Sealant coating machine

A glue coating machine and sealant technology, which is applied to the device, coating, optics and other directions of coating liquid on the surface, which can solve the problem of measuring the wrong cross-sectional area of the sealant pattern.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, a preferred embodiment of a sealant applicator according to the present invention will be described in detail with reference to the accompanying drawings.

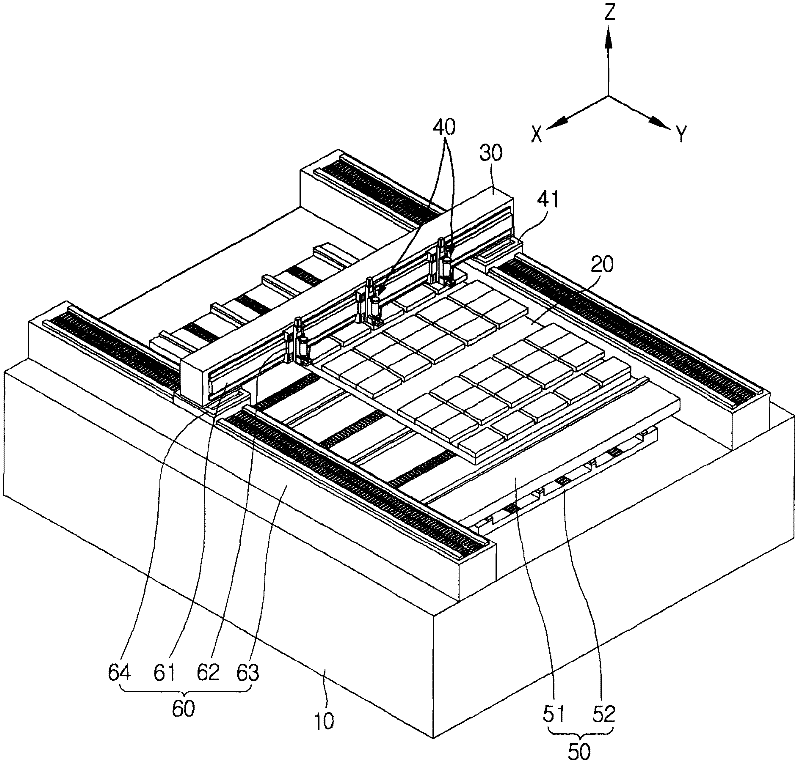

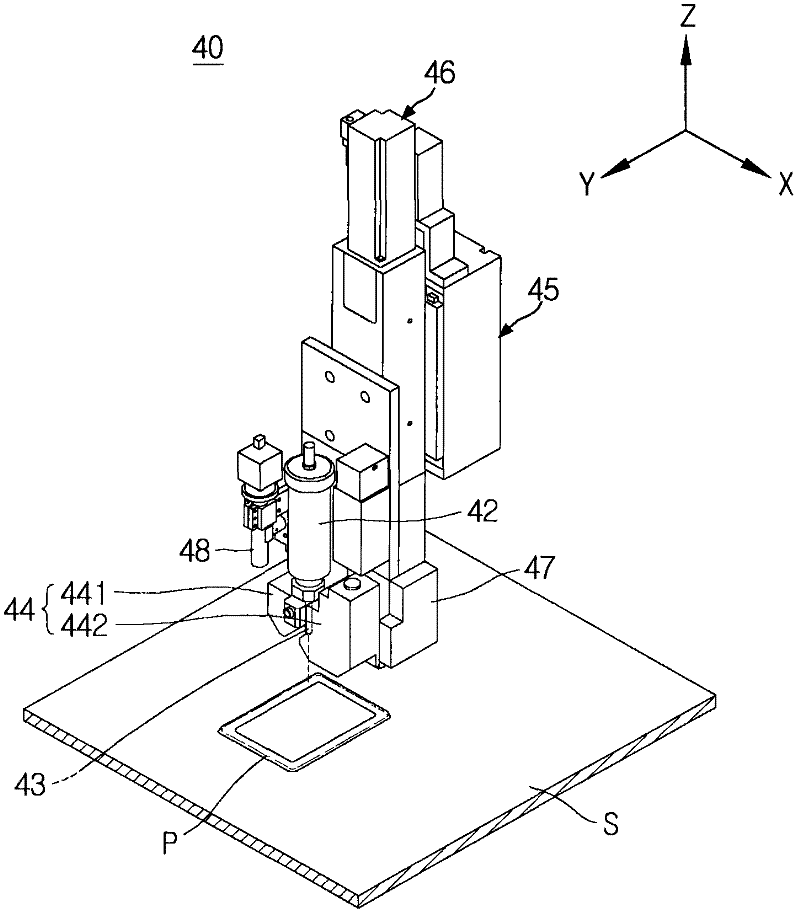

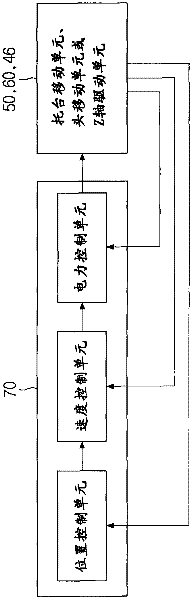

[0023] Such as figure 1 As shown, the sealant coating machine according to the embodiment of the present invention includes a frame 10, a pallet 20, a coating head unit support frame 30, a coating head unit 40, a pallet moving unit 50, a head moving unit 60, and a control unit 70( image 3 show). The pallet 20 is mounted on the frame 10 . The glass panel S is placed on the pallet 20 . The coating head unit support frame 30 is disposed above the pallet 20 and extends a predetermined length along the X-axis direction. The coating head unit 40 is movably supported by the coating head unit support frame 30 . The gantry moving unit 50 is provided on the frame 10, and moves the gantry 20 horizontally. The head moving unit 60 moves the coating head unit 40 horizontally. The control unit 70 controls the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com