Machining method of kidney-shaped round hole

A processing method and a waist hole technology, which are applied in the field of waist hole processing, can solve the problems of large vibration amplitude of milling cutters and low machining accuracy of waist holes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

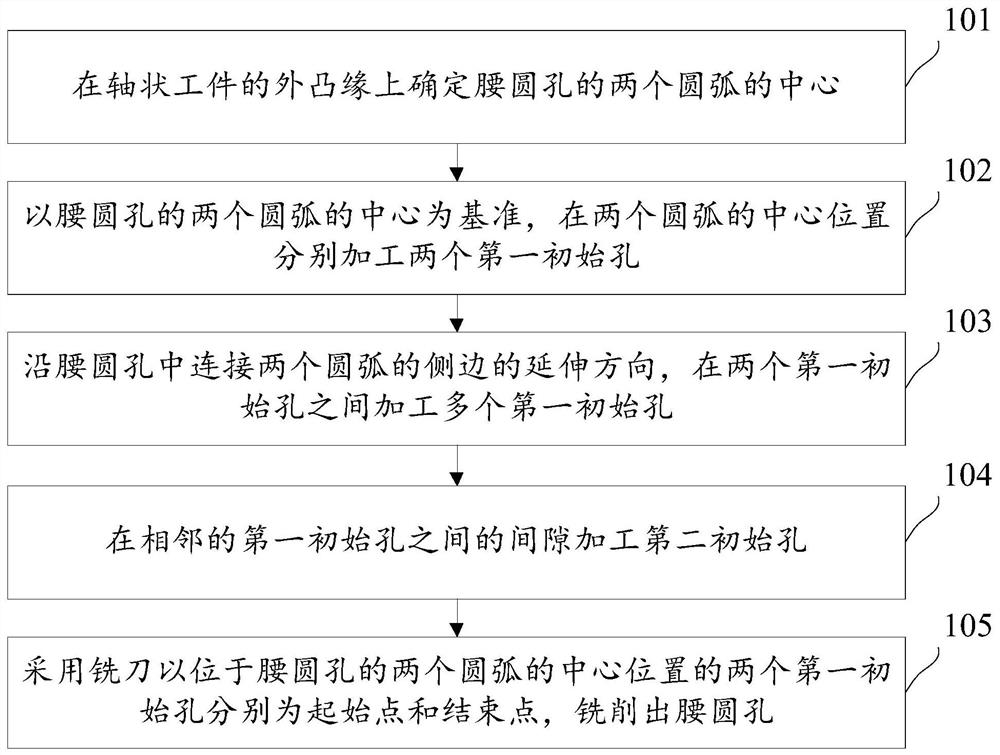

[0023] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

[0024] Hole processing usually includes drilling method, reaming method and milling method. The waist hole is usually processed by milling because of its non-circular shape. Milling refers to a processing method in which the workpiece is fixed and positioned, and a high-speed rotating milling cutter is used to move on the workpiece to cut out the required shape and features.

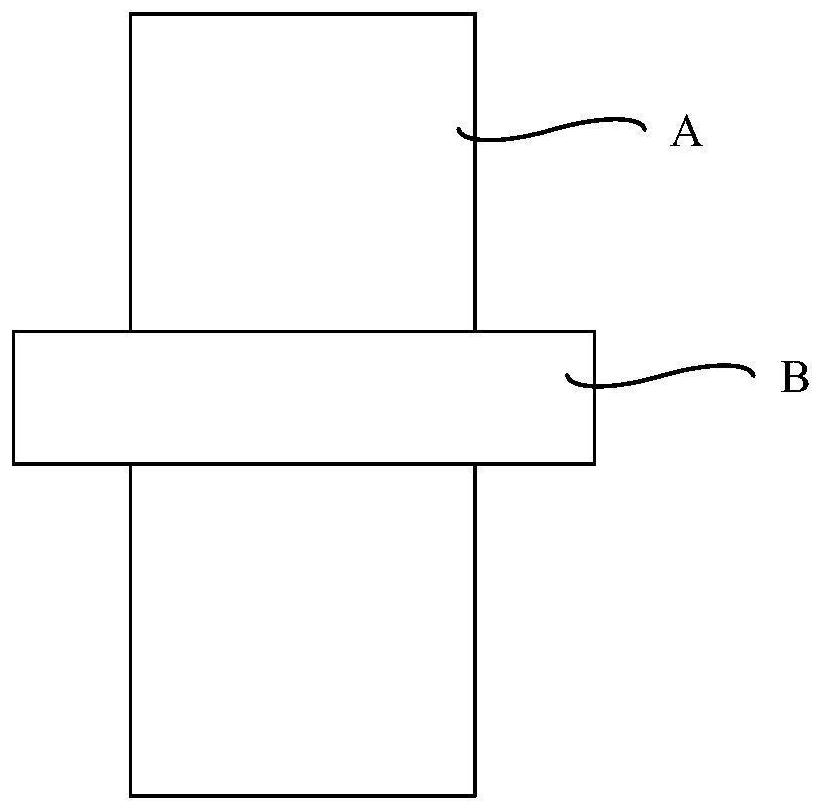

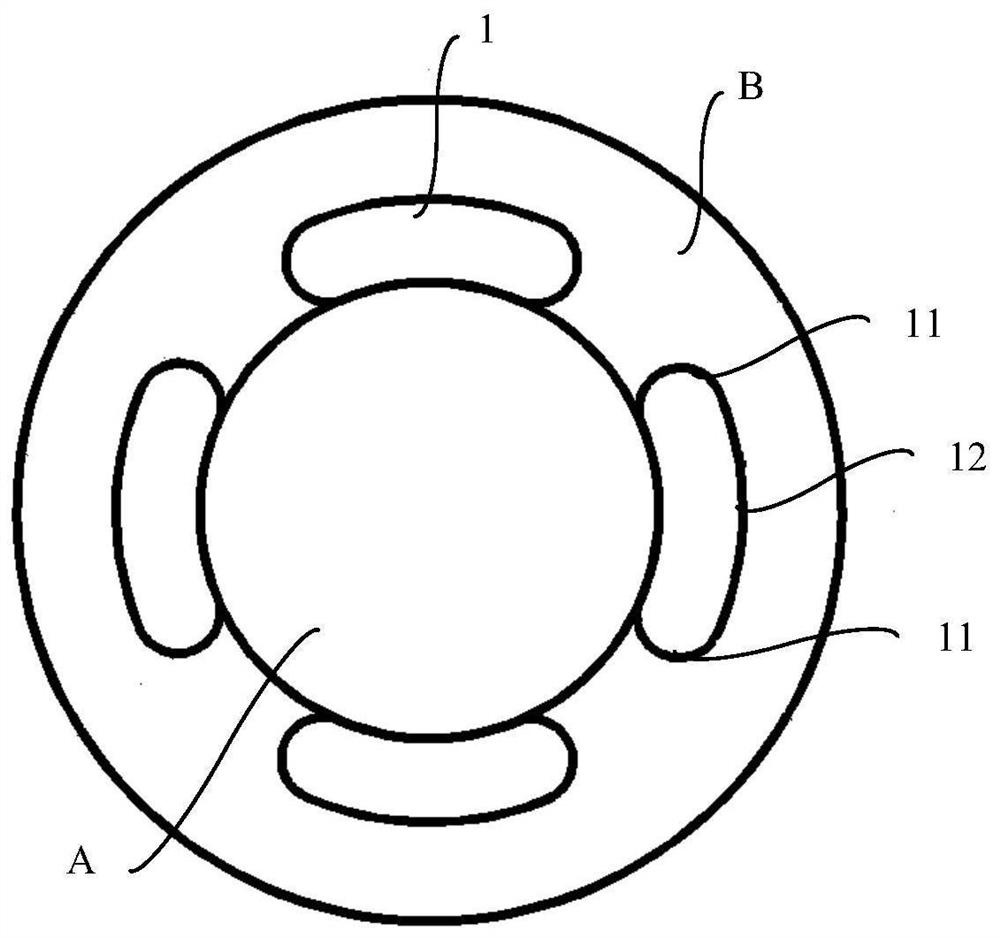

[0025] figure 1 It is a front view of a shaft-shaped workpiece provided by the related art. Such as figure 1 As shown, the shaft-shaped workpiece includes a main shaft A and an outer flange B located in the middle of the main shaft A. Because of the long distance between the end face of the outer flange B and the end face of the main shaft A of this kind ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com