Walking protection device and method of material piling and taking machine

A protection device and reclaimer technology, applied in conveyor control devices, conveyor objects, transportation and packaging, etc., can solve problems such as uneven carts, obstacles, and instability, and ensure normal operation The effect of reducing accident losses and improving monitoring capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

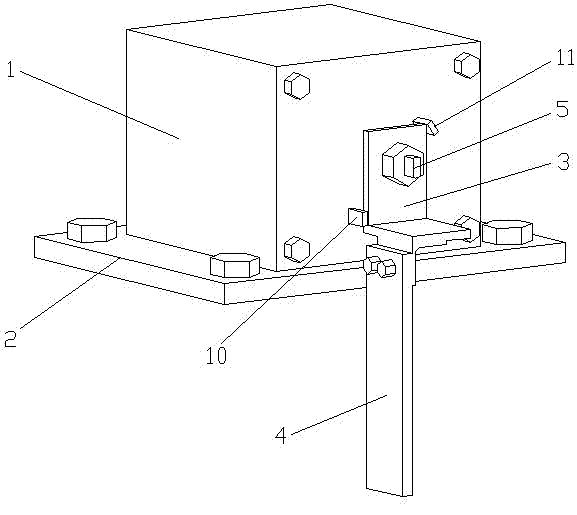

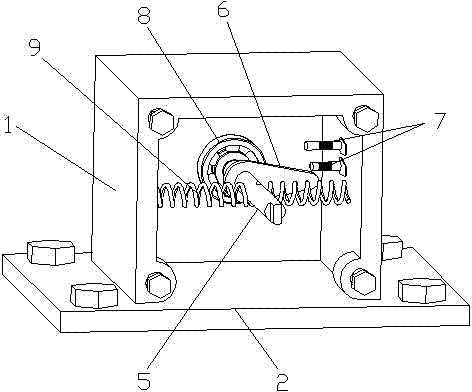

[0018] Such as figure 2 , 3 As shown, a running protection device for a stacker-reclaimer includes a casing 1, a bottom plate 2, a swing block 3, a pressure push plate 4, a rotating shaft 5, a trigger block 6 and a micro switch 7, and the casing 1 is fixedly installed On the bottom plate 2, one end of the rotating shaft 5 passes through the housing 1 and is mounted on the housing 1 through a bearing 8, and the pressure push plate 4 is arranged outside the housing 1 and is fixedly connected with one end of the rotating shaft 5 through the swing block 3, so that The trigger block 6 is set in the casing 1 and fixed on the other end of the rotating shaft 5. Considering the simple structure and the convenience of trigger control, the trigger block 6 in this embodiment is a cam, and the rotating shaft 5 is provided with a return spring. 9. The micro switch 7 is arranged in the housing 1 to cooperate with the trigger block 6 .

[0019] In this embodiment, in order to facilitate ze...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com