Production line of seal ring directly formed on part

A production line and sealing ring technology, applied in the field of automation, can solve the problems of low utilization of time and space, poor sealing effect of parts, poor sealing performance, etc., to avoid poor meshing, avoid chain vibration, and prolong service life. Effect

Inactive Publication Date: 2017-12-22

TONGJI UNIV

View PDF5 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The current sealing ring process is generally to produce the sealing ring separately, and then assemble it on the parts after processing. This production process is not only low in efficiency, but also has poor sealing performance. Therefore, a new sealing ring forming process MIP ( Mold-in-place), which directly forms the sealing ring on the part through the injection molding process, but the current injection molding process is different from the traditional injection molding process in terms of mold, injection and molding, and there are many imperfections. Places, such as slow production cycle, poor sealing effect of parts, low utilization rate of time and space

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

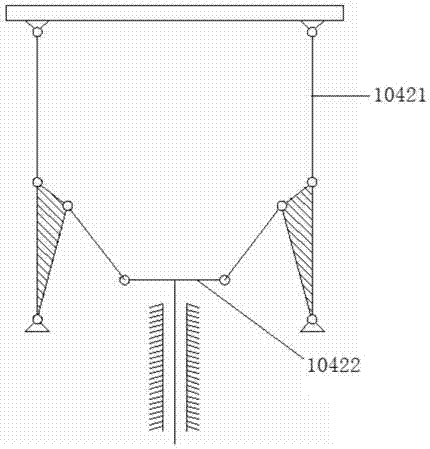

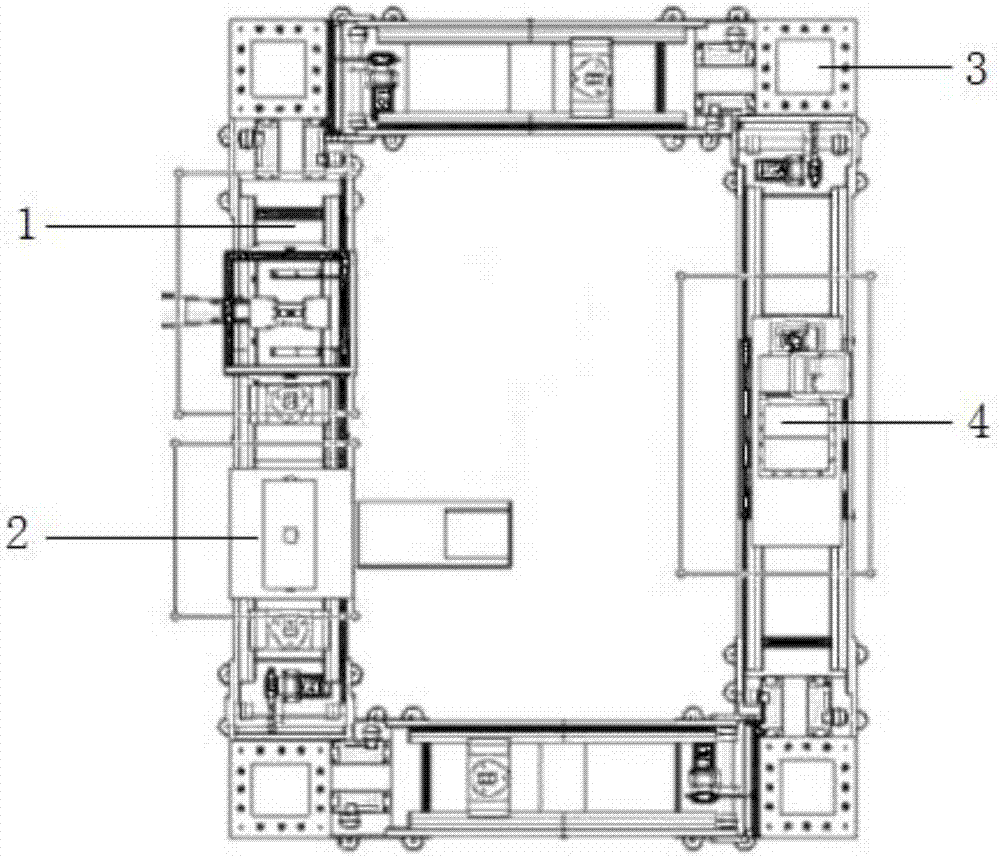

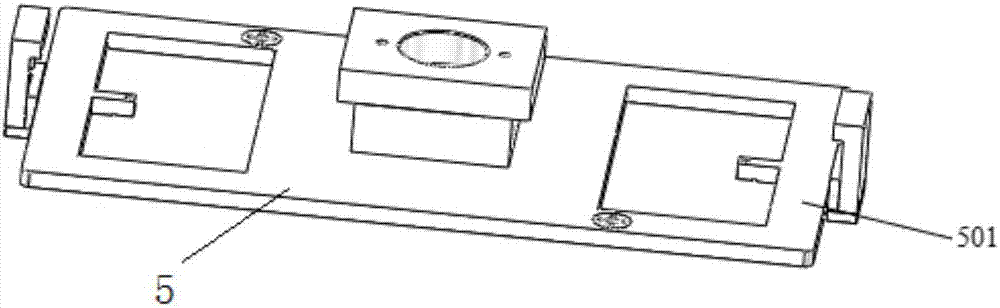

[0037] A production line in which sealing rings are formed directly on parts, such as figure 1 As shown, it includes a mold opening and closing system 1, an injection system 2, a curing system 4, a transportation system 3 and a detection system (not shown). Die 5 structure such as figure 2 , 3 As shown, it consists of an upper mold 501 and a lower mold 502.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a production line of a seal ring directly formed on a part. The production line comprises a die opening and assembling system for opening and assembling a die, an upper die picking and placing mechanism and a lower die lifting mechanism, an injection system for injecting a sizing material to the die, a curing system for curing and forming the sizing material and a transportation system which enables the die to move along stations of the production line. The transportation system comprises a production line body supporting rack and a chain transmission mechanism which drives the die to move; the die opening and assembling system, the injection system and the curing system are successively arranged along the transmission direction of the transportation system; the die is successively loaded by the die opening and assembling system, is injected by the injection system, cured by the curing system, and finally returns to the die opening and assembling system to be unloaded, so that the seal ring is directly formed on the part. The seal ring is directly formed on the surface of the part through an injection molding forming process, and the time utilization ratio and the space utilization ratio are increased in form of the production line.

Description

technical field [0001] The invention belongs to the technical field of automation, and in particular relates to a production line in which sealing rings are directly formed on parts. Background technique [0002] In recent years, my country's automobile industry has developed rapidly. The sealing products used in the automobile manufacturing process are used in automobile structure enhancement, sealing and rust prevention, vibration and noise reduction, heat insulation and noise reduction, fastening and anti-loosening, internal and external decoration, simplified manufacturing process, and lightened body. Application aspects such as weight play a special role. The current sealing ring process is generally to produce the sealing ring separately, and then assemble it on the parts after processing. This production process is not only low in efficiency, but also has poor sealing performance. Therefore, a new sealing ring forming process MIP ( Mold-in-place), which directly forms...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B29C45/14B29C45/17

CPCB29C45/14B29C45/17B29C2045/1785

Inventor 周爱国杨代军杨思静

Owner TONGJI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com