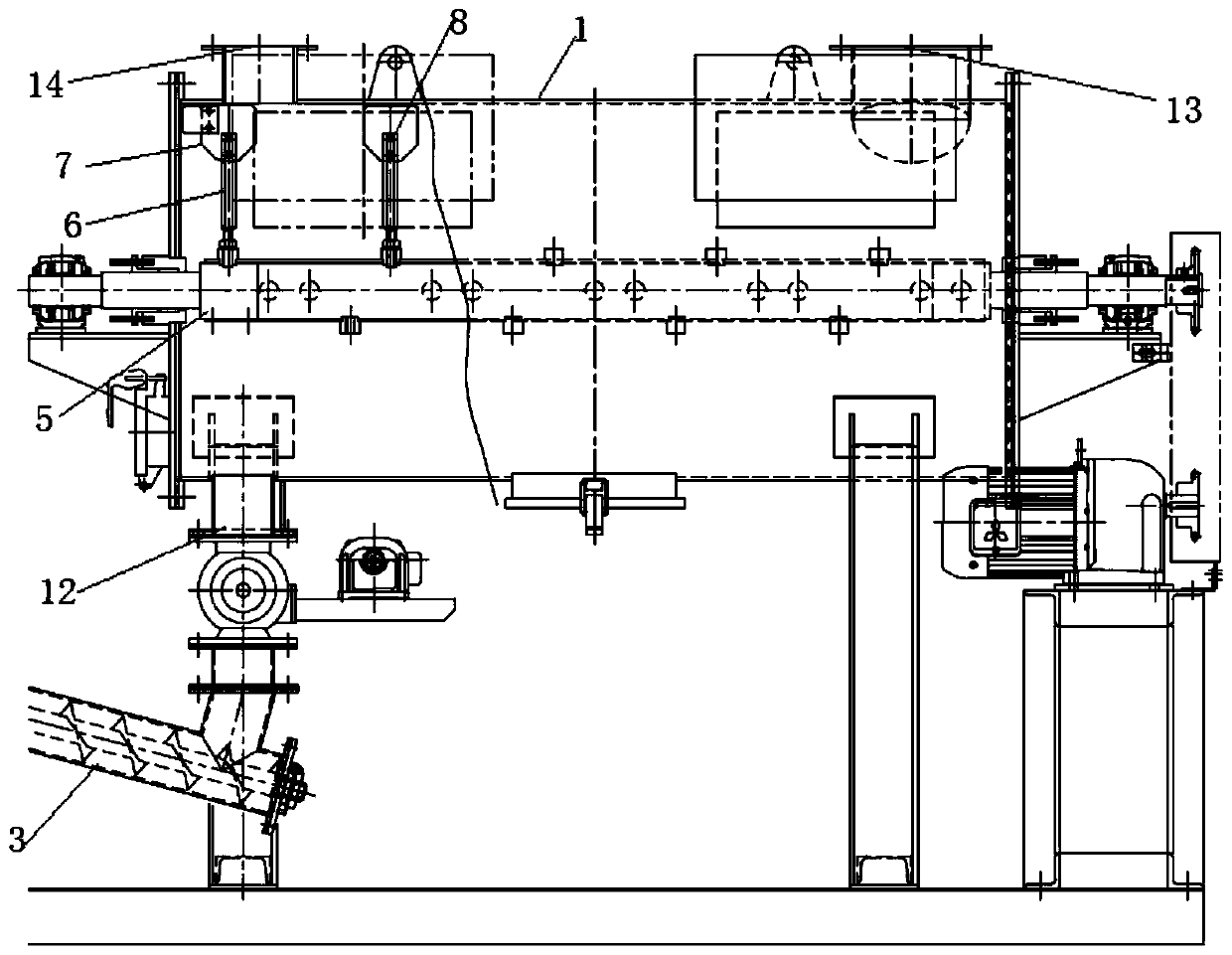

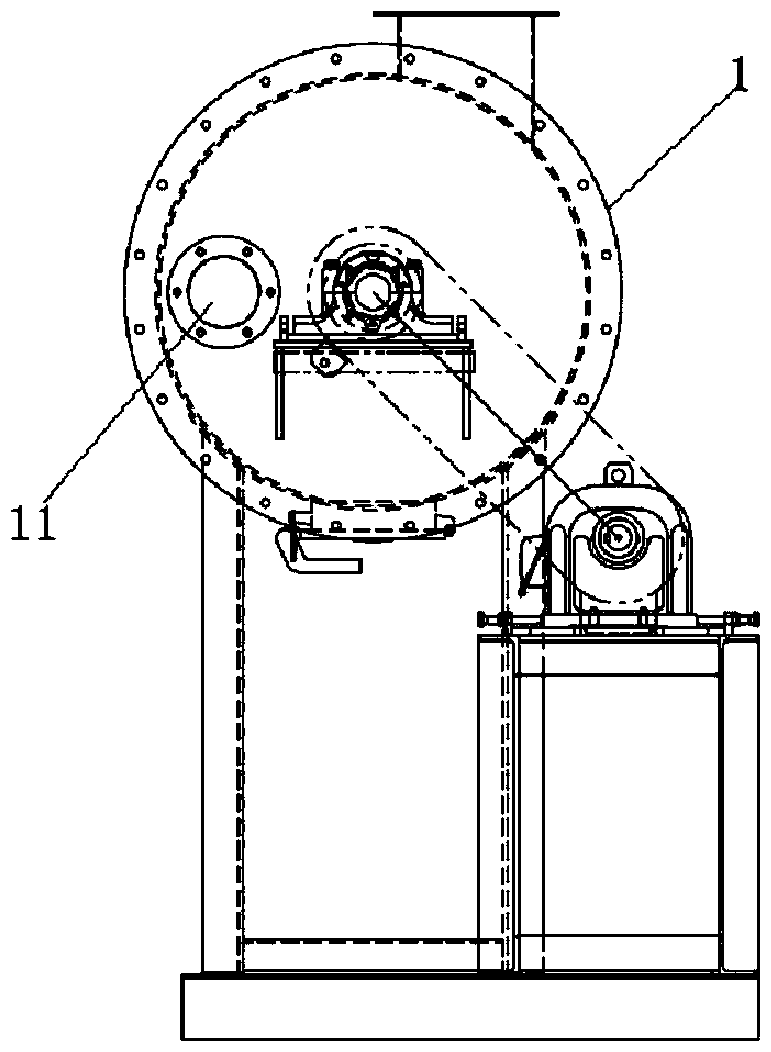

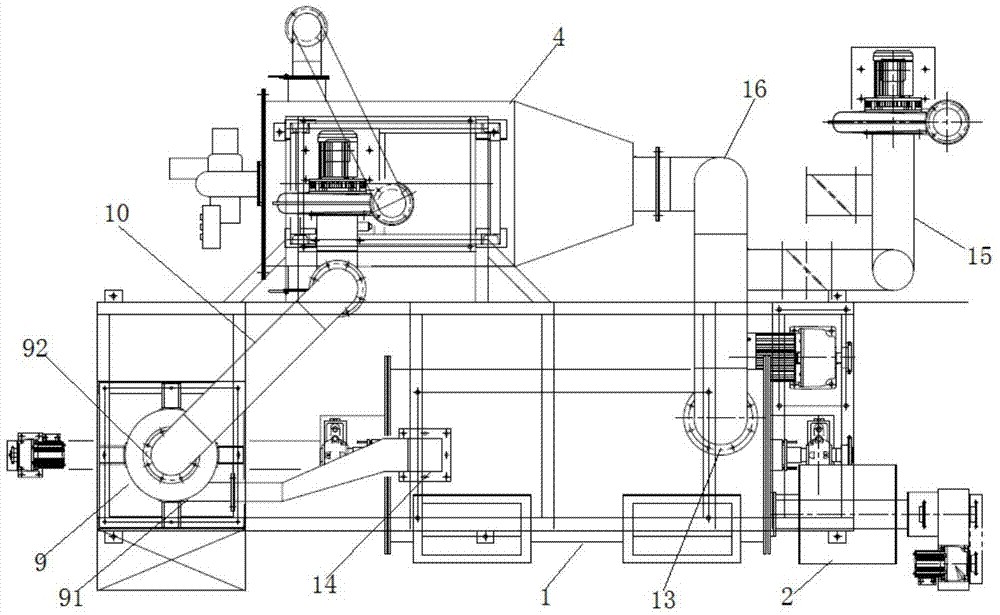

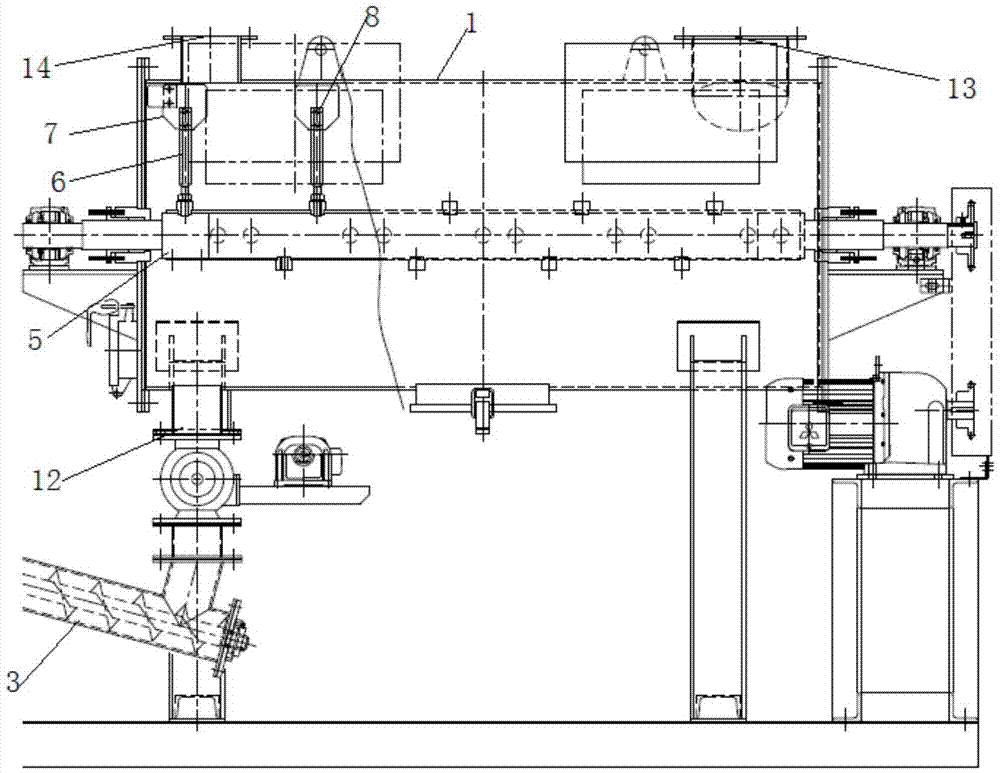

Sludge treatment system

ActiveCN105502881ASmoothly fall intoImprove space utilizationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningEngineeringTreatment system

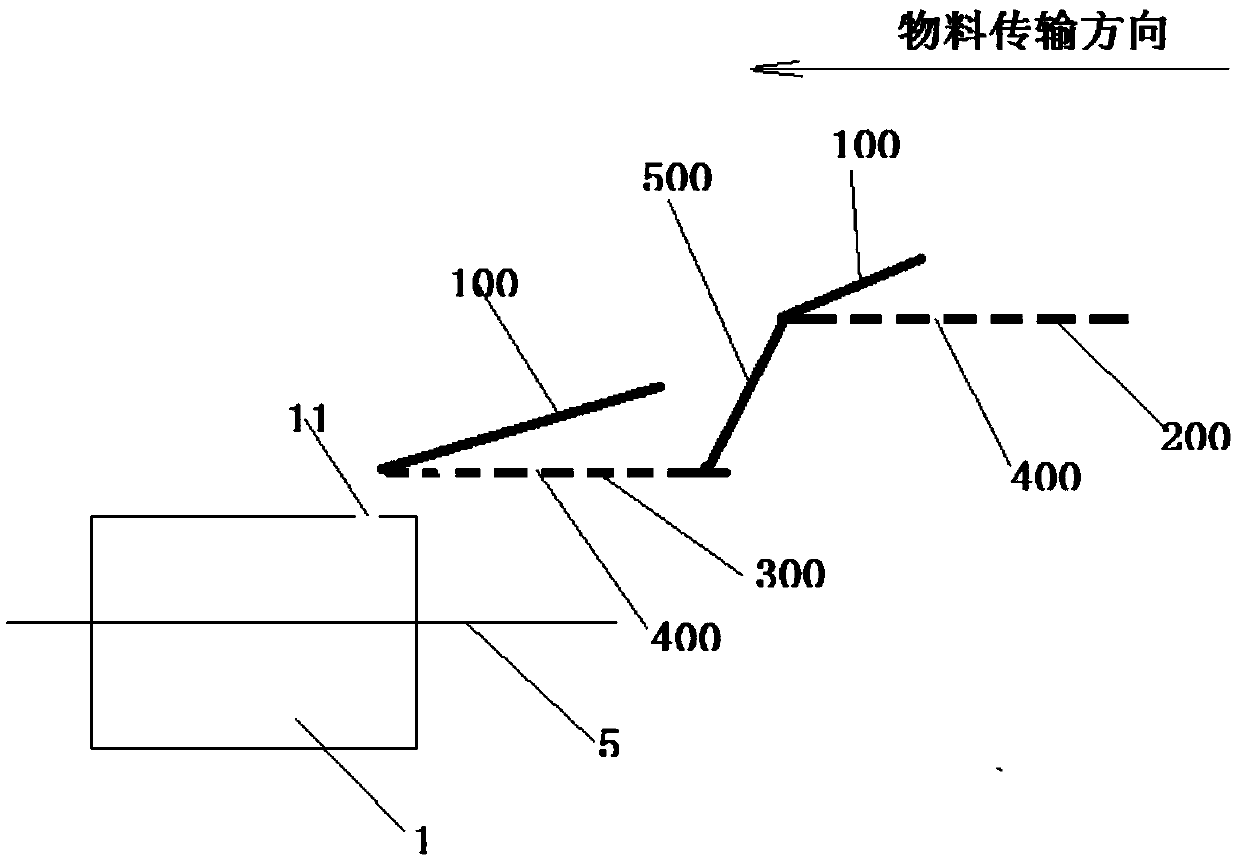

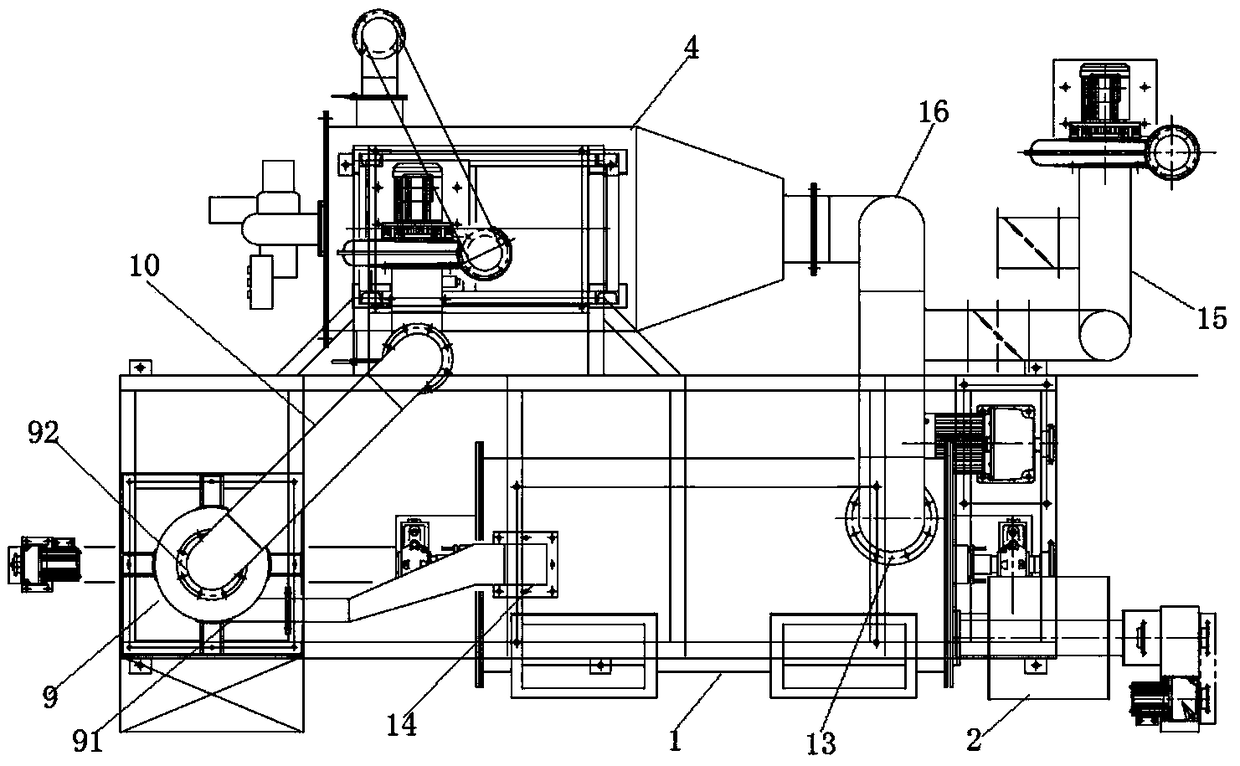

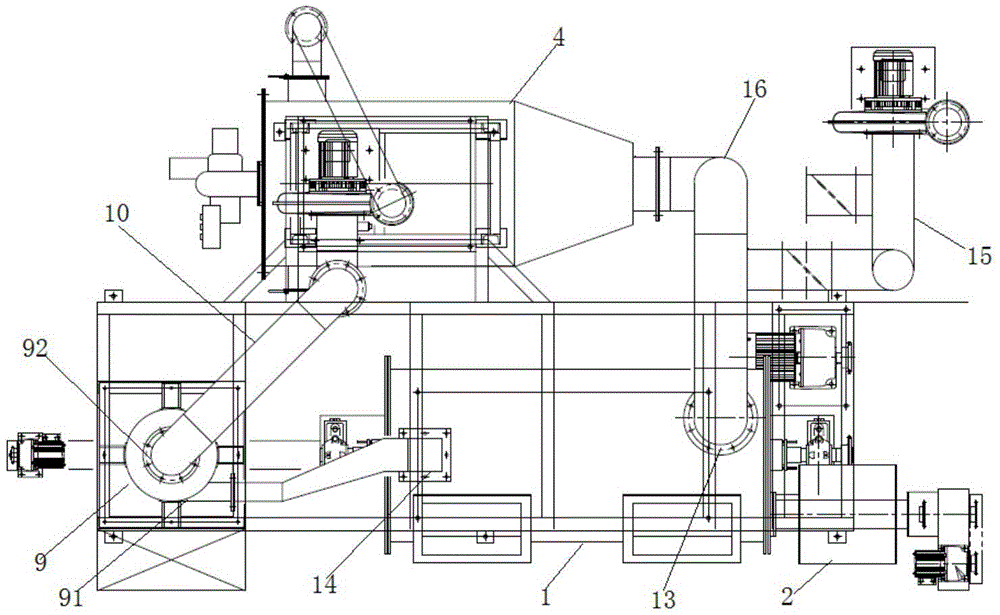

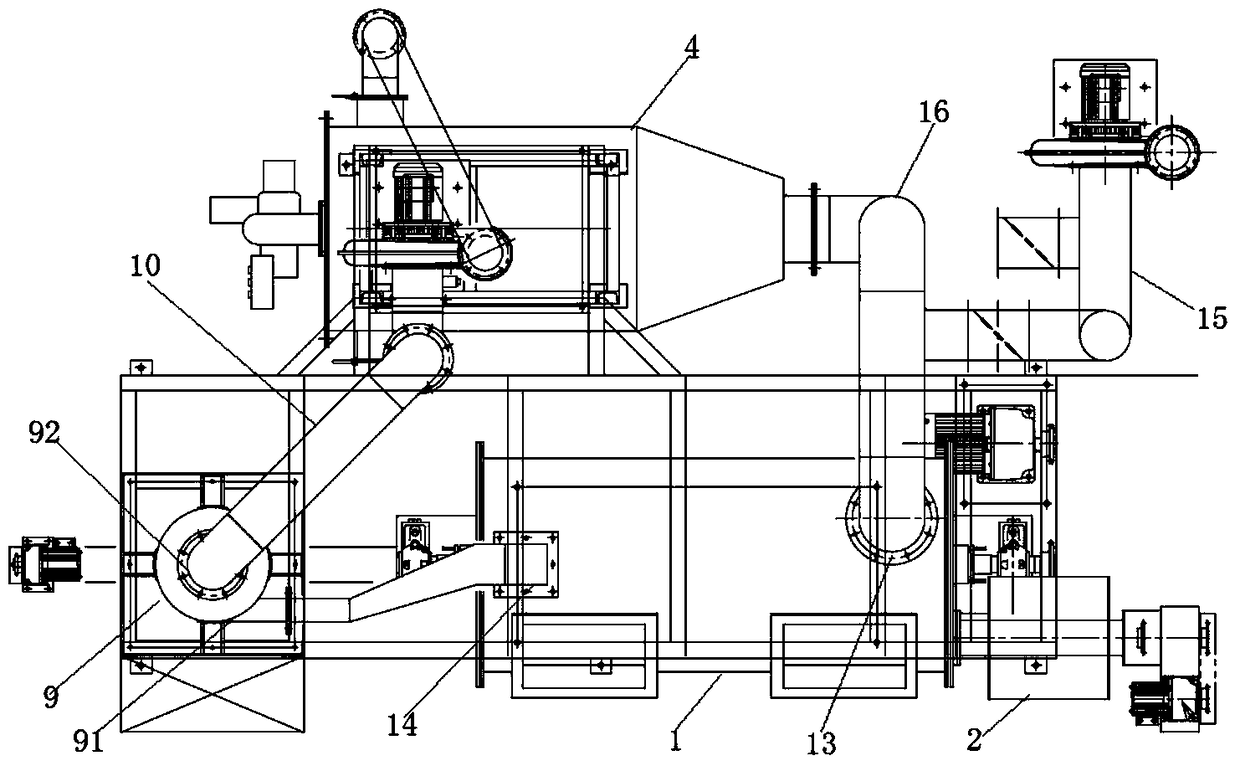

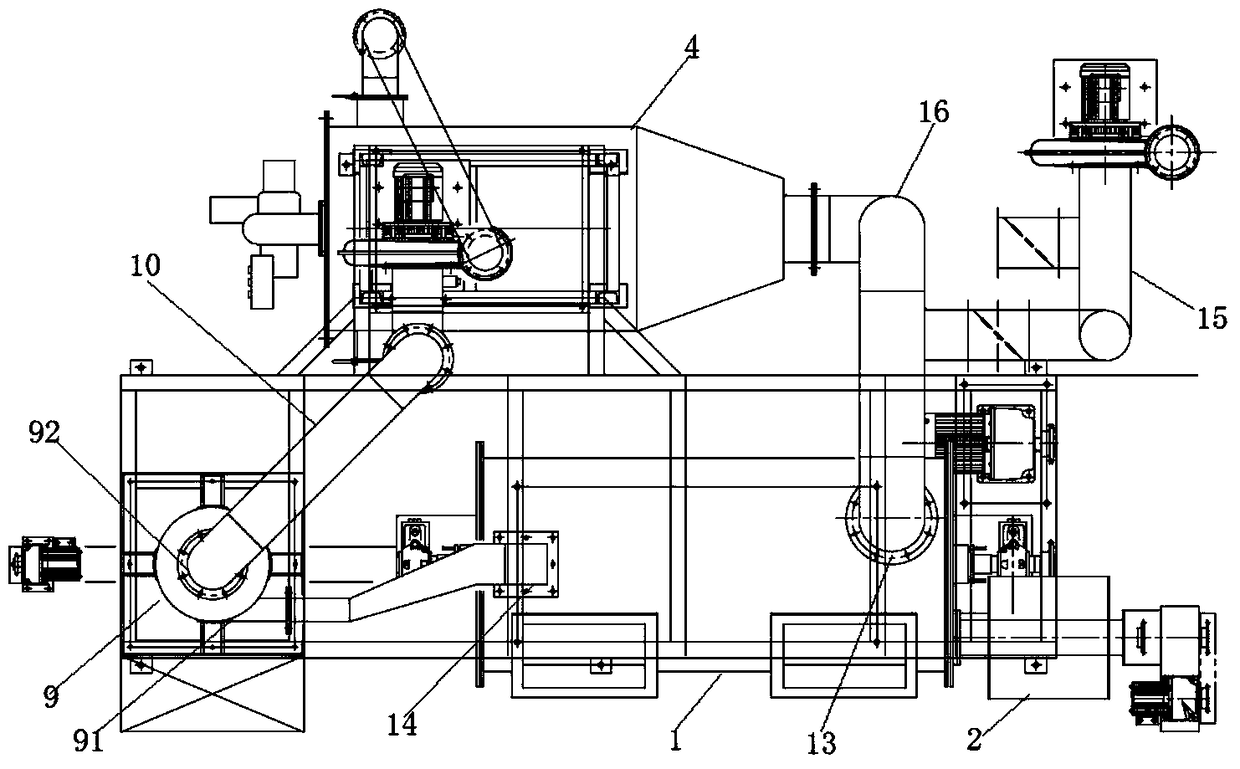

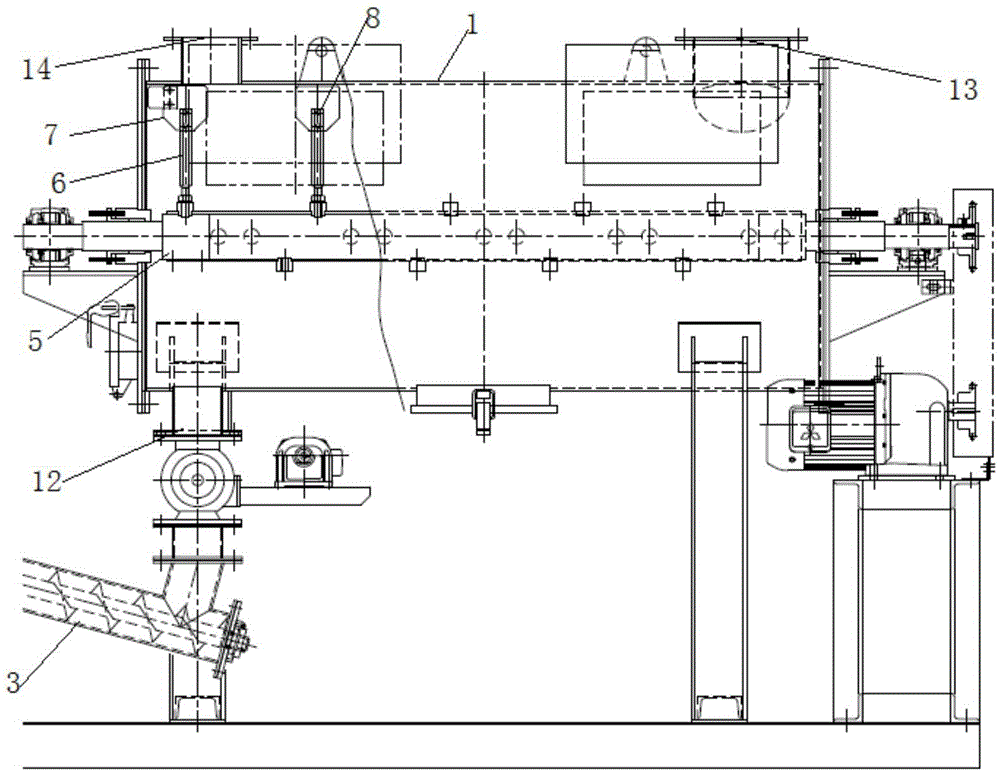

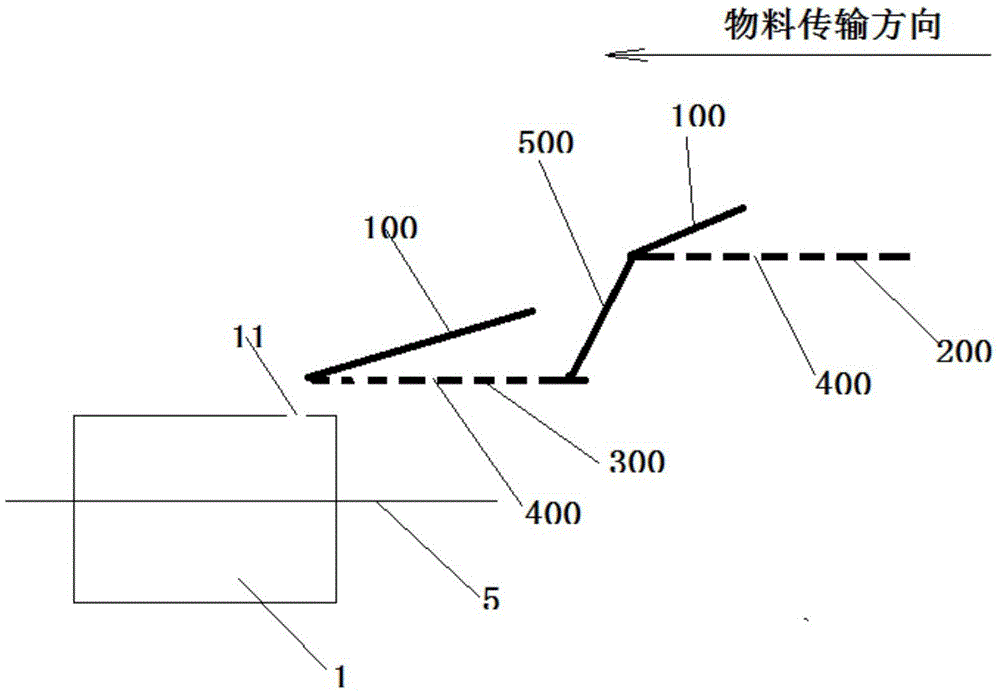

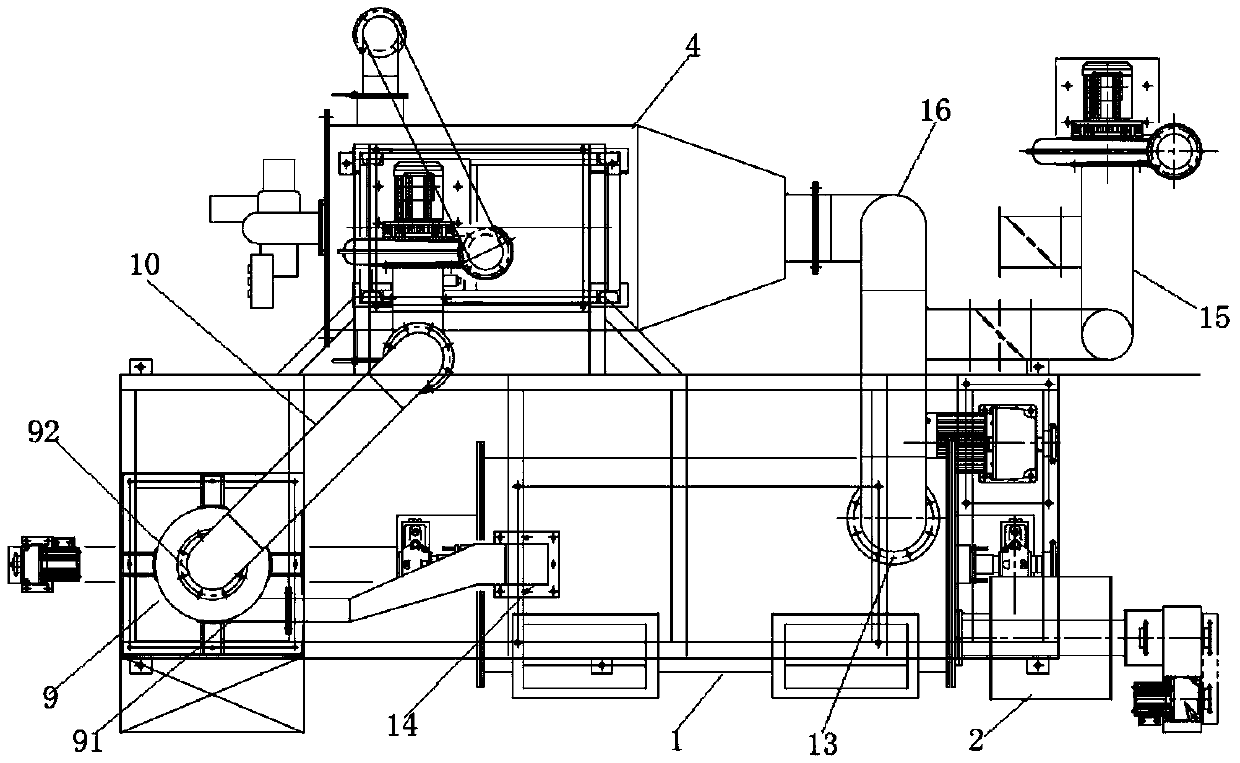

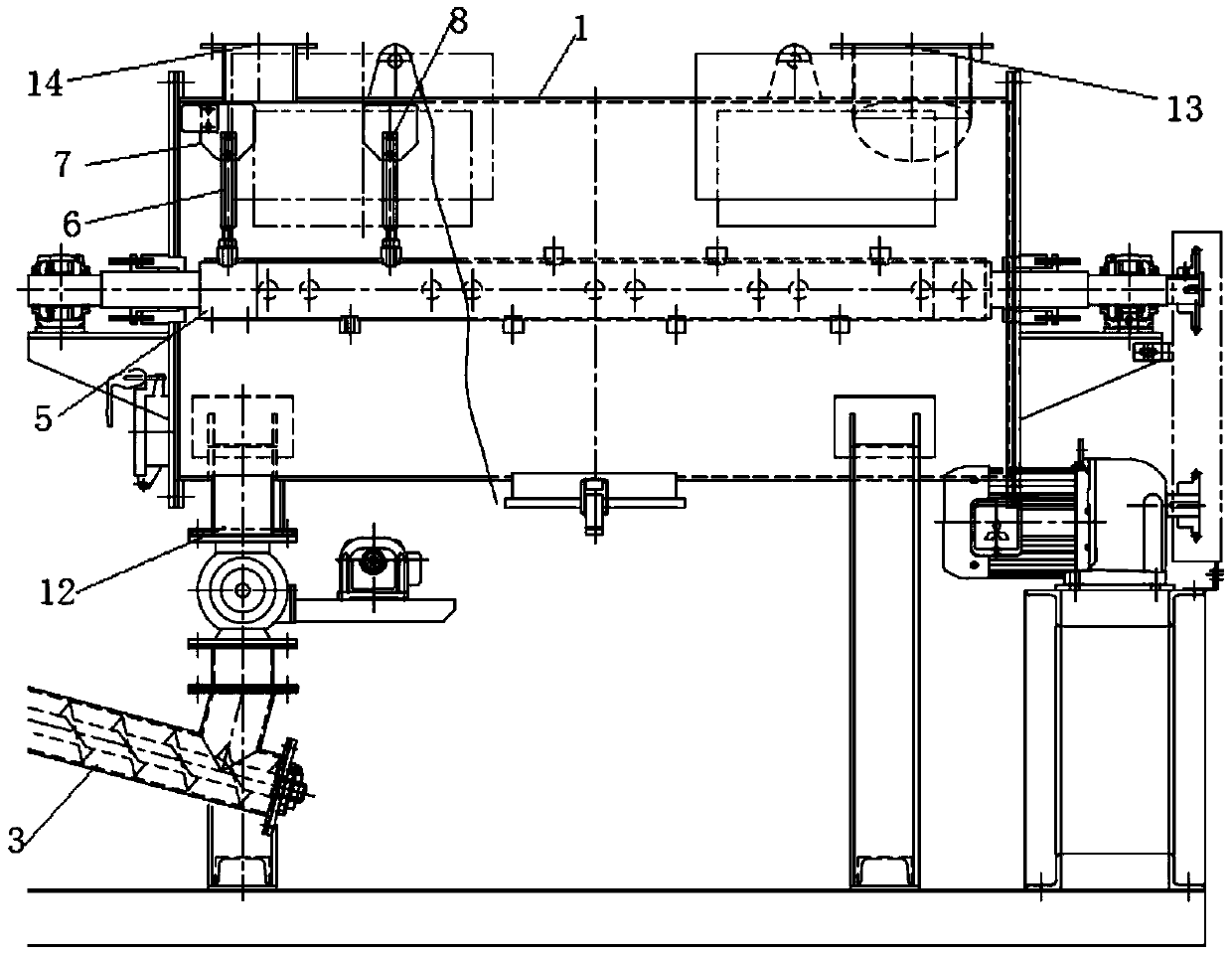

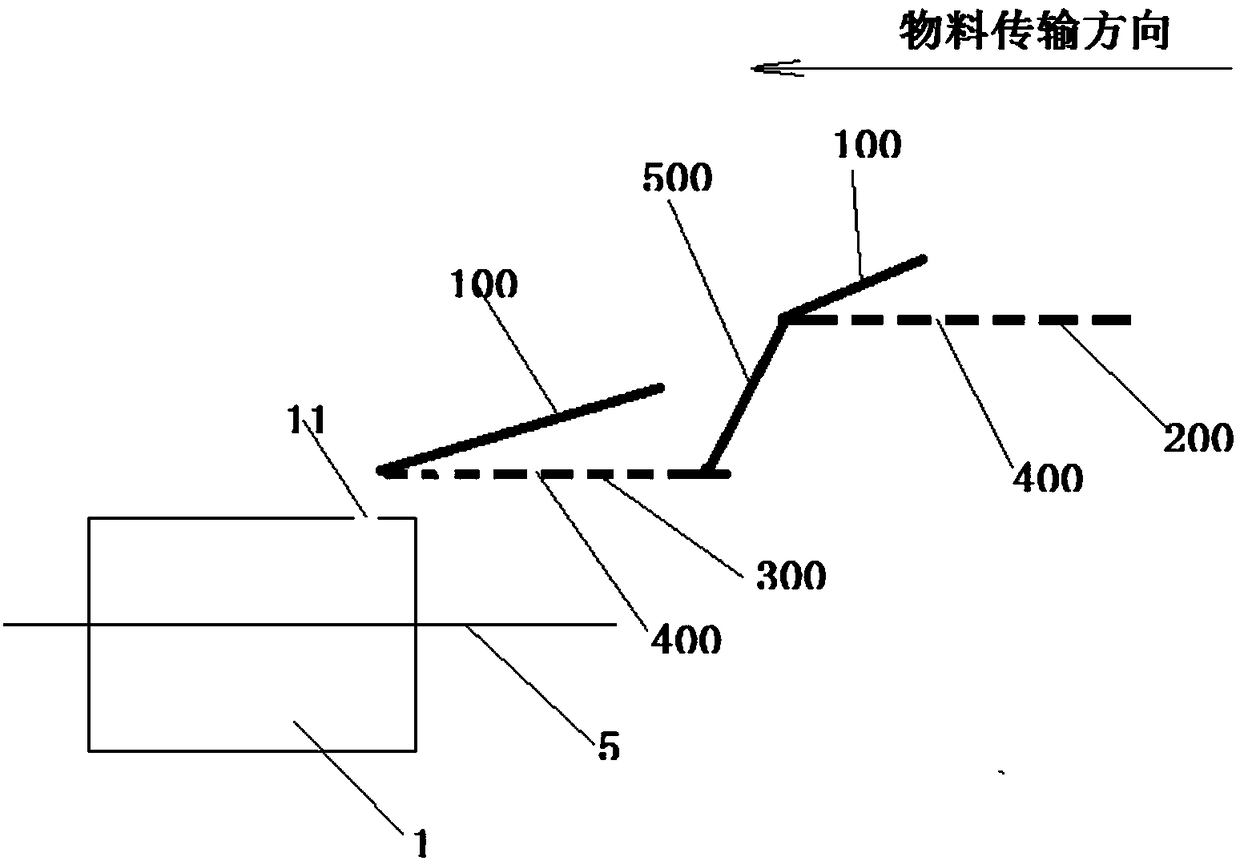

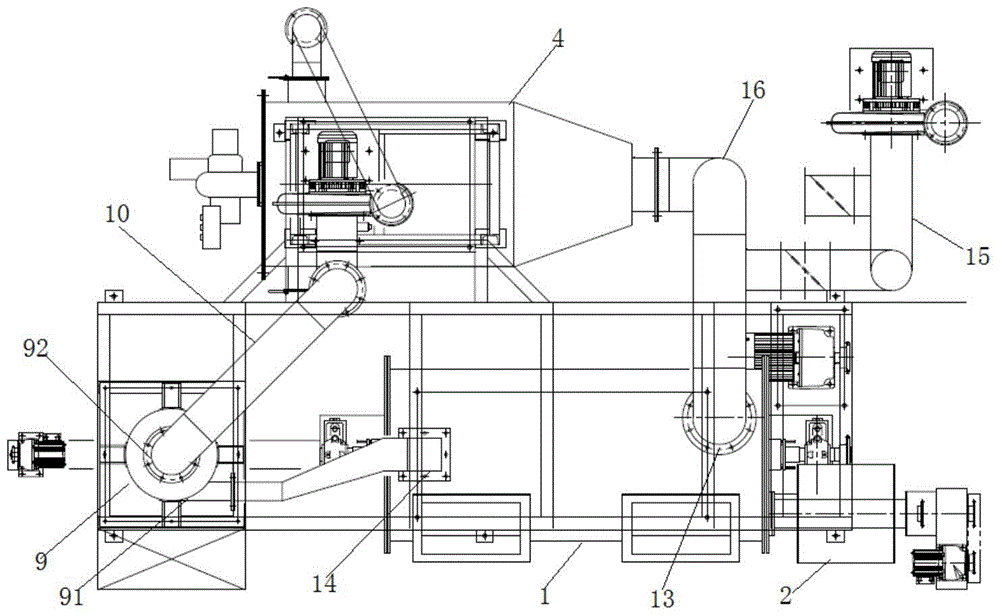

The invention relates to a sludge treatment system which comprises a conveying device, a water removal structure and a drying device. The drying device comprises a furnace body, a feed device used for adding materials into the furnace body, a material collection device used for collecting the dried materials in the furnace body, an air supply device used for leading external hot air into the furnace body through a first air inlet, and a stirring device used for stirring and smashing the materials. When the materials are dried, hot air is led into a cavity of the furnace body through the first air inlet, a second rotating shaft rotates and drives a stirring assembly on the second rotating shaft to unceasingly stir the materials in the radial direction and the axial direction of the second rotating shaft, and therefore the materials can roll in the axial direction and the radical direction of the second rotating shaft in the furnace body, the time during which the materials are stirred is prolonged, and the convective heat exchange area of the materials and hot air is enlarged. In addition, the materials can be smashed through the stirring assembly, materials with smaller particles can be formed, the convective heat exchange area of the materials and hot air is further enlarged, and the material drying efficiency and effect are improved.

Owner:GUYUAN XINYUE HALAL FOOD +1

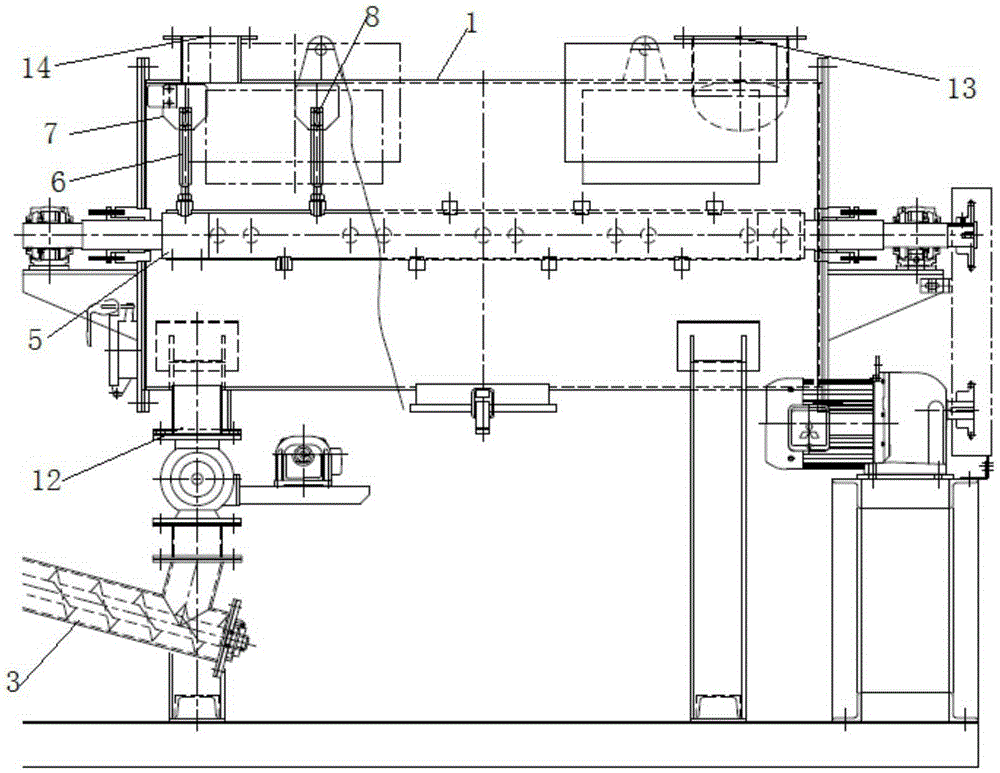

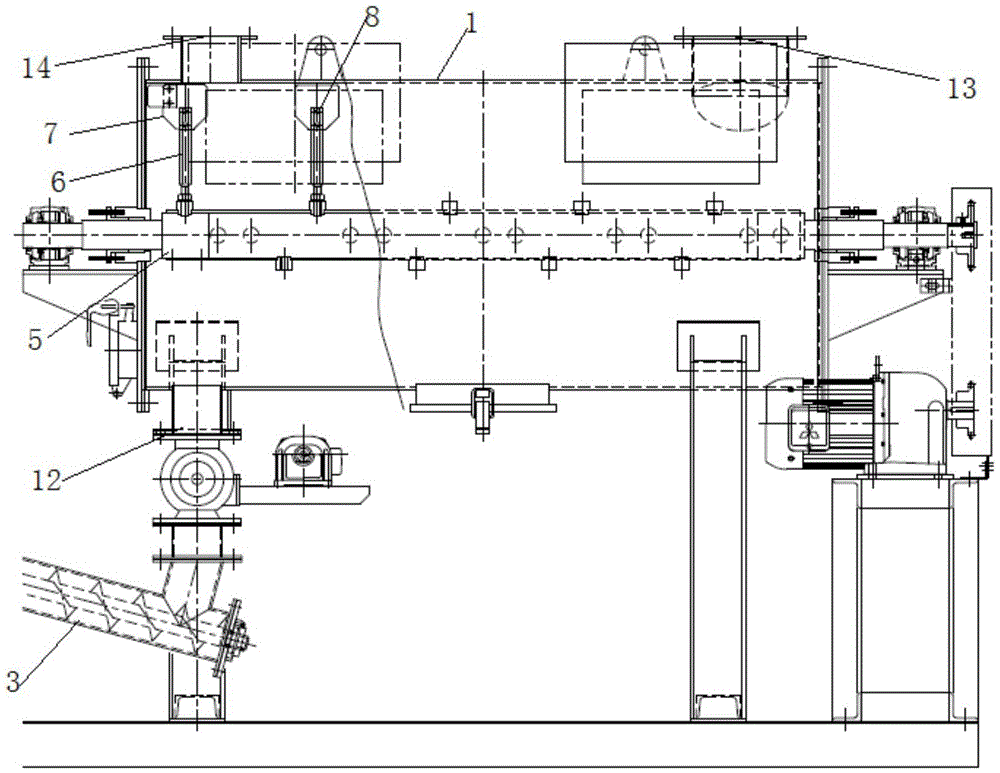

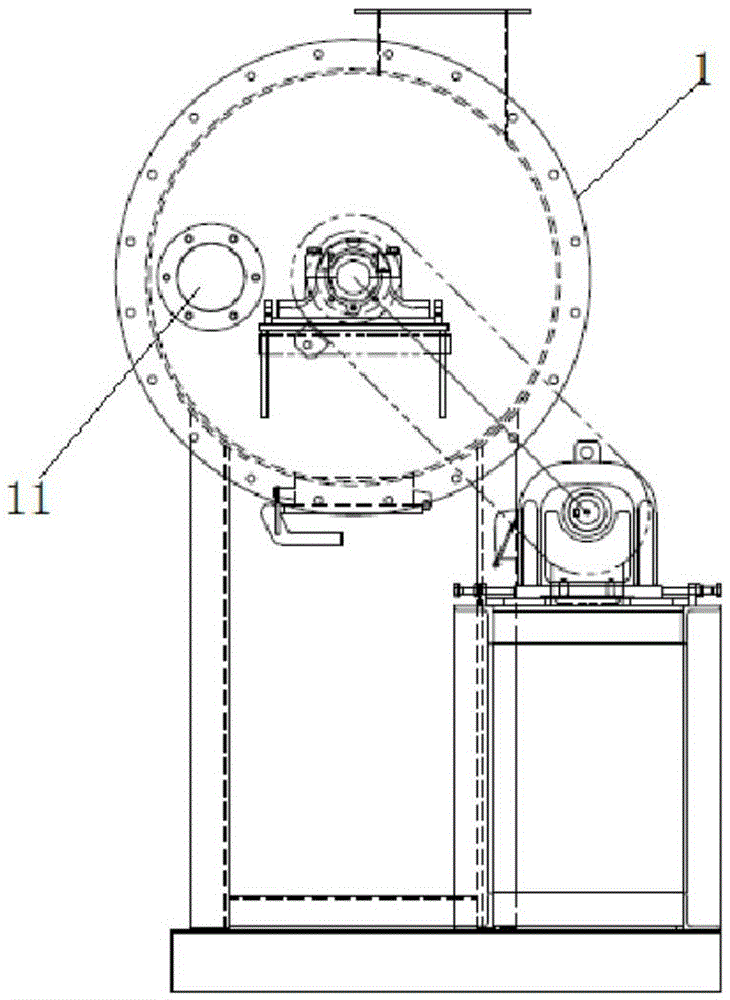

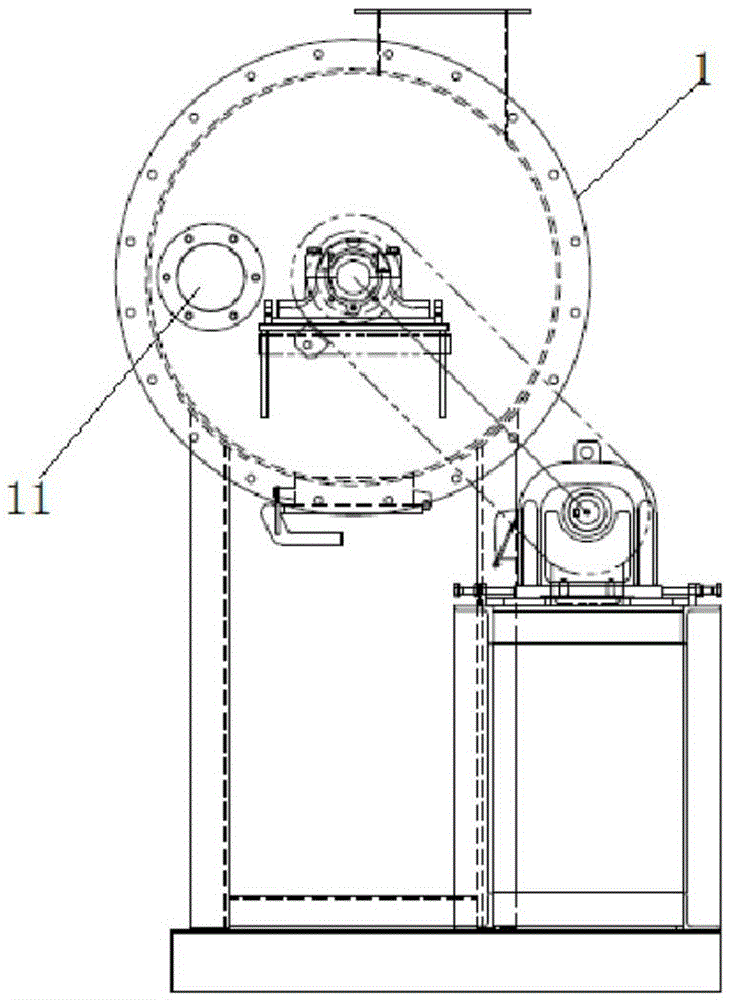

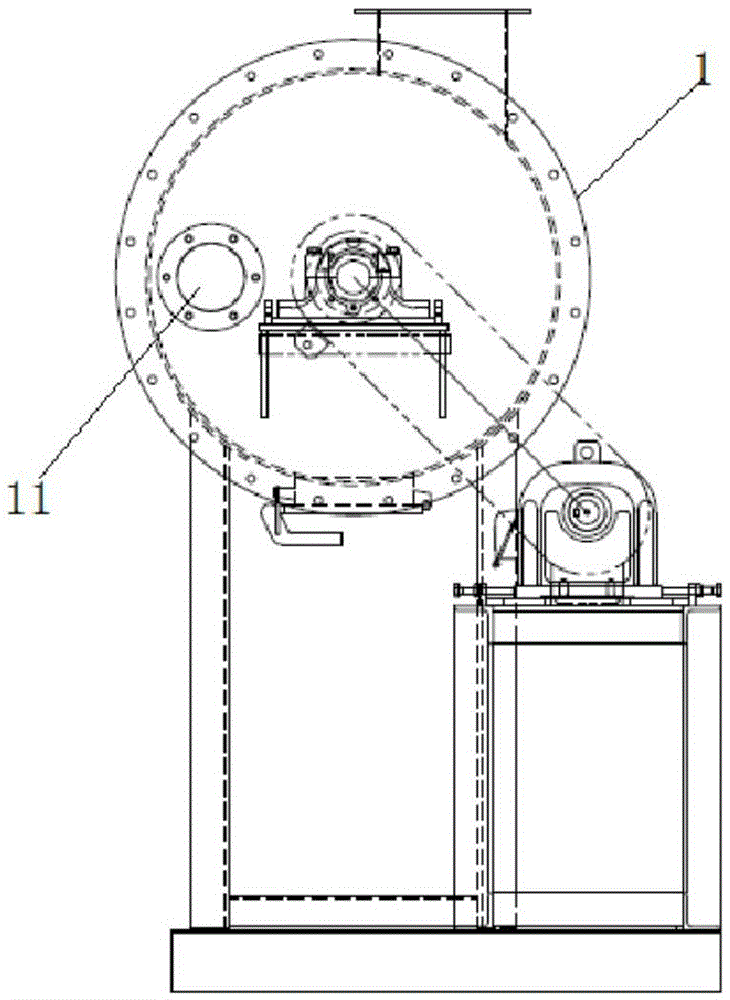

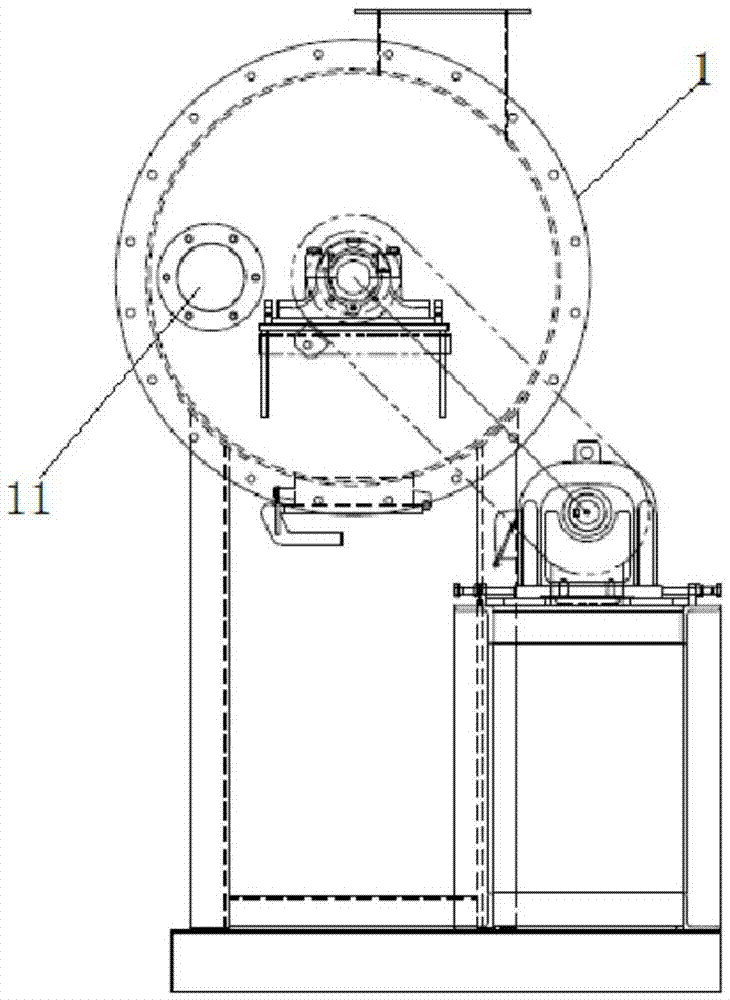

Drying machine

ActiveCN105333706AIncrease the areaImprove heat transfer efficiencyDrying machines with non-progressive movementsDrying solid materialsSmall particleMechanical engineering

The invention discloses a drying machine. The drying machine comprises a furnace body, rotating shafts, and stirring components, wherein the furnace body is arranged in the horizontal direction; the furnace body is provided with a feed opening through which materials are added and a discharge opening through which the materials are taken out; the rotating shafts are arranged in the cavity of the furnace body in a penetrating manner; the stirring components are arranged on the rotating shafts; the stirring components are used for stirring and crushing the materials in the axial directions of the rotating shafts and in the radial directions of the rotating shafts. According to the drying machine disclosed by the invention, when the materials are dried, under the driving of the rotating shafts, the stirring components can stir the materials in the axial directions of the rotating shafts and in the radial directions of the rotating shafts, so that the materials can be rolled in the furnace body in the axial directions of the rotating shafts and in the radial directions of the rotating shafts; besides, when the materials are stirred, the materials can also be crushed to form the materials with smaller particles, so that the area of heat convection between the materials and external environment is increased, the drying efficiency of the materials is improved, and the drying effect of the materials is improved.

Owner:江苏碧诺环保科技有限公司

A high-efficiency solid-liquid mixture treatment system

ActiveCN105605892BTake full advantage of the squeezeAffect the degree of loosenessDrying machines with non-progressive movementsHeating arrangementEngineeringGas supply

The invention relates to a high-efficiency solid-liquid mixture processing system, which includes a transmission device, a water removal structure and a drying device. The material receiving device, the air supply device that introduces the external hot gas into the furnace body through the first air inlet, and the stirring device for stirring and crushing the materials. Wherein, the stirring device includes a second rotating shaft, which is installed in the cavity of the furnace body. The second rotating shaft has a ventilating cavity, and several air jets are arranged on the venting cavity. The stirring direction of the stirring shaft and the stirring direction of the blades do not overlap and are not parallel; when drying the material, the hot gas is introduced into the cavity of the furnace body through the first air inlet, and the rotation of the second rotating shaft drives the gas on the second rotating shaft. The stirring assembly continuously stirs the materials along the radial and axial directions of the second rotating shaft.

Owner:王良源

Sludge Treatment System

ActiveCN105439416BAffect the degree of loosenessIncrease the convective heat transfer areaSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesMechanical engineeringTreatment system

Owner:淮安中顺环保科技有限公司

A drying system integrating heating and drying

ActiveCN105546957BAffect the degree of loosenessIncrease the convective heat transfer areaSludge treatment by de-watering/drying/thickeningDrying gas arrangementsEngineeringConvection

The invention discloses a drying system integrating heating with drying. The drying system comprises a furnace body, a feeding device used for adding materials into the furnace body, a material collecting device used for collecting dried materials in the furnace body, an air feeding device used for introducing outside hot gas into the furnace body through a first gas inlet, and a stirring device used for stirring and crushing the materials, wherein the stirring device comprises a second rotary shaft; the second rotary shaft is arranged in a cavity of the furnace body in a penetration mode, and is provided with a gas ventilating cavity; a plurality of gas vents are formed in the gas ventilating cavity; the gas spraying direction of the gas vents is not superposed with and is not parallel to the stirring direction of the stirring shaft and the stirring direction of blades; during material drying, the hot gas is introduced into the cavity of the furnace body through the first gas vents; the second rotary shaft drives a stirring assembly on the second rotary shaft to continuously stir materials in a radial direction and in an axial direction of the second rotary shaft, so that the materials can turn over in the axial direction and in the radial direction of the second rotary shaft in the furnace body, and therefore, the convection and heat exchange area of the materials and the hot gas is increased.

Owner:JUYE ZHONGHAI CHEM

Improved solid-liquid mixture treatment system

InactiveCN108800755ASmoothly fall intoTake full advantage of the squeezeSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermodynamicsEngineering

The invention discloses an improved solid-liquid mixture treatment system. The system comprises a transmission device, a dewatering structure and a drying device, wherein the drying device comprises afurnace body, a feeding device, a material receiving device, an air supply device and a stirring device, wherein the feeding device is used for feeding materials into a furnace body, the material receiving device is used for collecting the materials dried in the furnace body, the air supply device is used for introducing external hot air into the furnace body through a first air inlet, and the stirring device is used for stirring and crushing the materials; and the stirring device comprises a second rotating shaft, the second rotating shaft penetrates a cavity of the furnace body, the secondrotating shaft is provided with a ventilation cavity, a plurality of air jet holes are formed in the ventilation cavity, the air injection directions of the air jet holes are misalign and are not parallel to the stirring directions of stirring shafts and the stirring directions of blades; and when the materials are dried, the hot air is introduced into the cavity of the furnace body through the first air inlet, the materials can roll in the furnace body in the axial direction and the radial direction of the second rotating shaft, the time for stirring the materials is increased, and the area of convective heat exchange between the materials and the hot air is increased.

Owner:王良源

Improved sludge treatment system

InactiveCN105481220ASmoothly fall intoTake full advantage of the squeezeSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningEngineeringMechanical engineering

The invention relates to an improved sludge treatment system which comprises a transmission device, a water removal structure and a drying device. The drying device comprises a furnace body, a feed device for adding materials into the furnace body, a material collecting device for collecting the dried materials in the furnace body, an air supply device leading external hot gas into the furnace body through a first gas inlet, and a stirring device for stirring and smashing the materials. The stirring device comprises a second rotary shaft which is arranged in a cavity of the furnace body in a penetrating mode. The second rotary shaft is provided with a ventilating cavity. A plurality of gas spraying openings are formed in the ventilating cavity. The gas spraying direction of the gas spraying openings, the stirring direction of a stirring shaft and the stirring direction of blades are neither overlapped nor parallel. When the materials are dried, hot gas is led into the cavity of the furnace body through the first gas inlet, the second rotating shaft rotates to drive a stirring assembly on the second rotating shaft so that the materials can be continuously stirred in the radial and axial directions of the second rotating shaft and can roll in the axial and radial directions of the second rotating shaft in the furnace body.

Owner:王良源

Sludge treatment system

InactiveCN108821537AAffect the degree of loosenessIncrease the convective heat transfer areaSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeProcess engineering

The invention relates to a sludge treatment system which comprises a conveying device, a water removal structure and a drying device. The drying device comprises a furnace body, a feeding device for adding materials to the furnace body, a receiving device for collecting the materials dried in the furnace body, an air supply device for introducing external hot gas into the furnace body through a first air inlet, and a stirring device for stirring and pulverizing the materials. The stirring device comprises a second rotating shaft arranged in the cavity of the furnace body in a penetrating manner, the second rotating shaft is provided with a ventilation cavity, and the ventilation cavity is provided with a plurality of air jet holes, the air jet direction of the air jet holes is not coincident with or parallel to the stirring direction of the stirring shaft and the stirring direction of blades, the time of stirring material and the area of convective heat transfer between the material and the hot gas are increased.

Owner:王良源

Drying system integrating heating with drying

ActiveCN105546957AImprove space utilizationKeep drySludge treatment by de-watering/drying/thickeningDrying gas arrangementsEngineeringProduct gas

The invention discloses a drying system integrating heating with drying. The drying system comprises a furnace body, a feeding device used for adding materials into the furnace body, a material collecting device used for collecting dried materials in the furnace body, an air feeding device used for introducing outside hot gas into the furnace body through a first gas inlet, and a stirring device used for stirring and crushing the materials, wherein the stirring device comprises a second rotary shaft; the second rotary shaft is arranged in a cavity of the furnace body in a penetration mode, and is provided with a gas ventilating cavity; a plurality of gas vents are formed in the gas ventilating cavity; the gas spraying direction of the gas vents is not superposed with and is not parallel to the stirring direction of the stirring shaft and the stirring direction of blades; during material drying, the hot gas is introduced into the cavity of the furnace body through the first gas vents; the second rotary shaft drives a stirring assembly on the second rotary shaft to continuously stir materials in a radial direction and in an axial direction of the second rotary shaft, so that the materials can turn over in the axial direction and in the radial direction of the second rotary shaft in the furnace body, and therefore, the convection and heat exchange area of the materials and the hot gas is increased.

Owner:JUYE ZHONGHAI CHEM

Solid-liquid mixture processing system

ActiveCN105565641AImprove space utilizationDoes not affect the direction of travelSludge treatment by de-watering/drying/thickeningEngineeringTreatment system

The invention relates to a solid-liquid mixture processing system. The system comprises a transmission device, a water removing structure, and a drying device. The drying device comprises a furnace body, a feed device for feeding materials into the furnace body, a material receiving device for receiving the materials that have been dried in the furnace body, an air supplying device, which introduces external hot gas into the furnace body through a first gas inlet, and a stirring device, which is used to stir and grind the materials. The stirring device comprises a second rotation shaft, which is thoroughly arranged in the cavity of the furnace body. The second rotation shaft is provided with an aeration cavity, which is provided with a plurality of air jet holes. The air jetting direction of the air jet holes is not overlapped with or parallel to the stirring directions of the stirring shaft and blade. When the materials are dried, the hot gas is introduced into the cavity of the furnace body through the first gas inlet, and the second rotation shaft drives the stirring components arranged on the second rotation shaft to continuously stir the materials along the radial direction and axial direction of the second rotation shaft.

Owner:王良源

A sludge treatment system

ActiveCN105502881BSmoothly fall intoAffect the degree of loosenessSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningMechanical engineeringTreatment system

Owner:GUYUAN XINYUE HALAL FOOD +1

An improved solid-liquid mixture processing system

ActiveCN105585237BSmoothly fall intoTake full advantage of the squeezeSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningMixed materialsMechanical engineering

The invention relates to an improved solid-liquid mixture treatment system, which includes a transmission device, a water removal structure and a drying device. The drying device includes a furnace body, a feeding device for adding materials to the furnace body, and a collection device for collecting The material receiving device for the dried material, the air supply device that introduces the external hot gas into the furnace body through the first air inlet, and the stirring device for stirring and crushing the material. Wherein, the stirring device includes a second rotating shaft, which is installed in the cavity of the furnace body. The second rotating shaft has a ventilating cavity, and several air jets are arranged on the venting cavity. The stirring direction of the stirring shaft and the stirring direction of the blades do not overlap and are not parallel; when drying the material, the hot gas is introduced into the cavity of the furnace body through the first air inlet, and the rotation of the second rotating shaft drives the gas on the second rotating shaft. The stirring assembly continuously stirs the materials along the radial and axial directions of the second rotating shaft.

Owner:王良源

A solid-liquid mixture processing system

ActiveCN105565641BAffect the degree of loosenessIncrease the convective heat transfer areaSludge treatment by de-watering/drying/thickeningDrying solid materialsThermodynamicsEngineering

The invention relates to a solid-liquid mixture treatment system, which includes a transmission device, a water removal structure and a drying device. The drying device includes a furnace body, a feeding device for adding materials to the furnace body, and a collection of dried materials in the furnace body. The material receiving device, the air supply device that introduces the external hot gas into the furnace body through the first air inlet, and the stirring device for stirring and pulverizing the materials. Wherein, the stirring device includes a second rotating shaft, which is installed in the cavity of the furnace body. The second rotating shaft has a ventilating cavity, and several air jets are arranged on the venting cavity. The stirring direction of the stirring shaft and the stirring direction of the blades do not overlap and are not parallel; when drying the material, the hot gas is introduced into the cavity of the furnace body through the first air inlet, and the rotation of the second rotating shaft drives the gas on the second rotating shaft. The stirring assembly continuously stirs the materials along the radial and axial directions of the second rotating shaft.

Owner:王良源

Improved sludge treatment system

ActiveCN105621850AGuarantee the effect of squeezing waterImprove space utilizationSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesProduct gasEngineering

The invention relates to a sludge treatment system. The sludge treatment system comprises a transmission device, a water removal structure and a drying device, wherein the drying device comprises a furnace body, a feeding device, a material receiving device, a gas supply device and a stirring device, wherein the feeding device is used for feeding materials into the furnace body, the material receiving device is used for collecting dried materials in the furnace body, the gas supply device is used for introducing external hot gas into the furnace body through a first gas inlet, and the stirring device is used for stirring and grinding the materials. When the materials are dried, hot gas is introduced into a furnace body cavity through the first gas inlet, a second rotating shaft rotates to drive a stirring assembly on the second rotating shaft to continuously stir the materials along the radial and axial directions of the second rotating shaft, and then the materials can roll in the furnace body along the radial and axial directions of the second rotating shaft, so that the stirring time of the materials is prolonged, and the heat convection area between the materials and hot gas is increased; and besides, the materials can be ground into the materials with relatively small particles by the stirring assembly, so that the heat convection area between the materials and hot gas is further increased, and the drying efficiency and drying effect of the materials are improved.

Owner:中科创新发展(北京)科技有限公司

High-efficiency solid-liquid mixture processing system

ActiveCN105605892ATake full advantage of the squeezeAffect the degree of loosenessDrying machines with non-progressive movementsHeating arrangementEngineeringGas supply

The invention relates to a high-efficiency solid-liquid mixture processing system. The system comprises a conveying device, a de-watering structure and a drying device; the drying device comprises a furnace body, a feeding device, a material receiving device, a gas supplying device and a stirring device, wherein the feeding device is used for feeding materials into the furnace body, the material receiving device is used for collecting dried materials in the furnace body, the gas supplying device introduces hot external gas into the furnace body through a first gas inlet, and the stirring device is used for stirring and pulverizing the materials. The stirring device comprises a second rotating shaft, the second rotating shaft is arranged in a cavity in the furnace body in a penetrating mode and provided with a ventilation cavity, the ventilation cavity is provided with multiple air-jetting openings, and the gas-jetting direction of the gas-jetting openings does not coincide with or is not parallel to the stirring direction of stirring shafts and the stirring direction of blades; when the materials are dried, the hot gas is introduced into the cavity of the furnace body through the first gas inlet, and the second rotating shaft rotates to drive a stirring assembly on the second rotating shaft to continuously stir the materials in the radial direction and the axial direction of the second rotating shaft.

Owner:王良源

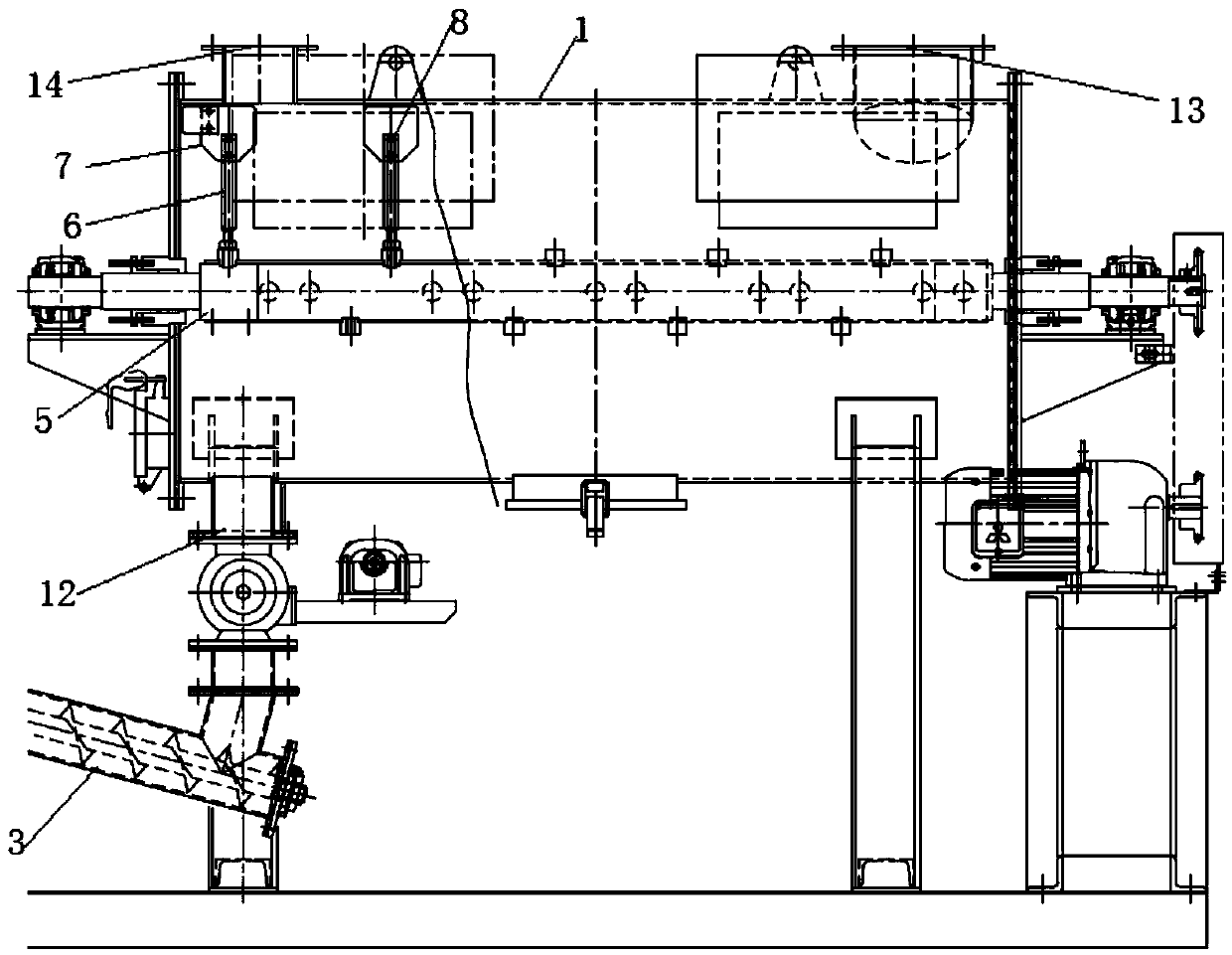

Heating-drying-stirring integrated material treatment system

ActiveCN105645716AAffect the degree of loosenessIncrease the convective heat transfer areaSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningAir blowerMaterials science

The invention relates to a heating-drying-stirring integrated material treatment system which comprises a furnace body, a feeding device for adding a material into the furnace body, a material receiving device for collecting the dried material in the furnace body, an air blower for introducing an outside hot gas into the furnace body through a first gas inlet, and a stirring device for stirring and pulverizing the material, wherein the stirring device comprises a second rotating shaft which penetrates through the cavity of the furnace body; the second rotating shaft is provided with a ventilation cavity; the ventilation cavity is provided with a plurality of jet nozzles; and the jet direction of the jet nozzles is not coincident with or parallel to the stirring direction of the stirring shaft and the stirring direction of the blades. When the system is used for drying the material, the hot gas is introduced into the cavity of the furnace body through the first gas inlet, and the second rotating shaft rotates and drives a stirring assembly on the second rotating shaft to continuously stir along the radial direction and axial direction of the second rotating shaft, so that the material can roll along the axial direction and radial direction of the second rotating shaft in the furnace body.

Owner:江苏金亿农牧机械有限公司

A material handling method

ActiveCN105645715BAffect the degree of loosenessIncrease the convective heat transfer areaSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningMetallurgyMaterials processing

The invention relates to a material treatment method. The material treatment method adopts a material treatment system integrating heating, stirring and drying, so that heating, stirring and drying can be performed at the same time. The material treatment system integrating heating, stirring and drying comprises a furnace body, a feeding device for feeding a material into the furnace body, a material receiving device for collecting the dried material in the furnace body, a wind supply device for introducing outside hot gas into the furnace body through a first gas inlet and a stirring device for stirring and pulverizing the material, wherein the stirring device comprises a second rotating shaft which is penetrated in the cavity of the furnace body; the second rotating shaft is provided with a ventilation chamber; the ventilation chamber is provided with a plurality of gas nozzles; and the injection direction of the gas nozzles, the stirring direction of a stirring shaft and the stirring direction of blades do not coincide and are not parallel.

Owner:江苏易诚干燥工程有限公司

Improved solid-liquid mixed material treatment system

ActiveCN105585237ASmoothly fall intoTake full advantage of the squeezeSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningEngineeringMixed materials

The invention relates to an improved solid-liquid mixed material treatment system. The improved solid-liquid mixed material treatment system comprises a conveying device, a water removal structure and a drying device, wherein the drying device comprises a furnace body, a feeding device for feeding a material into the furnace body, a receiving device for collecting dried material in the furnace body, an air supply device for introducing outside hot air into the furnace body through a first air inlet and a stirring device for stirring and smashing the material; the stirring device comprises a second rotating shaft, the second rotating shaft penetrates in a cavity of the furnace body and is provided with a ventilation cavity, a plurality of air jet holes are formed in the ventilation cavity, and air jet directions of the air jet holes do not coincide with and are not parallel to stirring directions of stirring shafts and stirring directions of blades; when drying the material, the hot air is introduced into the cavity of the furnace body through the first air inlet, the second rotating shaft rotates to drive a stirring assembly on the second rotating shaft to stir the material continuously in the radial and axial directions of the second rotating shaft.

Owner:王良源

A kind of solid-liquid mixture processing method

ActiveCN105668976BSmoothly fall intoTake full advantage of the squeezeSludge treatmentDrying solid materialsEngineeringConvection heat

The invention relates to a method for treating a solid-liquid mixture, which includes the steps of transporting the solid-liquid mixture, pressing the solid-liquid mixture to remove water, and drying the solid-liquid mixture. In the step, a drying device is used Dry the solid-liquid mixture that has been squeezed and dewatered. The drying device includes a second rotating shaft, which is installed in the cavity of the furnace body. The second rotating shaft has a ventilating cavity, and several Air injection port, the air injection direction of the air injection port does not coincide with the stirring direction of the stirring shaft and the stirring direction of the blades; when drying the material, the hot gas is introduced into the cavity of the furnace body through the first air inlet The rotation of the second rotating shaft drives the stirring assembly on the second rotating shaft to continuously stir the materials along the radial and axial directions of the second rotating shaft, so that the materials can roll in the furnace body along the axial and radial directions of the second rotating shaft, increasing The time when the material is stirred increases the convective heat exchange area between the material and the hot gas.

Owner:王良源

Drying system

ActiveCN105347650AIncrease the convective heat transfer areaImprove heat transfer efficiencySludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesMetallurgyConvection

The invention discloses a drying system which comprises a furnace body, a material feeding device for adding materials into the furnace body, a material collecting device for collecting the materials dried in the furnace body, a wind feeding device for introducing outside hot gas into the furnace body through a first air inlet, and a stirring device for stirring and pulverizing the materials, wherein the stirring device comprises a rotating shaft arranged in the cavity of the furnace body in a penetrating manner, and stirring assemblies arranged on the rotating shaft. When the materials are dried, the hot gas is introduced into the cavity of the furnace body through the first air inlet, and the rotating shaft rotates to drive the stirring assemblies on the rotating shaft to continuously stir the materials in the radial direction and the axial direction of the rotating shaft, so that the materials can overturn in the axial direction and the radial direction of the rotating shaft in the furnace body, the time of stirring the materials is prolonged, and the heat convection area of the materials and the hot gas is enlarged. Besides, the stirring assemblies can also pulverize the materials to form the materials with relatively small particles, the heat convection area of the materials and the hot gas is further enlarged, and the drying efficiency and the drying effect of the materials are improved.

Owner:江苏碧诺环保科技有限公司

An Improved Material Handling System

ActiveCN105712604BGuarantee the effect of squeezing waterAffect the degree of loosenessSludge treatment by de-watering/drying/thickeningThermodynamicsEngineering

The invention relates to a material processing system which comprises a conveying device, a water removal structure and a drying device. The drying device comprises a furnace body, a feeding device used for adding materials into the furnace body, a collection device used for collecting dried materials in the furnace body, an air feeding device used for leading external hot gas into the furnace body through a first gas inlet, and a stirring device used for stirring and smashing the materials. When the materials are dried, hot gas is led into a cavity of the furnace body through the first gas inlet, a second rotating shaft rotates to drive a stirring assembly on the second rotating shaft to unceasingly stir the materials in the radial direction and the axial direction of the second rotating shaft, the materials can be rolled in the furnace body in the axial direction and the radial direction of the second rotating shaft, the material stirring time is prolonged, and the convection heat exchange area between the materials and hot gas is enlarged. In addition, the stirring assembly can smash the materials to form smaller-grained materials, the convection heat exchange area between the materials and hot gas is further enlarged, and the material drying efficiency and effect are improved.

Owner:安徽初么纸业有限公司

Improved material processing system

ActiveCN105712604AGuarantee the effect of squeezing waterImprove space utilizationSludge treatment by de-watering/drying/thickeningEngineeringHandling system

The invention relates to a material processing system which comprises a conveying device, a water removal structure and a drying device. The drying device comprises a furnace body, a feeding device used for adding materials into the furnace body, a collection device used for collecting dried materials in the furnace body, an air feeding device used for leading external hot gas into the furnace body through a first gas inlet, and a stirring device used for stirring and smashing the materials. When the materials are dried, hot gas is led into a cavity of the furnace body through the first gas inlet, a second rotating shaft rotates to drive a stirring assembly on the second rotating shaft to unceasingly stir the materials in the radial direction and the axial direction of the second rotating shaft, the materials can be rolled in the furnace body in the axial direction and the radial direction of the second rotating shaft, the material stirring time is prolonged, and the convection heat exchange area between the materials and hot gas is enlarged. In addition, the stirring assembly can smash the materials to form smaller-grained materials, the convection heat exchange area between the materials and hot gas is further enlarged, and the material drying efficiency and effect are improved.

Owner:安徽初么纸业有限公司

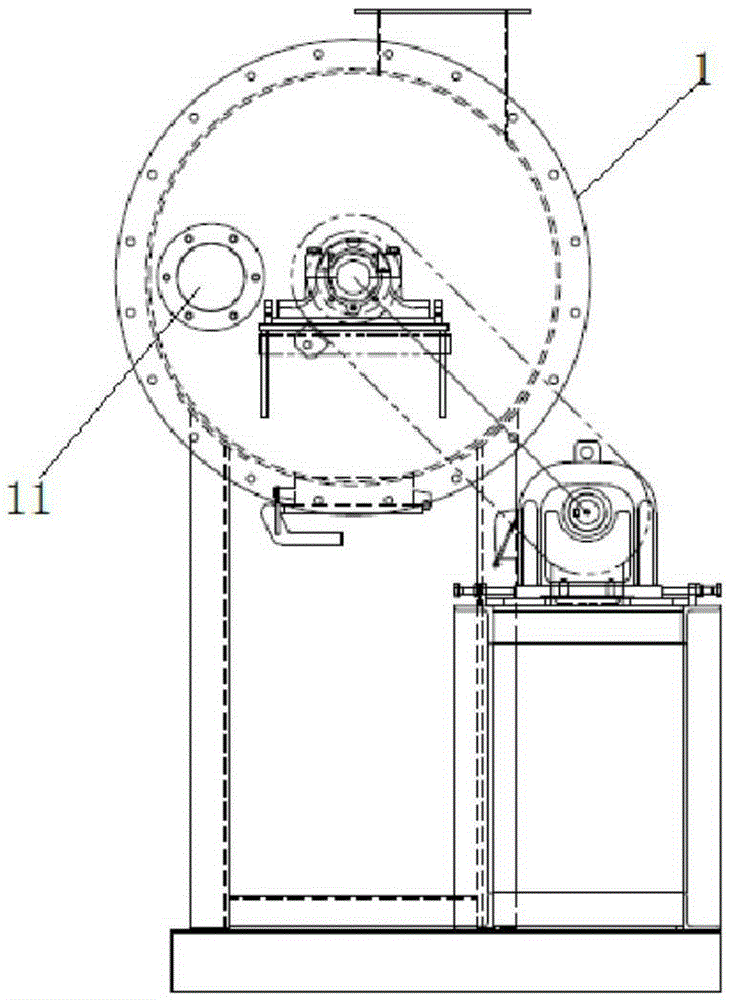

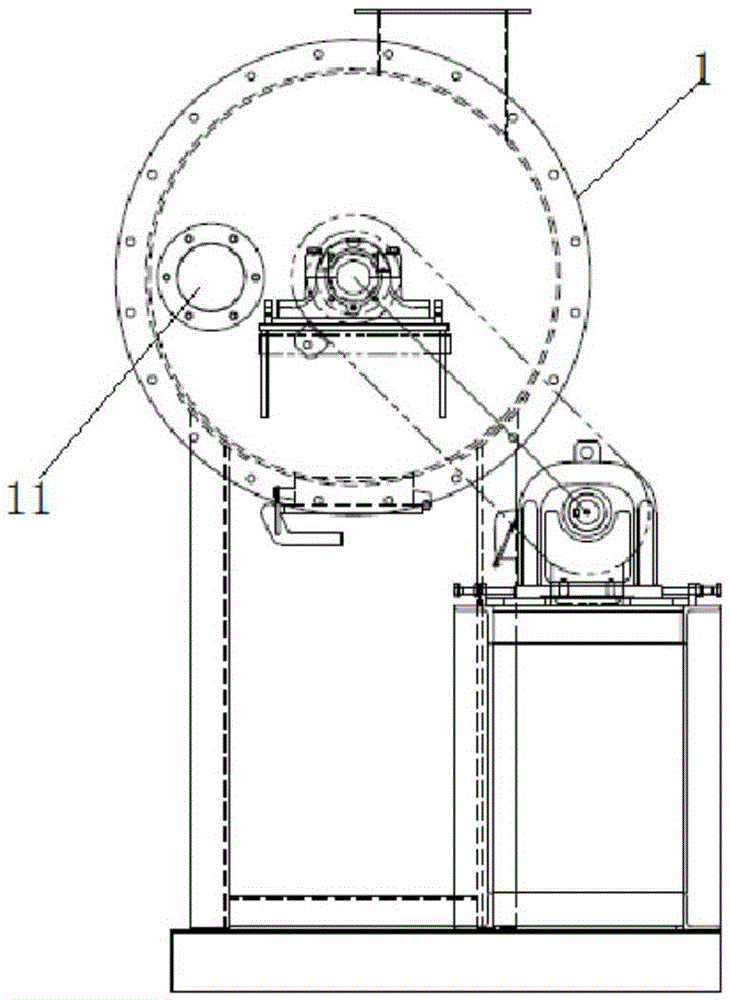

Cyclic drying device

ActiveCN105621847AChange stirringChange smash effectSludge treatment by de-watering/drying/thickeningMechanical engineering

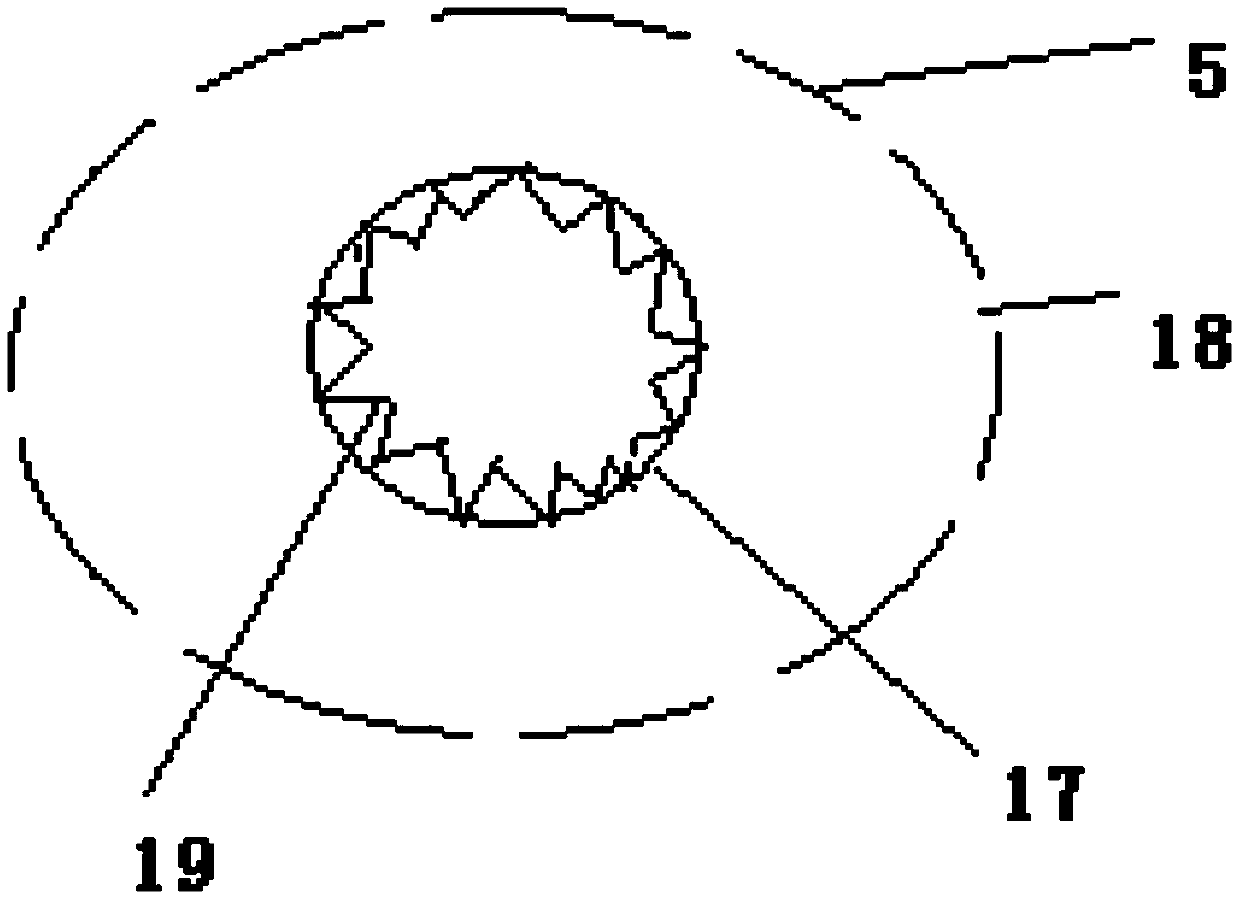

The invention discloses a cyclic drying device, which comprises a furnace body, a feeding device, a material collecting device, an air supply device and a stirring device, wherein the feeding device is used for adding materials into the furnace body; the material collecting device is used for collecting dried materials in the furnace body; the air supply device is used for introducing external hot gas into the furnace body through a first gas inlet; the stirring device is used for stirring and smashing the materials and comprises a rotating shaft; the rotating shaft is arranged in a cavity of the furnace body in a penetrating way, and is provided with a ventilation cavity; a plurality of gas spraying openings are formed in the ventilation cavity; the gas spraying direction of each gas spraying opening, the stirring direction of a stirring shaft and the stirring direction of blades are not coincident or parallel. During material drying, the hot gas is introduced into the cavity of the furnace body through the first gas inlet; the rotating shaft rotates to drive a stirring assembly arranged on the rotating shaft for continually stirring the materials in the radial direction and the axial direction of the rotating shaft, so that the materials can turn and roll in the axial direction and the radial direction of the rotating shaft in the furnace body; the stirred time of the materials is increased; the convection heat exchange area of the materials and the hot gas is increased.

Owner:湖南恒飞生物医药股份有限公司

An Improved Sludge Treatment System

ActiveCN105621850BGuarantee the effect of squeezing waterAffect the degree of loosenessSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSludgeEngineering

The invention relates to a sludge treatment system. The sludge treatment system comprises a transmission device, a water removal structure and a drying device, wherein the drying device comprises a furnace body, a feeding device, a material receiving device, a gas supply device and a stirring device, wherein the feeding device is used for feeding materials into the furnace body, the material receiving device is used for collecting dried materials in the furnace body, the gas supply device is used for introducing external hot gas into the furnace body through a first gas inlet, and the stirring device is used for stirring and grinding the materials. When the materials are dried, hot gas is introduced into a furnace body cavity through the first gas inlet, a second rotating shaft rotates to drive a stirring assembly on the second rotating shaft to continuously stir the materials along the radial and axial directions of the second rotating shaft, and then the materials can roll in the furnace body along the radial and axial directions of the second rotating shaft, so that the stirring time of the materials is prolonged, and the heat convection area between the materials and hot gas is increased; and besides, the materials can be ground into the materials with relatively small particles by the stirring assembly, so that the heat convection area between the materials and hot gas is further increased, and the drying efficiency and drying effect of the materials are improved.

Owner:中科创新发展(北京)科技有限公司

Drying device

InactiveCN108387082AAffect the degree of loosenessImprove drying efficiencySludge treatment by de-watering/drying/thickeningDrying gas arrangementsEngineeringConvection heat

The invention discloses a drying device comprising a furnace body, a feeding device, a material receiving device, an air feeding device and a stirring device. The feeding device is used for adding materials into the furnace body. The material receiving device is used for collecting the dried materials in the furnace body. The air feeding device introduces external hot air into the furnace body through a first air inlet. The stirring device is used for stirring and crushing the materials. The stirring device comprises a rotating shaft which penetrates into a cavity of the furnace body. The rotating shaft is provided with an air-through cavity. The air-through cavity is provided with a plurality of air jet holes, and the air jet directions of the air jet holes are neither overlapped with notparallel to the stirring direction of the stirring shaft and the stirring direction of a blade. When the materials are dried, the hot air is introduced into the cavity of the furnace body through thefirst air inlet, the rotating shaft rotates to drive the stirring device on the rotating shaft to continuously stir the materials in the radial and axial directions so that the materials can roll inthe furnace body in the axial and radial directions, the stirred time of the materials is increased, and the convection heat exchange area between the materials and the hot air is increased.

Owner:汪振朴

Solid-liquid mixture processing method

ActiveCN105668976ASmoothly fall intoTake full advantage of the squeezeSludge treatment by de-watering/drying/thickeningEngineeringConvection heat

The invention relates to a solid-liquid mixture processing method including the steps of transportation of a solid-liquid mixture, squeezing dehydration of the solid-liquid mixture, and drying of the solid-liquid mixture; in the drying step, a drying device is used for drying the solid-liquid mixture after squeezing dehydration and comprises a second rotary shaft which is arranged in a cavity of a furnace body in a penetration manner; the second rotary shaft is provided with a ventilation cavity; the ventilation cavity is provided with a plurality of gas jet holes, and the gas jet direction of the gas jet holes does not coincide with and is not parallel to the stirring direction of a stirring shaft and the stirring direction of blades; when the material is dried, hot gas is introduced into the cavity of the furnace body through a first gas inlet, the second rotary shaft rotates to drive a stirring assembly on the second rotary shaft to continuously stir the material in the radial and axial directions of the second rotary shaft, so that the material can roll over in the furnace body in the axial and radial directions of the second rotary shaft, the material stirring time is increased, and the convection heat transfer area of the material with the hot gas is increased.

Owner:王良源

A circulating drying device

ActiveCN105621847BAffect the degree of loosenessIncrease the convective heat transfer areaSludge treatment by de-watering/drying/thickeningDrying solid materialsEngineeringConvection heat

The invention discloses a circulation drying device, comprising a furnace body, a feeding device for adding materials into the furnace body, a material receiving device for collecting dried materials in the furnace body, and introducing hot gas from the outside through a first air inlet. The air supply device in the furnace body, and the stirring device for stirring and crushing the materials. Wherein, the stirring device includes a rotating shaft, which is installed in the cavity of the furnace body. The rotating shaft has a ventilating cavity, and several air injection ports are arranged on the ventilating cavity. The stirring directions of the blades and the stirring directions of the blades do not coincide and are not parallel; when the material is dried, the hot gas is introduced into the cavity of the furnace body through the first air inlet, and the rotation of the rotating shaft drives the stirring assembly on the rotating shaft to move in the radial direction of the rotating shaft. The material is continuously stirred in the axial and axial directions, so that the material can roll in the axial and radial direction of the rotating shaft in the furnace body, increasing the time for the material to be stirred, and increasing the convective heat exchange area between the material and the hot gas.

Owner:湖南恒飞生物医药股份有限公司

a drying system

ActiveCN105347650BExtension of timeAffect the degree of loosenessSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesMetallurgyConvection

The invention discloses a drying system which comprises a furnace body, a material feeding device for adding materials into the furnace body, a material collecting device for collecting the materials dried in the furnace body, a wind feeding device for introducing outside hot gas into the furnace body through a first air inlet, and a stirring device for stirring and pulverizing the materials, wherein the stirring device comprises a rotating shaft arranged in the cavity of the furnace body in a penetrating manner, and stirring assemblies arranged on the rotating shaft. When the materials are dried, the hot gas is introduced into the cavity of the furnace body through the first air inlet, and the rotating shaft rotates to drive the stirring assemblies on the rotating shaft to continuously stir the materials in the radial direction and the axial direction of the rotating shaft, so that the materials can overturn in the axial direction and the radial direction of the rotating shaft in the furnace body, the time of stirring the materials is prolonged, and the heat convection area of the materials and the hot gas is enlarged. Besides, the stirring assemblies can also pulverize the materials to form the materials with relatively small particles, the heat convection area of the materials and the hot gas is further enlarged, and the drying efficiency and the drying effect of the materials are improved.

Owner:江苏碧诺环保科技有限公司

Sludge treatment system

ActiveCN105439416AImprove space utilizationDoes not affect the direction of travelSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesEngineeringMechanical engineering

The invention relates to a sludge treatment system, comprising a conveying device, a dewatering structure and a drying device; the drying device comprises a furnace body, a charging device for charging materials into the furnace body, a collecting device for collecting dried materials in the furnace body, an air feeder introducing external air into the furnace body by a first air inlet and a stirring device for stirring and crushing the materials. The stirring device comprises a second rotary shaft which is arranged in a cavity of the furnace body in a penetrating manner, and the second rotary shaft has a venting cavity; the venting cavity is provided with a plurality of air jet holes; an air jet direction of the air jet holes is not coincided and is not parallel with a stirring direction of the stirring shaft and a stirring direction of a blade; when the materials are dried, hot air is introduced into the cavity of the furnace body by the first air inlet, and the second rotary shaft rotates to drive a stirring assembly on the second rotary shaft to continuously stir the materials along a radial direction and an axial direction of the second rotary shaft.

Owner:淮安中顺环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com