An Improved Material Handling System

A technology for processing systems and materials, applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., which can solve the problems of low drying efficiency, complex structure and poor drying effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

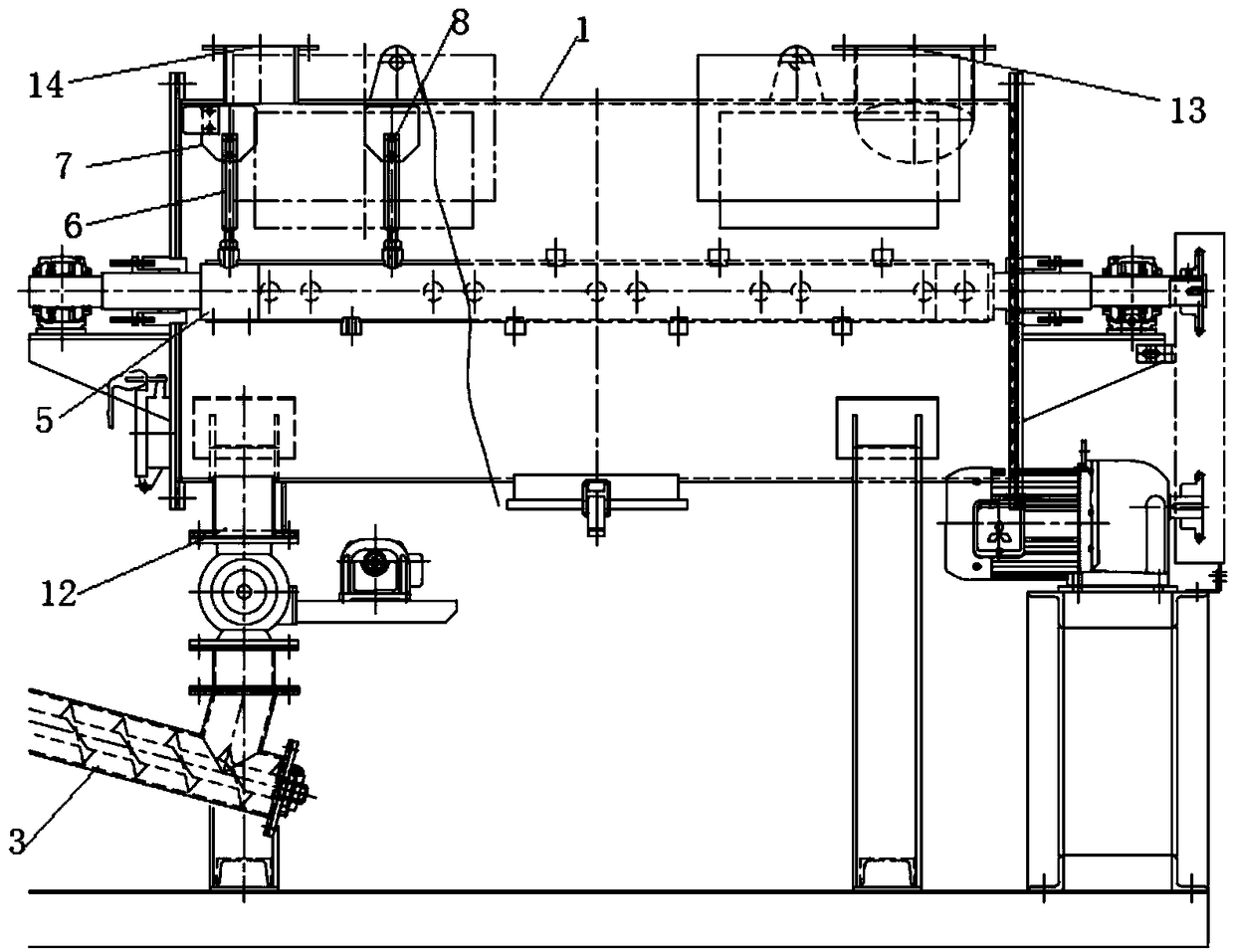

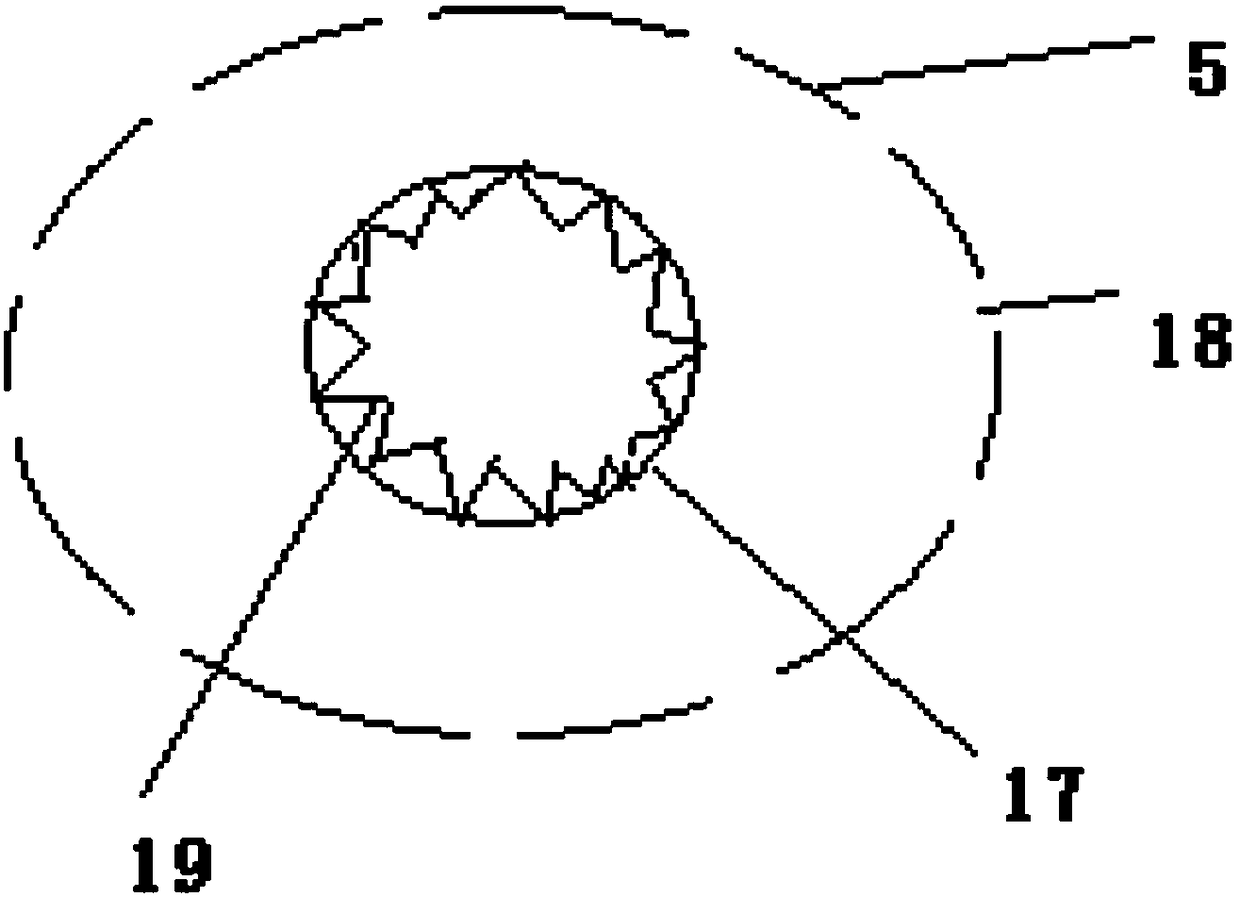

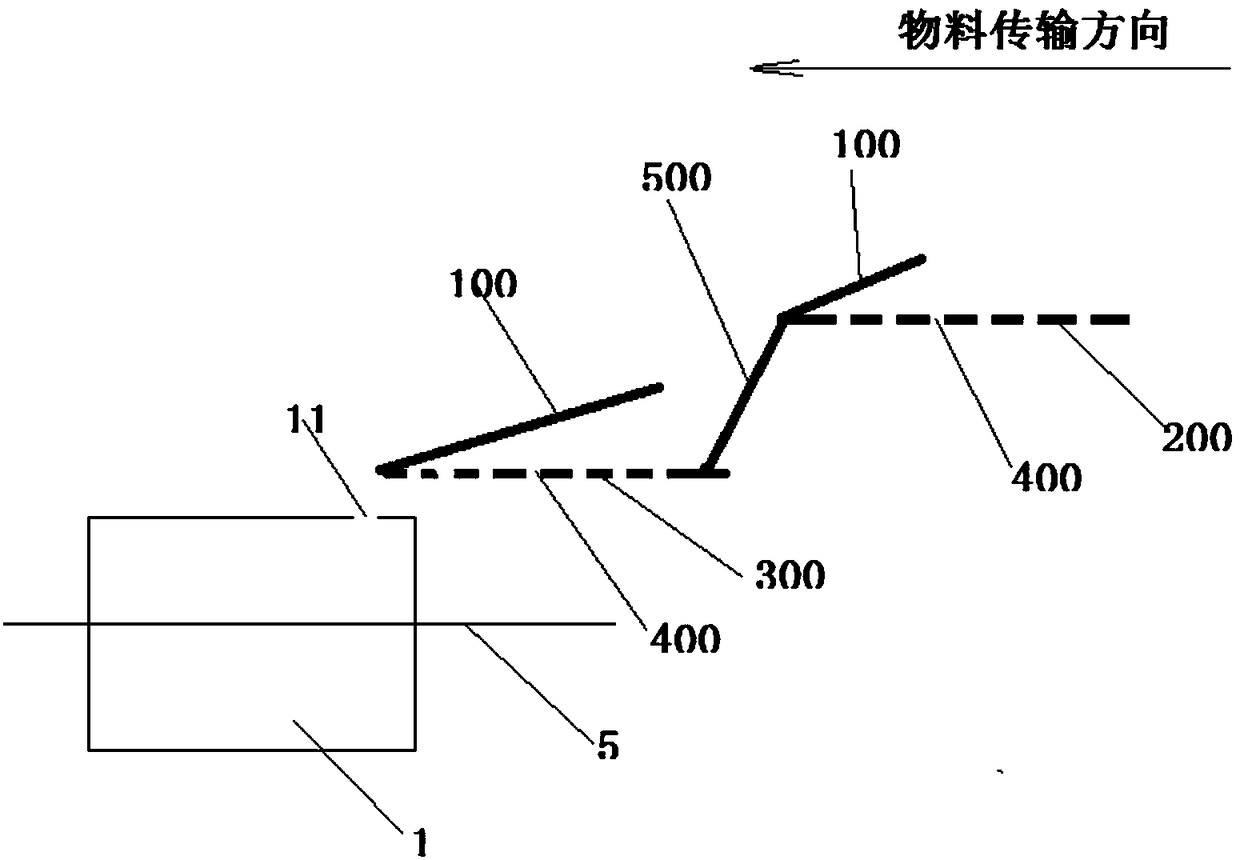

[0039] like Figure 1-3 As shown, the present embodiment provides a material handling system, including

[0040] The transmission device has a three-level transmission surface, the first-level transmission surface is located above the side of the second-level transmission surface, the second-level transmission surface is located above the side of the third-level transmission surface, the first-level transmission surface 200 and the second-level transmission surface Between the planes 300, and between the second-level transmission plane 300 and the third-level transmission plane are respectively connected through transition devices 500, and the height between the first-level transmission plane 200 and the second-level transmission plane 300 is smaller than that of the second-level transmission plane 300 and the height between the third-stage transmission surface, the transmission device can transport the solid-liquid mixed sludge from the head end of the first-stage transmissio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com