Mould for machining engine main shaft bearing inner ring with inner diameter oil groove and machining method

A technology for spindle bearings and bearing inner rings, applied in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve problems such as poor dimensional accuracy, achieve small radial resistance, ensure accuracy, and reduce cutting force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

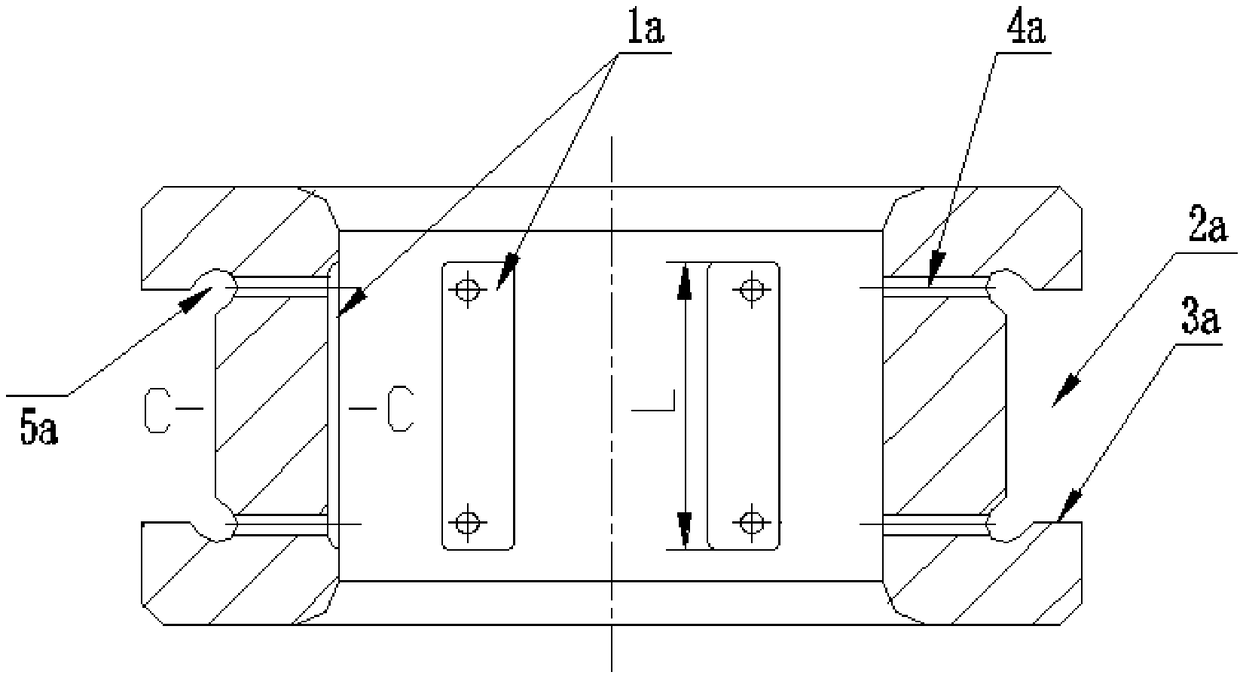

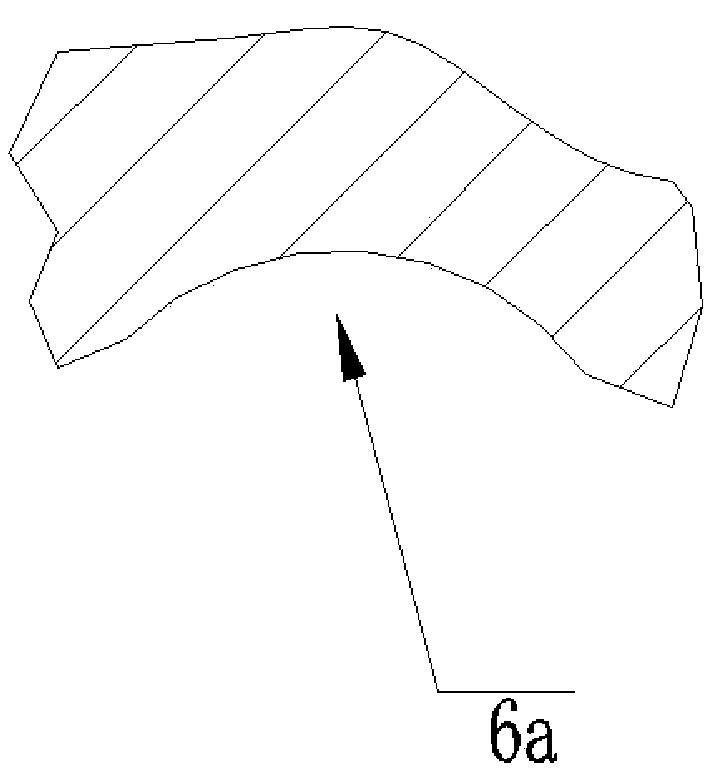

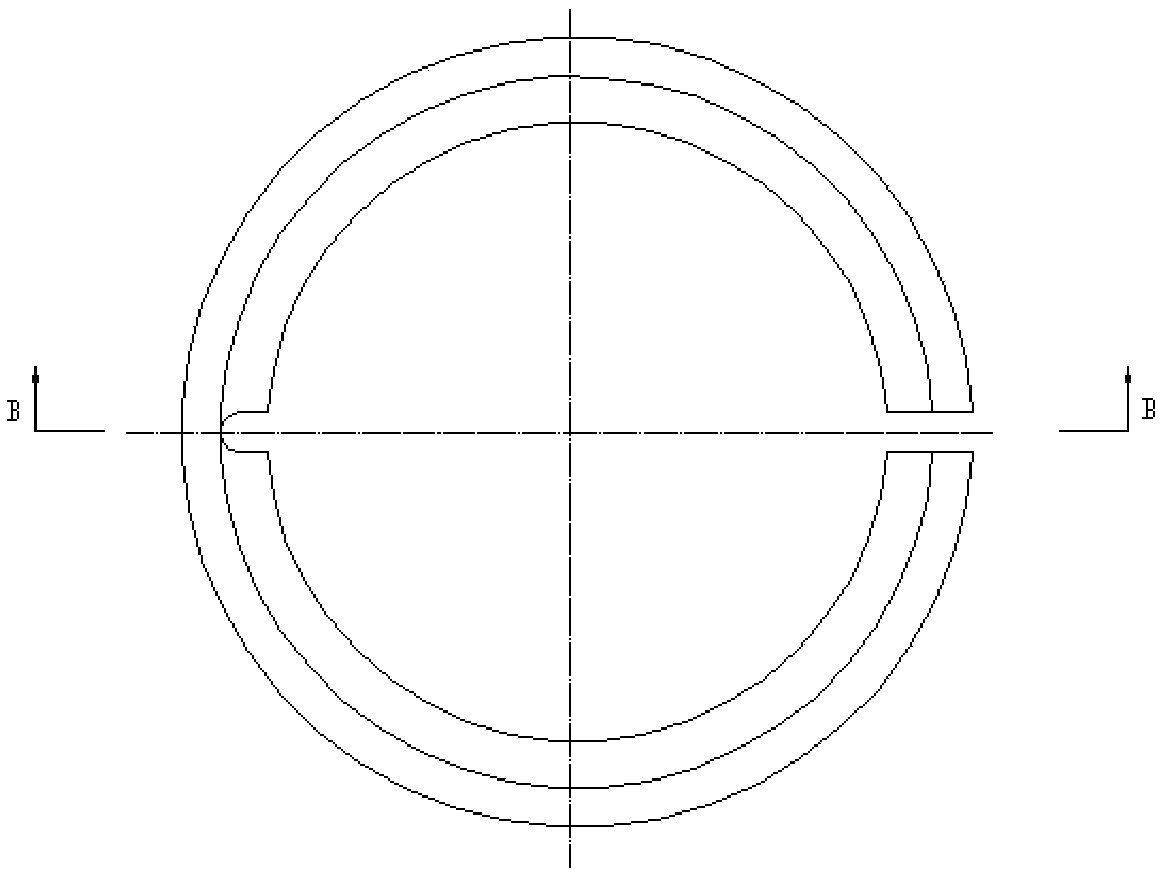

[0037] Specific implementation mode one: combine Figure 1-8 Describe this embodiment, the mold used in this embodiment to process the inner ring of the engine main shaft bearing containing the inner diameter oil groove is composed of a mold base 1, a pressure plate 2 and a connecting bolt 3;

[0038] The lower part of the mold base 1 is a cylindrical clamping part, the upper end of the mold base 1 is a circular supporting plane, the supporting plane is provided with an annular flange, and the center of the supporting plane is provided with a threaded hole; the pressing plate 2 is a disc shape, the center of the pressing plate 2 is provided with a circular through hole, and the circumference of the pressing plate 2 is uniformly provided with half-waisted notches equal to the number of inner diameter oil tanks, and one of the half-waisted notches communicates with the circular through-hole arranged at the center of the pressing plate 2; The center line of 2 is set coaxially wit...

specific Embodiment approach 2

[0043] Embodiment 2: This embodiment differs from Embodiment 1 in that: the outer diameter of the cylindrical clamping portion is smaller than the outer diameter of the supporting plane. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0044] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: 6 semi-waist-shaped notches are uniformly arranged on the circumference of the pressing plate 2 . Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com