Food stirring pot

A technology for stirring tanks and food, which is applied to mixers, dissolvers, and mixers with rotating stirring devices. It can solve the problems of reducing the service life of the stirring shaft, inconvenient cleaning, and wear of the stirring shaft, so as to avoid vibration and use Effect of long life and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

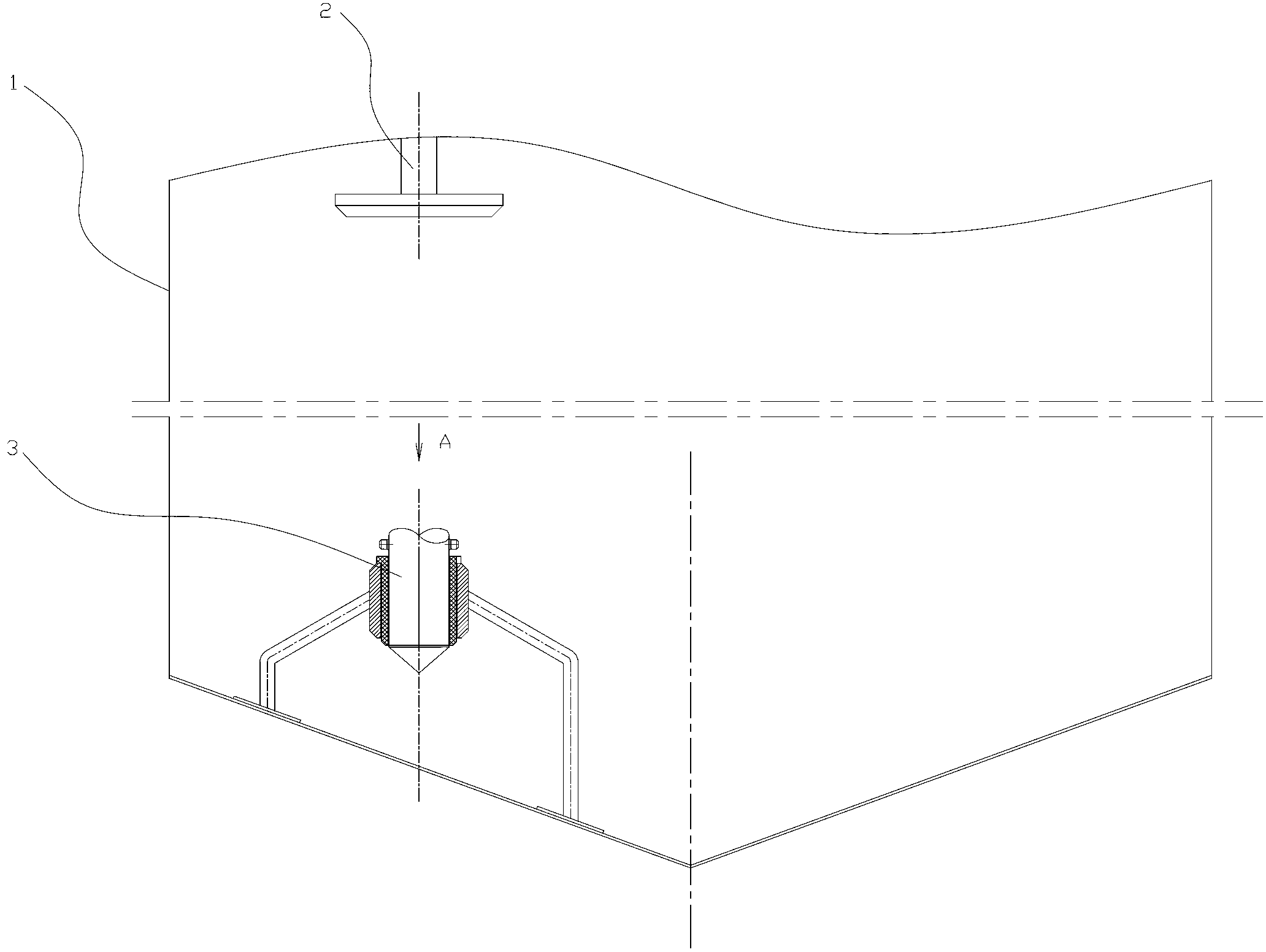

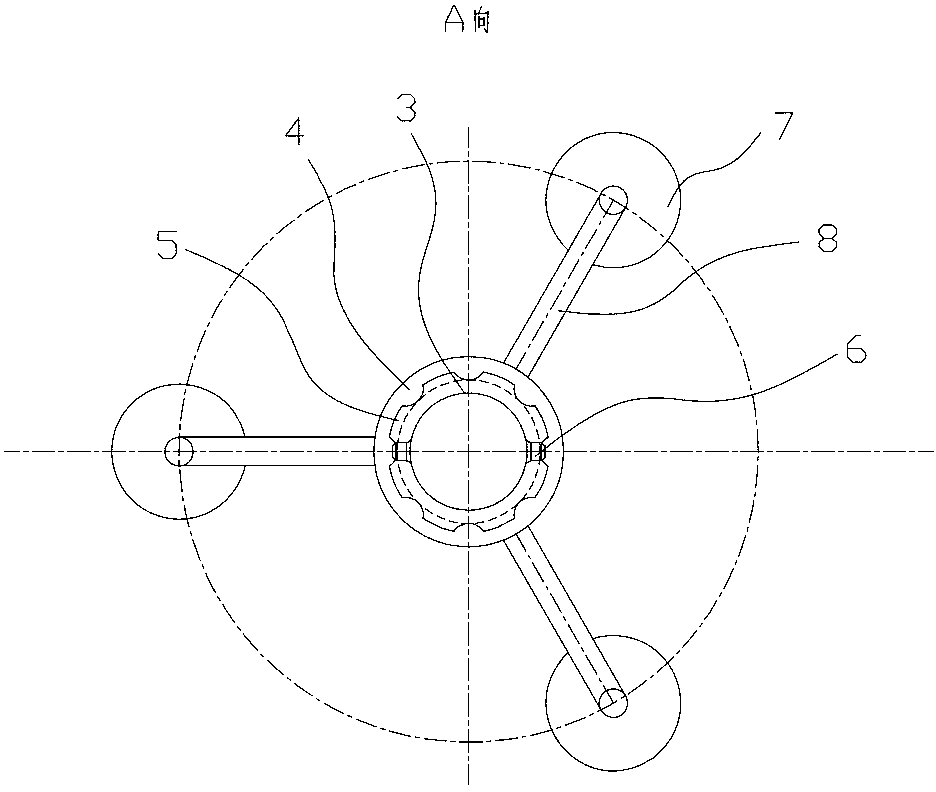

[0022] The present invention as Figure 1-6 As shown, it includes a tank body 1 and an agitator, and the agitator includes an agitating shaft 3 and an agitating blade arranged on the agitating shaft 3; it also includes an agitating shaft supporting mechanism, and the agitating shaft supporting mechanism is arranged on the tank The bottom of the body 1 and is located below the stirring blade;

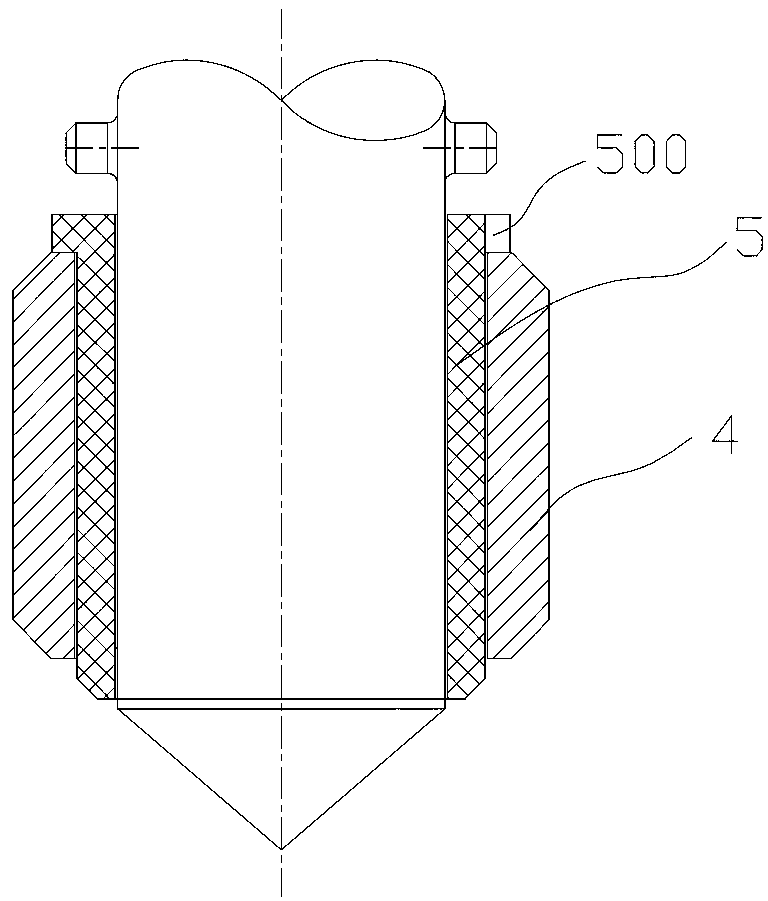

[0023] The stirring shaft support mechanism includes a shaft sleeve 4, a bearing sleeve 5 and at least one pair of support rods 8,

[0024] The support rod 8 is fixedly connected to the bottom of the tank body 1, that is, welded and fixed by the head 7 at the bottom of the tank body, and the bushing 4 is sleeved on the lower part of the stirring shaft 3 through the support rod 8;

[0025] The top of the bearing sleeve 5 is provided with an annular bead 50, the diameter of which is greater than the inner diameter of the shaft sleeve 4, and the bearing sleeve 5 is arranged on the stirrin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com