Reluctance motor and self-control optical coupled switch and motion control, structure damp and radiating method

A technology of reluctance motors and motors, applied in the direction of magnetic circuit shape/style/structure, electronic switches, electric components, etc., can solve the problems of reluctance motor torque ripple, vibration and noise, complex control system, etc., and achieve frequency Effects of self-sufficiency and positioning control, increased mechanical angle width, and simple control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

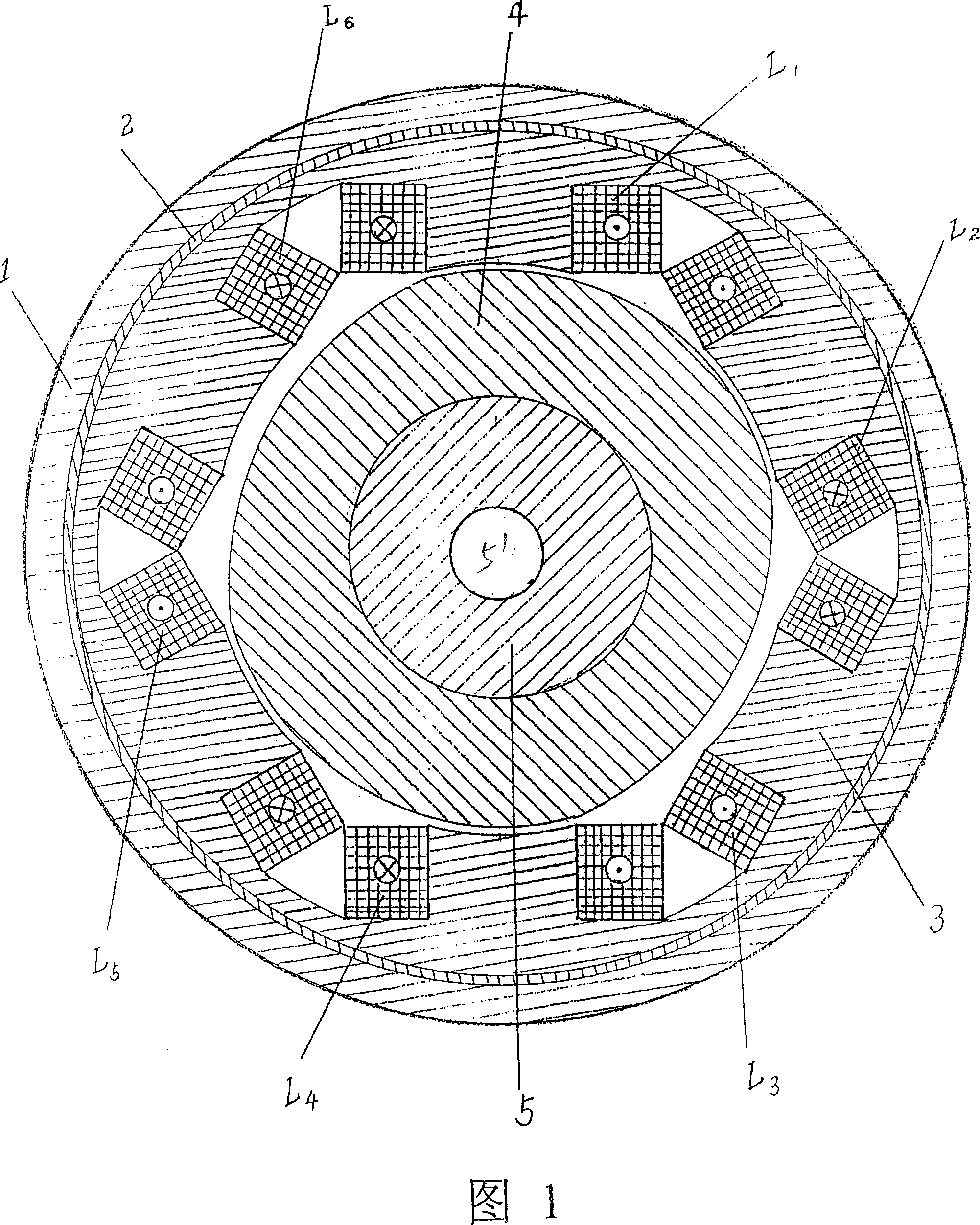

[0040] According to Fig. 1, the reluctance motor of the present invention adopts a three-phase stator structure, that is, six stator poles are distributed equidistantly on the circumference, and the width of each stator pole is equal to the spacing. A simple concentrated winding is installed on each stator pole, and the windings on the two radially opposite stator poles are connected in series or in parallel to form a phase. That is: the L 1 and L 4 Form A phase, L 2 and L 5 Form B phase, L 3 and L 6 To form the C phase, the magnetic flux polarity between the adjacent stator poles should be designed to be opposite to each other. Then, the elliptical two-pole rotor core 4 is installed on the hollow rotor shaft 5, and passed through the two ends of the motor. Bearings, end caps (not shown in the figure) are connected and fixed with the machine base 1. The motion mechanism that constitutes the entire motor. Among them, at both ends of the long axis of the elliptical two-po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com