Method for composite machining of blisk flow passage

An integral blisk and composite machining technology, applied in the field of aero-engines, can solve the problems of narrow tool space in the flow channel area, unsuitable control of the machining process, serious tool wear, etc. The effect of increased durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

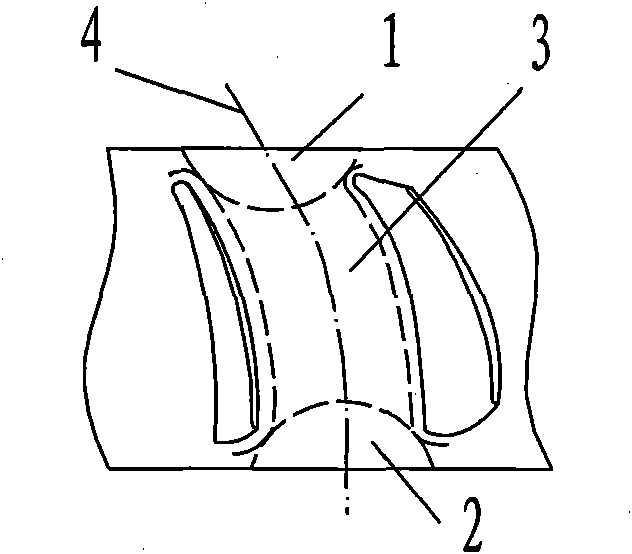

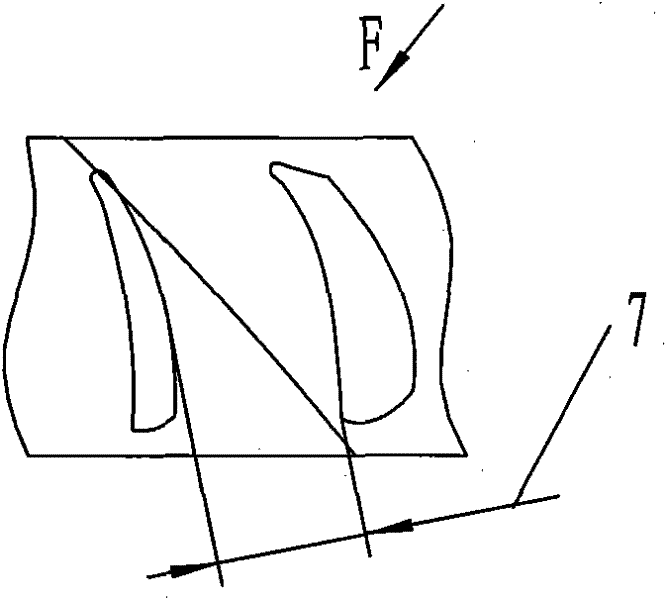

[0063] Such as image 3 with Figure 4 As shown, a compressor blisk is processed, the blisk is composed of a disc and blades, the material is titanium alloy, the blade length = 60mm, the blade width = 50mm, the minimum blade distance = 10mm, and the minimum machining allowance is 1mm.

[0064] According to a method for compound processing of the overall blisk flow channel of the present invention, the specific processing steps are as follows:

[0065] Step 1: Division of processing areas:

[0066] 1. Tool diameter D=10×2=20mm.

[0067] 2. Airfoil safety distance=1+0.2=1.2mm.

[0068] 3. Airfoil safety clearance = 1mm.

[0069] 4. Determine the triangular area: such as figure 1 As shown, using the CAD model, on the vertical projection plane,

[0070] (1) Determine the edge projection contour line of the leaf back of the adjacent blade and the leaf pot;

[0071] (2) Considering the machining allowance of the rough opening channel, the most edge contour line area is offset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com