Patents

Literature

74results about How to "Avoid vibration phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

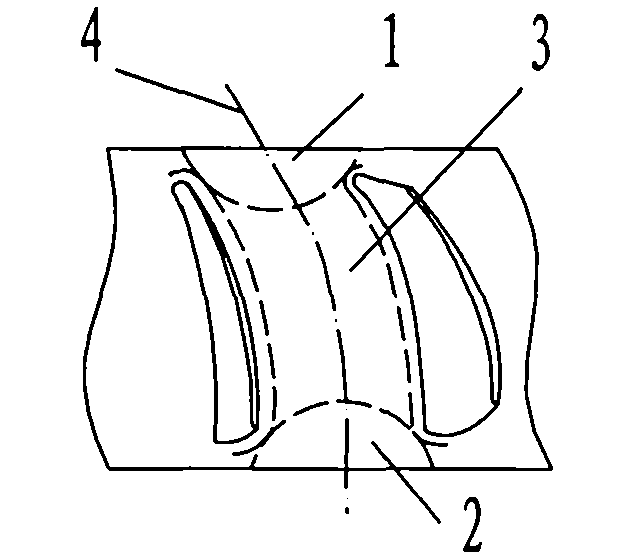

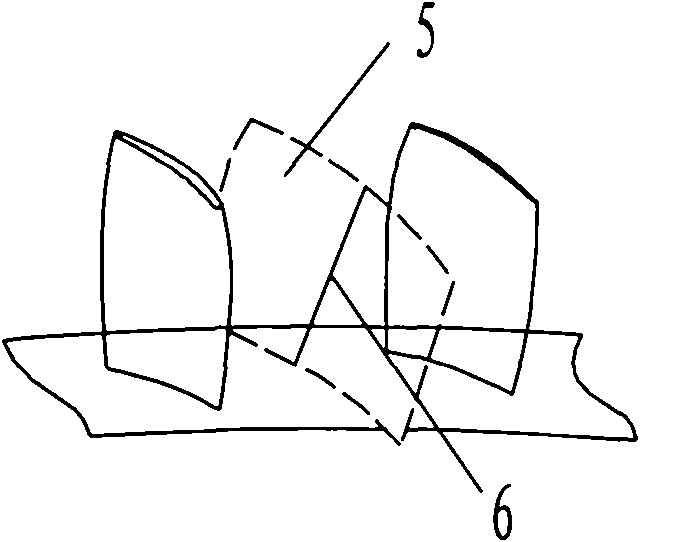

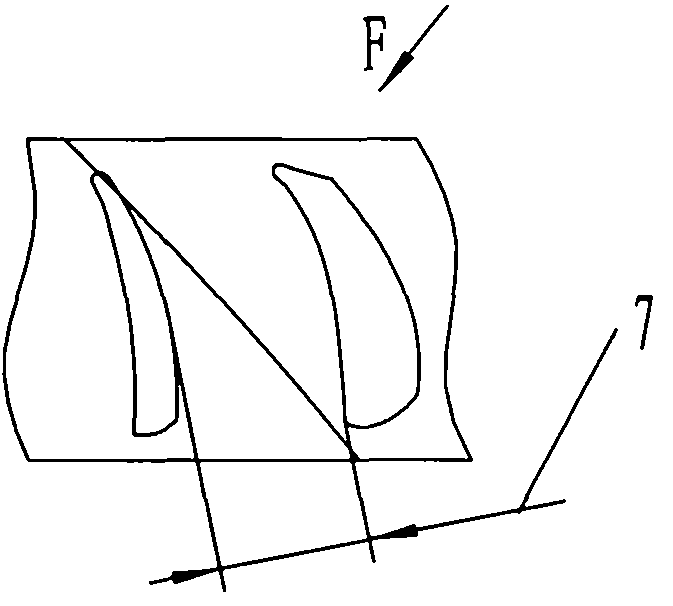

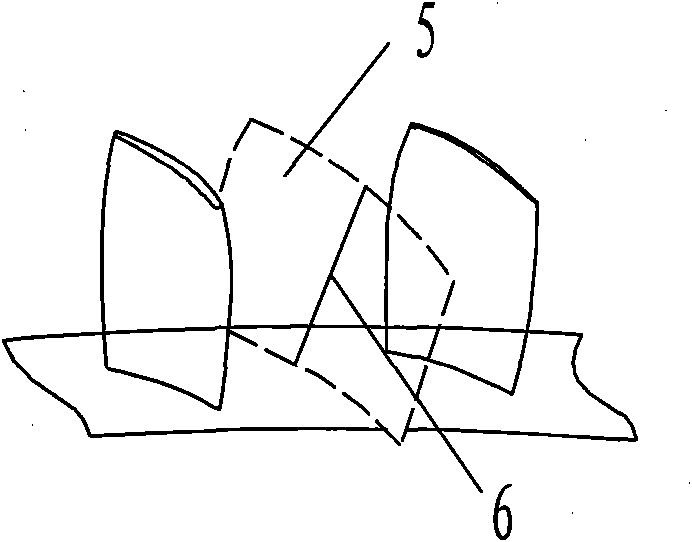

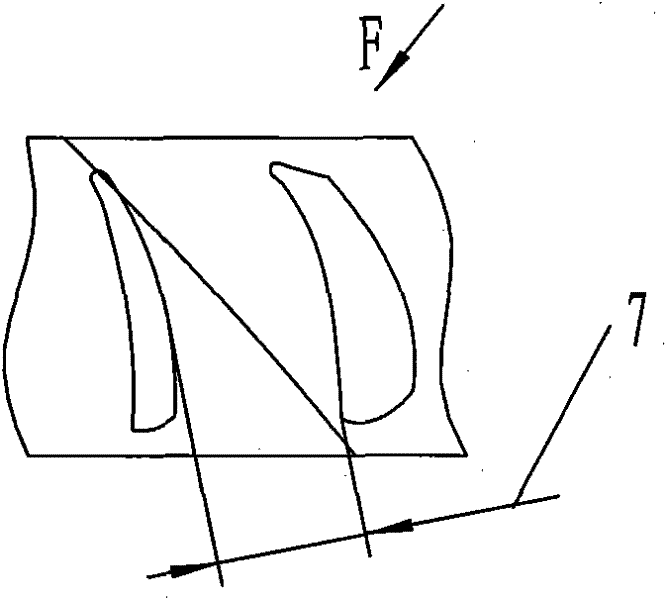

Method for composite machining of blisk flow passage

InactiveCN101966604AImprove rigidityImprove processing stabilityMilling equipment detailsNumerical controlBoundary contour

The invention belongs to the technical field of aircraft engines, and discloses a method for the composite machining of a blisk flow passage. The method is a numerical control machining method of selecting the adaptive machining strategy based on regional characteristics. The method comprises the following steps of: (1) dividing a machining region; and (2) selecting the adaptive numerical control machining strategy based on the regional characteristics. In the method, a rough slotting numerical control machining method of combining milling, drilling milling and slotting milling of a cycloid is adopted, so that a medial cambered surface is approximate to a curved surface of a blade profile, and the boundary contour and the optimal cutter-axis vector of a rough machining region in a channel are determined. The method has the advantages that the machining method of region division and cutting-in changing enhances the rigidity and machining stability of blades; a process method of combining the milling and slotting milling of the cycloid improves the durability of cutters and the removal rate of materials; and the vibration phenomenon in the rough machining process is prevented effectively, the cutting force is reduced, the movement space of the cutters is expanded farthest, and the machining efficiency is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

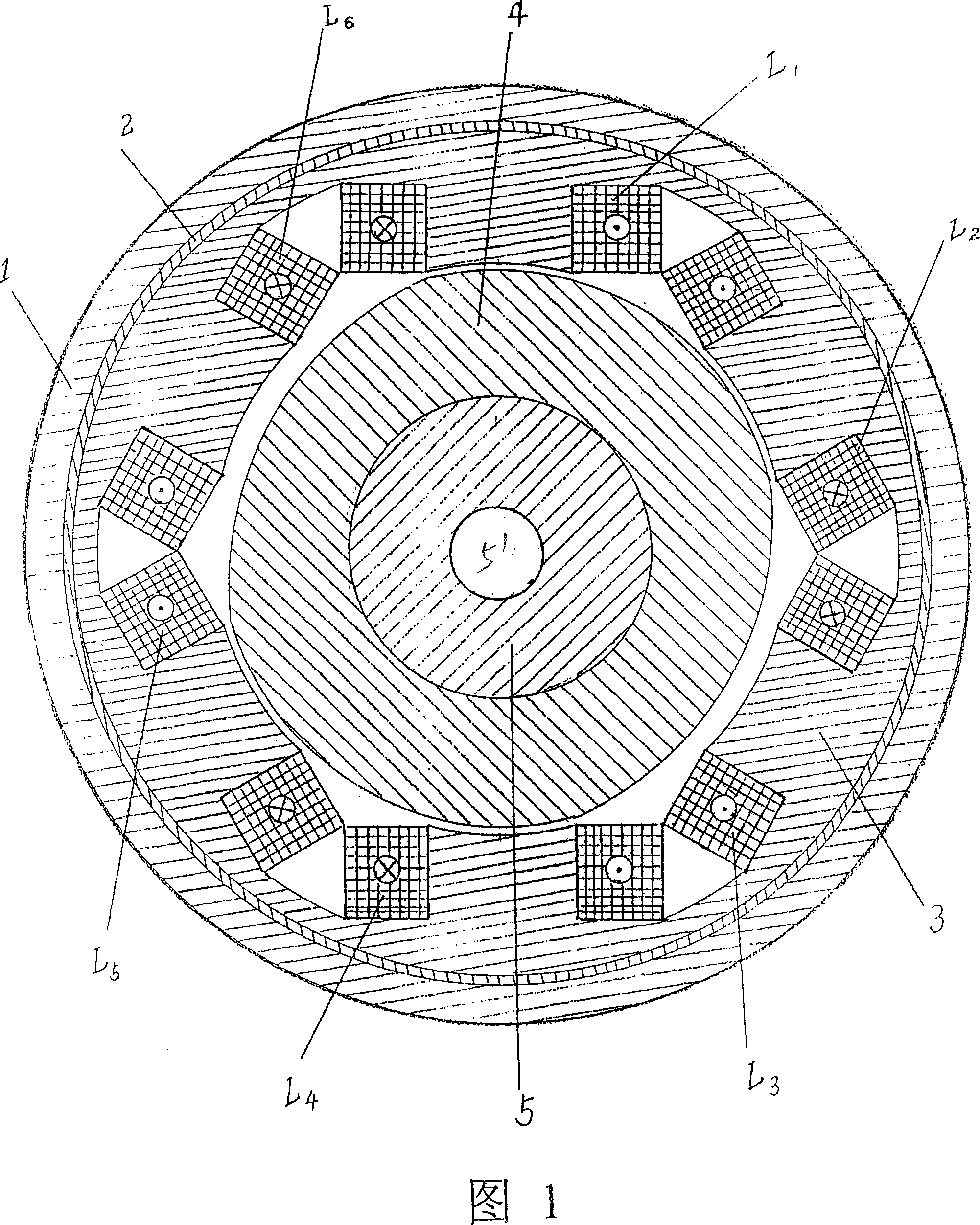

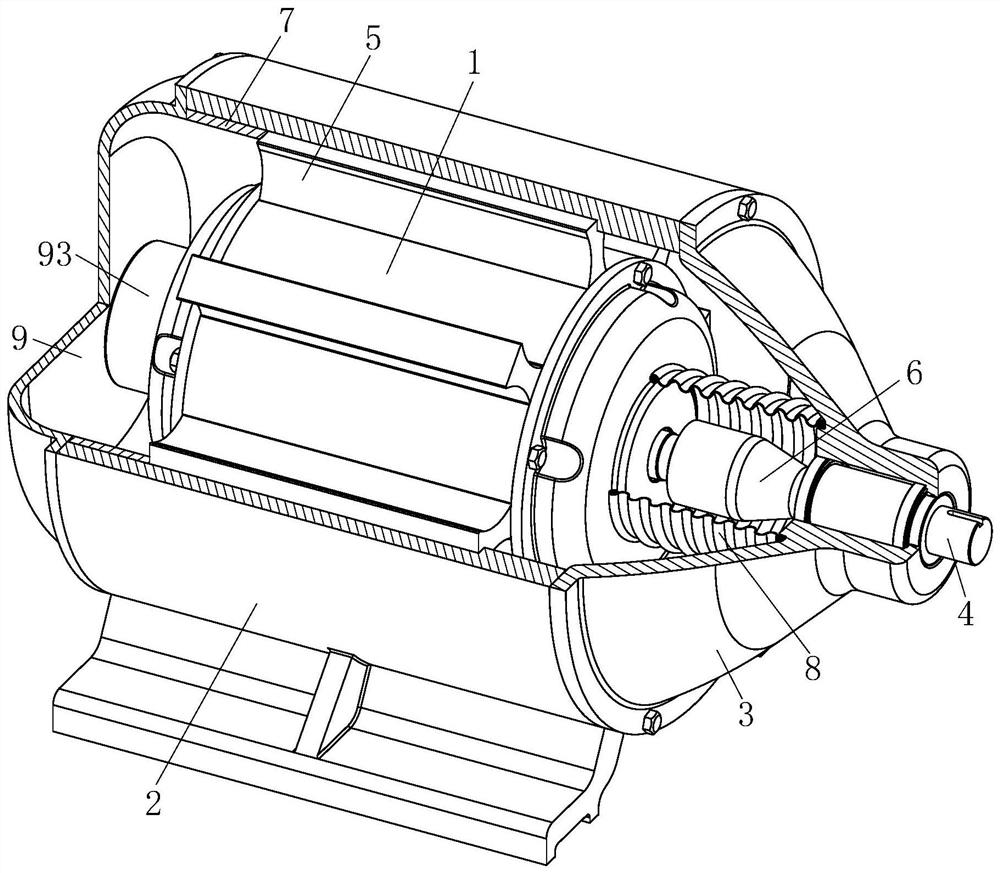

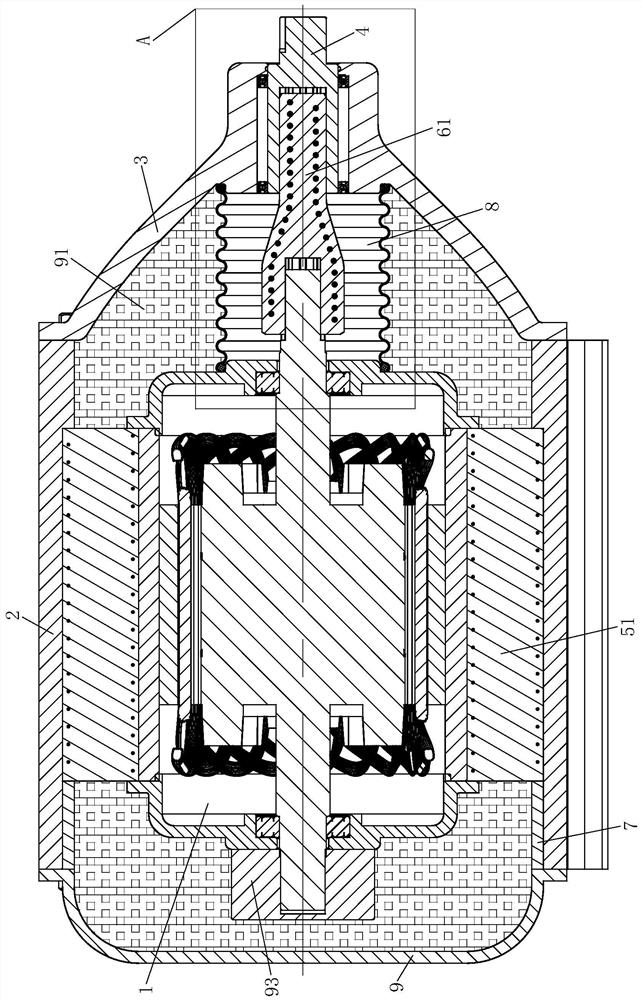

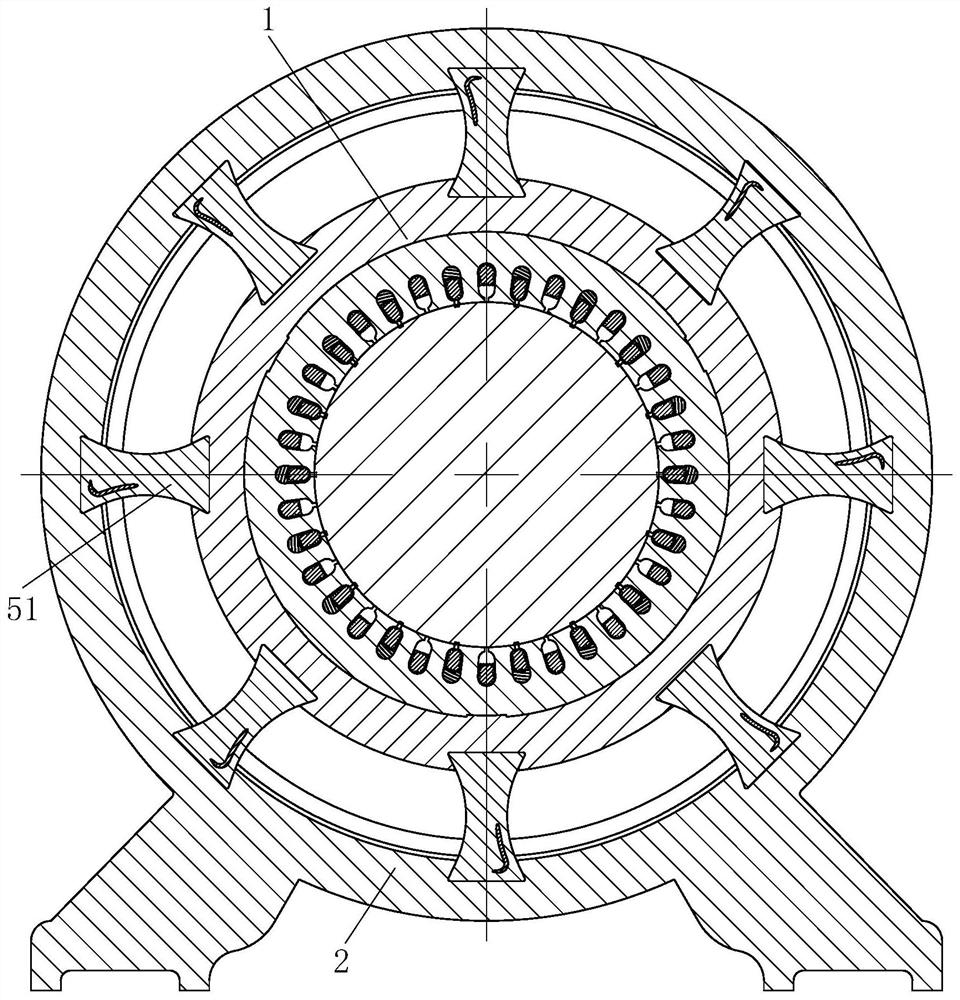

Reluctance motor and self-control optical coupled switch and motion control, structure damp and radiating method

InactiveCN101090226AAvoid a stepped second air gapAvoid electromagnetic noiseMagnetic circuit rotating partsMagnetic circuit stationary partsAxostyleSynchronous motor

This invention discloses a three-phase magnetic resistance motor, which replaces the multi-stage rotor core with a ladder-type convex pole with an ellipse two pole rotor core and utilizes a self-controlled light-coupled switch mounted on the axostyle of the rotor to realize location control and frequency self-support having the character of a self-controlled synchronous motor, and its unit volumepower reaches to over 4 times of the present one.

Owner:张玉宝

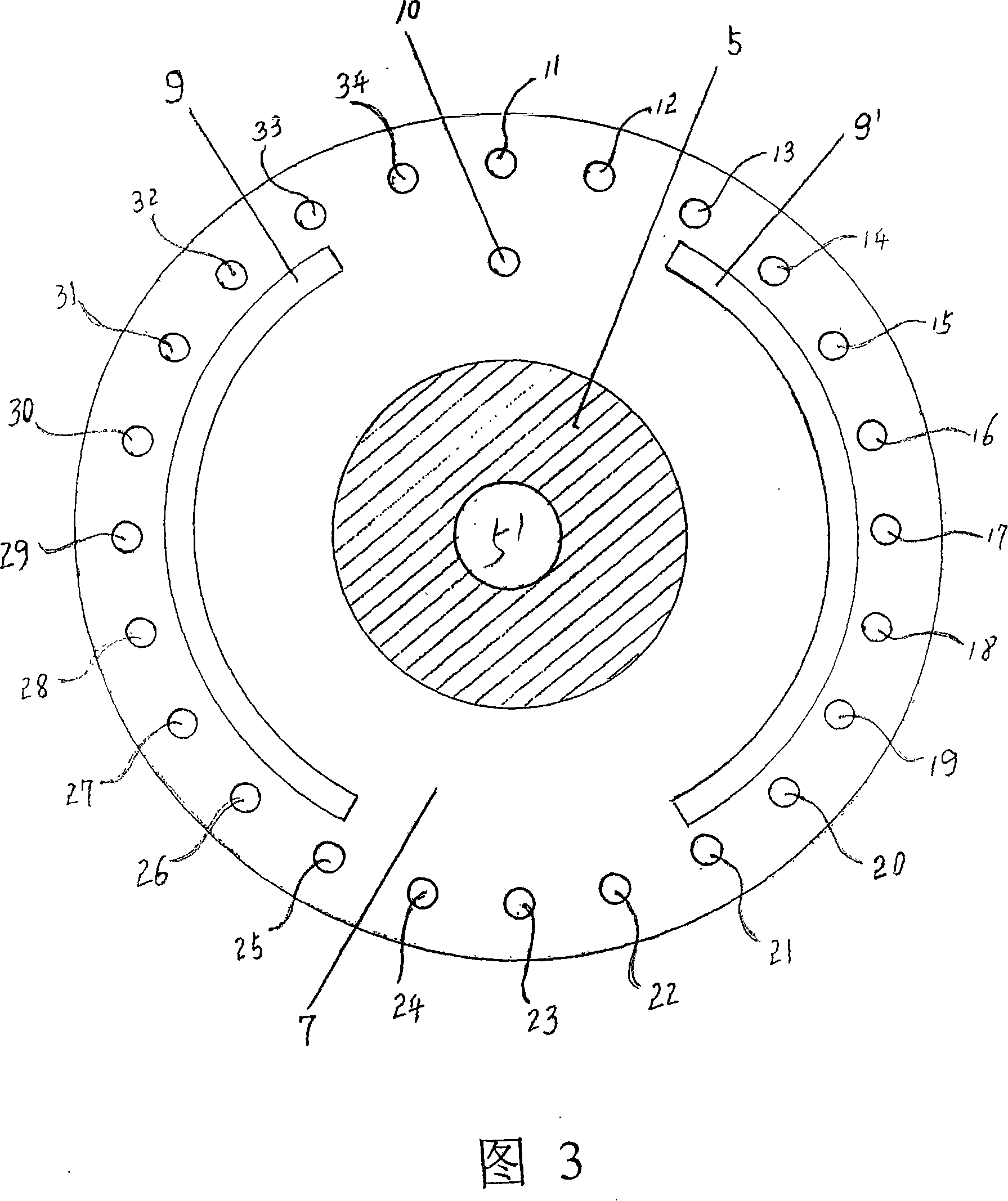

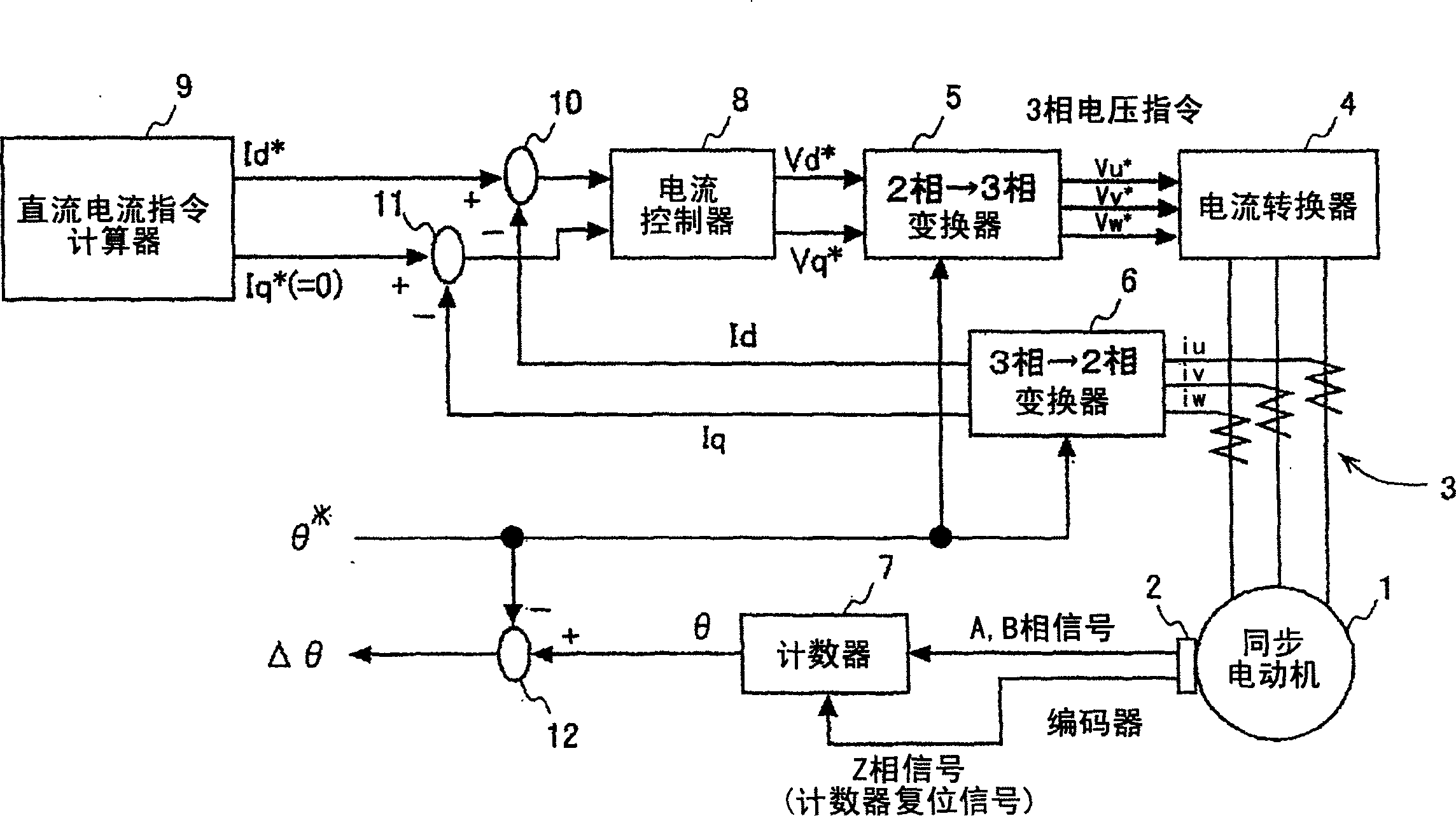

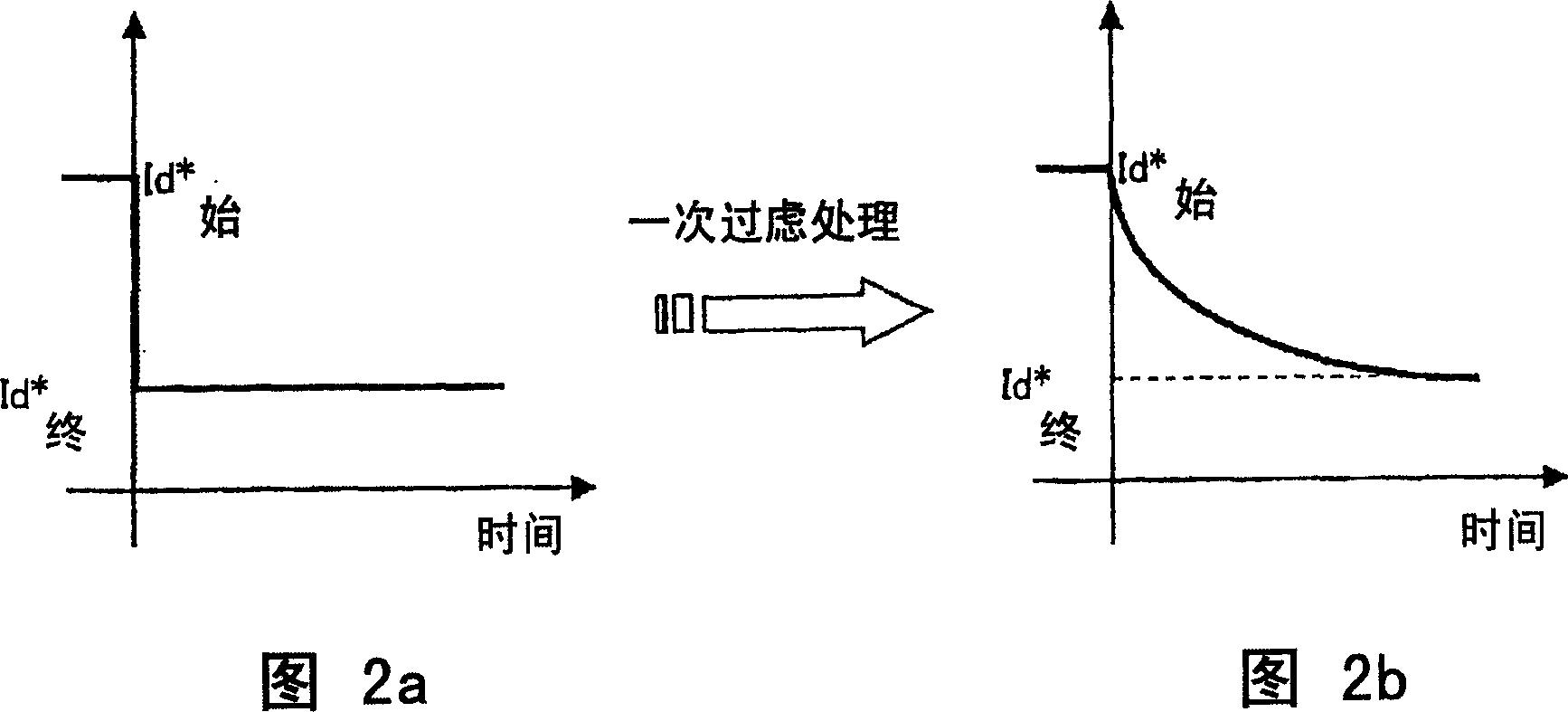

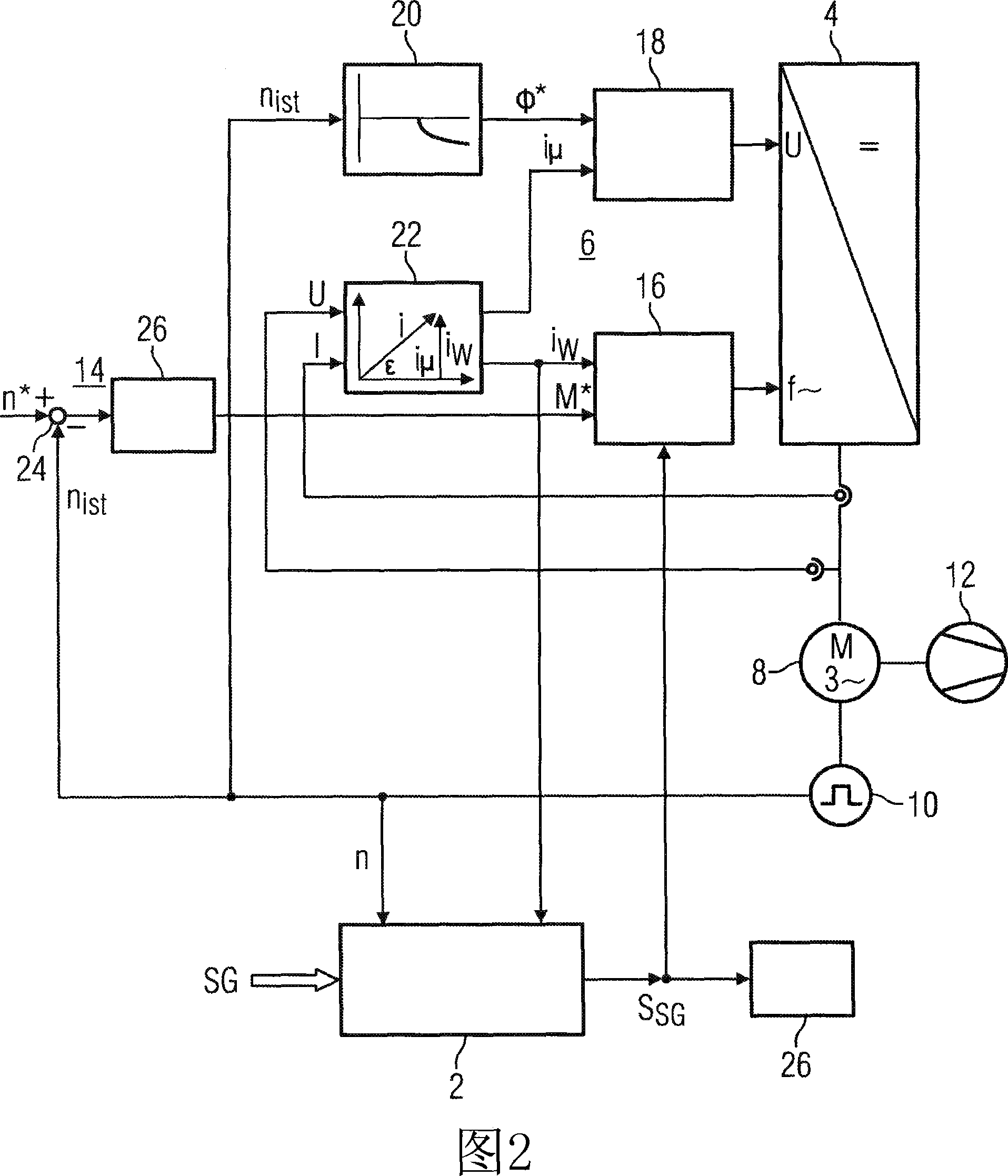

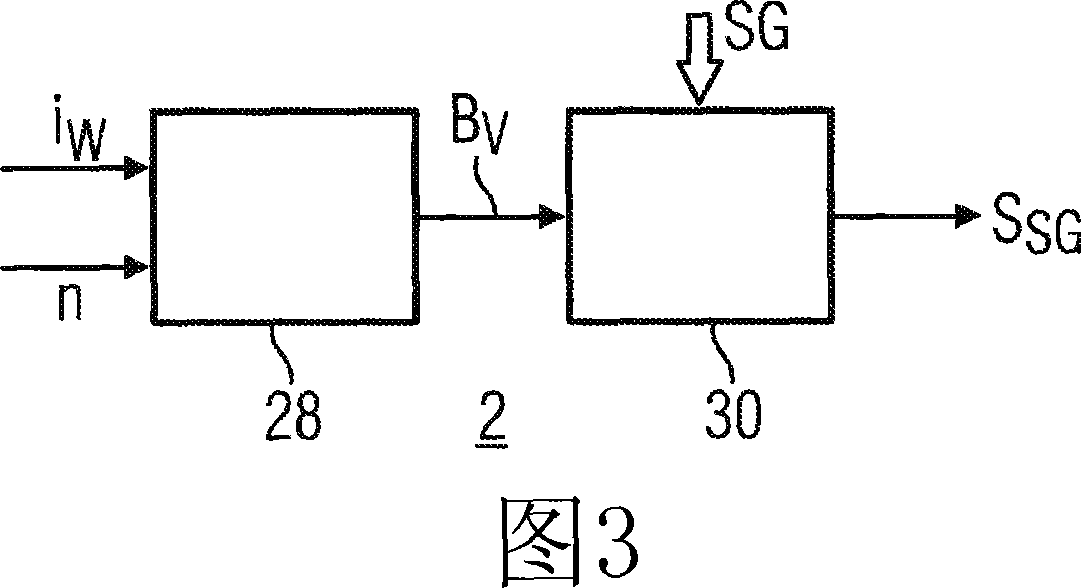

Method for detecting angular difference and apparatus for controlling synchronous motor

InactiveCN1641981AAvoid vibration phenomenonMotor/generator/converter stoppersAC motor controlSynchronous motorExcitation current

Owner:FANUC LTD

Hamming formula-based milling stability predicting method

InactiveCN106843147AAvoid vibration phenomenonImprove surface qualityProgramme controlComputer controlNumerical controlTransfer matrix

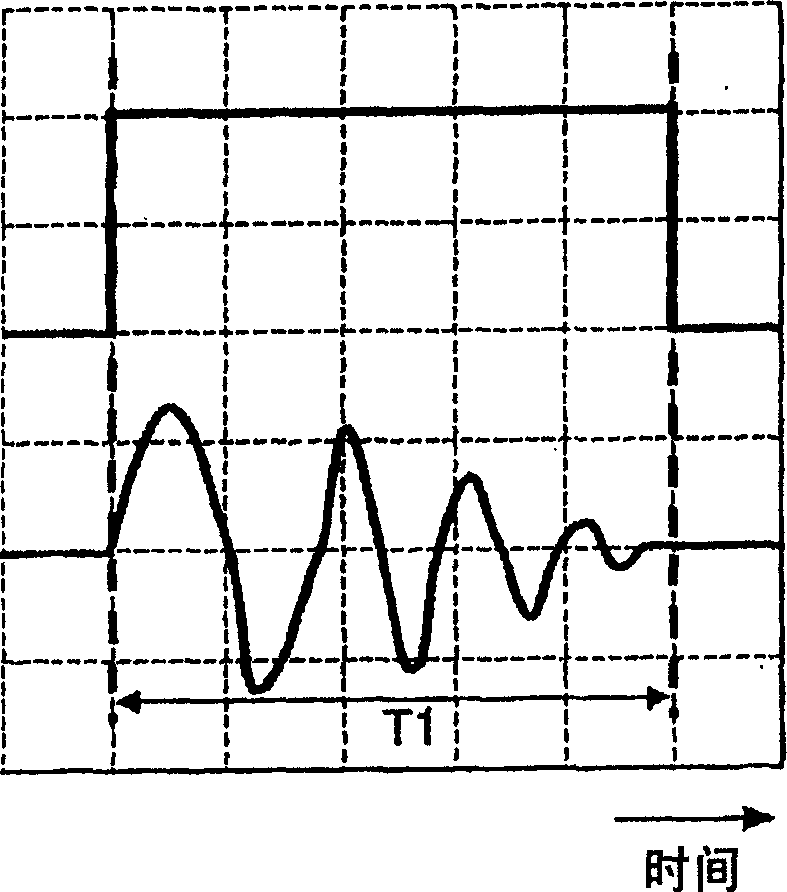

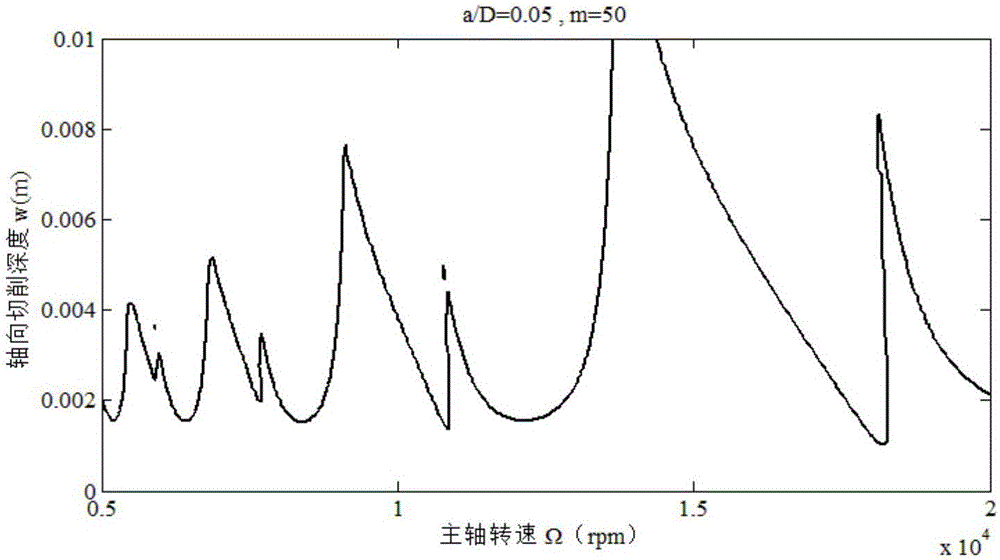

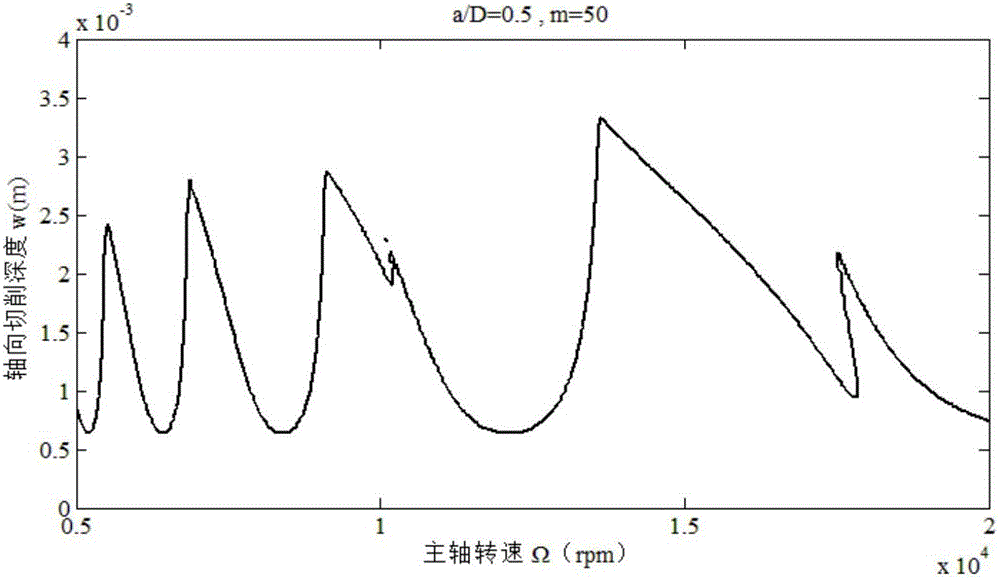

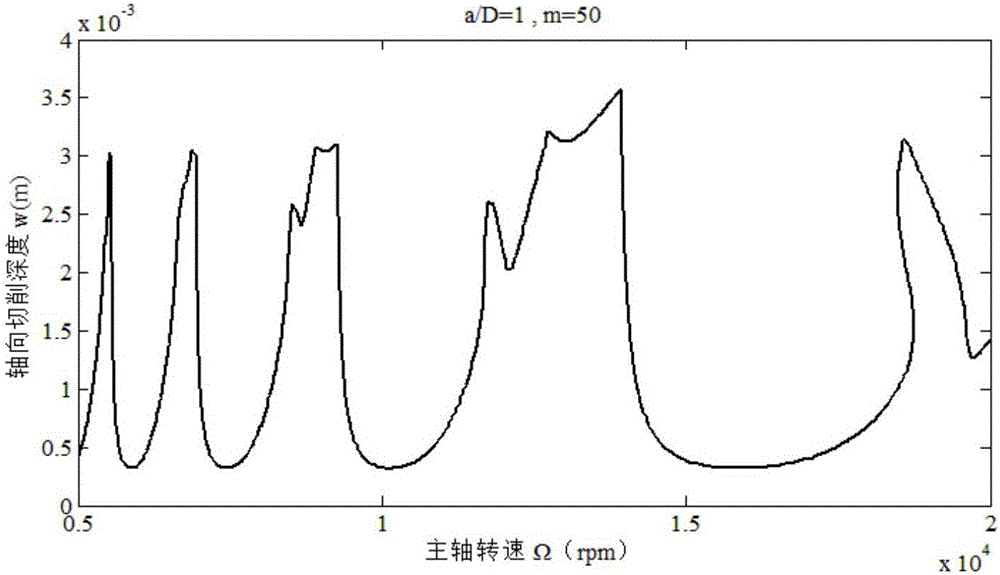

Disclosed is a Hamming formula-based milling stability predicting method. The Hamming formula-based milling stability predicting method is mainly applied to selecting reasonable milling parameters for part machining. The Hamming formula-based milling stability predicting method is characterized by comprising dispersing a forced oscillation period into evenly-spaced intervals through the Hamming formula to obtain the transfer matrix of a milling system, and determining the characteristic value of the transfer matrix of the milling system according to the Fourier theories to predict the stability of the milling system. During high-speed numerical controlled machining processes, the Hamming formula-based milling stability predicting method can help select reasonable milling parameters according to a stability labe graph to ensure achieve high-speed and high-efficiency machining without oscillation, thereby optimizing machining parameters, ensuring high surface quality and achieving precise machining.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

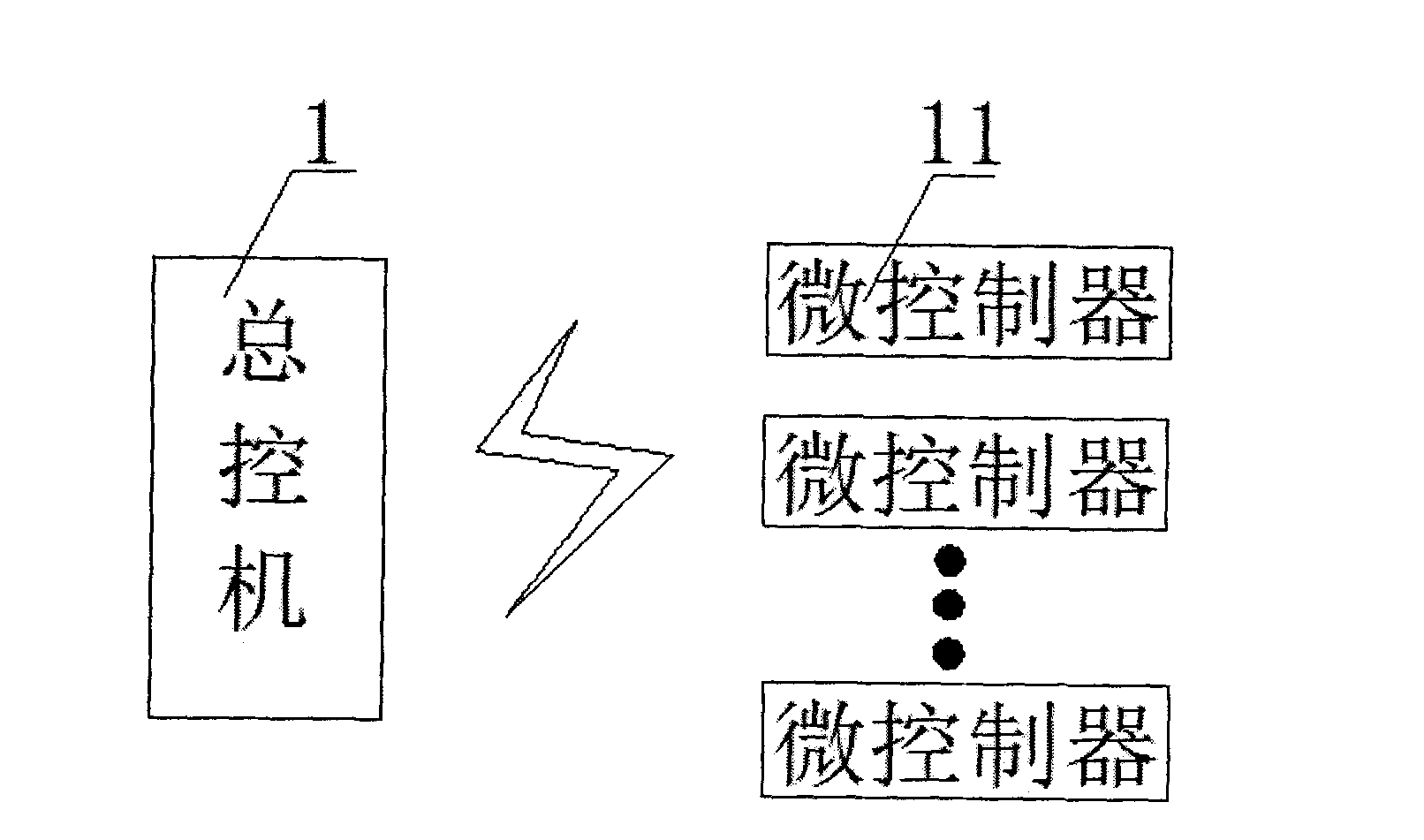

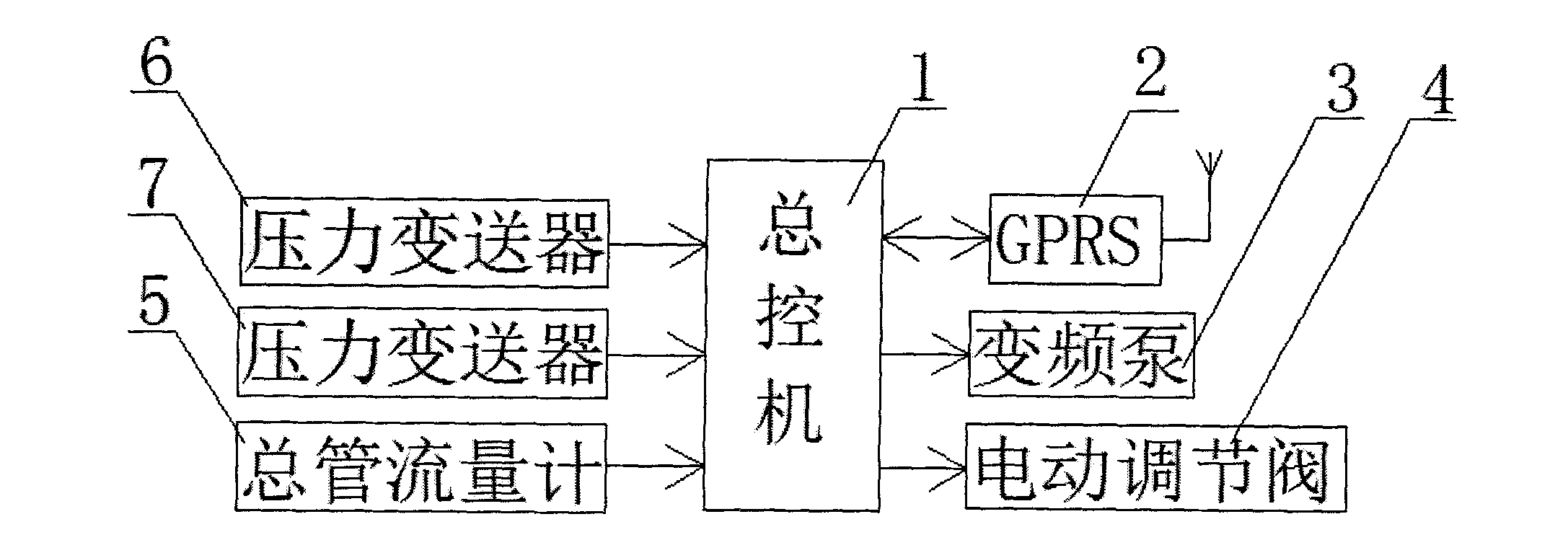

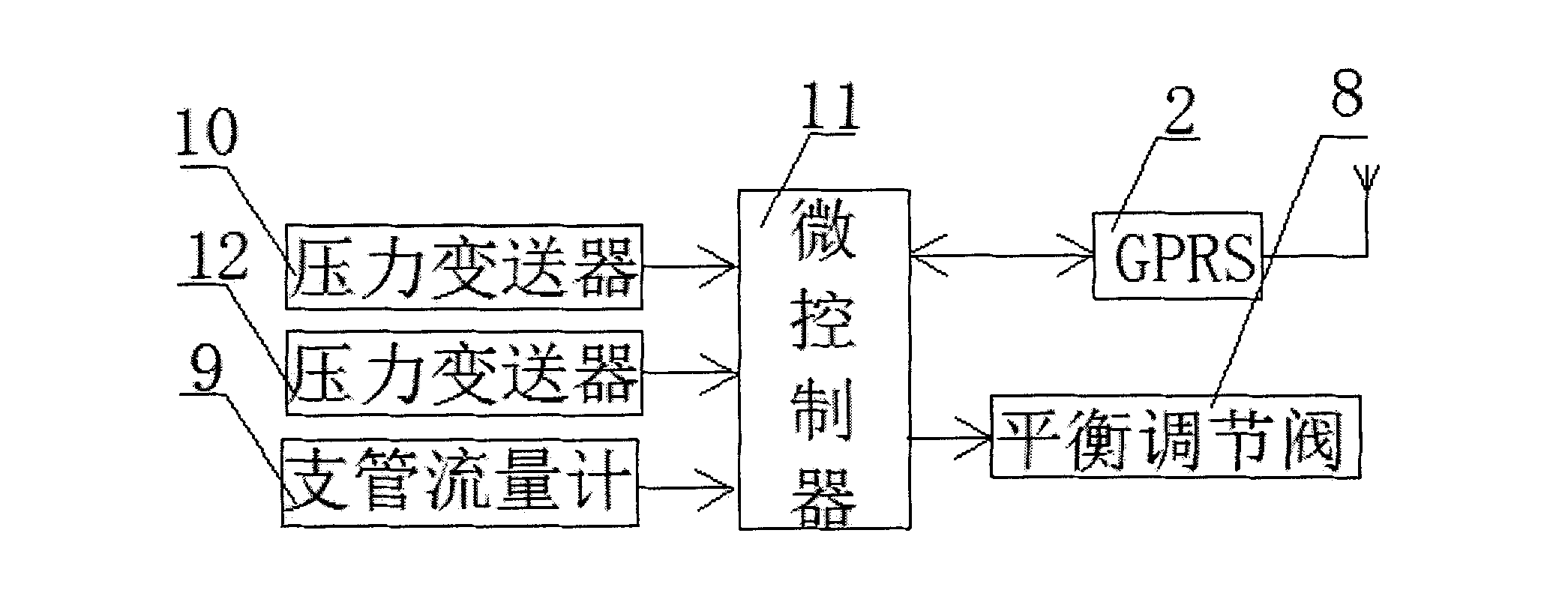

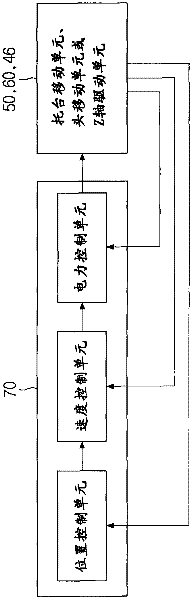

Heat supply secondary pipe network distributed balance control system and control method thereof

ActiveCN102494365ARun smoothlyAvoid vibration phenomenonLighting and heating apparatusEfficient regulation technologiesControl systemControl valves

The invention discloses a heat supply secondary pipe network distributed balance control system and a control method thereof. The system comprises a front-end control system and a tail-end control system and is provided with a master control machine and microcontrollers; and the system is characterized in that: the master control machine is connected with a plurality of microcontrollers through wireless communication; a first pressure transmitter, a second pressure transmitter, a header pipe flowmeter, a variable frequency pump, an electric control valve and a general packet radio service (GPRS) module are connected to the master control machine respectively; and a third pressure transmitter, a fourth pressure transmitter, a branch pipe flowmeter, a balancing control valve and a GPRS module are connected to the microcontrollers respectively. The invention has the advantages that: the pressure difference and flow of a pipe network in each building can be detected, pressure difference between an input end and an output end of the pipe network in each building is guaranteed, pressure difference between a heat supply header pipe and a backflow header pipe is guaranteed, and flow balance between the heat supply header pipe and a heat supply branch pipe is monitored simultaneously; and therefore, the secondary pipe network is operated stably, pipelines are prevented from vibrating, and the service life of the pipelines is prolonged.

Owner:CHONGQING WECAN PRECISION INSTR

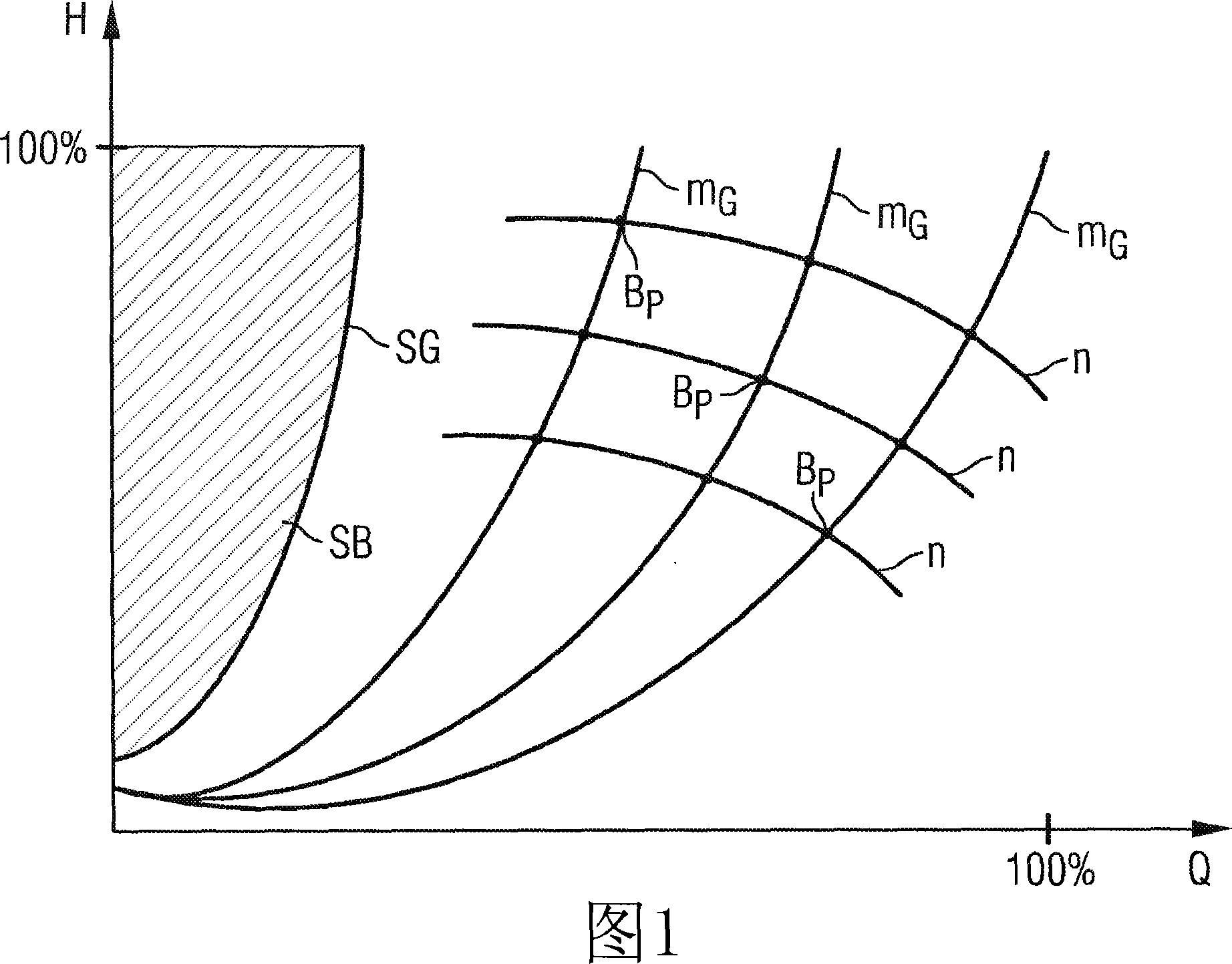

Method for operation of a compressor supplied by a power converter

ActiveCN101076671AReduce a signal variableAccurately determineEfficient regulation technologiesPump controlPower flowControl signal

Owner:SIEMENS AG

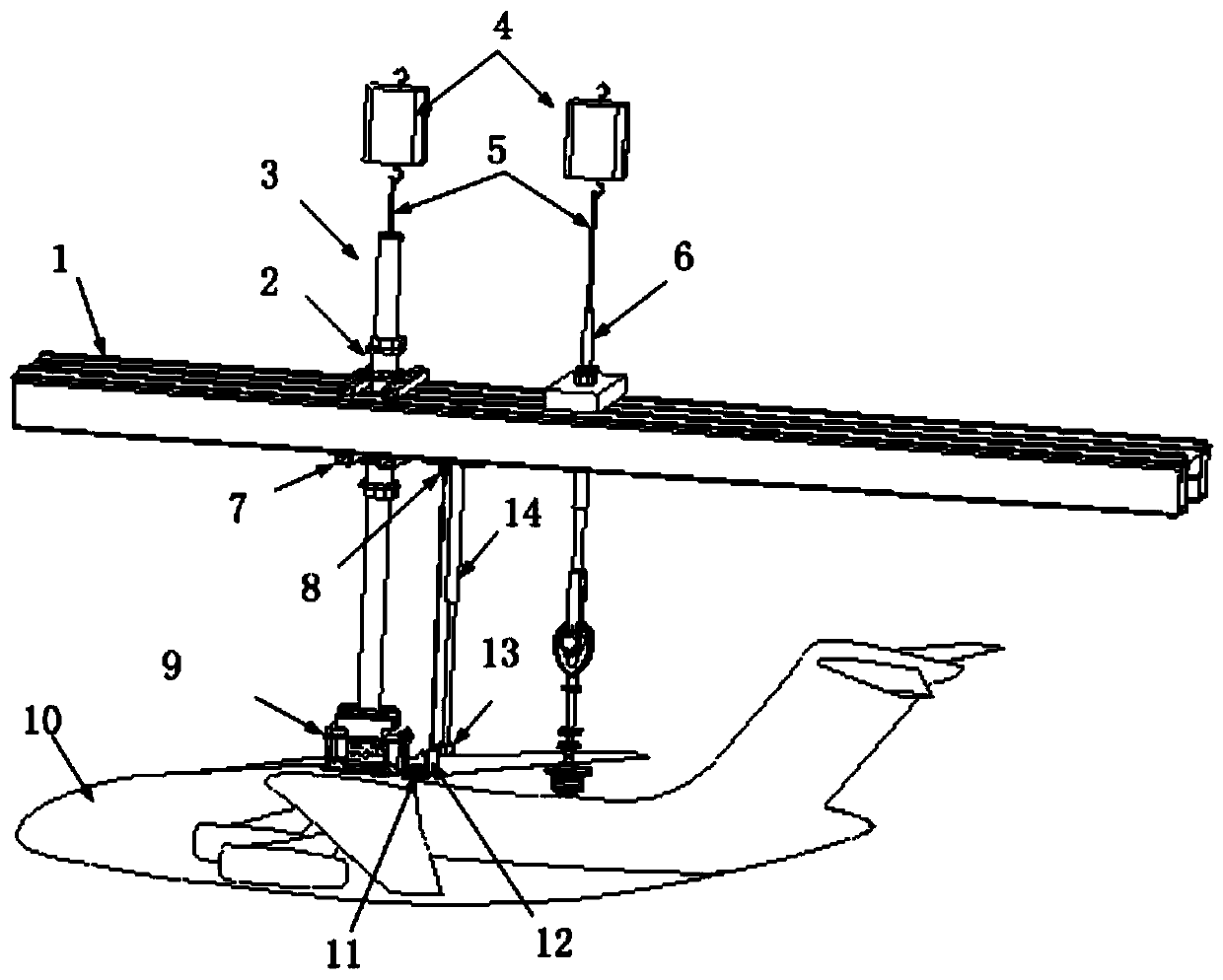

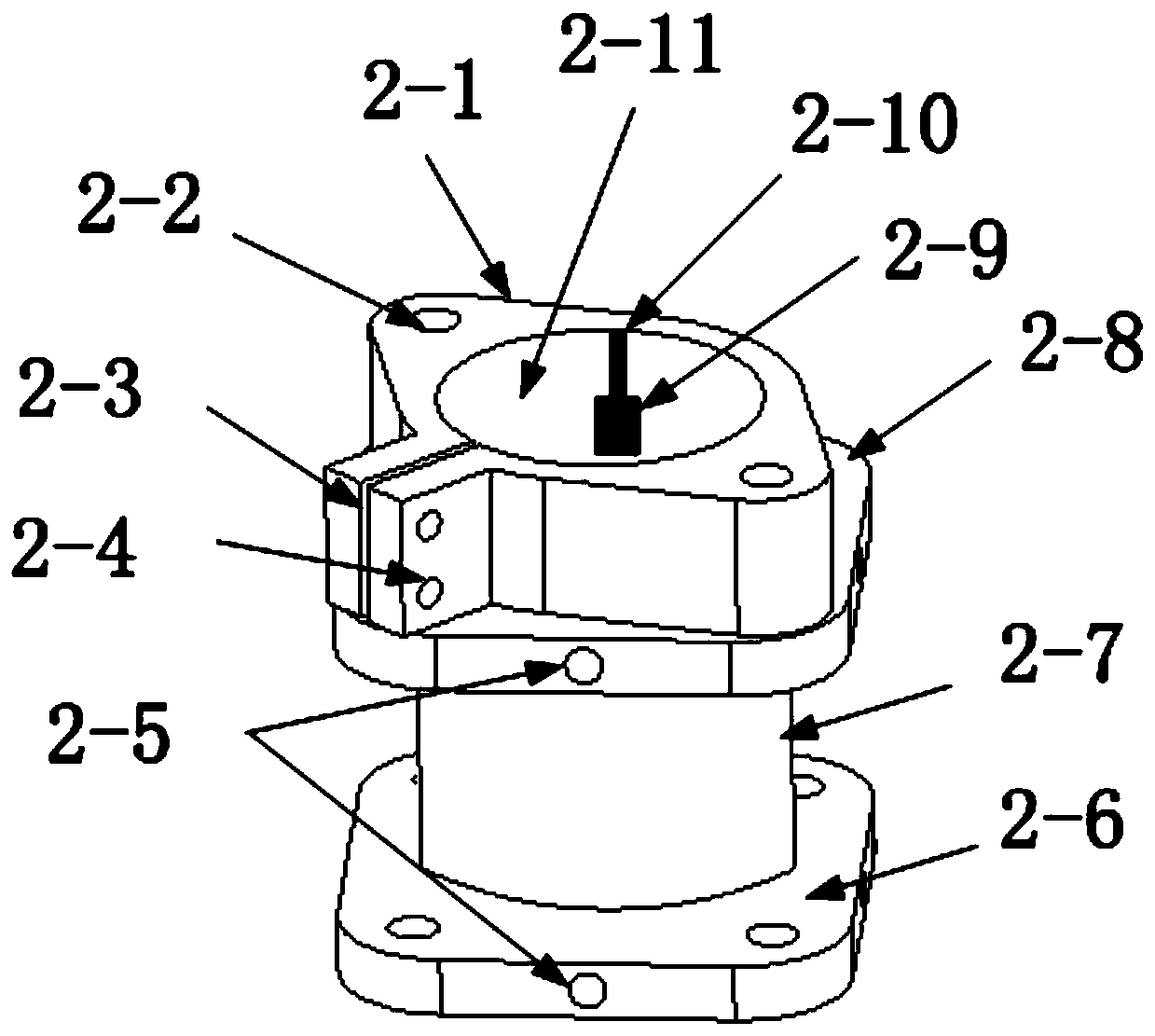

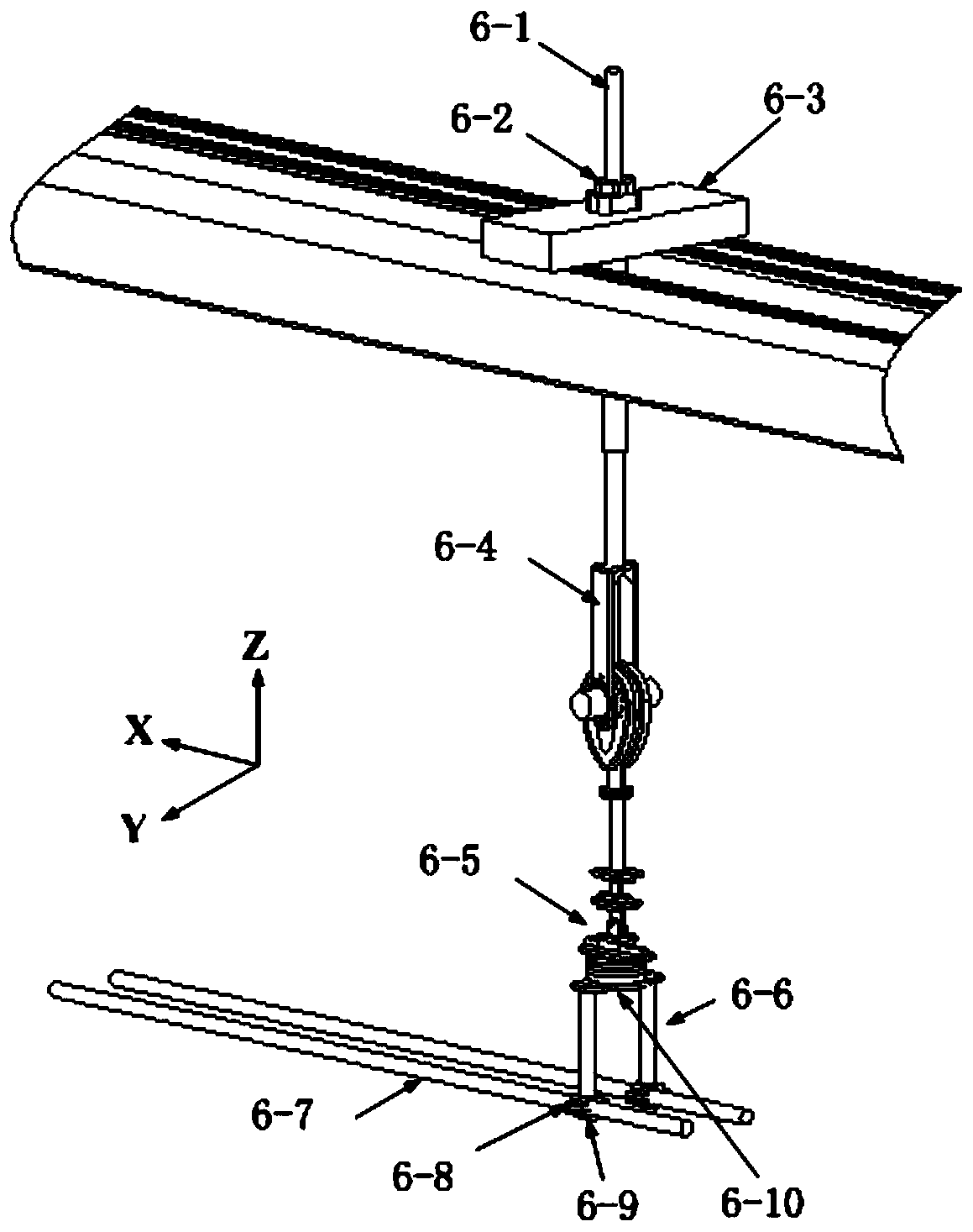

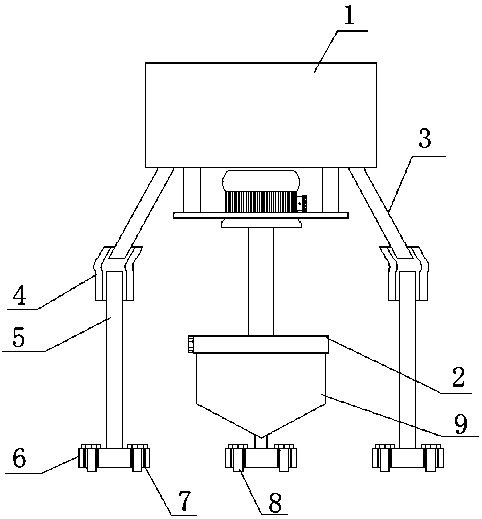

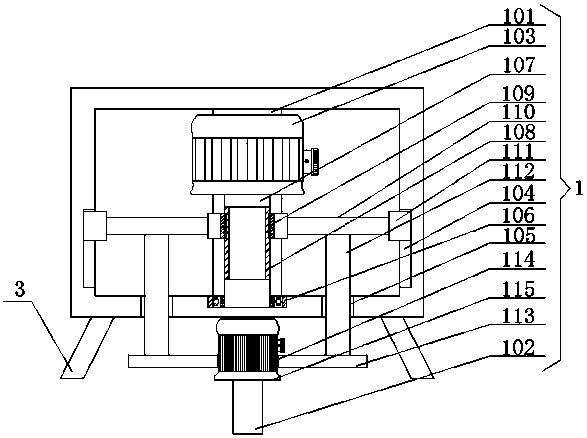

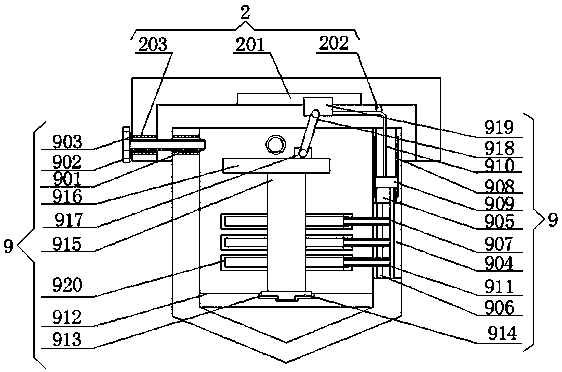

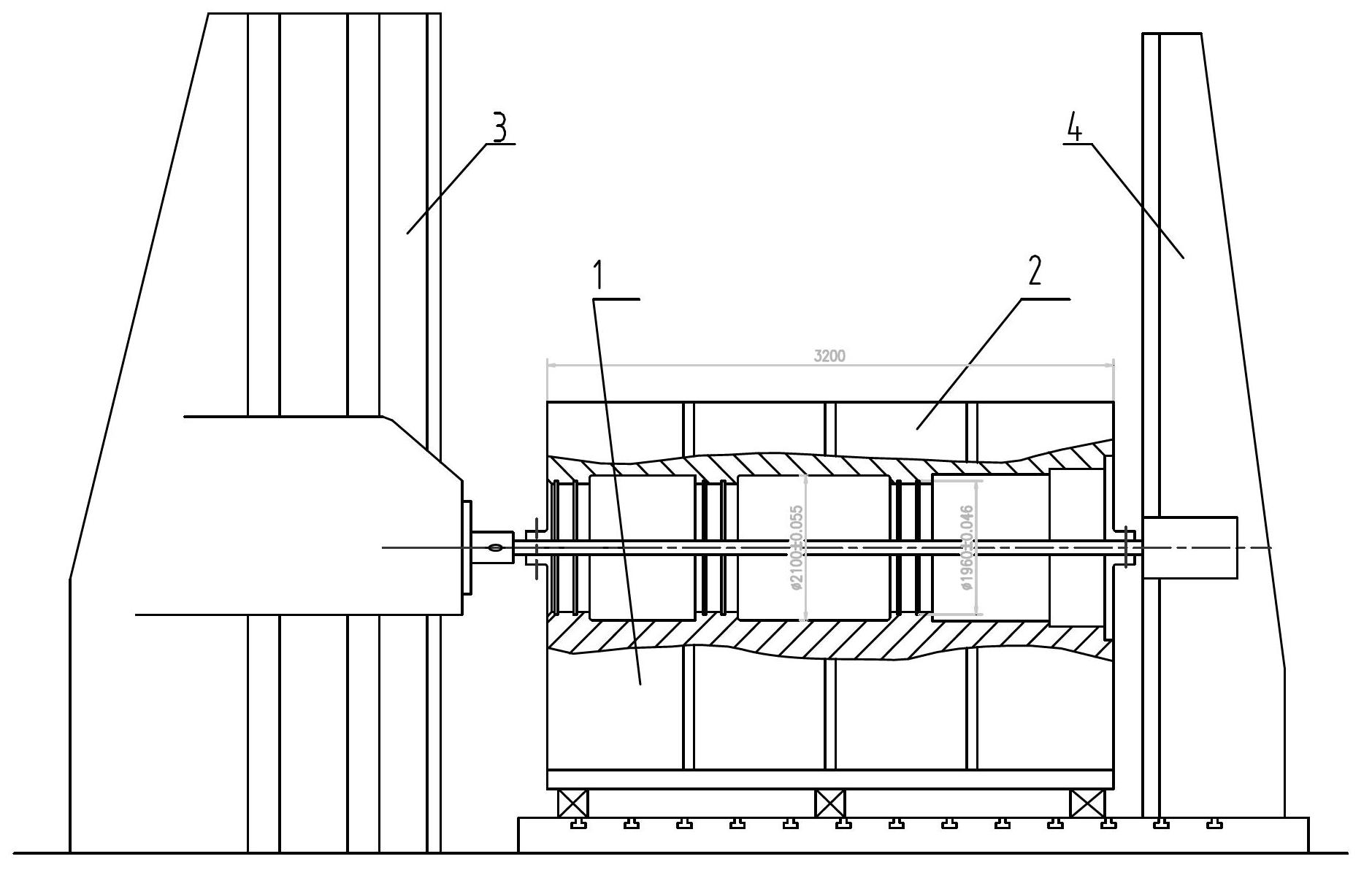

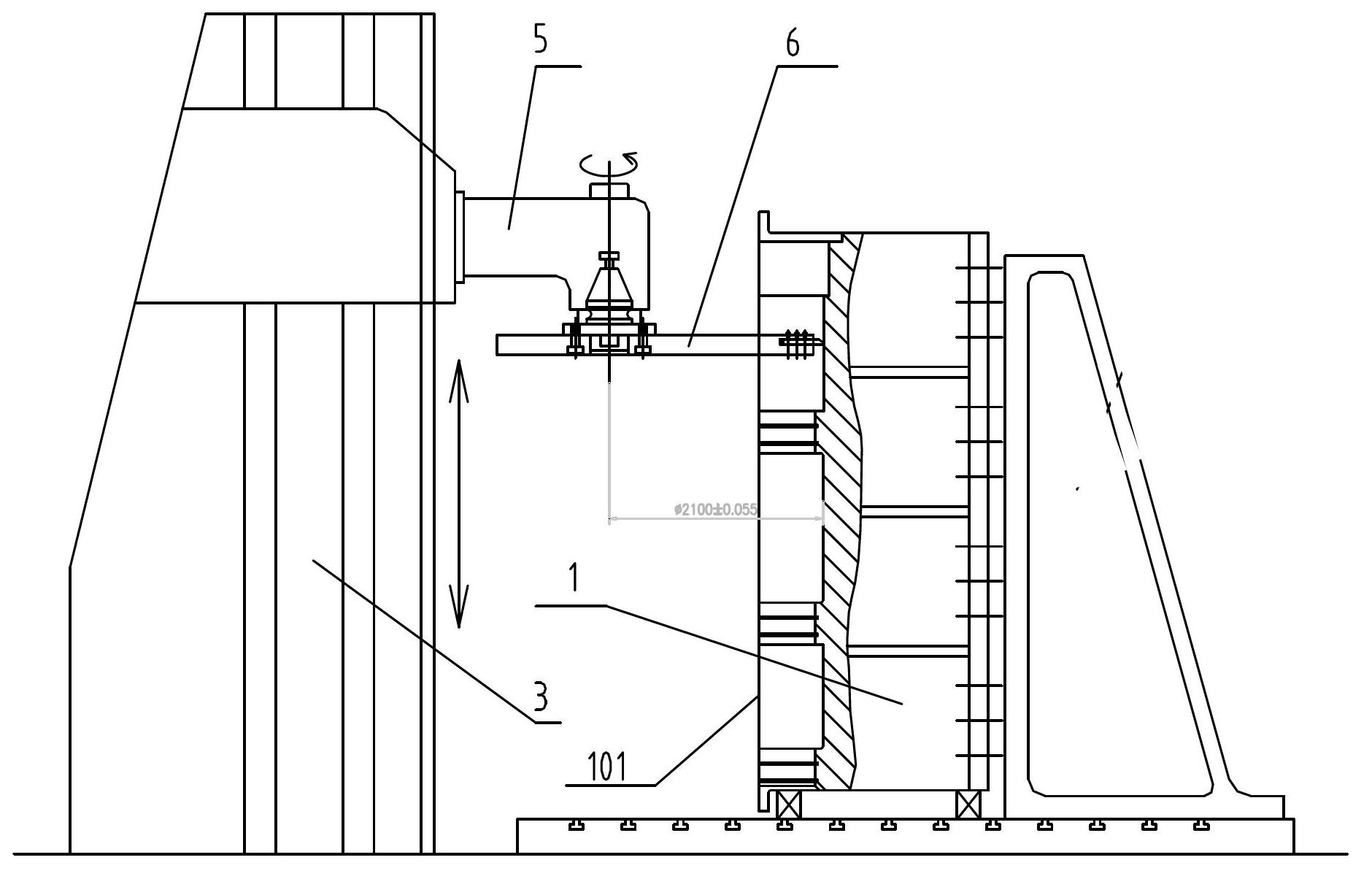

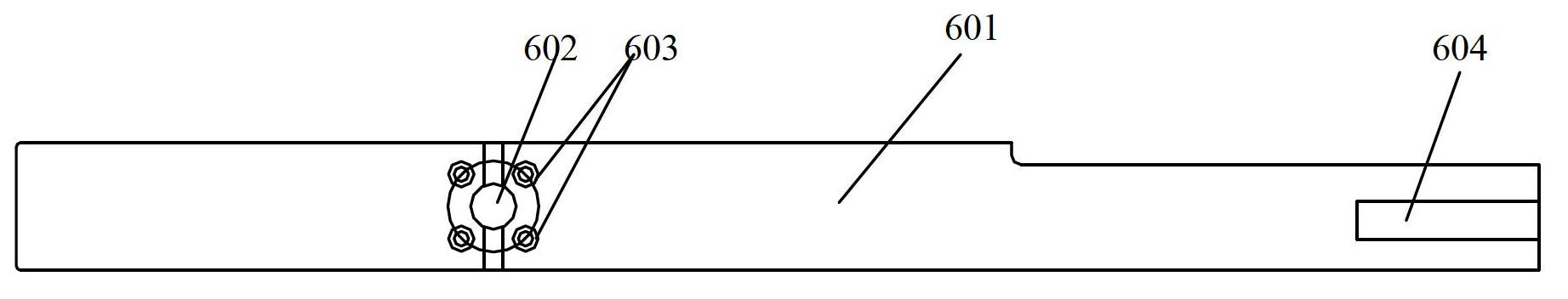

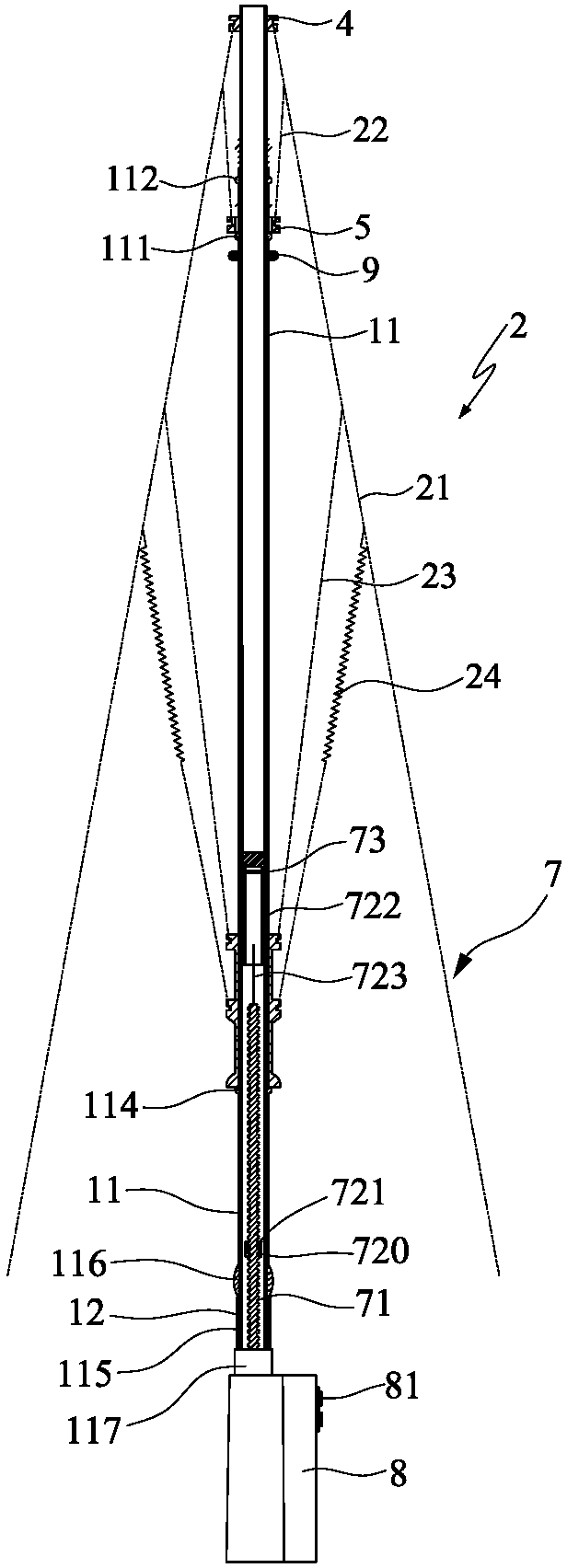

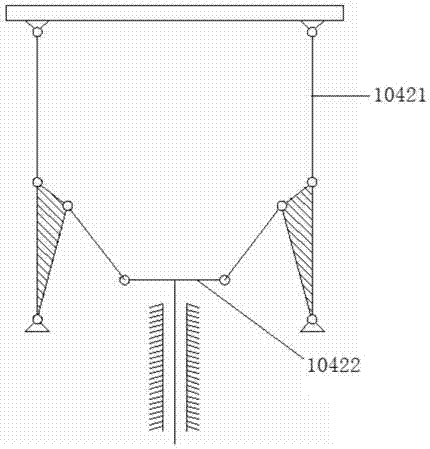

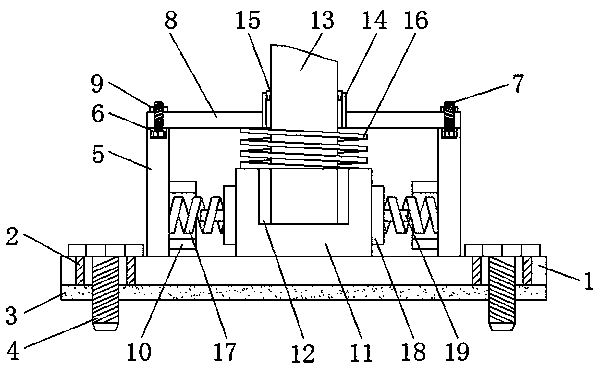

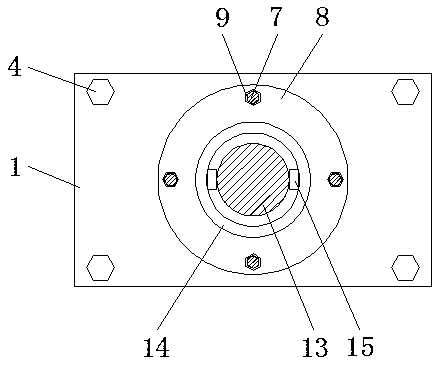

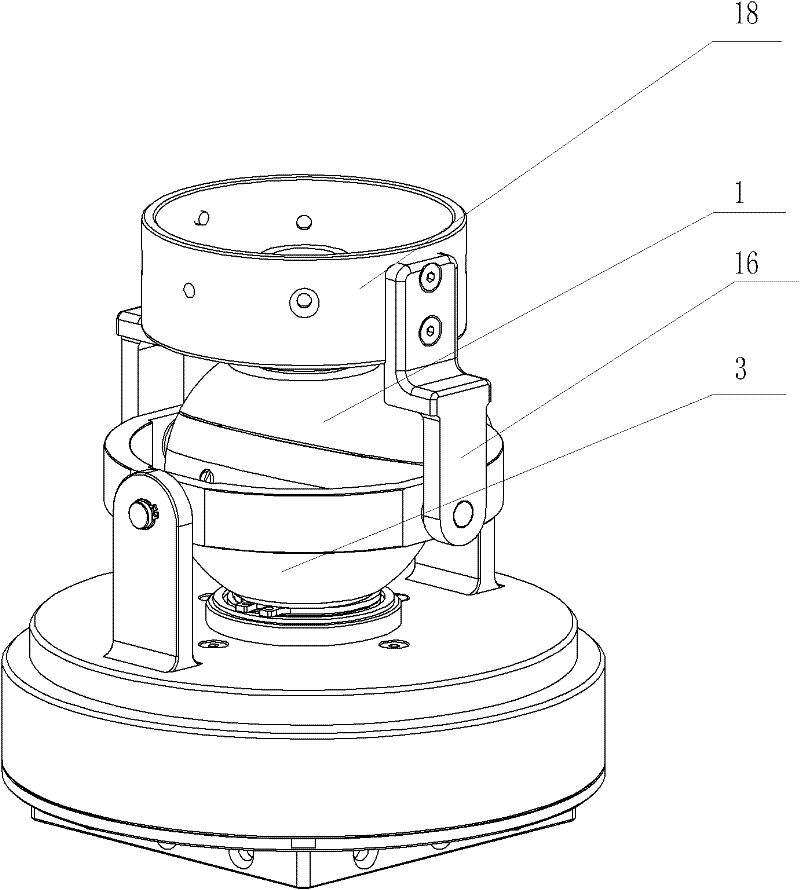

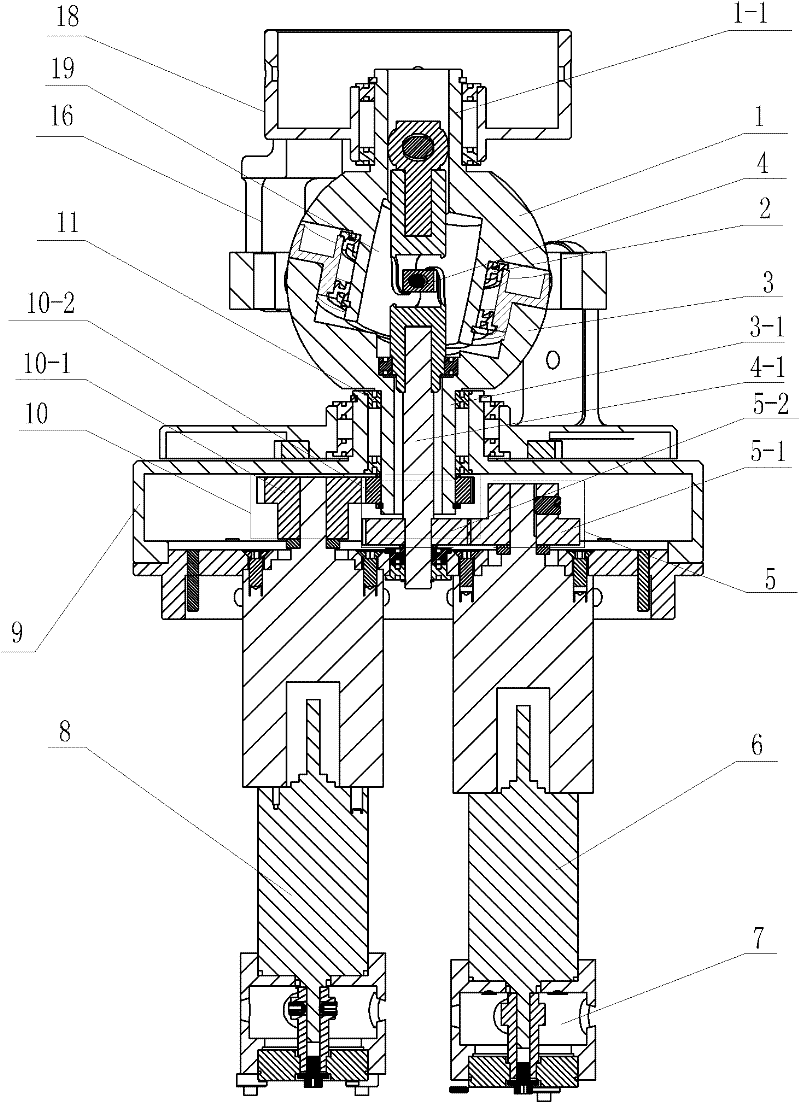

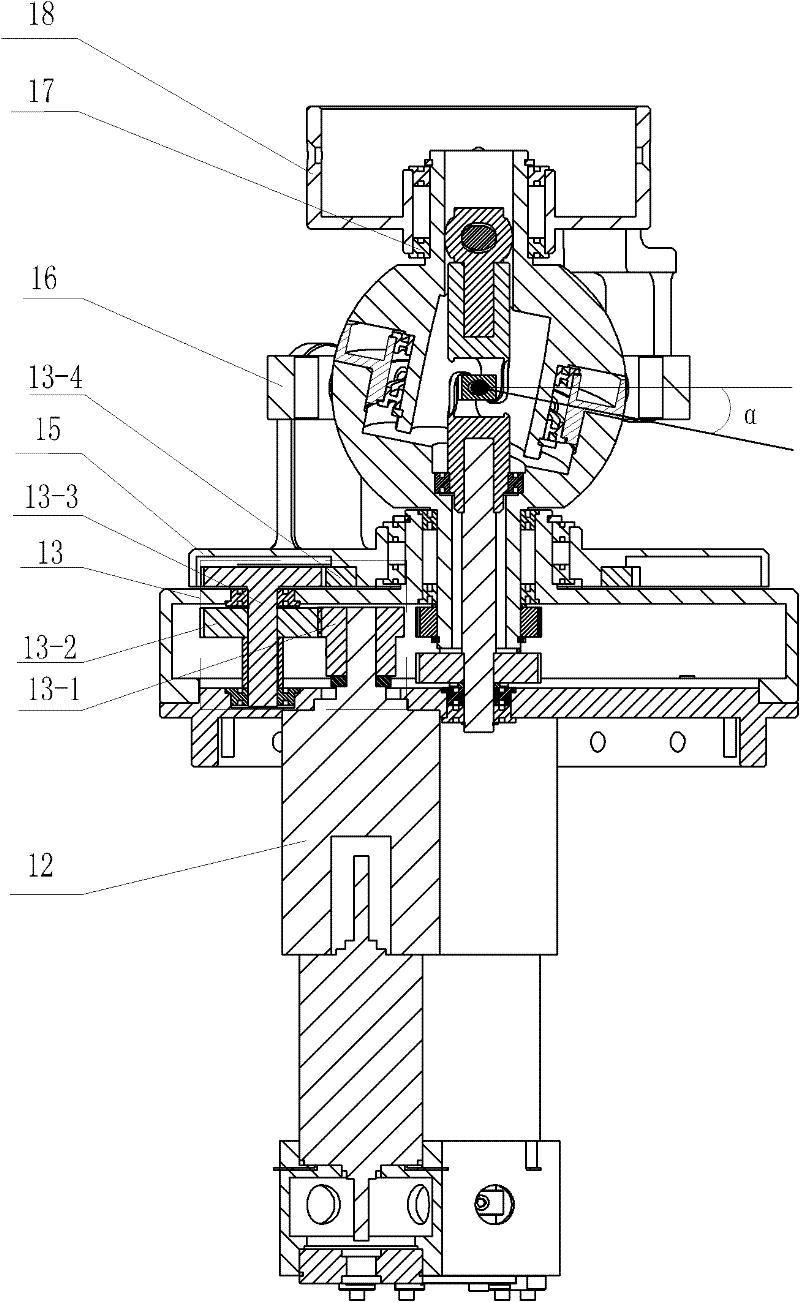

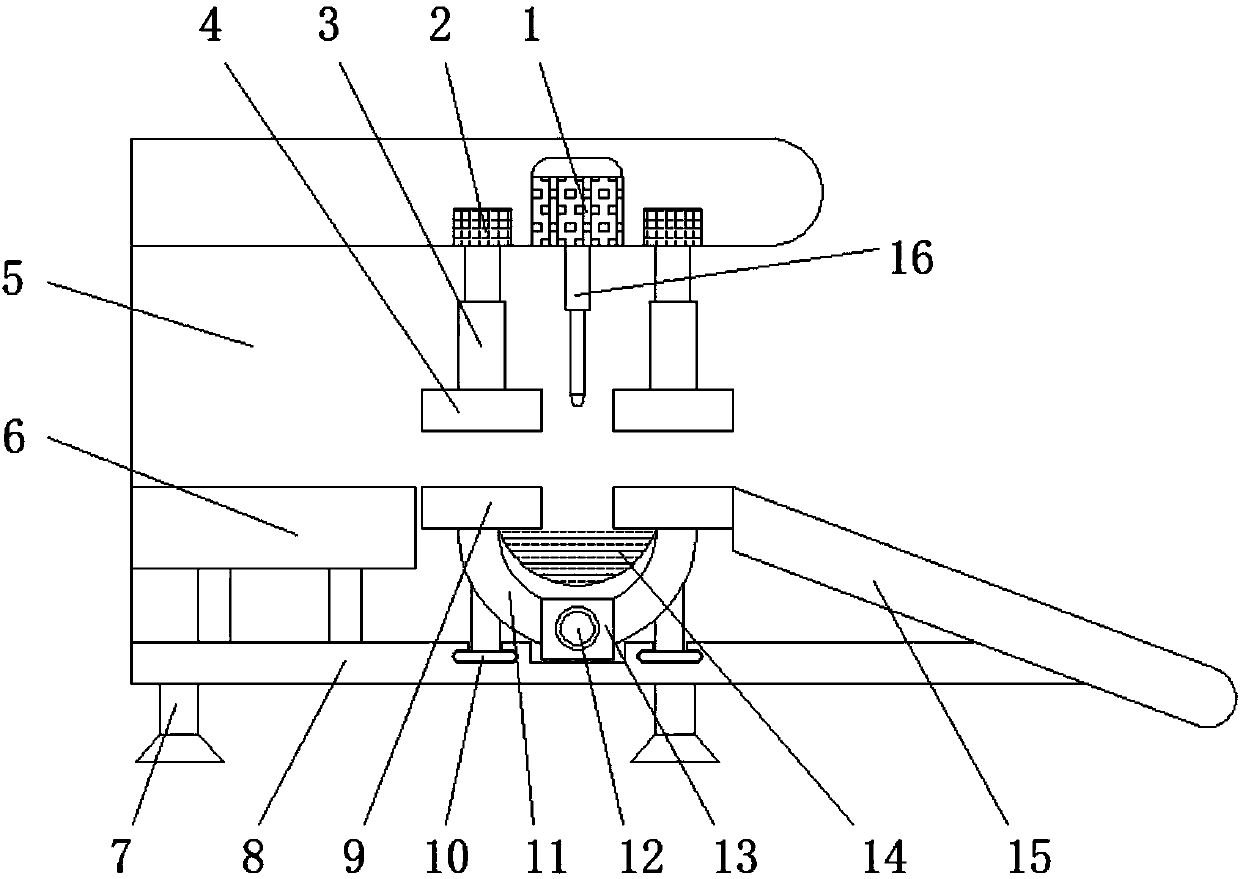

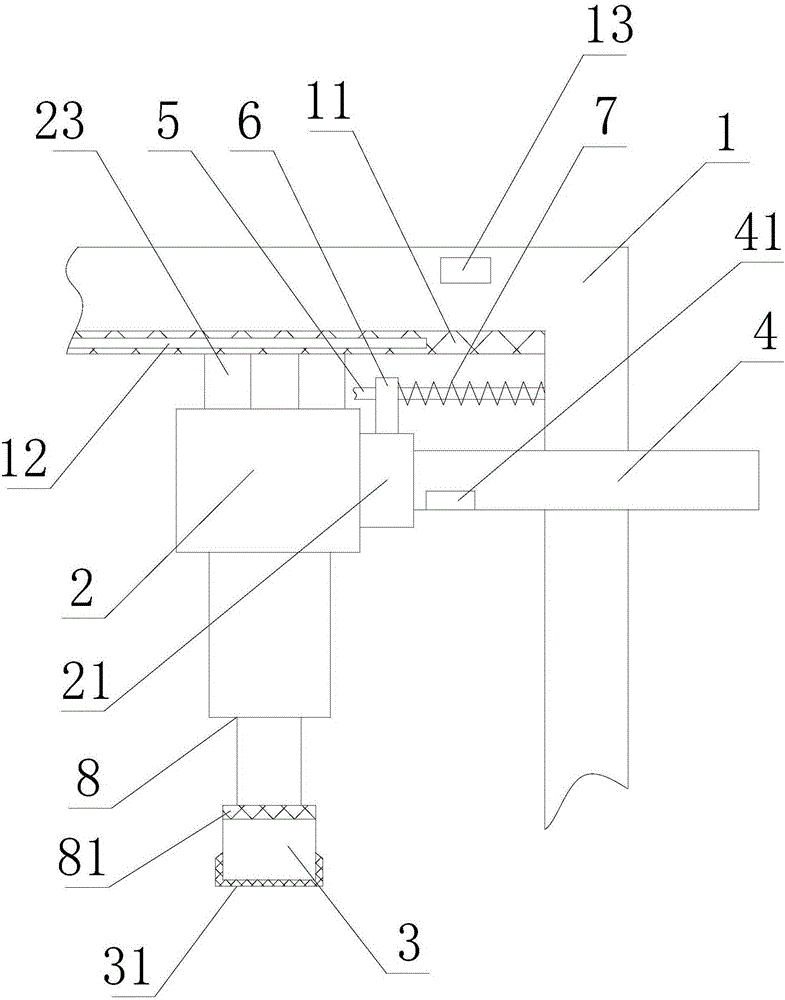

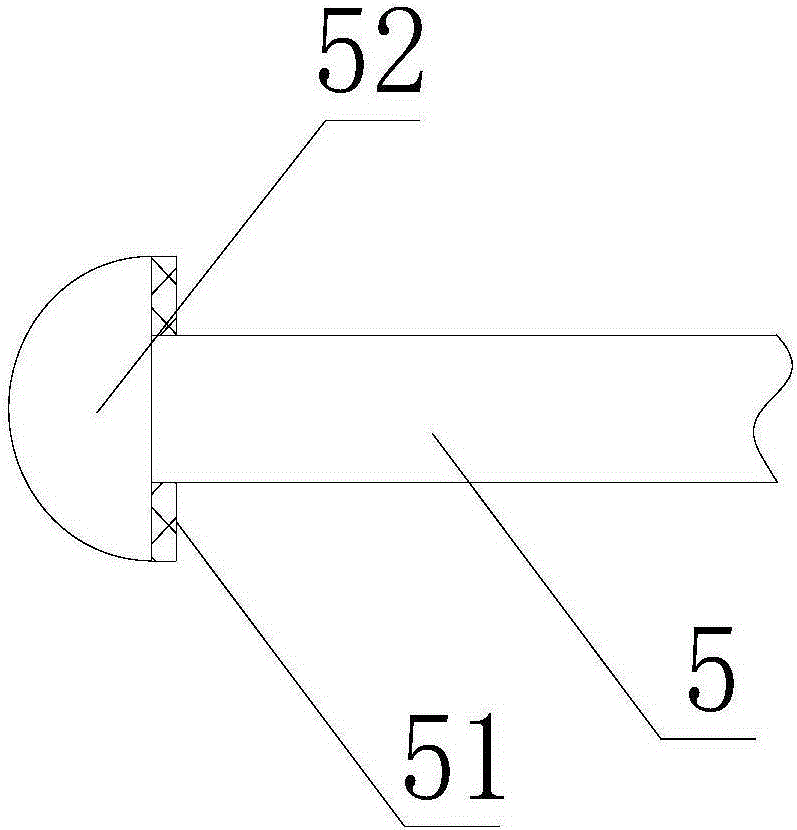

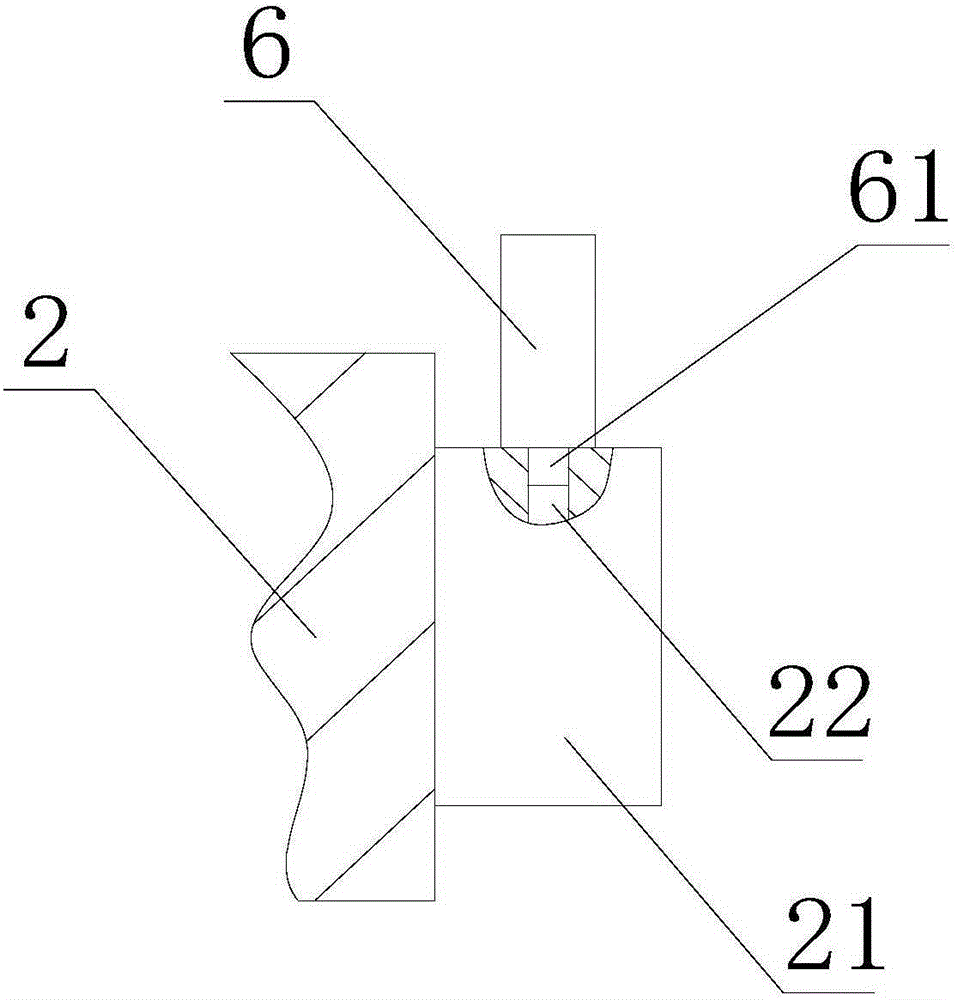

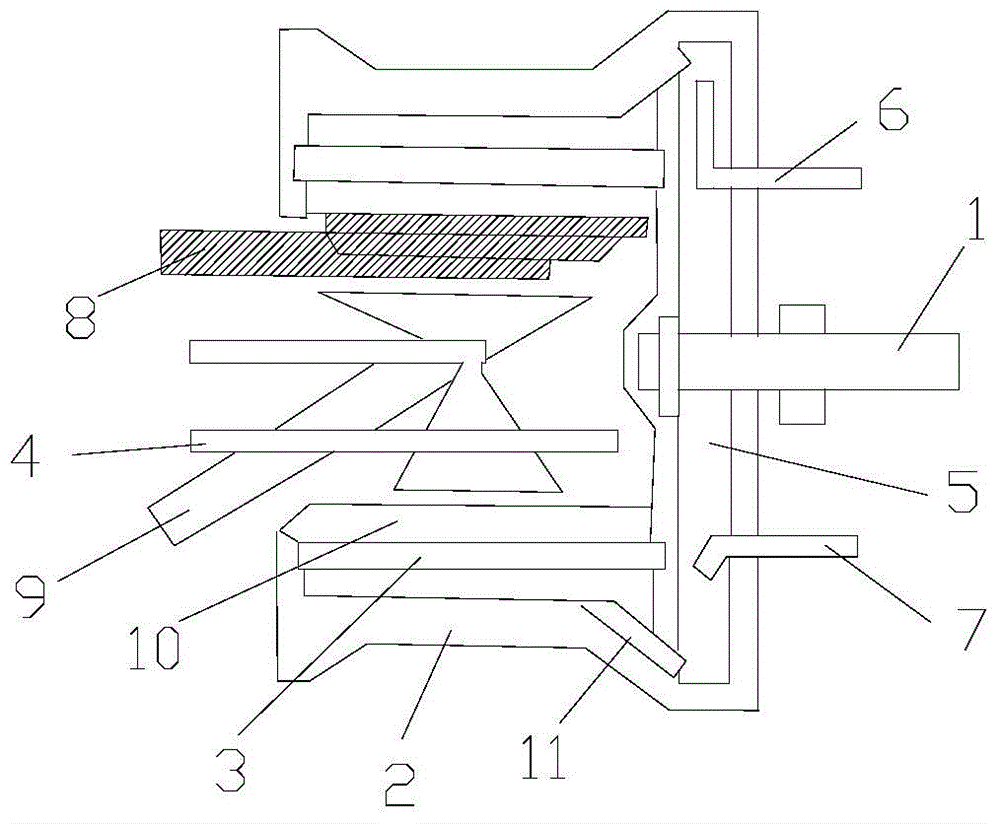

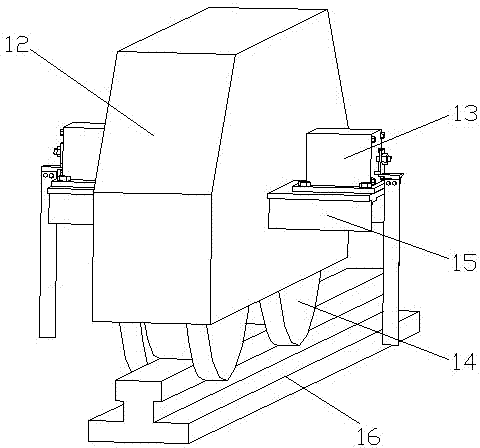

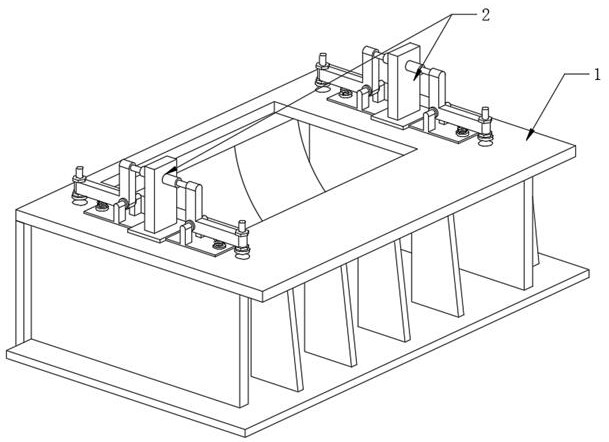

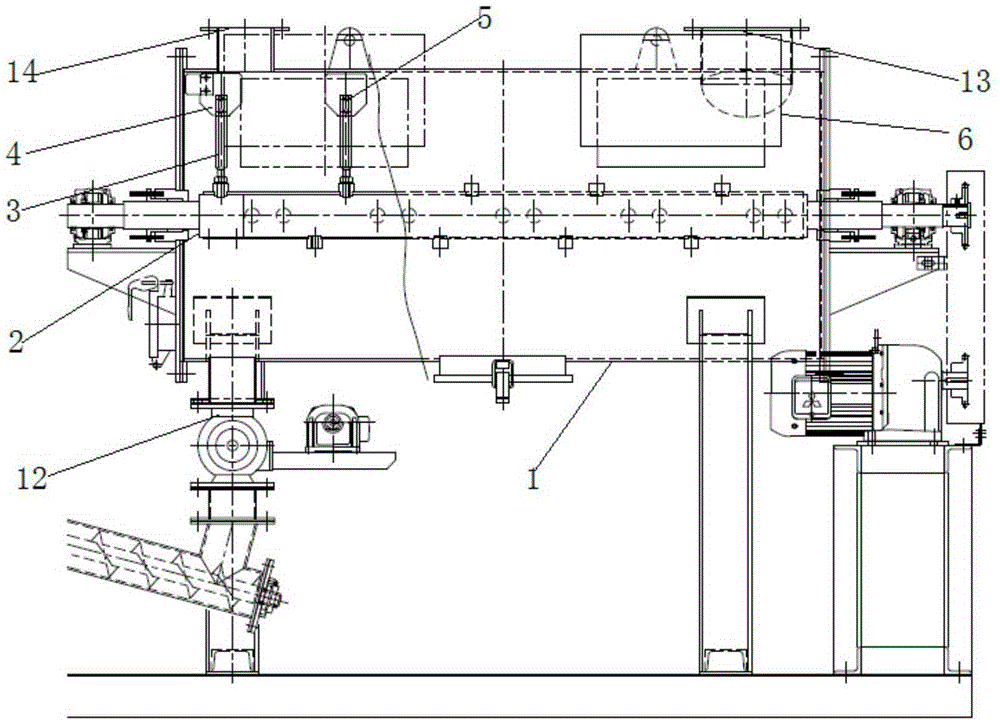

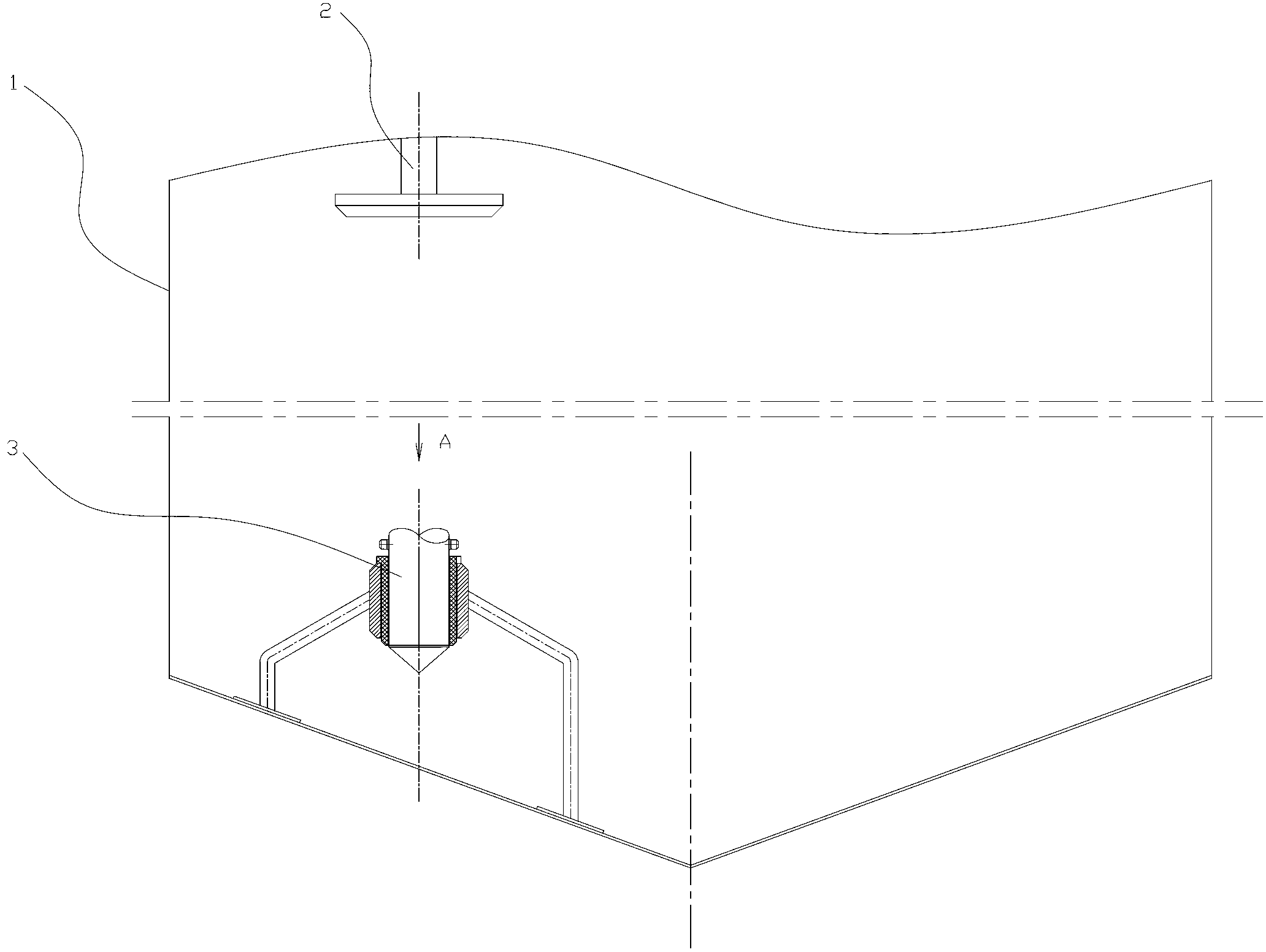

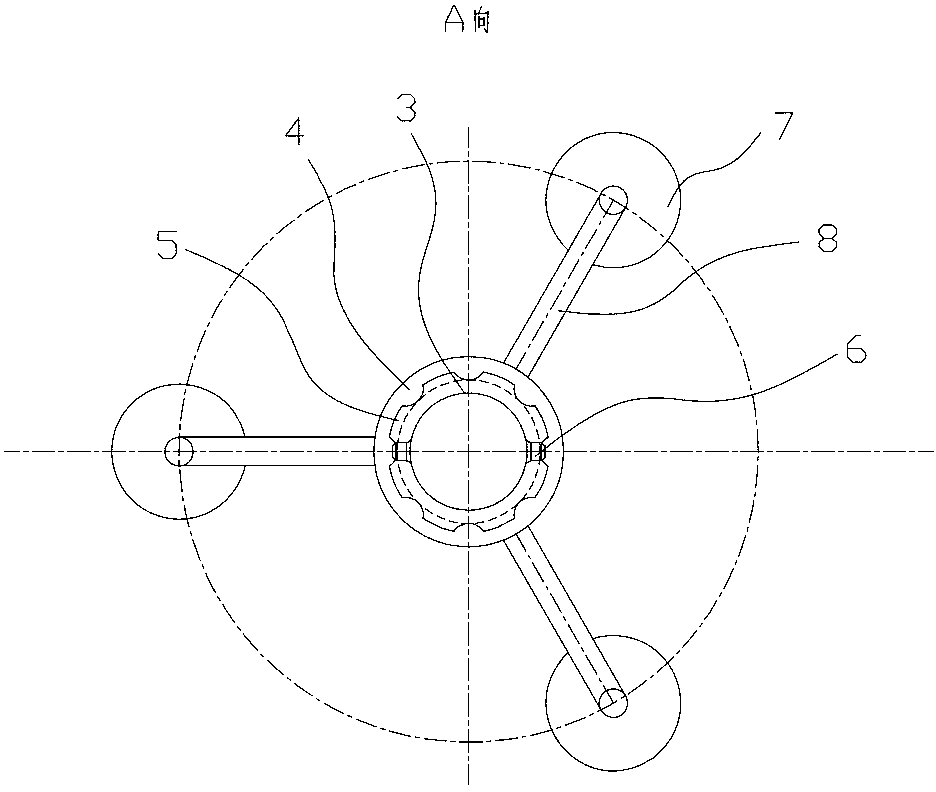

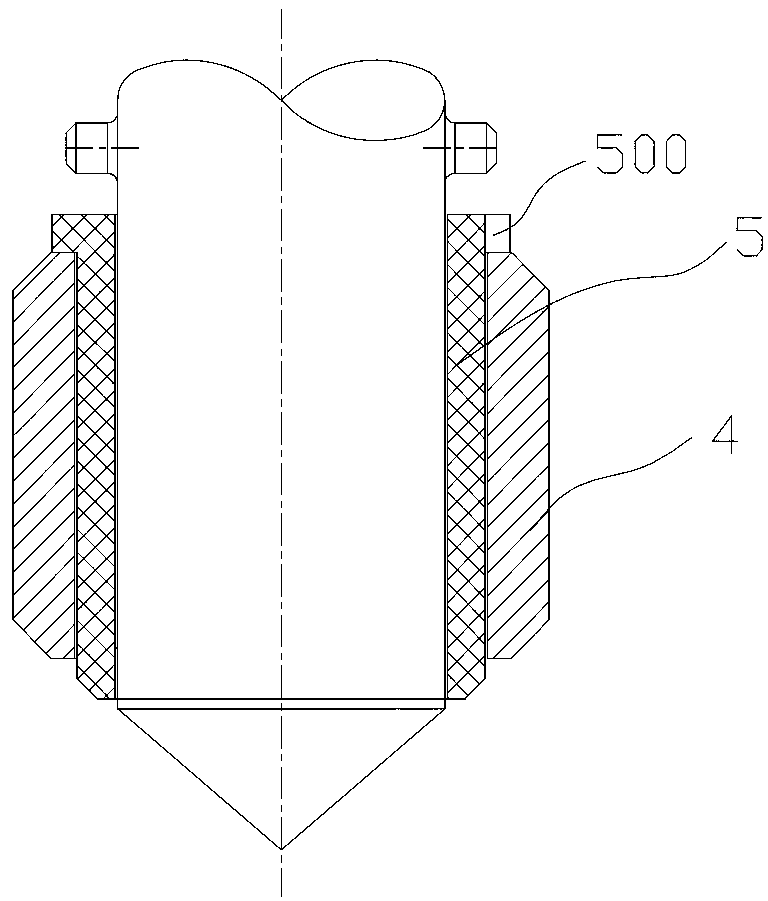

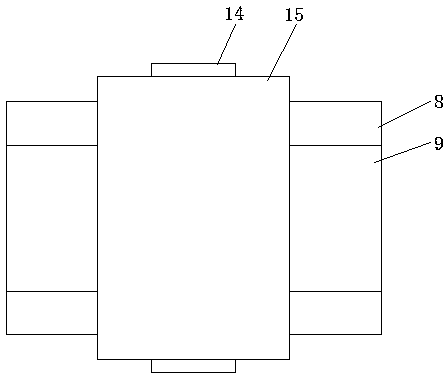

Aerodynamic lift resistance test device with controllable and adjustable pitch angle of airplane model

ActiveCN111017256AAvoid vibration phenomenonHigh precisionSustainable transportationAircraft components testingGyroscopeModel test

The invention belongs to the technical field of hydrodynamic test simulation systems. The invention discloses an aerodynamic lift resistance testing device with a controllable and adjustable pitch angle of an airplane model. The device comprises: a trailer lift axle 1, a first monitorable locking structure 2, a front main dragging rod 3, an electric lifter 4, a rope 5, a multi-degree-of-freedom adjusting reinforcing rod 6, an axle locking structure 7, a vertical linear displacement sensor 8, a pitching posture quantitative adjusting structure 9, a test model 10, a gyroscope 11, a qualitative steel plate 12, a horizontal line displacement sensor 13 and a rigid rod structure 14. Inertia and centroid debugging accuracy of a hydrodynamic test model can be improved, and model test accuracy is improved.

Owner:CHINA SPECIAL TYPE FLIER RES INST

Soil environment collection extraction equipment and soil extraction method thereof

ActiveCN108548688AAvoid blockingAchieve fixationWithdrawing sample devicesEngineeringUltimate tensile strength

The invention discloses soil environment collection extraction equipment and a soil extraction method thereof, and relates to the technical field of soil collection extraction. The equipment comprisesa power box, wherein three support rods are fixedly connected to the bottom of the power box; one end, far away from the power box, of each support rod is connected with a threaded sleeve pipe through screw threads; one end, far away from each support rod, of each threaded sleeve pipe is connected with a support foot through a screw thread; one end, far away from each threaded sleeve pipe, of each support foot is fixedly connected with an anti-slip plate; a fixing mechanism is arranged at the bottom of the power box; the bottom of the fixing mechanism is provided with an extraction mechanism.The soil environment collection extraction equipment and the soil extraction method thereof have the advantages that through the rotation of a second motor, a third rotating shaft drives an eccentricwheel to rotate; further, a fixing block drives a second connecting rod to swing to and fro; the vertical movement of a baffle plate is realized; a soil rolling pipeline is fixedly communicated witha third through hole; the goal of collecting soil by a collecting box is finally achieved; the work intensity is reduced; the layered collection is convenient.

Owner:安徽省通源环境节能股份有限公司

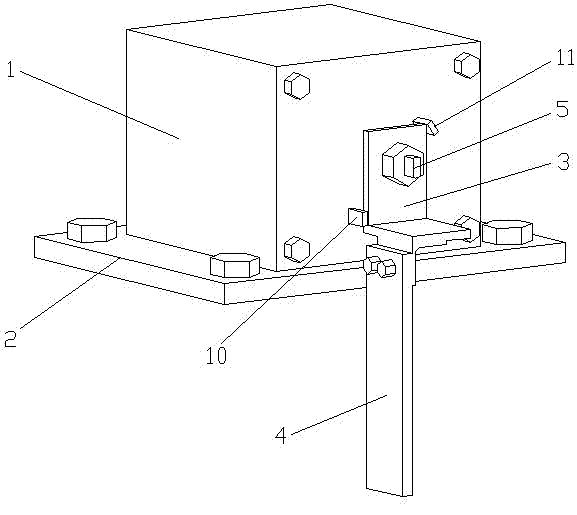

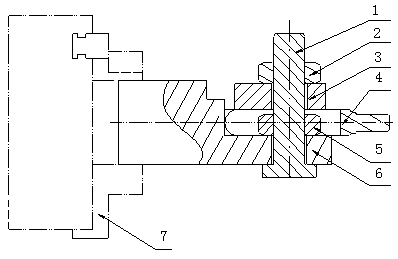

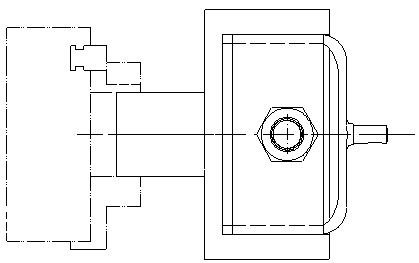

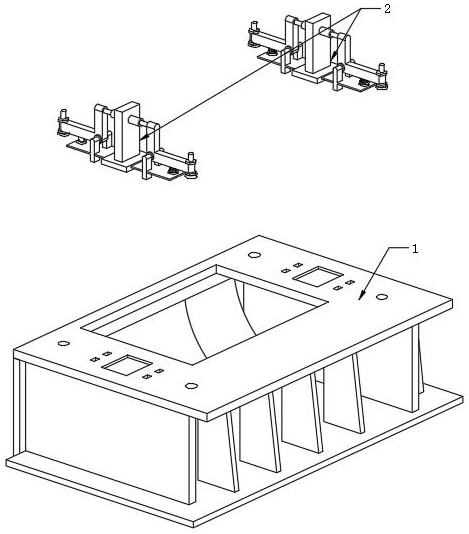

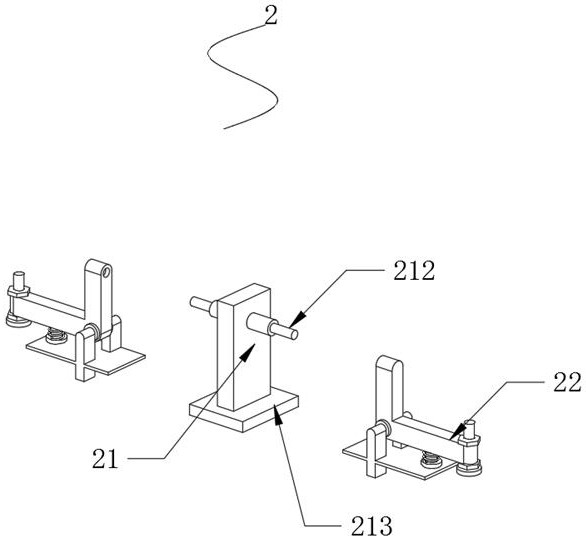

Machining method for large box body hole series and jig cutter box

ActiveCN102649177ASolve hole system straightnessSolve the roundness errorMilling equipment detailsPositioning apparatusMilling cutterLinearity

The invention discloses a machining method for a large box body hole series and a jig cutter box. The method performs boring on an upper box body and a lower box body of a large box body, which are independent from each other, the clamping mode during machining ensures that a center line of the main shaft of a boring machine is perpendicular to the axes of the hole series, and a vertical milling head is adopted for machining the hole series. The jig cutter box comprises a strip-shaped box body; an internal spline hole matched with the vertical milling head of the boring machine is formed at the tail of the box body; thread through holes are formed at the periphery of the internal spline hole; a notch structure used for clamping a milling cutter is arranged at the head of the box body; and a plurality of threaded holes and bolts matched with the threaded holes and used for fixing the milling cutter are formed on one side of the notch structure. The machining method breaks the existing machining thinking, adopts a box body split machining mode, can effectively guarantee the machining accuracy of the large box body hole series, and solves the problems of error of the linearity and the circularity of the hole series and the like caused by the drooping of a boring rod because of the deadweight in the prior art.

Owner:SINOSTEEL XIAN MACHINERY

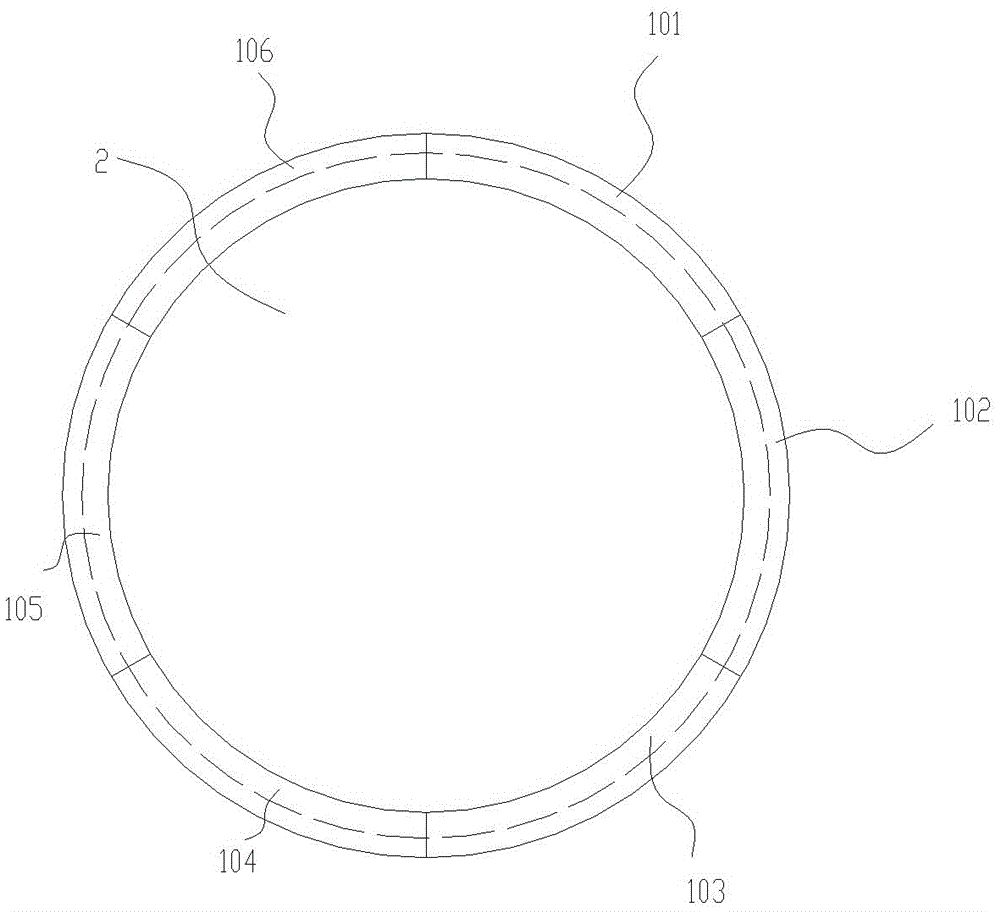

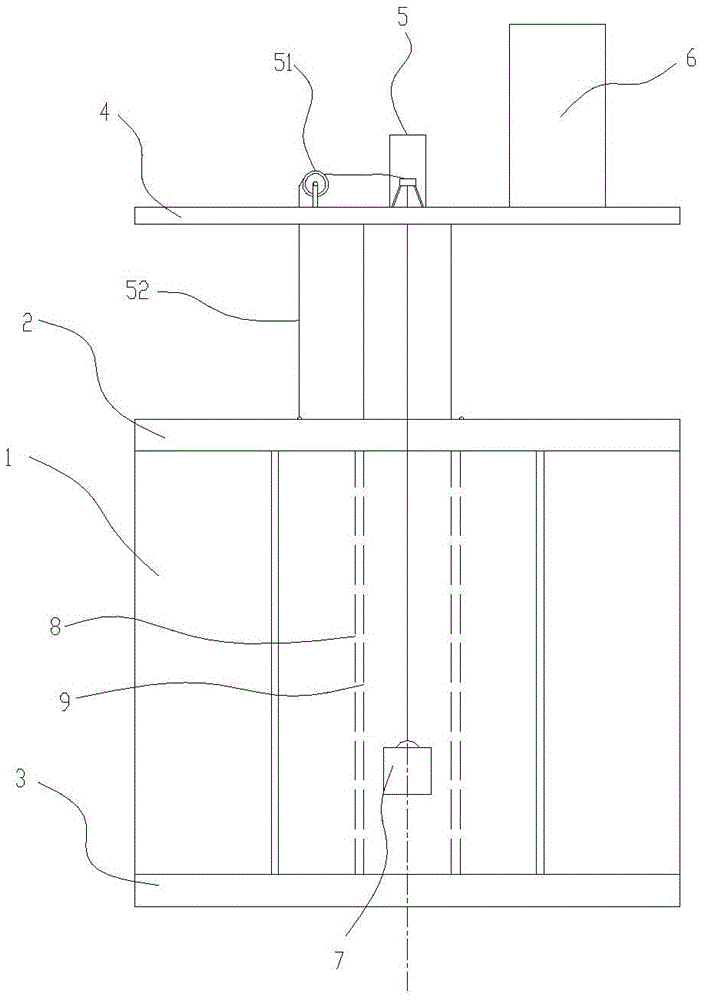

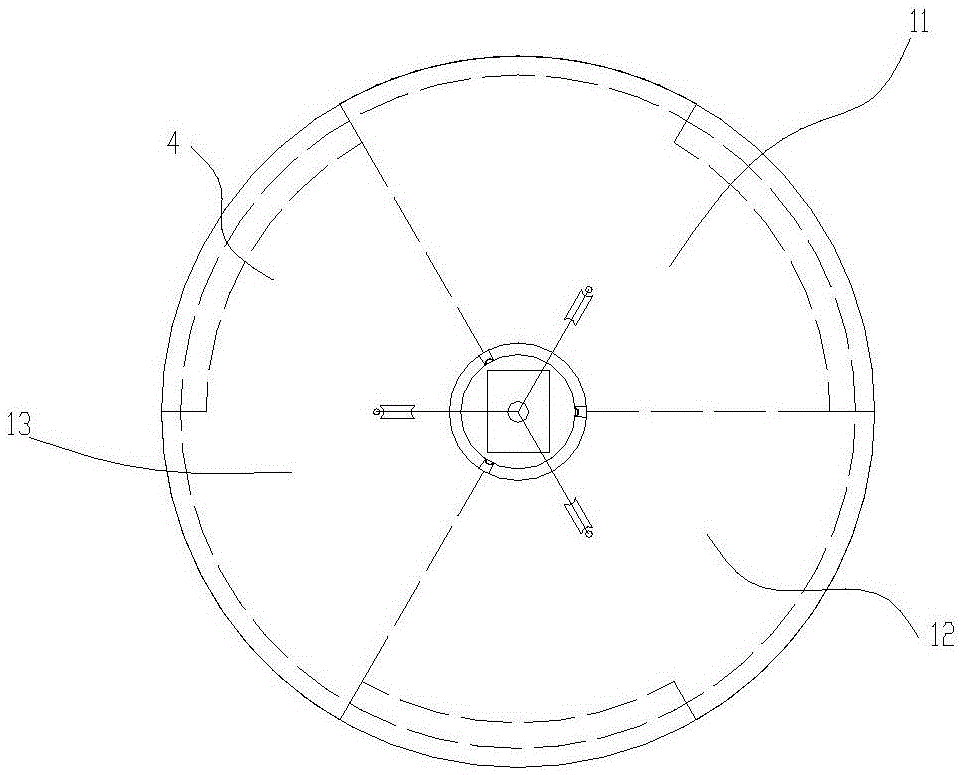

A fully open elevator

ActiveCN103910269BMeet the needs of different directionsGuaranteed utilizationBuilding liftsTraction systemElectrical control

A full-open type elevator simple in structure, convenient to operate and capable of realizing 360-degree opening comprises a workbench, an elevator car body, an elevator car top plate, an elevator car bottom plate, a portal crane, an elevator car frame, a guide rail, a hauling cable, a counter weight block, a traction system and an electric control system. The workbench is disposed above the elevator car body. The traction system and the electric control system are respectively disposed on the workbench. The elevator car body is annular. A guide passage is arranged at the center of the elevator car body. The elevator car body comprise a first elevator car, a second elevator car and a third elevator car which are respectively separated through elevator car walls. The elevator car frame is vertically disposed in the guide passage. The counter weight block is disposed in the elevator car frame. By the arrangement, lifting of the elevator car body is achieved, centralized operation is achieved, cost is saved and reliability is increased.

Owner:JIANGSU SUAO ELEVATOR

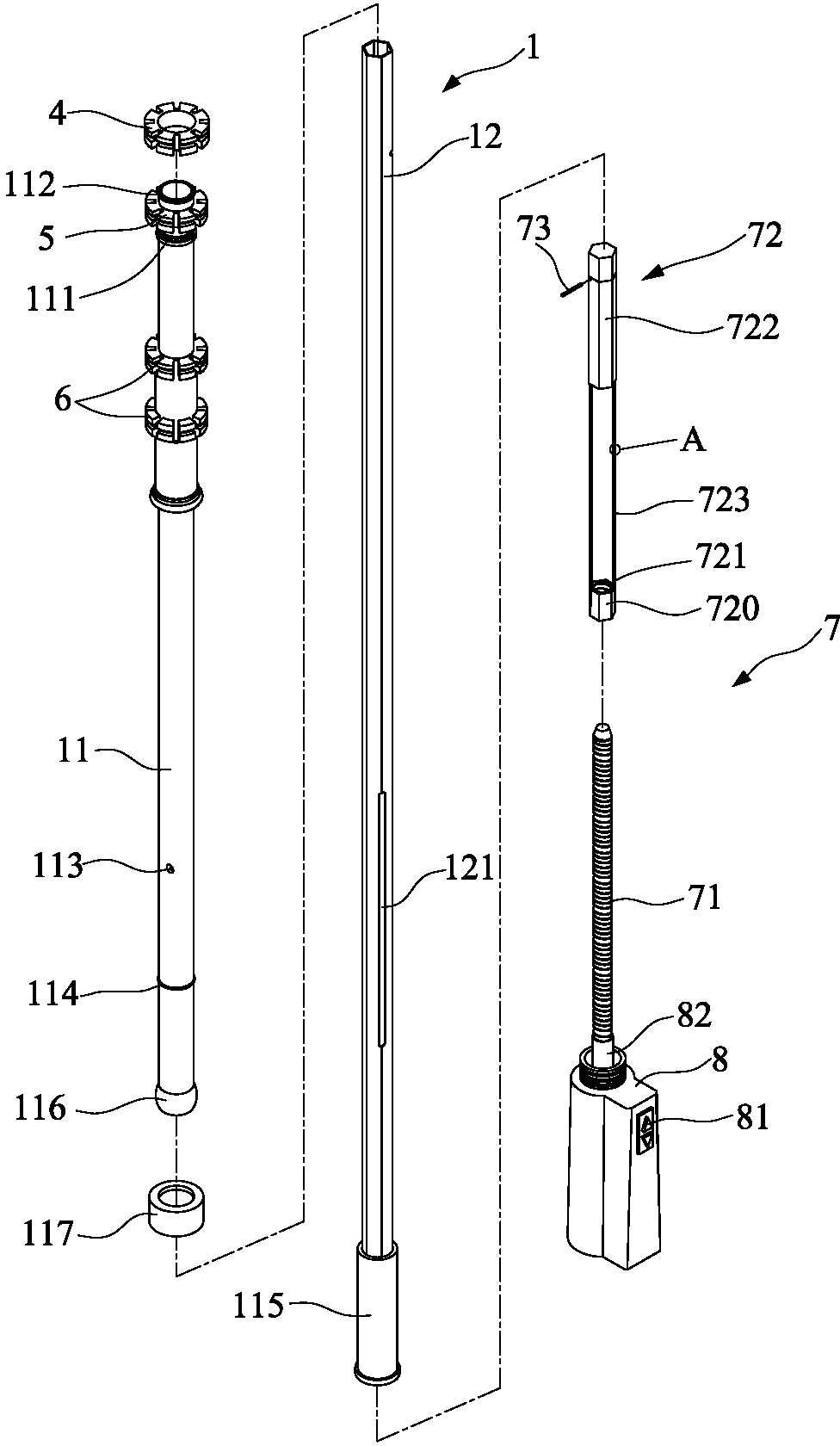

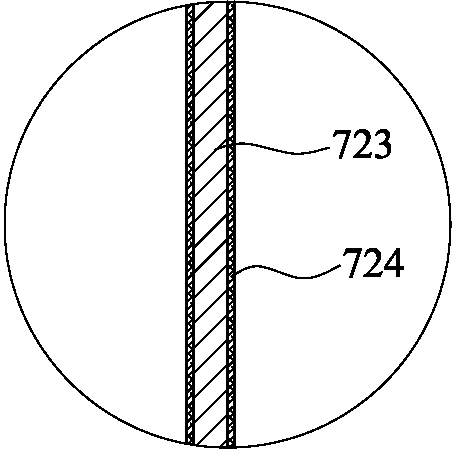

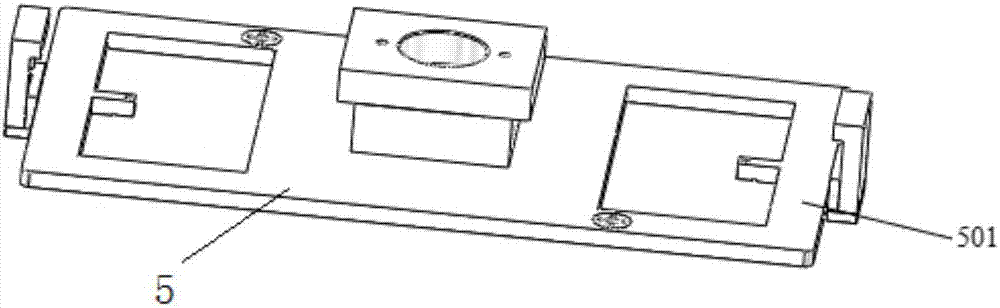

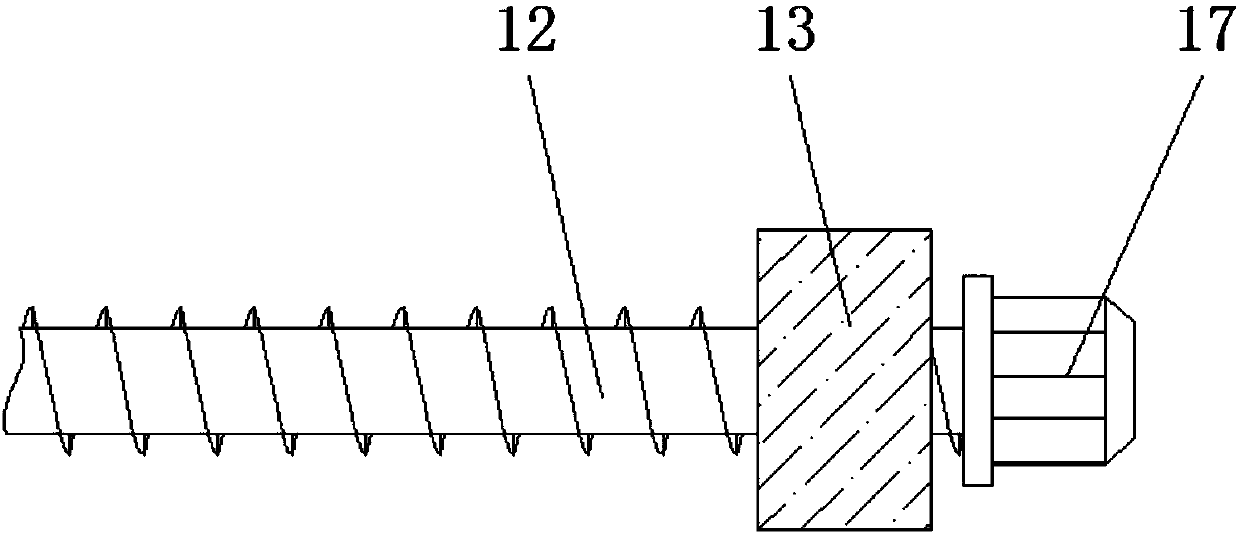

Unfolding structure of full-automatic stick umbrella

ActiveCN104161364AGuaranteed comfortGuaranteed service lifeWalking sticksEngineeringPotential energy

The invention provides an unfolding structure of a full-automatic stick umbrella. The unfolding structure of the full-automatic stick umbrella is used in cooperation with a central rod assembly, an umbrella framework, an umbrella cloth, an upper sleeve, a middle sleeve and an umbrella handle, wherein the central rod assembly, the umbrella framework, the umbrella cloth, the upper sleeve, the middle sleeve and the umbrella handle are arranged in the umbrella, the umbrella cloth is fixed to the umbrella framework, the upper sleeve is fixed to the top end of the central rod assembly, and the central rod assembly is sleeved with the middle sleeve. An unfolding and folding drive mechanism comprises a lead screw and a push tube which is driven by the lead screw to vertically move. The lower end of the lead screw is connected to a power source, used for forward drive and reverse drive, located in the umbrella handle. The central rod assembly comprises a central tube and a movable outer tube, wherein the two ends of the central tube are connected with the umbrella handle and the upper sleeve respectively, the central tube is sleeved with the movable outer tube, and the push tube penetrates through the central tube to be connected with the outer tube. The push tube comprises a lower nut portion, an upper connection portion and a deformation portion, wherein the lower nut portion is matched with the lead screw, the upper connection portion is connected with the outer tube, and the deformation portion is connected with the lower nut portion and the upper connection portion. Due to the fact that the torsion potential energy of the nut portion can be counteracted by the deformation energy of the deformation portion, the connection portion is not influenced by the rotation tendency of the nut portion, the stability of operation of the outer tube is guaranteed, the phenomenon that a central rod of an umbrella vibrates is avoided, the use comfort of the umbrella is guaranteed, and the service life of the umbrella is guaranteed.

Owner:XIAMEN MINGHO BROS MFG

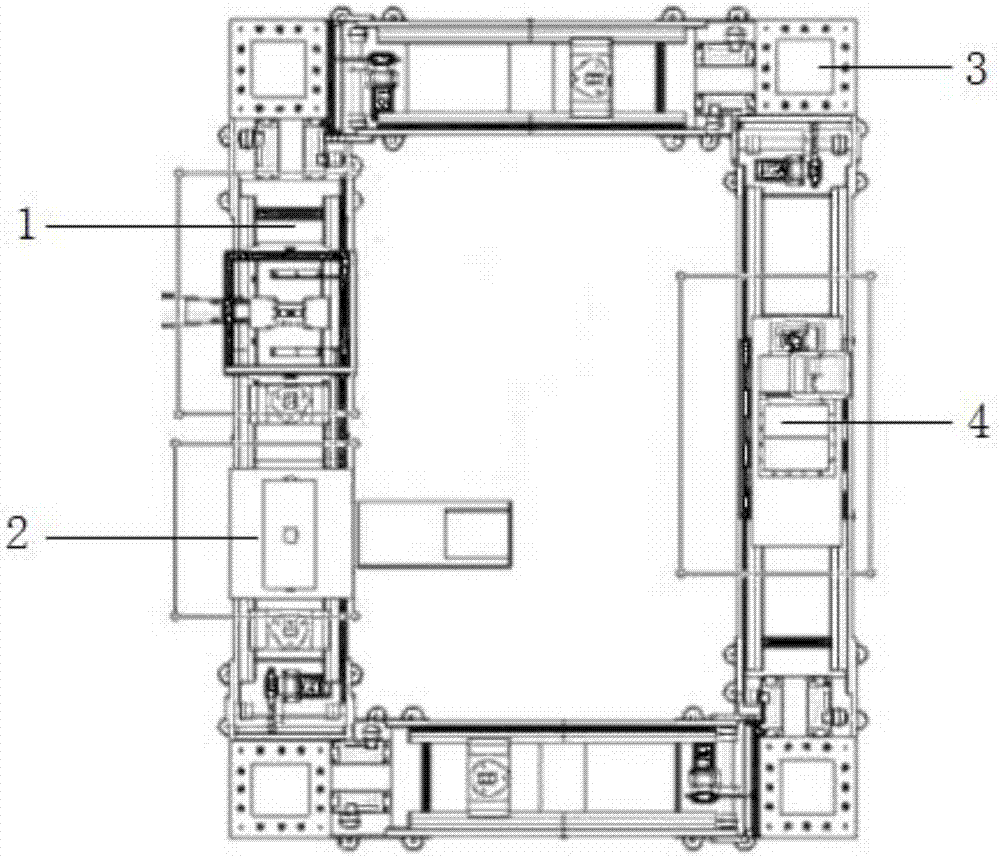

Production line of seal ring directly formed on part

InactiveCN107498779AImprove time utilization and space utilizationImprove production taktCoatingsSizingForming processes

The invention relates to a production line of a seal ring directly formed on a part. The production line comprises a die opening and assembling system for opening and assembling a die, an upper die picking and placing mechanism and a lower die lifting mechanism, an injection system for injecting a sizing material to the die, a curing system for curing and forming the sizing material and a transportation system which enables the die to move along stations of the production line. The transportation system comprises a production line body supporting rack and a chain transmission mechanism which drives the die to move; the die opening and assembling system, the injection system and the curing system are successively arranged along the transmission direction of the transportation system; the die is successively loaded by the die opening and assembling system, is injected by the injection system, cured by the curing system, and finally returns to the die opening and assembling system to be unloaded, so that the seal ring is directly formed on the part. The seal ring is directly formed on the surface of the part through an injection molding forming process, and the time utilization ratio and the space utilization ratio are increased in form of the production line.

Owner:TONGJI UNIV

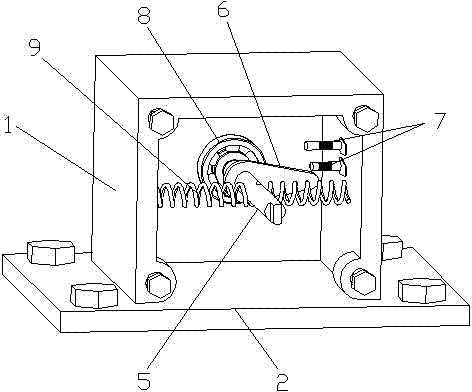

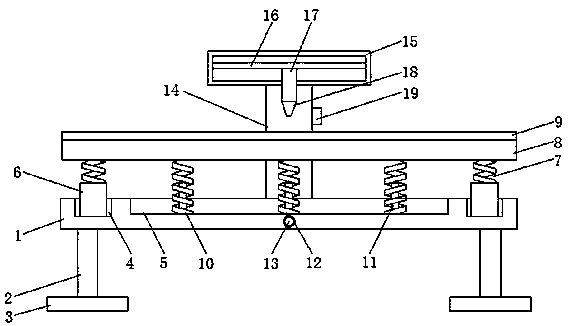

Textile machinery damping device

InactiveCN108679155AImprove shock absorptionGuaranteed normal operationMachine framesNon-rotating vibration suppressionAgricultural engineeringScrew thread

The invention discloses a textile machinery damping device. The damping device comprises a mounting base, threaded holes are formed in the upper surface of the mounting base, and an anti-skid plate isfixedly connected to the bottom of the mounting base; a damping sleeve is fixedly connected to the middle of the upper surface of the mounting base, a side surface, far away from the mounting base, of the damping sleeve is provided with clamping grooves, pre-buried screws are connected inside the clamping grooves in a clamping mode, a fixing plate is arranged above the damping sleeve, a first fixing sleeve pipe fixedly communicates with the upper surface of the fixing plate, one end, far away from the fixing plate, of the first fixing sleeve pipe penetrates through the fixing plate and extends to the position above the fixing plate, and a supporting leg is arranged inside the first fixing sleeve pipe; and a buffer block is fixedly connected to the upper surface of the mounting base, a fixing groove matched with the supporting leg is formed in the upper surface of the buffer block, and the bottom of the supporting leg is fixedly connected with the inner bottom wall of the fixing groove. The textile machinery damping device has the advantages of being convenient to install and good in damping effect and facilitating market popularization.

Owner:芜湖撼江智能科技有限公司

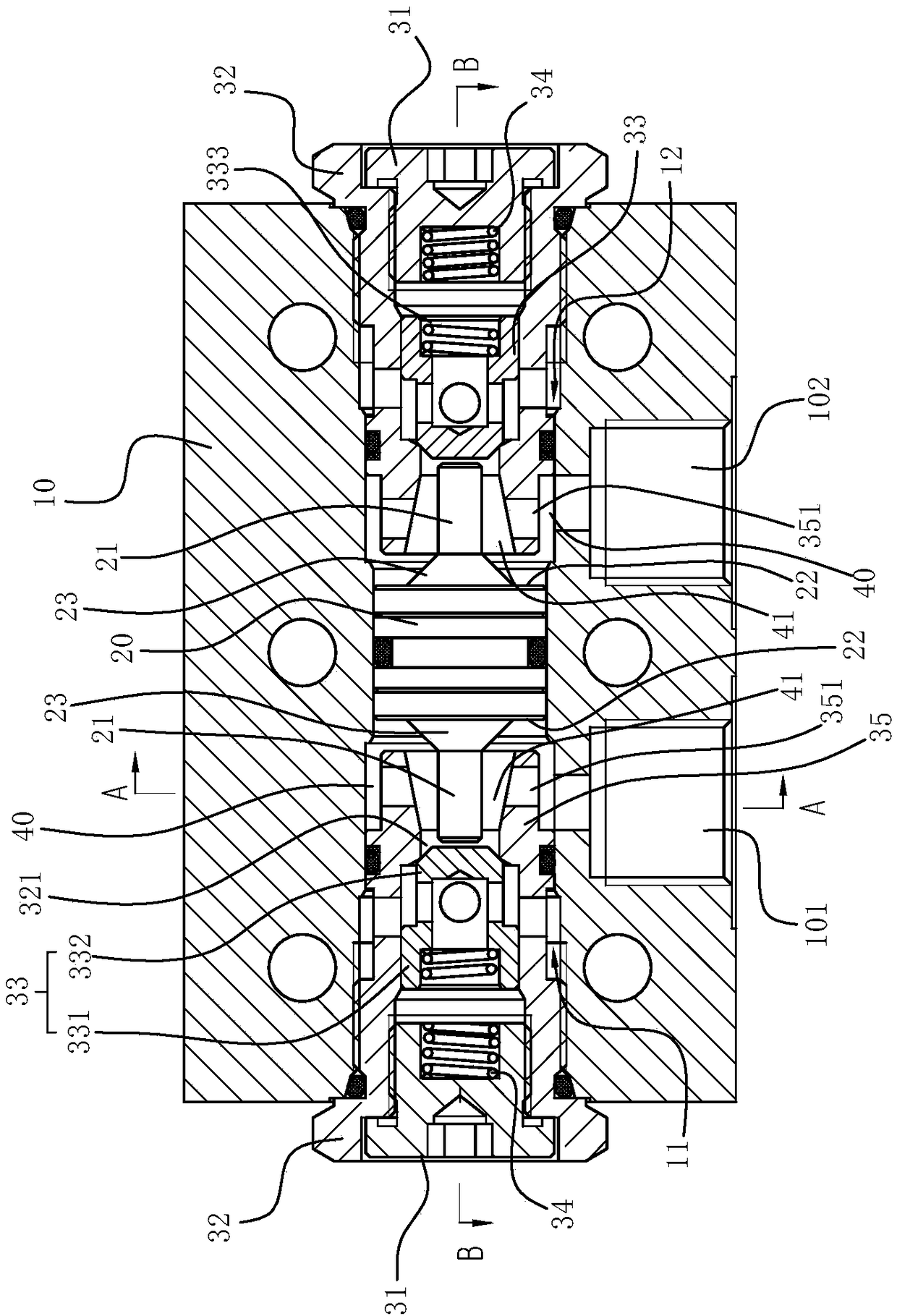

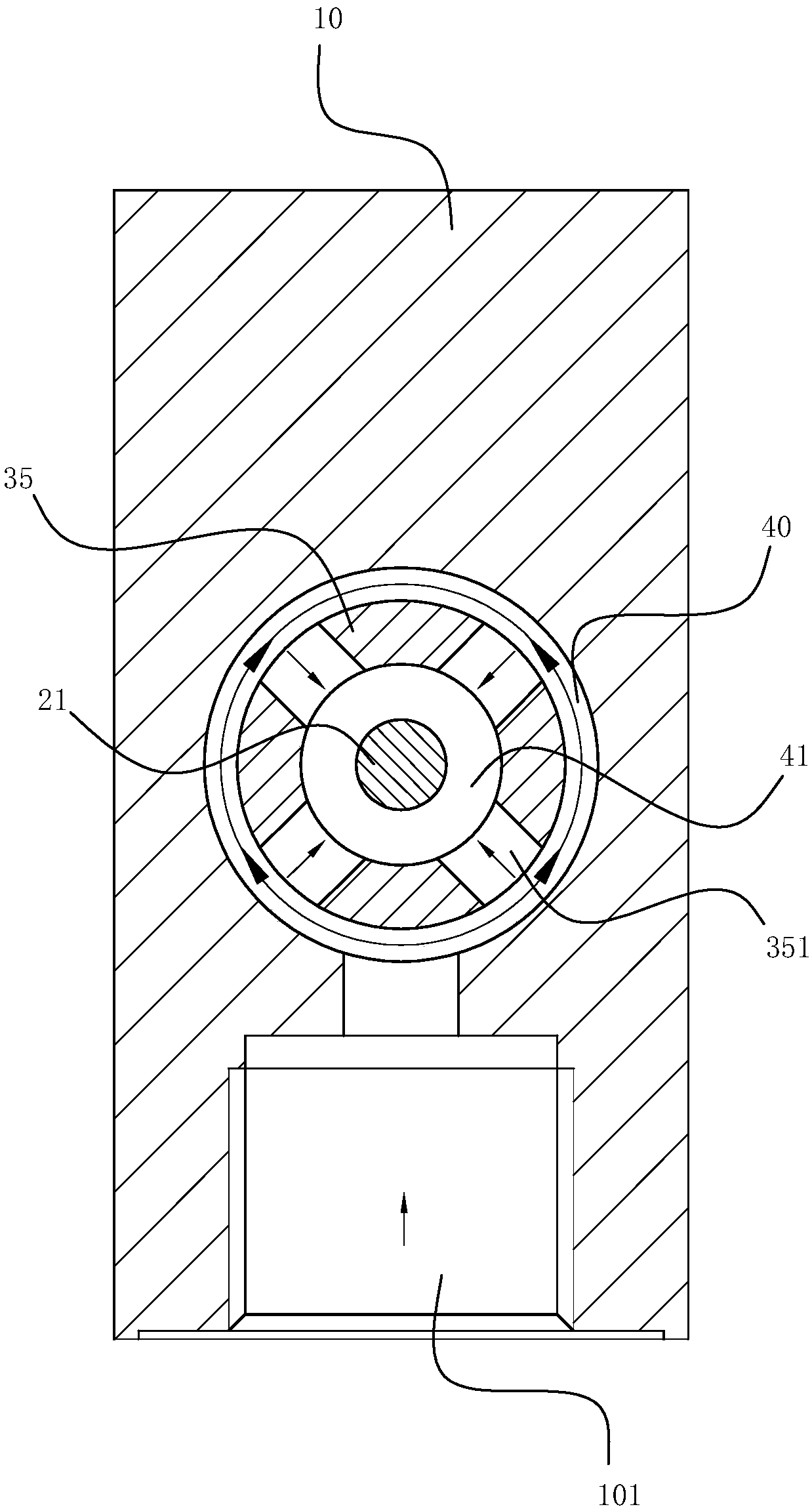

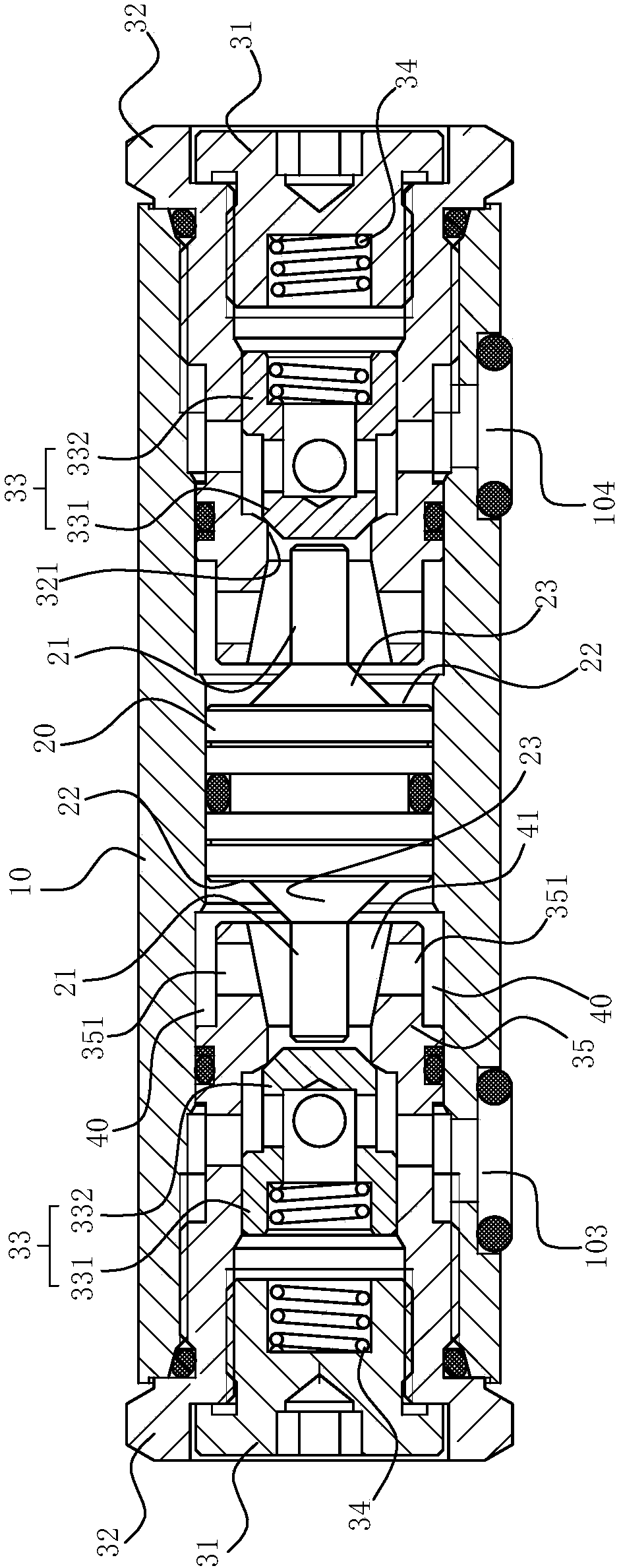

Bidirectional hydraulic lock

PendingCN108561355AExtended service lifeAvoid deformationServomotor componentsValve members for absorbing fluid energyEngineeringMechanical engineering

The invention relates to a bidirectional hydraulic lock. An annular extension part which can extend from the position of a valve hole to a plunger and prop against a corresponding side of the prop tolimit the movement of the plunger is formed on the peripheral wall of the valve hole of a valve sleeve of a one-way valve of the bidirectional hydraulic lock, and the extension length of the annular extension part is smaller than that of a plunger rod, so that the plunger rod can penetrate through the annular extension part to drive a valve element; and a first gap for hydraulic oil to flow is formed between the outer wall of the annular extension part and the inner wall of a valve body, and a second gap for hydraulic oil to flow is formed between the inner wall of the annular extension part and the outer wall of the plunger rod, and a plurality of throttling channels for hydraulic oil to flow between the first gap and the second gap is further formed in the annular extension part. According to the bidirectional hydraulic lock, the propelling stroke of the plunger can be limited by the annular extension part, so that the situation that the plunger rod is deformed or broken due to an overlarge force can be avoided, the service life of the hydraulic lock is prolonged, and the bidirectional hydraulic lock is relatively smooth and steady in the working process.

Owner:宁波善研液压有限公司

Three-degree-of-freedom spherical space robot wrist

InactiveCN102029614BEasy to adjust directionAchieve large-angle rotationJointsKinematic couplingSpherical space

The invention discloses a three-degree-of-freedom spherical space robot wrist and relates to a robot wrist. The three-degree-of-freedom spherical space robot wrist solves the problems of complex structure, low integrated level, large own weight and coupling motion of the three-degree-of-freedom robot wrist. In the three-degree-of-freedom spherical space robot wrist, an upper semisphere shaft is rotationally connected with an interface of an end effector; an upper semisphere is rotationally connected with a lower semisphere; the contact surface of the upper semisphere and the lower semisphere is an offset inclined plane; the angle between the offset inclined plane and the horizontal plane is 10 to 25 degrees; an upper semisphere motor and a speed reducing mechanism are fixedly connected with a universal joint shaft through an upper semisphere gear transmission mechanism; the universal joint shaft is fixedly connected with the upper semisphere shaft through an internal universal joint; the upper semisphere shaft is rotationally connected with the interface of the end effector; a lower semisphere motor and the speed reducing mechanism are fixedly connected with a lower semisphere shaft through a lower semisphere gear transmission mechanism; a rotation motor and the speed reducing mechanism are fixedly connected with a turnplate through a rotation gear transmission mechanism; and the turnplate is in transmission connection with the interface of the end effector through an external universal joint. The three-degree-of-freedom spherical space robot wrist is applied to aerospace robots.

Owner:HARBIN INST OF TECH

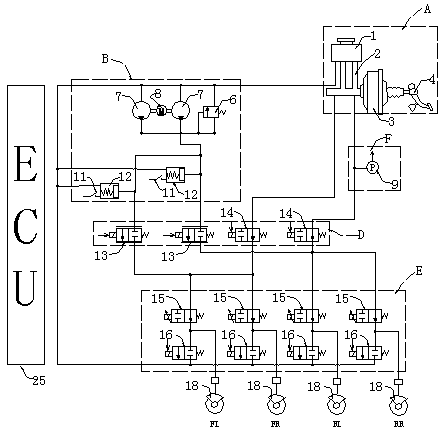

Active high-pressure brake system

PendingCN108528423AImprove scalabilityImprove compatibilityFluid braking transmissionMaster cylinderEngineering

The invention relates to an active high-pressure brake system, belongs to the technical field of car hydraulic power assisted brake systems, and mainly aims to solve the problem of contradiction between the brake force increasing and brake response speed increasing of an existing commercial vehicle traditional air brake system and hydraulic brake system. The active high-pressure brake system mainly comprises a manual and power assisted brake device, a multi-component pump control device, an electric control high-pressure device, a switching control loop and a break master cylinder pressure sensor and is characterized in that the electric control high-pressure device, the switching control loop and the multi-component pump control device are sequentially connected through brake pipelines; the break master cylinder pressure sensor is communicated to the output end of a brake master cylinder and connected with the switching control loop. By the active high-pressure brake system, the problem that the brake force of the existing commercial vehicle hydraulic brake system is insufficient is solved, and the problems of rough brake and high system cost caused by the fact that the existing commercial vehicle air brake system is slow in response are solved.

Owner:襄阳市智悦信诚智能科技有限责任公司

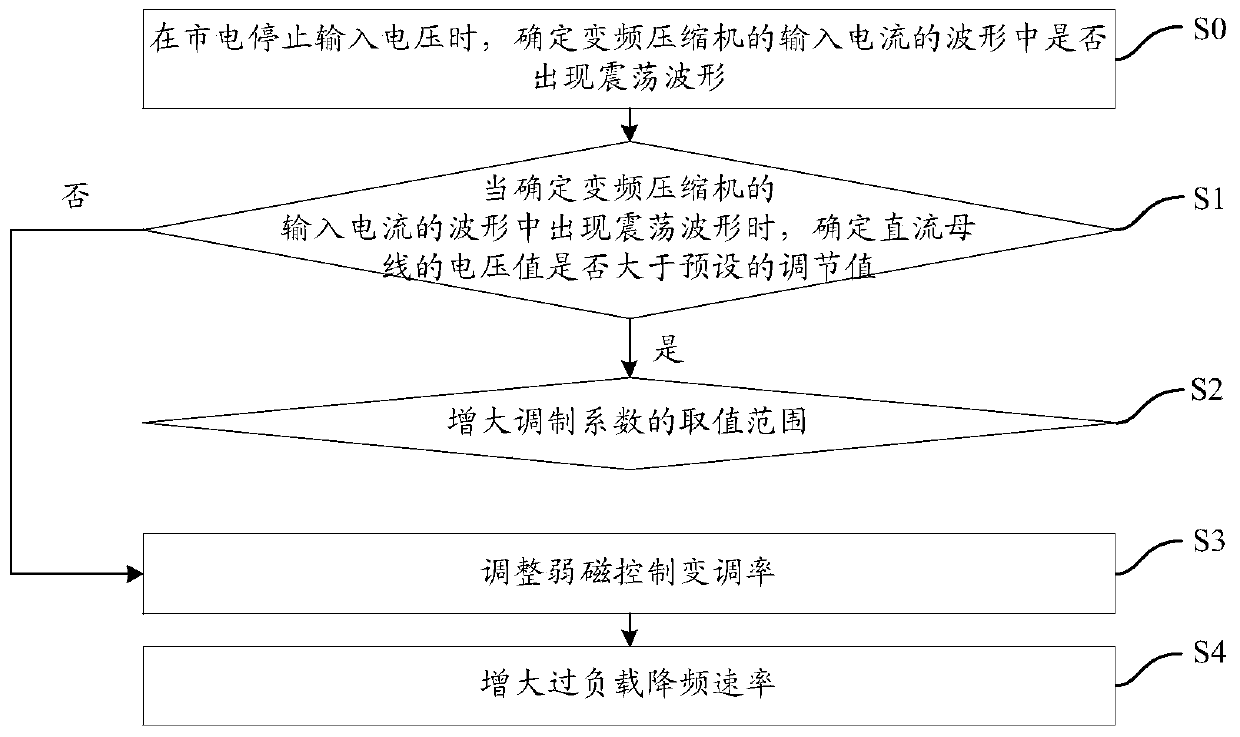

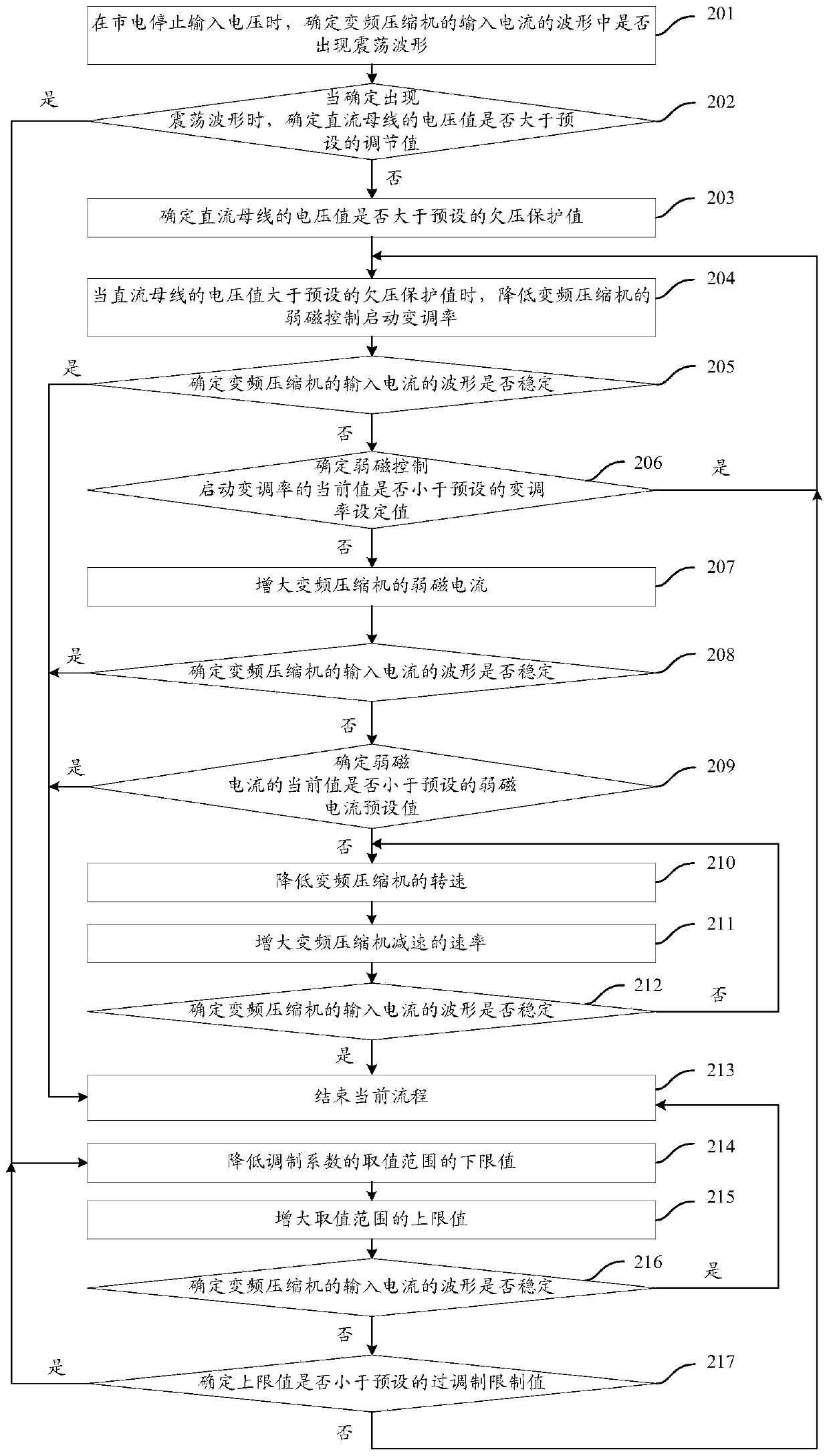

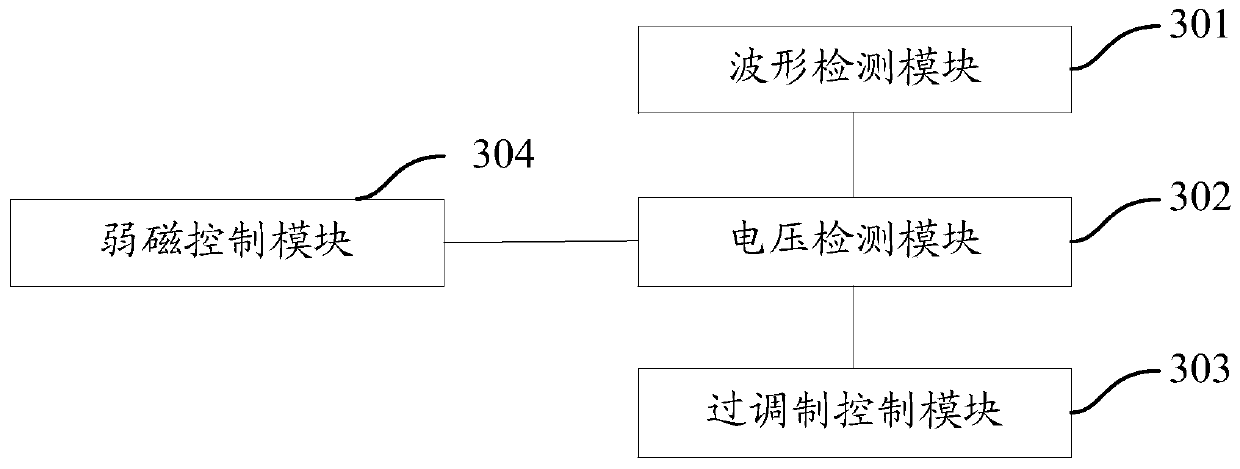

Processing method and device for power-down shutdown of variable-frequency compressor

ActiveCN109713978AAvoid vibration phenomenonAvoid chargingMotor control for motor oscillations dampingElectricityPower flow

The invention provides a processing method and a processing device for the power-down shutdown of a variable-frequency compressor. The method comprises the following steps of determining whether an oscillation waveform occurs in the waveform of the input current of the variable-frequency compressor or not when the voltage input of the commercial power is stopped; when it is determined that the oscillation waveform appears in the waveform of the input current of the variable-frequency compressor, determining whether the voltage value of a direct current bus is larger than a preset adjustment value or not; if yes, increasing the value range of a modulation coefficient; otherwise, adjusting the flux weakening control modulation rate, and increasing the overload frequency reduction rate. According to the scheme, the vibration of the variable-frequency compressor during the power-down shutdown process can be avoided.

Owner:SICHUAN HONGMEI INTELLIGENT TECH CO LTD

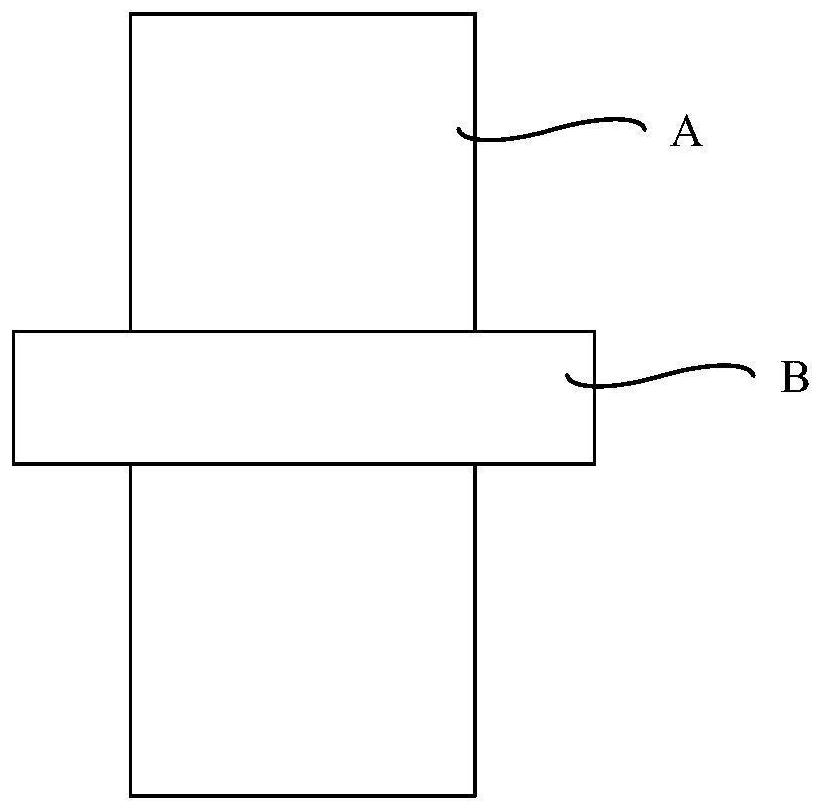

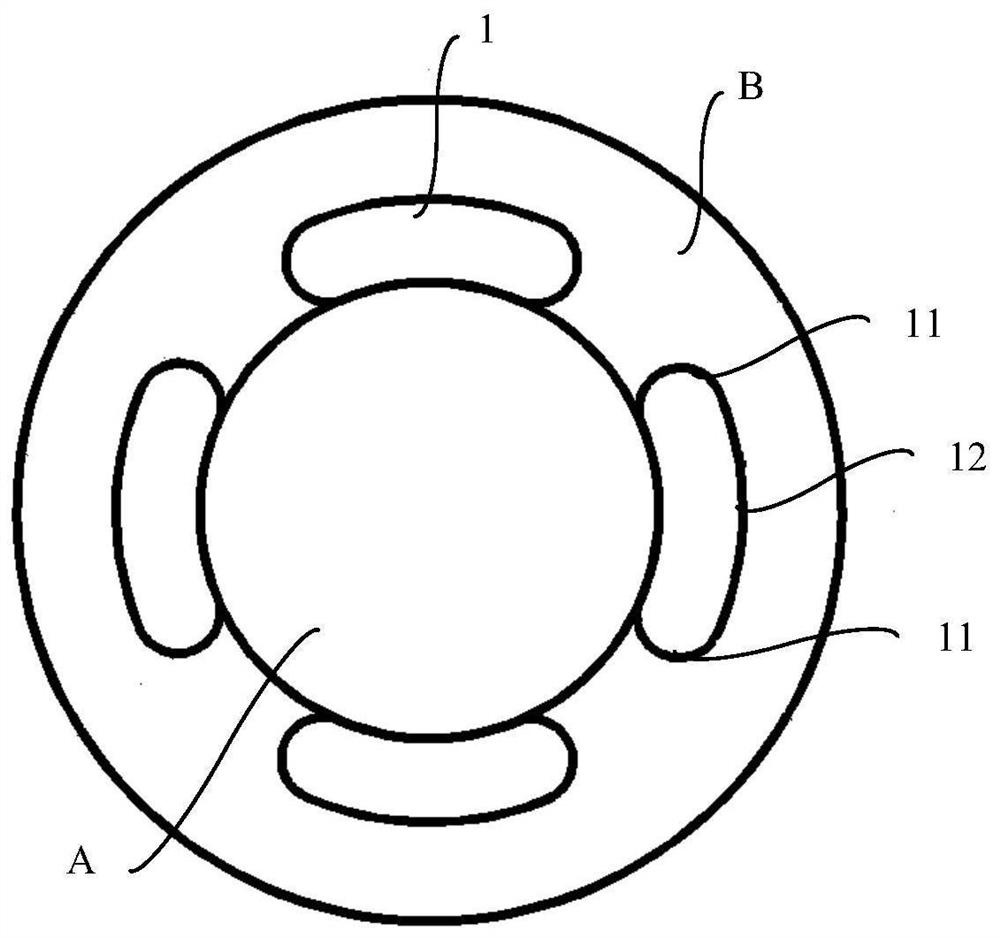

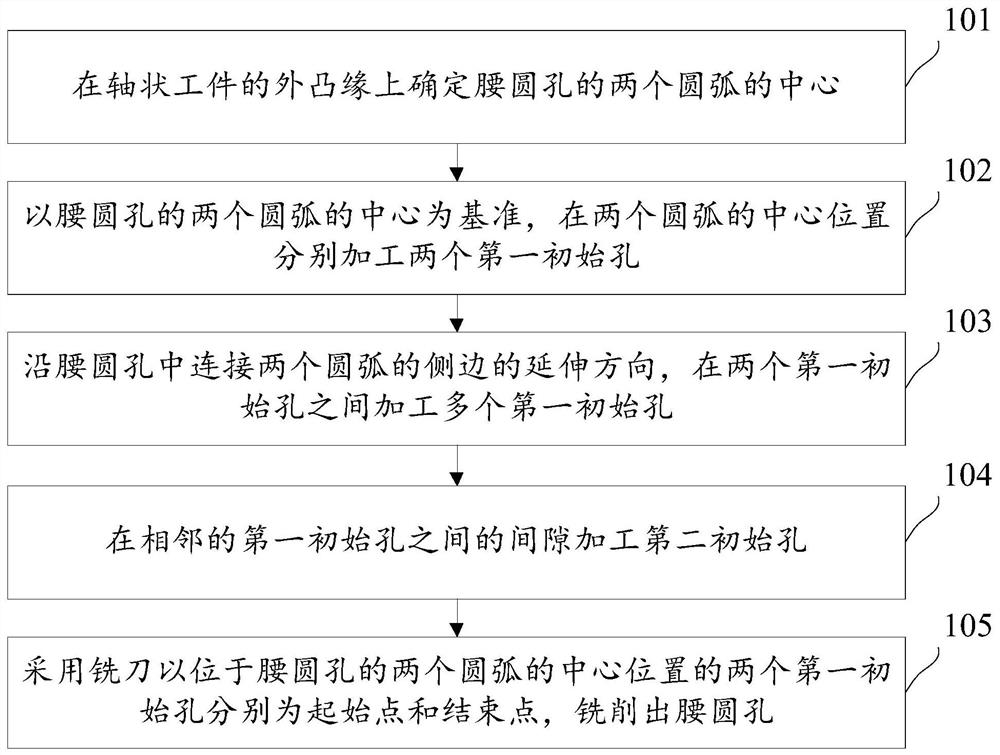

Machining method of kidney-shaped round hole

PendingCN111822761AReduce the amount of cuttingReduce depth of cutMilling equipment detailsKidneyMilling cutter

The invention provides a machining method of a kidney-shaped round hole. The machining method comprises the steps that the centers of two arcs of the kidney-shaped round hole are determined on an outer flange of a shaft-shaped workpiece; with the centers of the two arcs of the kidney-shaped hole as the benchmark, two first initial holes are machined in the centers of the two arcs correspondingly,and allowance gaps are formed between the first initial holes and the two arcs; a plurality of first initial holes are machined between the two first initial holes in the extending direction of the side edges, connected with the two arcs, in the kidney-shaped hole; and a second initial hole is machined in a gap between every two adjacent first initial holes, and allowance gaps are formed between the second initial holes and the side edges, connected with the two arcs, of the kidney-shaped holes. The kidney-shaped hole is milled by adopting a milling cutter by taking the two first initial holespositioned in the central positions of the two arcs of the kidney-shaped hole as a starting point and an ending point correspondingly. When the milling cutter with the large suspension length is usedfor machining the kidney-shaped round hole, the precision of the milled kidney-shaped round hole can be guaranteed.

Owner:WUHAN MARINE MACHINERY PLANT

Motor for medical equipment

InactiveCN113965005AGuaranteed stabilityImprove stabilityMechanical energy handlingSupports/enclosures/casingsPhysical medicine and rehabilitationMedical equipment

The invention belongs to the technical field of motors, and particularly relates to a motor for medical equipment. The motor comprises a motor body, a shell, a front end cover, an output shaft, a vibration reduction component and a flexible transmission component. According to the invention, the vibration reduction component is arranged between the motor body and the shell, and the flexible transmission component is arranged between the output shaft and the rotating shaft of the motor body so that vibration generated in the operation process of the motor body is transmitted to the vibration reduction component and the flexible transmission component, and the vibration reduction component and the flexible transmission component buffer and absorb the vibration. Therefore, vibration of the motor body is isolated and absorbed from the inside of the motor, the situation that the vibration is transmitted to the shell and the shell vibrates along with the motor body is avoided, stable torque transmission of the output shaft is guaranteed, the running stability of the medical instrument is improved, the running stability of the motor is guaranteed, therefore, the precision of the medical equipment is improved, and interference to a user of the medical equipment is avoided.

Owner:王显正

Plate cutting equipment

InactiveCN107627032AAvoid vibration phenomenonImprove cutting effectLaser beam welding apparatusSheet steelEngineering

The invention discloses plate cutting equipment. The plate cutting equipment comprises a plate cutting machine and a fixing base; the fixing base is arranged inside the plate cutting machine; an inside groove of the fixing base is glidingly connected with a semi-cylindrical supporting plate through limiting pulleys; a connecting seat is welded in the middle of the bottom of the semi-cylindrical supporting plate; and the inside of the connecting seat is in transmission connection with a motor through a screw rod. According to the plate cutting equipment, the groove of the fixing base is connected with the semi-cylindrical supporting plate through the limiting pulleys, the connecting seat in the semi-cylindrical supporting plate is connected with the motor through the screw rod, and the screw rod is driven by the motor to rotate, so that the semi-cylindrical supporting plate can move, and a steel material on second pressing plates can be driven to move; and in the manner, the vibration phenomenon of the steel plate during moving can be avoided, the position is more stable during moving, and the plate cutting effect for the steel material is better.

Owner:天津贵和建设集团有限公司

Pressing device for silicon rod clamp

InactiveCN105235087AGuaranteed stabilityGuarantee the effect of pressingWorking accessoriesEngineeringMechanical engineering

The invention relates to a pressing device for a silicon rod clamp. The pressing device for the silicon rod clamp comprises a support and a sliding block. The sliding block slides in the horizontal direction of the support. A height-adjustable pressing block is arranged at the bottom end of the sliding block. A screw is arranged on the support. A guide rod is also arranged on the support. A guide sleeve is arranged on the sliding block. A spring is arranged on the guide rod. The pressing block is fixedly connected to the sliding block through a push rod. A shock pad used for fixing the pressing block is arranged on a piston rod of the push rod. An infrared sensor connected with the push rod is arranged on the screw. The pressing device for the silicon rod clamp has the advantages that the sliding block is controlled through the screw to slide in the horizontal direction of the support, and the silicon rod clamp is clamped through the height-adjustable pressing block; through the arrangement of the guide sleeve and the guide rod, the sliding stability of the sliding block can be guaranteed, the pressing effect of the pressing block is guaranteed, and looseness of the silicon rod clamp is avoided; through the arrangement of the spring, the buffering force generated when the sliding block restores is reduced, damage to the sliding block is prevented, the pressing effect is good, and the workload of existing manual adjustment is reduced.

Owner:矽盛光电(宁夏)有限公司

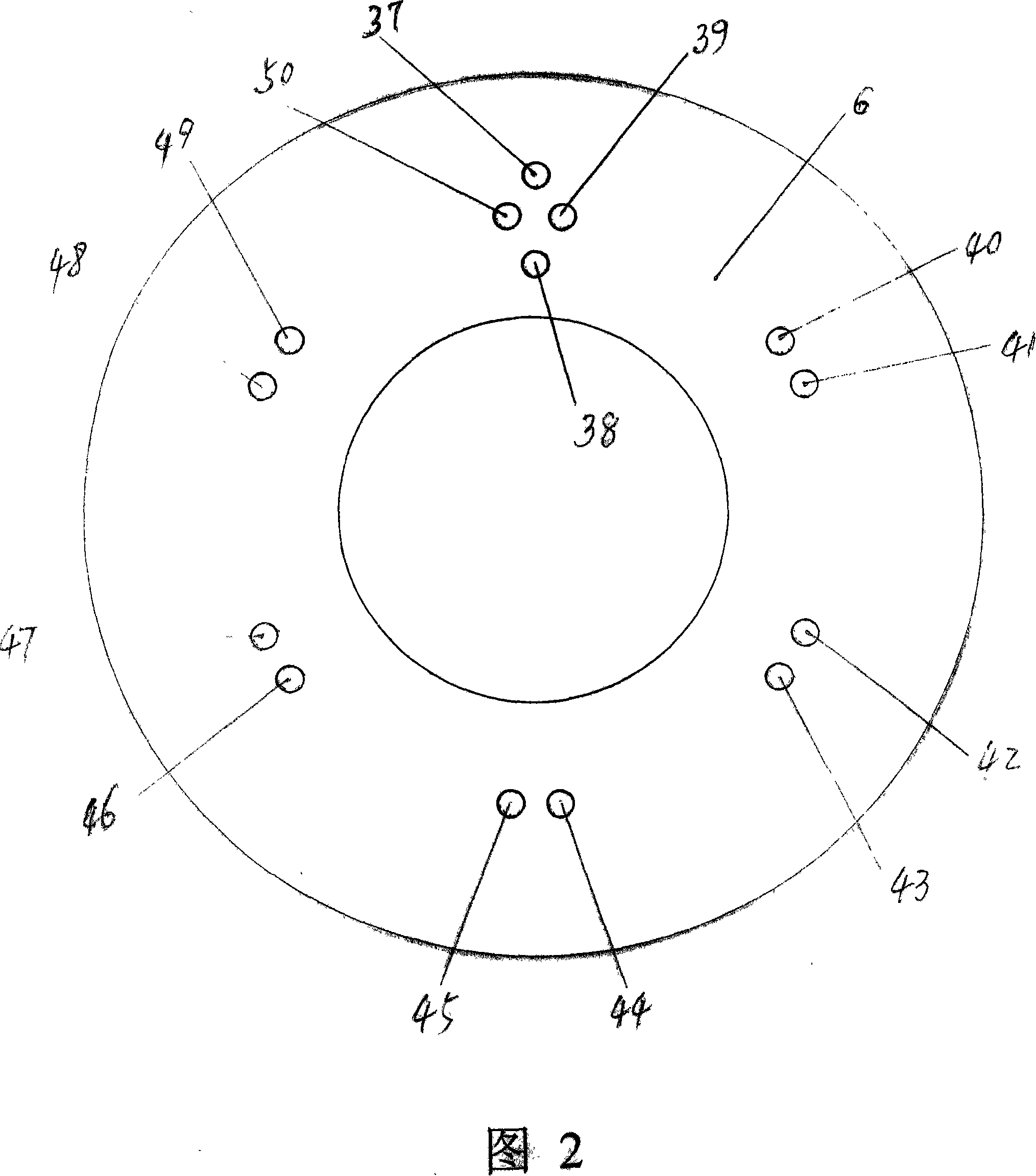

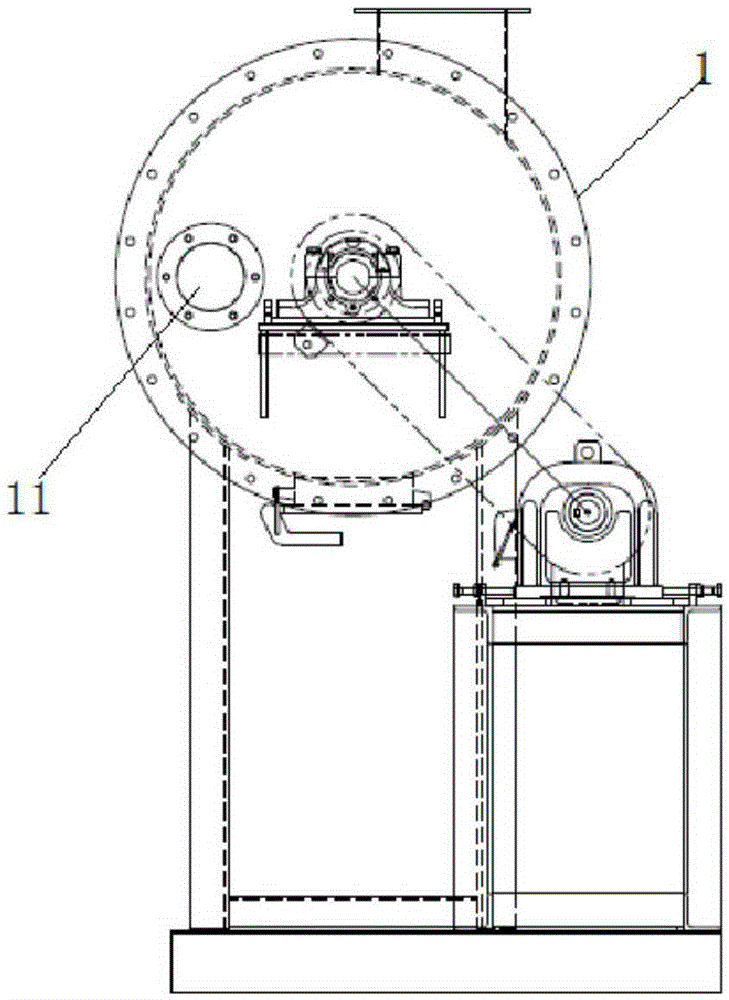

Centrifugal machine with double-layer rotary drum structure

InactiveCN104984836ARealize solid-liquid separationAvoid vibration phenomenonRotary centrifugesFilter mediaEngineering

The invention discloses a centrifugal machine with a double-layer rotary drum structure. The centrifugal machine comprises a main shaft and a rotary drum connected with the main shaft; the rotary drum is divided into an outer rotary drum body and an inner rotary drum body, the inner rotary drum body is located inside the outer rotary drum body, and a cavity is formed by the side portion of the inner rotary drum body and the outer rotary drum body; the main shaft penetrates the cavity to be connected with the inner rotary drum body, and therefore the outer rotary drum body and the inner rotary drum body rotate in the negative directions; slant sliding ways are arranged on the inner rotary drum body and the outer rotary drum body and are communicated with the cavity, and a suction tube is arranged in the cavity; and a filtering medium is installed on the inner layer of the inner rotary drum body, a feeding tube, a scraper and a discharging hopper are contained in internal space of the inner rotary drum body, and the scraper is located nearby the filtering medium. Though the double-layer structure of the inner rotary drum body and the outer rotary drum body, solid-liquid separation is efficiently achieved, and meanwhile vibration can be effectively avoided.

Owner:ZHENJIANG GANGHE NEW BUILDING MATERIAL

Walking protection device and method of material piling and taking machine

ActiveCN104773524AAvoid damageAvoid vibration phenomenonControl devices for conveyorsLoading/unloadingEngineering

The invention relates to the field of walking protection of material piling and taking machines, in particular to a walking protection device and method of a material piling and taking machine. According to the walking protection device of the material piling and taking machine, a shell is fixedly mounted on a bottom plate, and one end of a rotating shaft penetrates the shell and is mounted on the shell through a bearing; a pressure pushing plate is arranged outside the shell and is fixedly connected with one end of the rotating shaft through a swing block; a touching rotating block is arranged in the shell and is fixed to the other end of the rotating shaft in a sleeved manner; and a reset spring is arranged on the rotating shaft, and microswitches are arranged in the shell and are matched with the touch rotating block. According to a walking protection method of the material piling and taking machine, two touch positions including an alarm position and a stop position are provided, and when the pressure pushing rod is blocked by a barrier to rotate to the stop position, the microswitches send signals to a controller, and the controller directly stops walking of the material piling and taking machine. No matter how the structural mode of the material piling and taking machine is changed, mounting and detecting use of the protection device are not affected, normal operation of the device is ensured, and accident losses are reduced.

Owner:BAOSHAN IRON & STEEL CO LTD

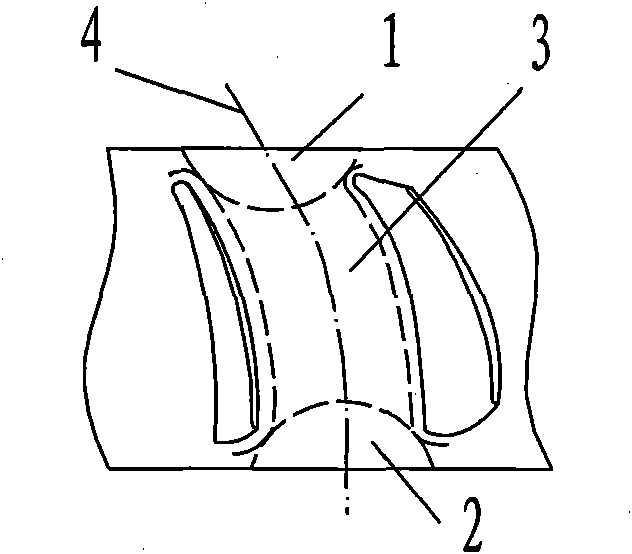

Method for composite machining of blisk flow passage

InactiveCN101966604BImprove rigidityImprove processing stabilityMilling equipment detailsNumerical controlAviation

The invention belongs to the technical field of aircraft engines, and discloses a method for the composite machining of a blisk flow passage. The method is a numerical control machining method of selecting the adaptive machining strategy based on regional characteristics. The method comprises the following steps of: (1) dividing a machining region; and (2) selecting the adaptive numerical controlmachining strategy based on the regional characteristics. In the method, a rough slotting numerical control machining method of combining milling, drilling milling and slotting milling of a cycloid is adopted, so that a medial cambered surface is approximate to a curved surface of a blade profile, and the boundary contour and the optimal cutter-axis vector of a rough machining region in a channelare determined. The method has the advantages that the machining method of region division and cutting-in changing enhances the rigidity and machining stability of blades; a process method of combining the milling and slotting milling of the cycloid improves the durability of cutters and the removal rate of materials; and the vibration phenomenon in the rough machining process is prevented effectively, the cutting force is reduced, the movement space of the cutters is expanded farthest, and the machining efficiency is improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

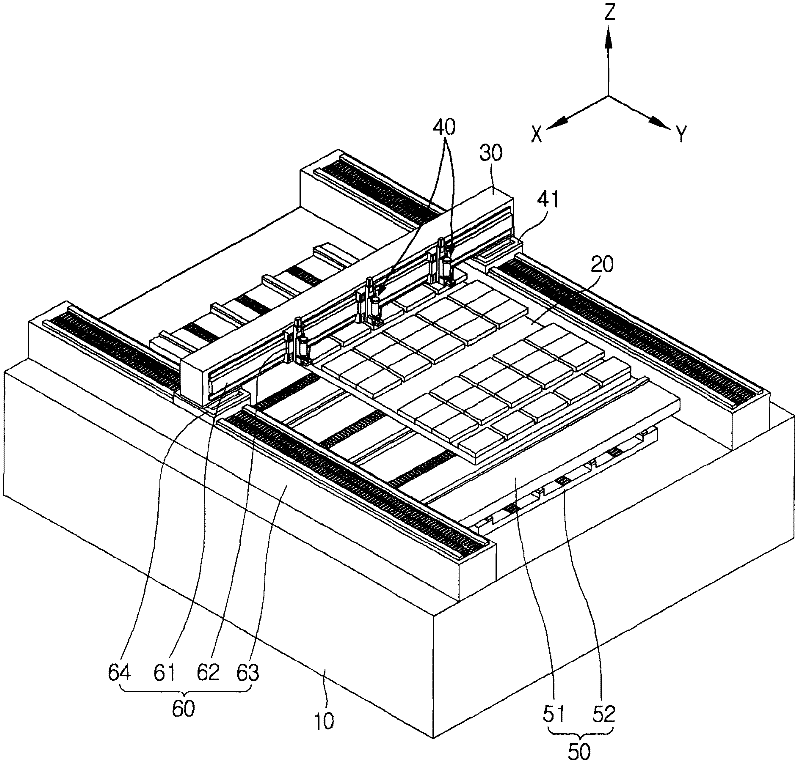

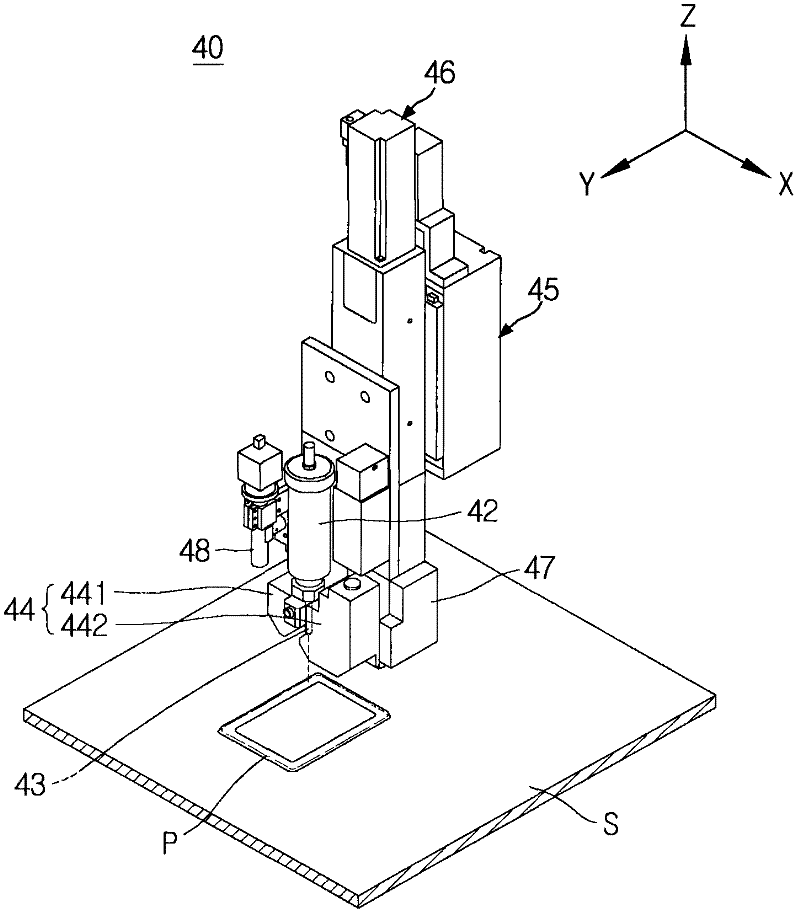

Sealant coating machine

InactiveCN102566149AFix bugsDecrease the gain valueLiquid surface applicatorsCoatingsEngineeringSealant

Disclosed herein is a sealant coating machine, wherein the position for preventing the breakage of a glass panel and the installation of a cross-sectional sensor on the part for measuring the cross-sectional area of the sealant can be minimally changed. Therefore, when measuring the sectional area of the sealant, no error has occurred.

Owner:TOP ENG CO LTD

Non-revolution body part lathe clamp

InactiveCN109807666AGuaranteed machining accuracyReduce fixture weightPositioning apparatusMetal-working holdersMachining processEngineering

The invention belongs to the technical field of machining, and particularly relates to a non-revolution body part lathe clamp which is used for assisting a non-revolution body part to realize the lathe rotary cutting function in the non-revolution body part cutting machining process. The non-revolving body part lathe clamp comprises a clamp base body, the left end of the clamp base body is of a cylindrical structure, the right end of the clamp base body is a mounting end, a through hole is formed in the mounting end, a fixed bolt penetrates through the through hole, the part is located on themounting end, a pressing plate is arranged above the part, a tightening nut and a fixing nut are arranged on the fixing bolt respectively, the axis of the machining center of the part coincides with the axis of the outer circle of the cylindrical structure, and the rotary cutting function is realized. According to the non-revolution body part lathe clamp, the reunion of the machining axis of the non-revolution body part and the axis of the main shaft of the machine tool is realized, so that the machining precision of the part can be effectively guaranteed, the weight of the clamp is reduced compared with that of a traditional splicing clamp, so that the phenomenon of machine tool vibration caused by unbalanced weight is avoided, and the processing precision is ensured.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

Convenient-to-fix test tool for locomotive ventilator vibration detection

PendingCN113883081APlay a supporting roleAvoid leaningPump controlNon-positive displacement fluid enginesVibration detectionSupport plane

The invention relates to the technical field of technological equipment, and discloses a convenient-to-fix test tool for locomotive ventilator vibration detection. The test tool comprises a supporting mechanism, wherein a set of positioning mechanisms are arranged on the upper side of the supporting mechanism, each positioning mechanism comprises a supporting frame and positioning frames, a positioning base is arranged on the lower side of each supporting frame, electric telescopic rods are arranged on the two sides of each supporting frame, and each positioning frame comprises a rotating arm, a square bottom plate and a positioning rod. According to the test tool, the electric telescopic rods can drive the rotating arms to rotate after being started, the rotating arms drive the positioning rods and positioning blocks to move downwards when rotating, meanwhile, guiding rods move downwards, meanwhile, buffering springs are pressed to play a buffering role, and the guiding rods are bound in the middles of the buffering springs to play a guiding role; and when the positioning blocks perform pressing, a ventilator can be fixed, the fastening time of a worker is shortened, and the worker can conveniently detect the ventilator.

Owner:DALIAN DINGLI RAIL TRANSIT EQUIP CO LTD

Drying machine

ActiveCN105333706AIncrease the areaImprove heat transfer efficiencyDrying machines with non-progressive movementsDrying solid materialsSmall particleMechanical engineering

The invention discloses a drying machine. The drying machine comprises a furnace body, rotating shafts, and stirring components, wherein the furnace body is arranged in the horizontal direction; the furnace body is provided with a feed opening through which materials are added and a discharge opening through which the materials are taken out; the rotating shafts are arranged in the cavity of the furnace body in a penetrating manner; the stirring components are arranged on the rotating shafts; the stirring components are used for stirring and crushing the materials in the axial directions of the rotating shafts and in the radial directions of the rotating shafts. According to the drying machine disclosed by the invention, when the materials are dried, under the driving of the rotating shafts, the stirring components can stir the materials in the axial directions of the rotating shafts and in the radial directions of the rotating shafts, so that the materials can be rolled in the furnace body in the axial directions of the rotating shafts and in the radial directions of the rotating shafts; besides, when the materials are stirred, the materials can also be crushed to form the materials with smaller particles, so that the area of heat convection between the materials and external environment is increased, the drying efficiency of the materials is improved, and the drying effect of the materials is improved.

Owner:江苏碧诺环保科技有限公司

Food stirring pot

InactiveCN103301771ASmooth runningAvoid vibration phenomenonRotary stirring mixersTransportation and packagingSanitationCircular arch

The invention provides a food stirring pot which is simple in structure and convenient to wash, meets sanitation grade requirements and prolongs the service life of a stirring shaft. The food stirring pot comprises a pot body and a stirrer, wherein the stirrer comprises the stirring shaft and a stirring blade arranged on the stirring shaft. The food stirring pot further comprises a stirring shaft supporting mechanism, wherein the stirring shaft supporting mechanism is arranged at the bottom of the pot body and is located below the stirring blade; the stirring shaft supporting mechanism comprises a shaft sleeve, a bearing sleeve and at least one pair of supporting rods; an annular convex ring is arranged on the top of the bearing sleeve; a plurality of circular-arch grooves are uniformly distributed on the annular convex ring. In a working process of the food stirring pot disclosed by the invention, materials generate the effect of lubricating liquid and the operation of the stirring shaft is more stable, so that a vibration phenomenon is avoided. The stirring shaft is provided with a limiting pin so that a phenomenon that the bearing sleeve is moved in the working process can be avoided and the reliability is improved. Meanwhile, when the stirring shaft is operated, certain swing amplitude appears below the stirring shaft due to clearance fit, the material materials between the stirring shaft and the bearing sleeve and the materials between the bearing sleeve and the shaft sleeve can be conveniently cleaned, and sanitation grades are met.

Owner:JIANGSU NEW TIANBAO MACHINERY

Circuit board cutting machine having shockproof function

InactiveCN108449878AWith shock absorption functionEasy to operatePrinted circuit manufacturePistonComputer engineering

The invention discloses a circuit board cutting machine having a shockproof function. The circuit board cutting machine comprises an operation table body, wherein two symmetric clamping grooves are formed in an upper surface of the operation table body, a groove is formed in the top of the operation table body, a clamping block is clamped into each clamping groove and is adaptive to the clamping groove, a first spring is fixedly connected to one end, far away from the operation table body, of the clamping groove, a shockproof plate is fixedly connected to one end, far away from the clamping block, of the first spring, a fixed groove is formed in an upper surface of the shockproof plate, a through hole is formed in an outer side surface of the operation table body, a shaft rod is movably connected to the through hole, support plates are fixedly connected to two ends of the shaft rod, hydraulic boxes are fixedly connected to side surfaces, near to each other, of the support plates, and pistons are arranged in the hydraulic box and are adaptive to the hydraulic box. The circuit board cutting machine having the shockproof function has the shockproof function, a user is convenient to use, and market promotion is facilitated.

Owner:芜湖致新信息科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com