Non-revolution body part lathe clamp

A lathe fixture, non-rotating body technology, applied in metal processing mechanical parts, clamping, manufacturing tools, etc., can solve the problems of unbalanced assembly weight, long production cycle, unqualified size processing, etc., to avoid machine vibration, reduce Fixture weight, the effect of ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

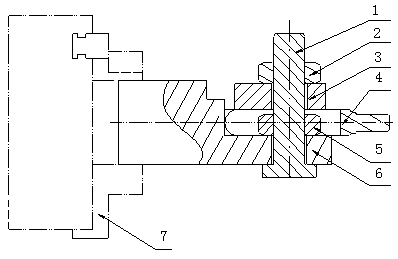

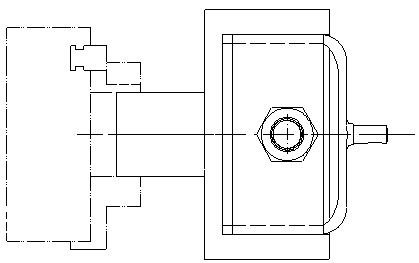

[0022] A lathe fixture for non-revolving parts includes a fixture base 6. The left end of the fixture base 6 is a cylindrical structure, and the right end is a mounting end. A through hole is provided on the mounting end, and a fixing bolt 1 is pierced in the through hole. 4 is located on the installation end, a pressure plate 3 is arranged above the part 4, a tightening nut 2 and a fixing nut 5 are respectively arranged on the fixing bolt 1, the machining center axis of the part 4 is connected with the outer axis of the cylindrical structure Overlap to realize the rotary cutting function.

[0023] The tightening nut 2 is located above the pressing plate 3 . The fixing nut 5 is located below the pressing plate 3 . The left end of the clamp base 6 is fixed on the chuck 7 of the machine tool. The fixing bolt 1 passes through the part 4 . The mounting end has a rectangular structure.

[0024] This fixture realizes the coincidence of the machining axis of the non-rotating body...

Embodiment 2

[0026] A lathe fixture for non-revolving parts includes a fixture base 6. The left end of the fixture base 6 is a cylindrical structure, and the right end is a mounting end. A through hole is provided on the mounting end, and a fixing bolt 1 is pierced in the through hole. 4 is located on the installation end, a pressure plate 3 is arranged above the part 4, a tightening nut 2 and a fixing nut 5 are respectively arranged on the fixing bolt 1, the machining center axis of the part 4 is connected with the outer axis of the cylindrical structure Overlap to realize the rotary cutting function.

[0027] The tightening nut 2 is located above the pressing plate 3 . The fixing nut 5 is located below the pressing plate 3 . The left end of the clamp base 6 is fixed on the chuck 7 of the machine tool. The fixing bolt 1 passes through the part 4 . The mounting end has a rectangular structure.

[0028] This fixture realizes the coincidence of the machining axis of the non-rotating body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com