Active high-pressure brake system

A brake system, high-pressure technology, applied in the direction of hydraulic brake transmission, brake, brake transmission, etc., can solve the problems of slow response time, rough braking, and weak braking force of the air pressure braking system, and achieve improved Braking controllability and sensory comfort, braking force and response speed are improved, driving comfort and controllability are improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

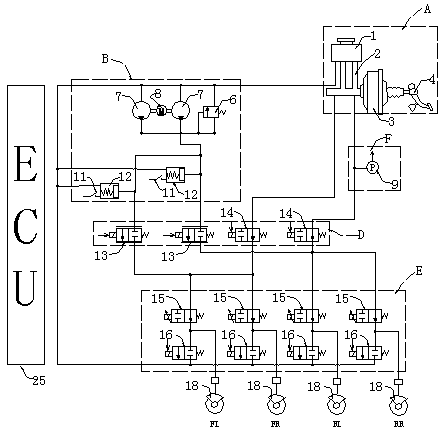

[0020] Such as figure 1 shown. An active high-voltage braking system of the present invention includes a manual + power-assisted braking device A, an electronically controlled high-voltage device B, a switching control device D, a multi-component pump control device E, a brake master cylinder pressure sensor F and a controller ECU25, the system The dynamic master cylinder pressure sensor F adopts the pressure sensor 9, and can also be replaced by a pressure switch. Wherein, the manual+assisted braking device A is composed of an oil pot 1, a master brake cylinder 2, a vacuum booster 3 and a brake pedal 4, all of which are the same as those of the prior art. The oil pot 1 has one more oil outlet, which is connected to the liquid intake port of the electronically controlled high-pressure device B, and is connected to the pressure relief valve port of the multi-component pump control device E at the same time. The electronically controlled high-voltage device B, the switching co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com