Bidirectional hydraulic lock

A two-way hydraulic lock and one-way valve technology, applied in the direction of fluid pressure actuators, valve details, engine components, etc., can solve problems such as equipment abnormalities, large propulsion strokes, and vibrations, and achieve the goal of improving service life and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

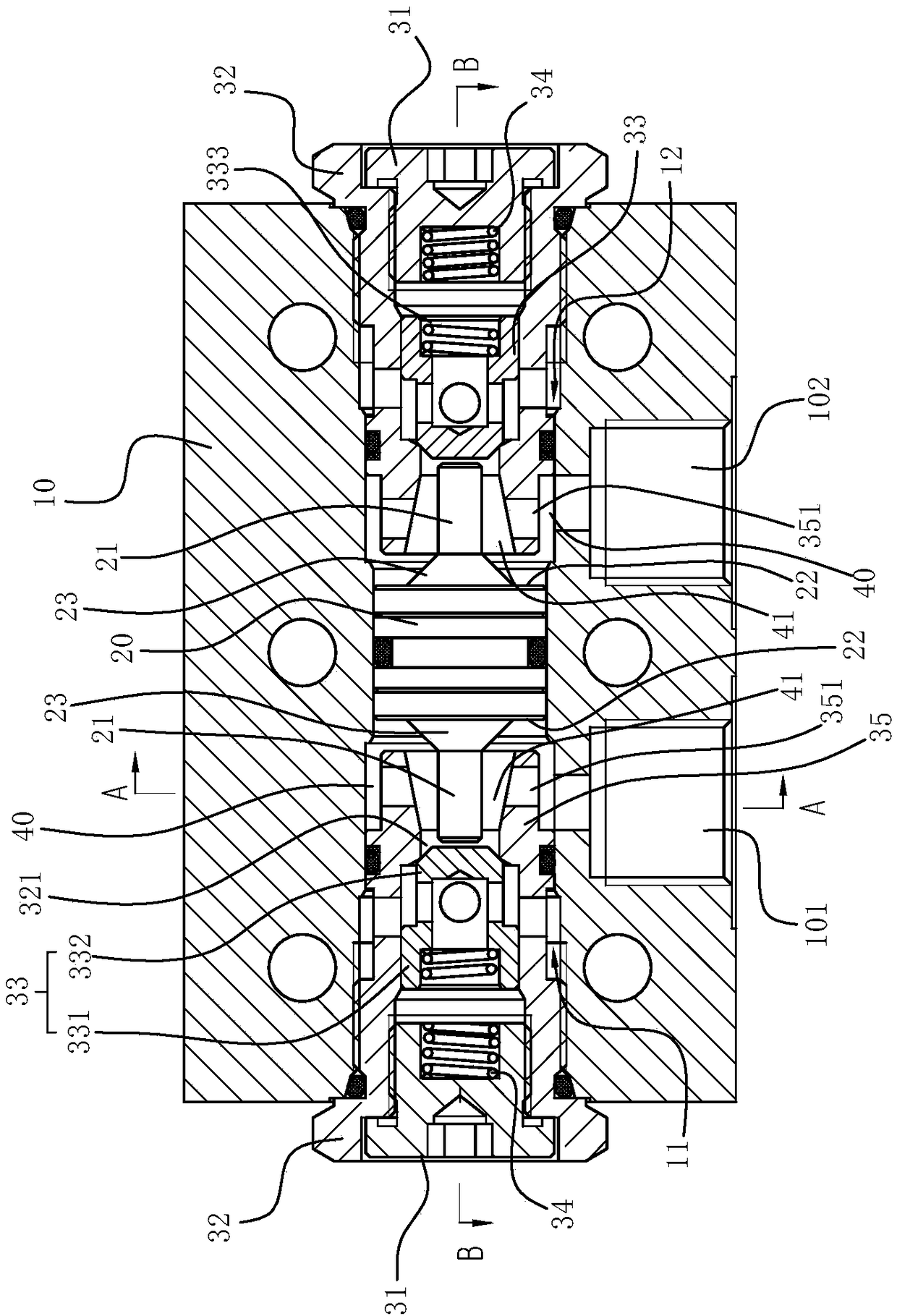

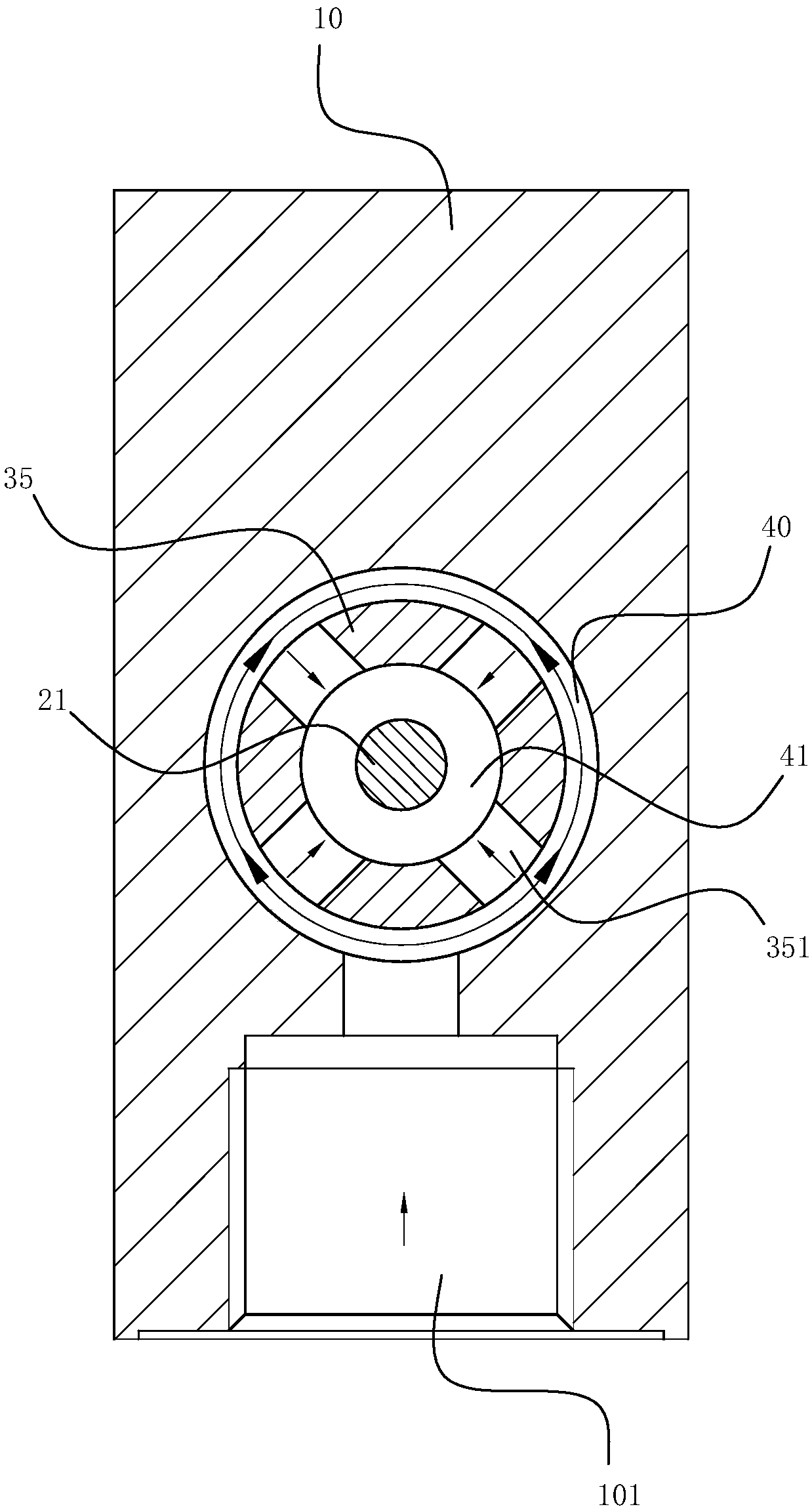

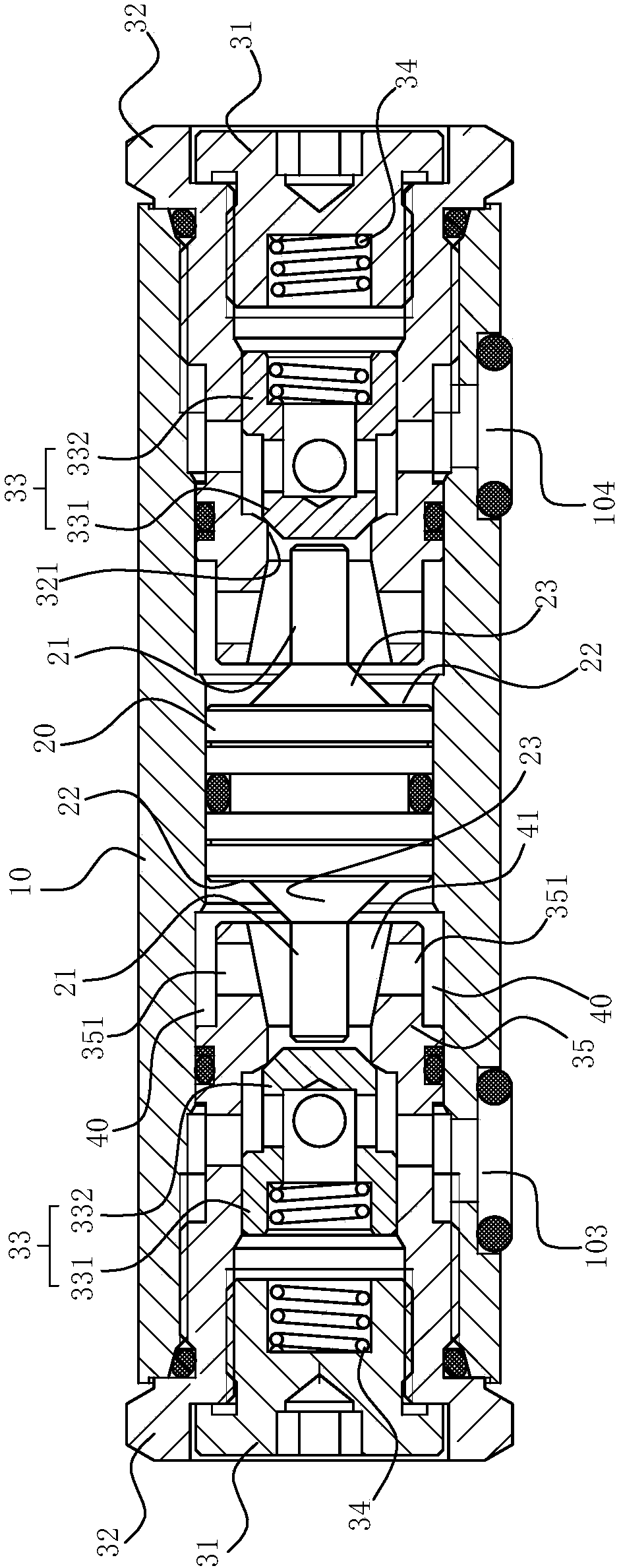

[0023] Such as Figure 1 ~ Figure 3 As shown, the two-way hydraulic lock includes a valve body 10, a plunger 20 and a one-way valve, wherein the valve body 10 has a coaxial first valve chamber 11 and a second valve chamber 12, and the plunger 20 is slidably arranged on the valve body 10, and isolate the first valve chamber 11 from the second valve chamber 12, there are two check valves, which are respectively located in the first valve chamber 11 and the second valve chamber 12, refer to Figure 4 , in this embodiment, the one-way valve includes an end cover 31, a valve sleeve 32, a valve core 33, and an elastic member 34 disposed in the inner cavity of the valve sleeve 32 and held between the end cover 31 and the valve core 33, Wherein, the valve sleeve 32 has a valve port 321, the valve core 33 can be movably arranged in the inner cavity of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com