Pressing device for silicon rod clamp

A compression device and fixture technology, which is applied in the direction of manufacturing tools, work accessories, stone processing equipment, etc., can solve the problem of low working efficiency of silicon rods, achieve good compression effect, reduce workload, and reduce buffer force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

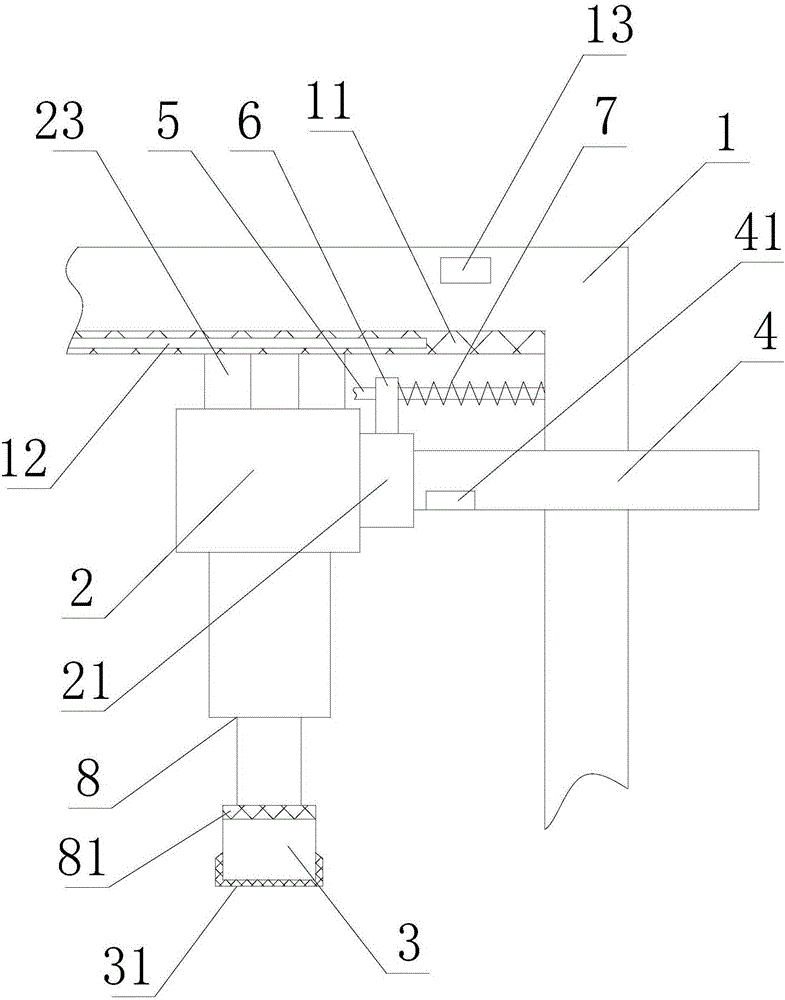

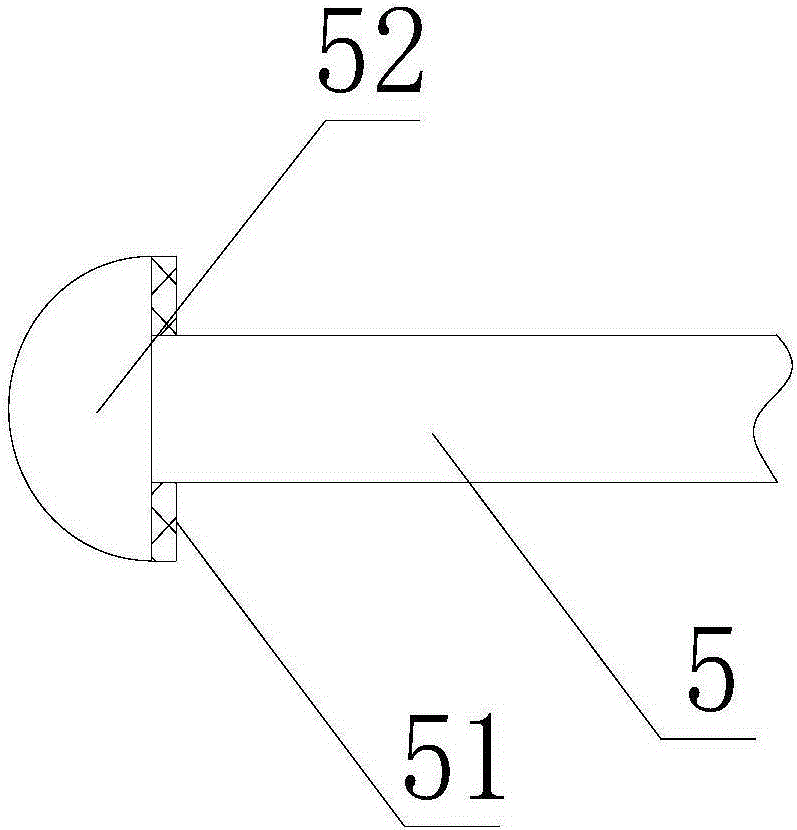

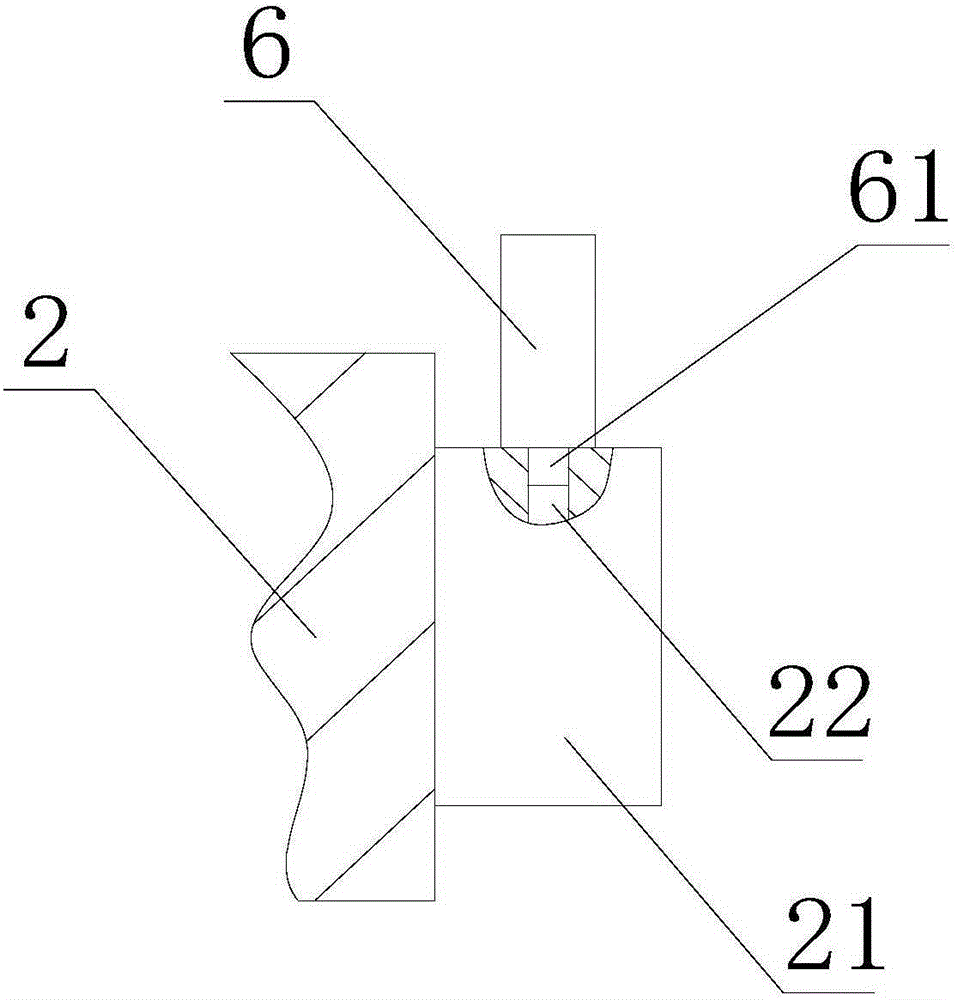

[0014] Such as figure 1 , figure 2 , image 3 As shown, a pressing device for a silicon rod clamp includes a bracket 1 and a slider 2 arranged on the bracket 1, the slider 2 slides along the horizontal direction of the bracket 1, and the bottom end of the slider 2 is provided with a height-adjustable Press block 3, screw rod 4 connected with slide block 2 is provided on support 1, guide rod 5 that controls slide block 2 to move on support 1 is provided on support 1, guide sleeve 6 is provided on slide block 2, guide sleeve 6 Slide on the guide rod 5, the guide rod 5 is provided with a spring 7, the spring 7 is arranged between the guide sleeve 6 and the bracket 1, one end of the spring 7 is connected with the guide sleeve 6, and the other end of the spring 7 is connected with the bracket 1, press The block 3 is fixedly connected on the slider 2 through the push rod 8, the piston rod of the push rod 8 is provided with a shock absorber 81 for fixing the pressing block 3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com