Electric heating equipment

An electric heating and equipment technology, applied in lighting and heating equipment, electric heating systems, household heating, etc., can solve problems such as short circuit of heating wires and short-circuit wires, hidden safety hazards, and melting of heat-sensitive layers, so as to avoid heating wires The effects of fire, high safety, and high product value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

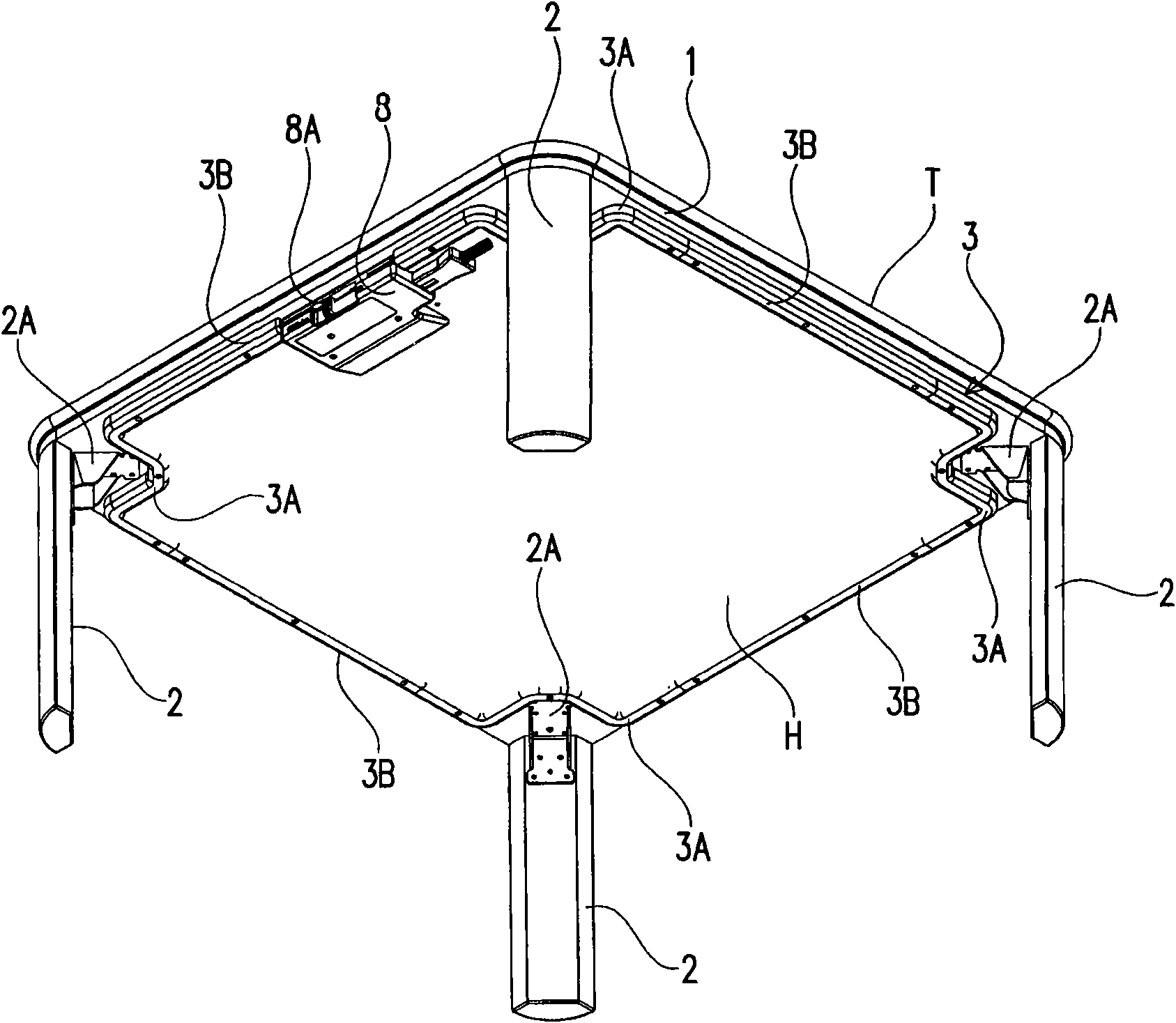

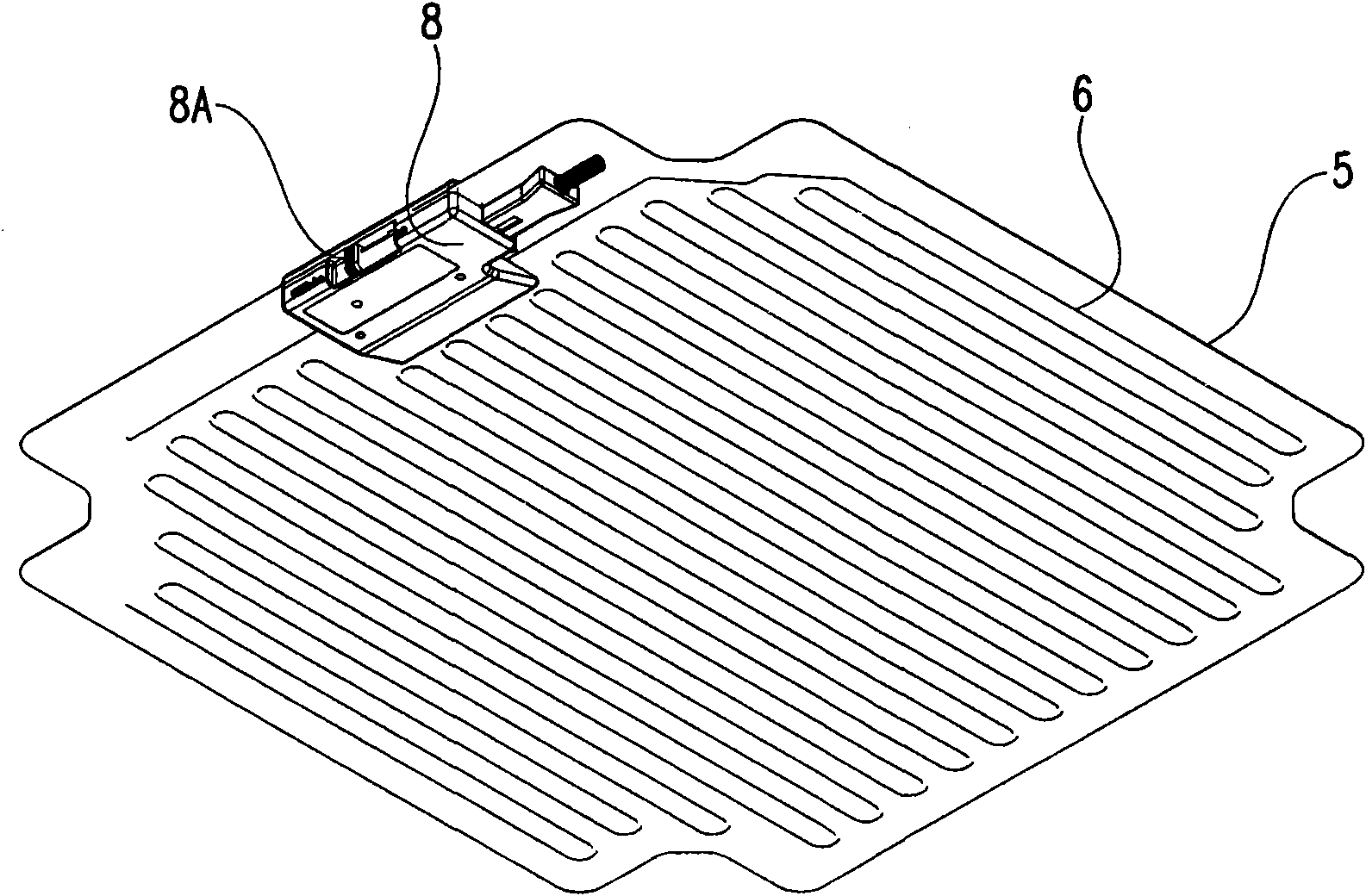

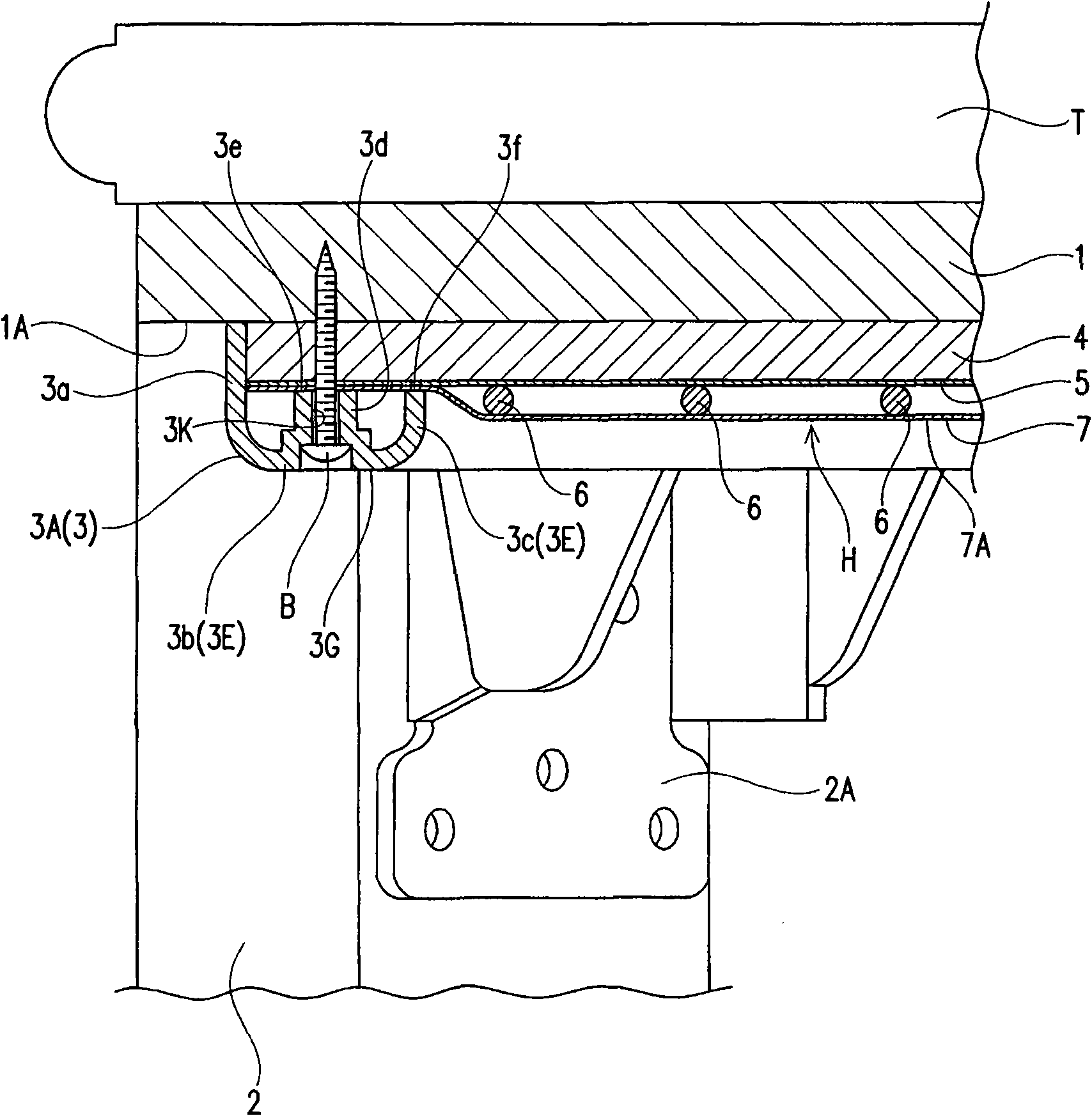

[0023] figure 1 An electric kotatsu with the heating unit of the present invention is shown.

[0024] The electric kotatsu includes an upper plate 1 and four legs 2, the upper plate 1 is arranged on the upper end of the main body of the wooden frame, the upper and lower sides are flat plates, and the top is rectangular ( figure 1 The center is a square, but it can also be a rectangle), four legs 2 are respectively foldably installed at the corners of the four corners of the upper plate 1, and the lower surface of the upper plate 1 is equipped with a planar heating element H that constitutes the heating unit. in addition, figure 1 Shown T is a top plate placed on the above-mentioned top plate 1, and a quilt (not shown) is arranged between the top plate 1 and the top plate T. FIG.

[0025] The said planar heating element H is provided with the controller 8 for ON-OFF, and the electric wire (not shown) with a socket connected to a controller.

[0026] The material of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com