Method for detecting angular difference and apparatus for controlling synchronous motor

A technology of synchronous motor and detection method, which is applied in the direction of motor generator control, AC motor control, single motor speed/torque control, etc., can solve problems such as long time, high price, vibration, etc., to prevent vibration, shorten time, Effect of preventing vibration phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

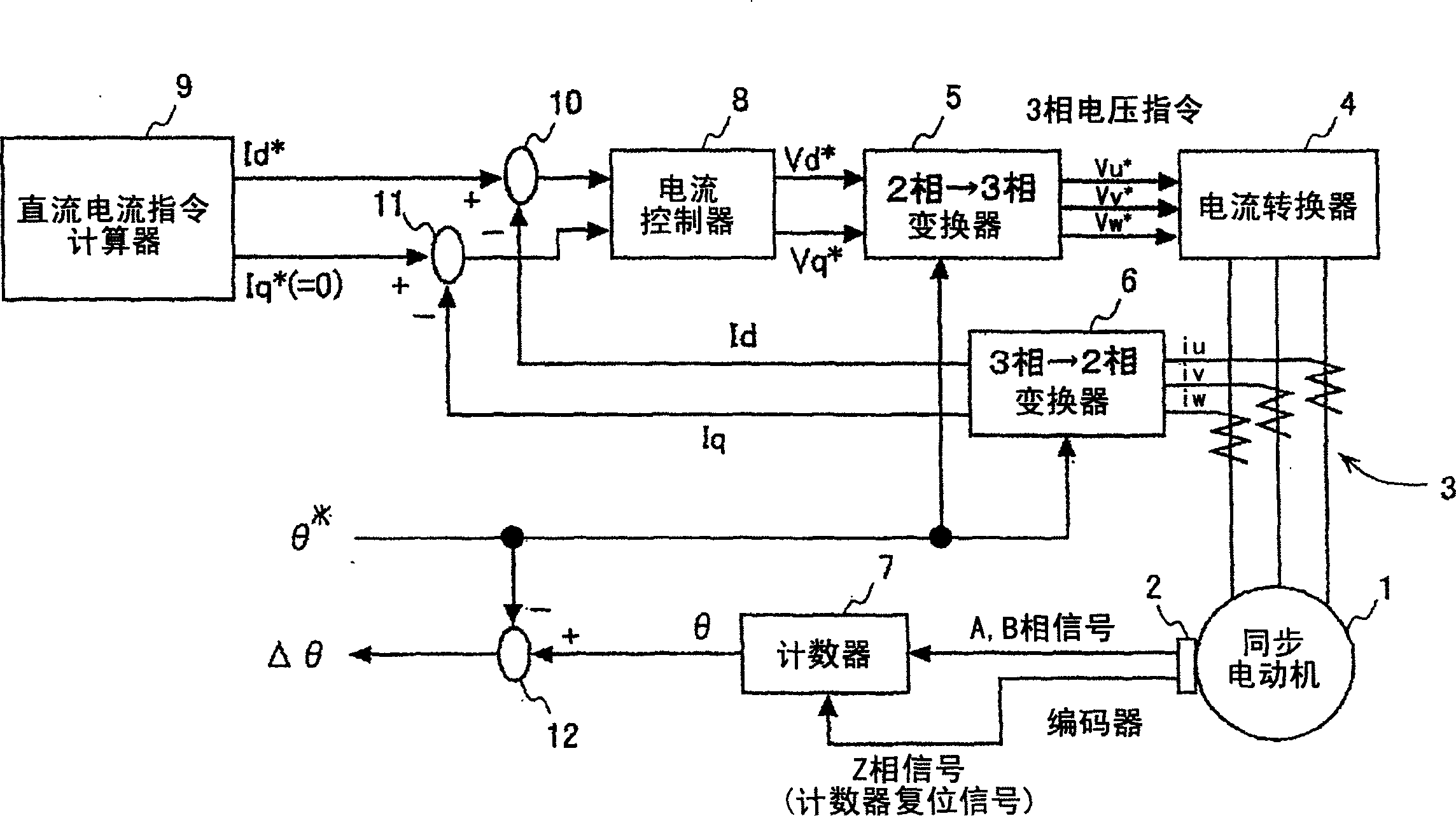

[0031] Hereinafter, the angle difference detection method and the synchronous motor control device of the present invention will be described with reference to the drawings.

[0032] figure 1 It is a schematic diagram for briefly explaining the control apparatus of the synchronous motor of this invention. figure 1 The symbol 1 in the symbol is a permanent magnet synchronous motor, and the incremental encoder 2 outputs the rotation of the permanent magnet synchronous motor 1, detects the direction of forward rotation and reverse rotation, and the position A and B phase signals in one revolution, and as a rotation The Z-phase signal of the reference position signal is output once per revolution.

[0033] Here, the permanent magnet synchronous motor 1 and the incremental encoder 2 are in a state where the rotor magnetic pole position of the synchronous motor 1 does not match the reference position of the encoder.

[0034] In addition, in the figure, symbol 3 is a current detect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com