Three-degree-of-freedom spherical space robot wrist

A space robot and degree-of-freedom technology, applied in the directions of manipulators, manufacturing tools, joints, etc., can solve the problems of motion coupling, large weight, low integration, etc., and achieve the effect of friction compensation, compact structure, and simple processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

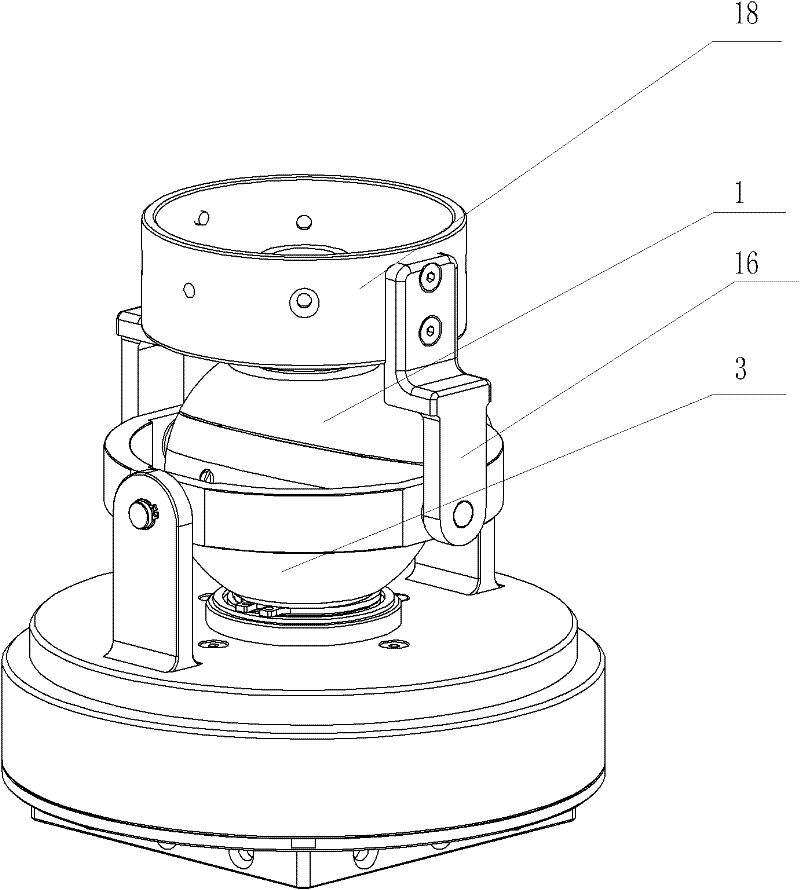

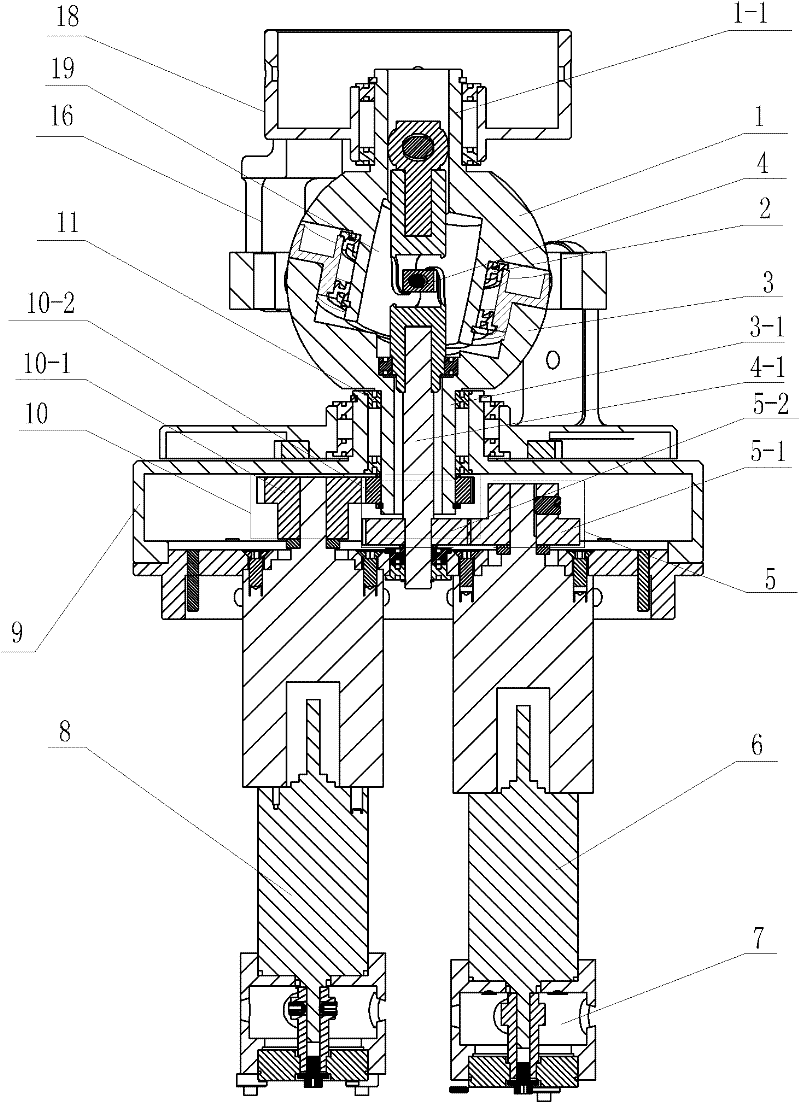

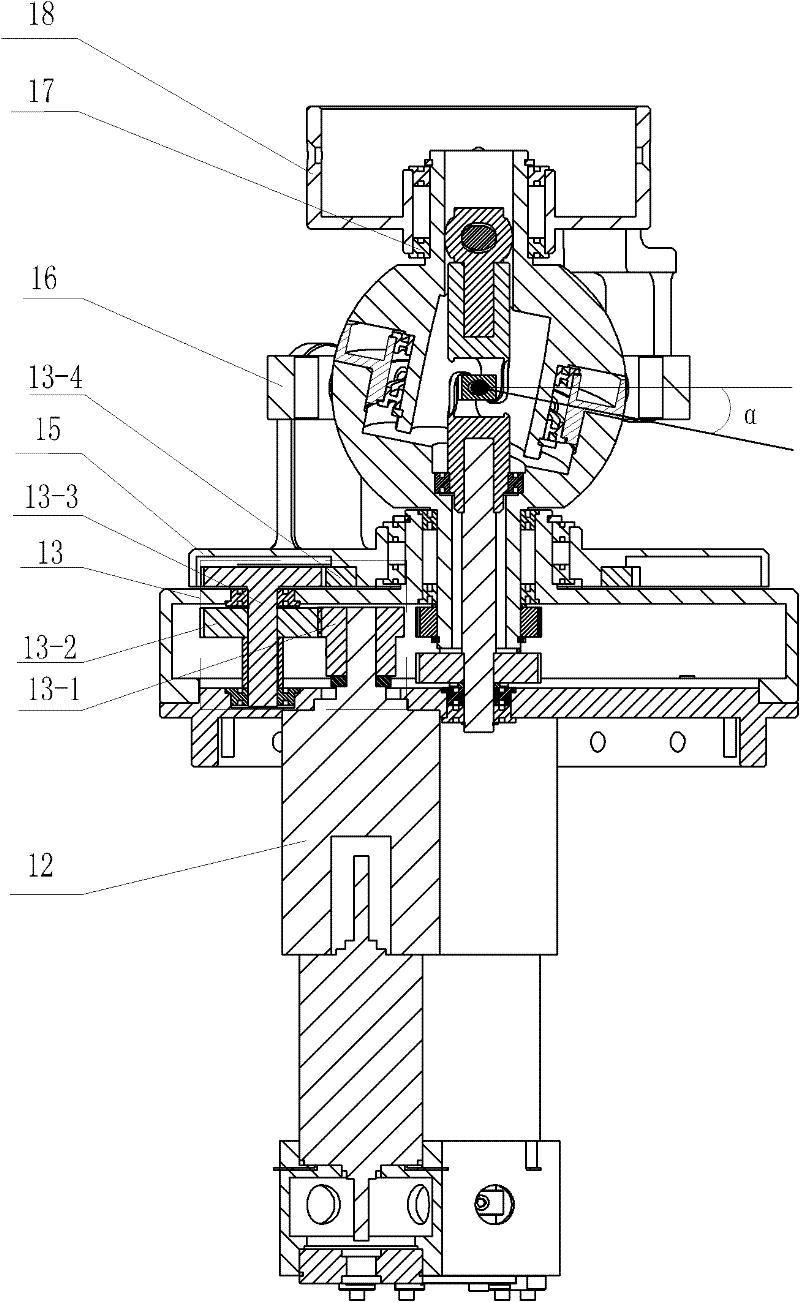

[0021] Specific implementation mode one: combine Figure 1-Figure 3Describe this embodiment, the wrist of this embodiment comprises spherical assembly, upper hemispherical gear transmission mechanism 5, upper hemispherical motor and deceleration mechanism 6, lower hemispherical motor and deceleration mechanism 8, frame 9, lower hemispherical gear transmission mechanism 10, rotation Motor and reduction mechanism 12, self-rotation gear transmission mechanism 13, turntable 15, external universal joint 16, end effector interface 18 and three absolute angle sensors 7, the spherical assembly includes upper hemispherical shaft 1-1, upper hemisphere 1, lower The hemisphere 3, the lower hemisphere shaft 3-1, the inner universal joint 4 and the inner universal joint shaft 4-1, the upper hemisphere shaft 1-1 and the upper hemisphere 1 are coaxially arranged and integrated, and the upper hemisphere shaft 1-1 and The end effector interface 18 is rotatably connected, the upper hemisphere 1 ...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination figure 2 To illustrate this embodiment, the wrist of this embodiment also includes a thin-walled bearing 2, and the upper hemisphere 1 and the lower hemisphere 3 are rotatably connected by the thin-walled bearing 2, which can ensure that the upper hemisphere axis 1-1 is around the normal line of the offset slope of the lower hemisphere 3 Rotate freely so that the working space of the upper hemispherical shaft 1-1 at the output end takes the normal line of the offset slope as the axis and a cone with a cone angle of 2α. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0027] Specific implementation mode three: combination figure 2 Describe this embodiment, the wrist of this embodiment also includes a flange bearing 11, the lower hemispherical shaft 3-1 and the frame 9 are rotationally connected through the flange bearing 11, which can ensure the free rotation of the lower hemisphere 3 around the central axis of the frame 9, Make the lower hemisphere 3 offset slope normal rotate 360° around the central axis of the frame 9, and then expand the working space of the upper hemispherical shaft 1-1 at the output end to a cone with a cone angle of 4α around the central axis of the frame 9. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com