Bolt and method of mfg. bolt

A manufacturing method and technology of bolts, applied in the directions of bolts, screws, nuts, etc., can solve the problems of reduced mechanical strength, failure to consider the durability and strength of thread parts, thread synchronization, and increase of thread truncated parts, etc., to prevent mechanical strength. The effect of reducing, improving the utilization rate of raw materials, and easy quality management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

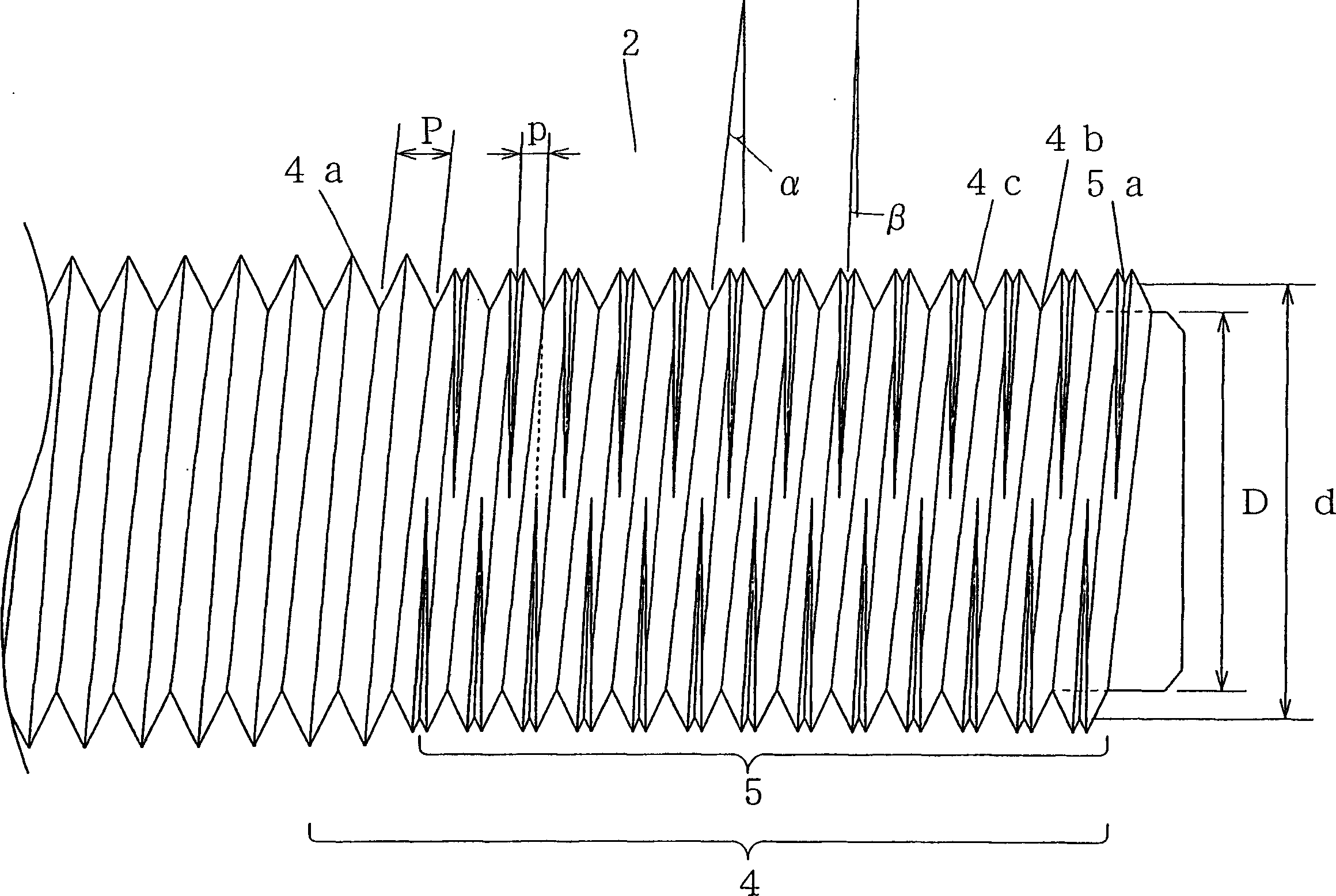

[0138] On a bolt having an outer diameter of 12 mm and a coarse thread portion with a pitch P=1.75 mm, a fine thread portion with a pitch p=0.875 mm (p=1 / 2P) was cut out with a manual die thread.

[0139] Figure 10 It is a side view of the main part of the bolt manufactured in Example 1.

[0140] exist Figure 10 Among them, 51 is the bolt produced in Example 1, 52 is the coarse thread portion of the bolt 51, and 53 is the fine thread portion cut out on the thread.

[0141] like Figure 10 As shown, it can be seen that the fine thread portion 53 (the root portion of the thread) is neatly formed on the coarse thread portion 52, making the appearance more beautiful.

[0142] It can be seen from the following that although the size of the bolt can be changed into various sizes, it has nothing to do with the size of the bolt, as long as the relationship between the pitch of the coarse thread part and the pitch of the fine thread part is an integer multiple, then The fine thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com