Machining method for large box body hole series and jig cutter box

A processing method and tooling tool technology, which are applied in the processing method of large-scale box hole systems and the field of tooling tool boxes, can solve the problems that cannot meet the needs of high-precision large-scale box hole processing, and the distance between the 3 spindles of the boring machine and the tailstock of the boring machine is far away. It does not meet the manufacturing precision requirements of large-scale cabinets, and achieves the effects of avoiding vibration, simple and practical processing, and light weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

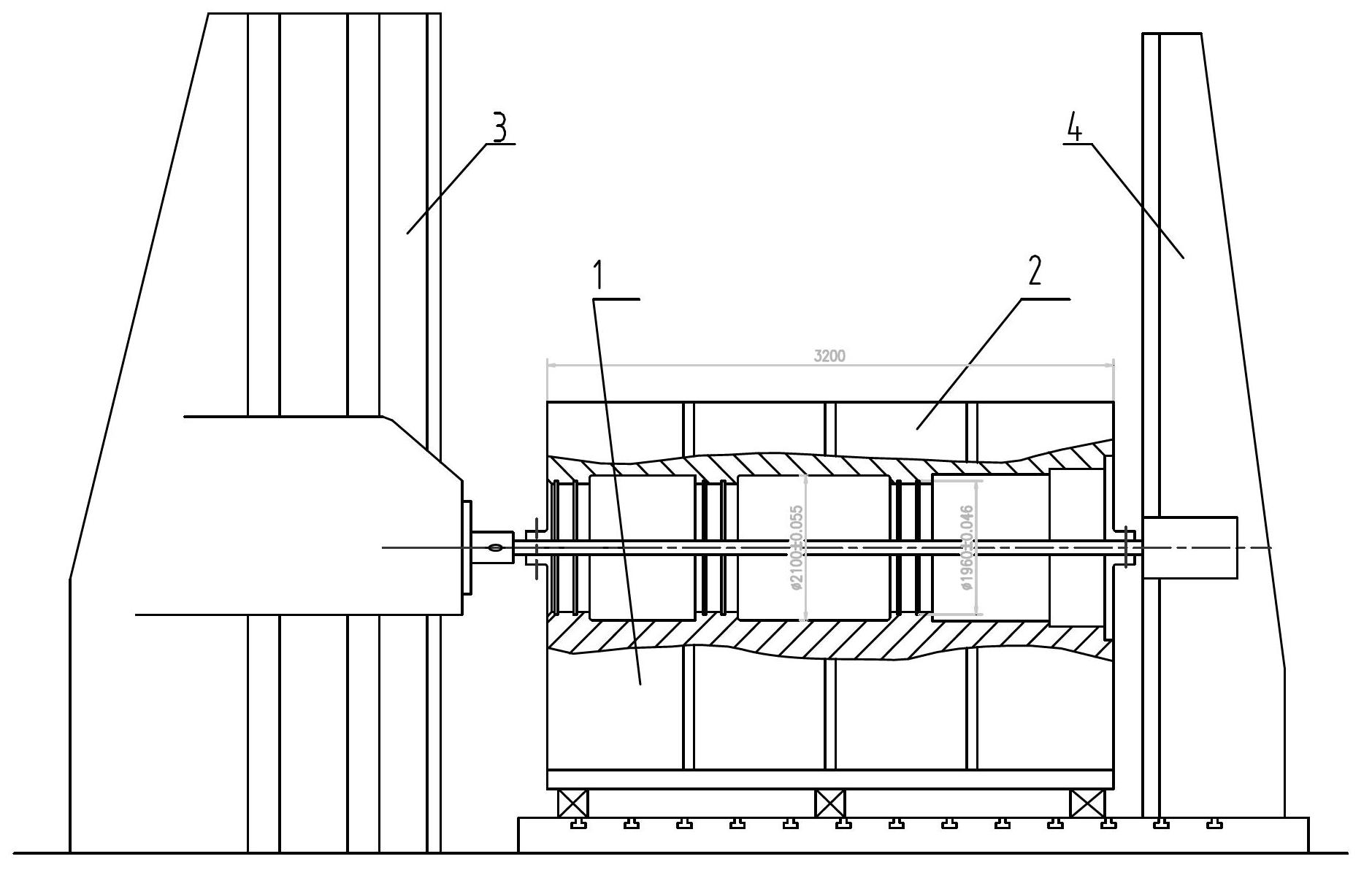

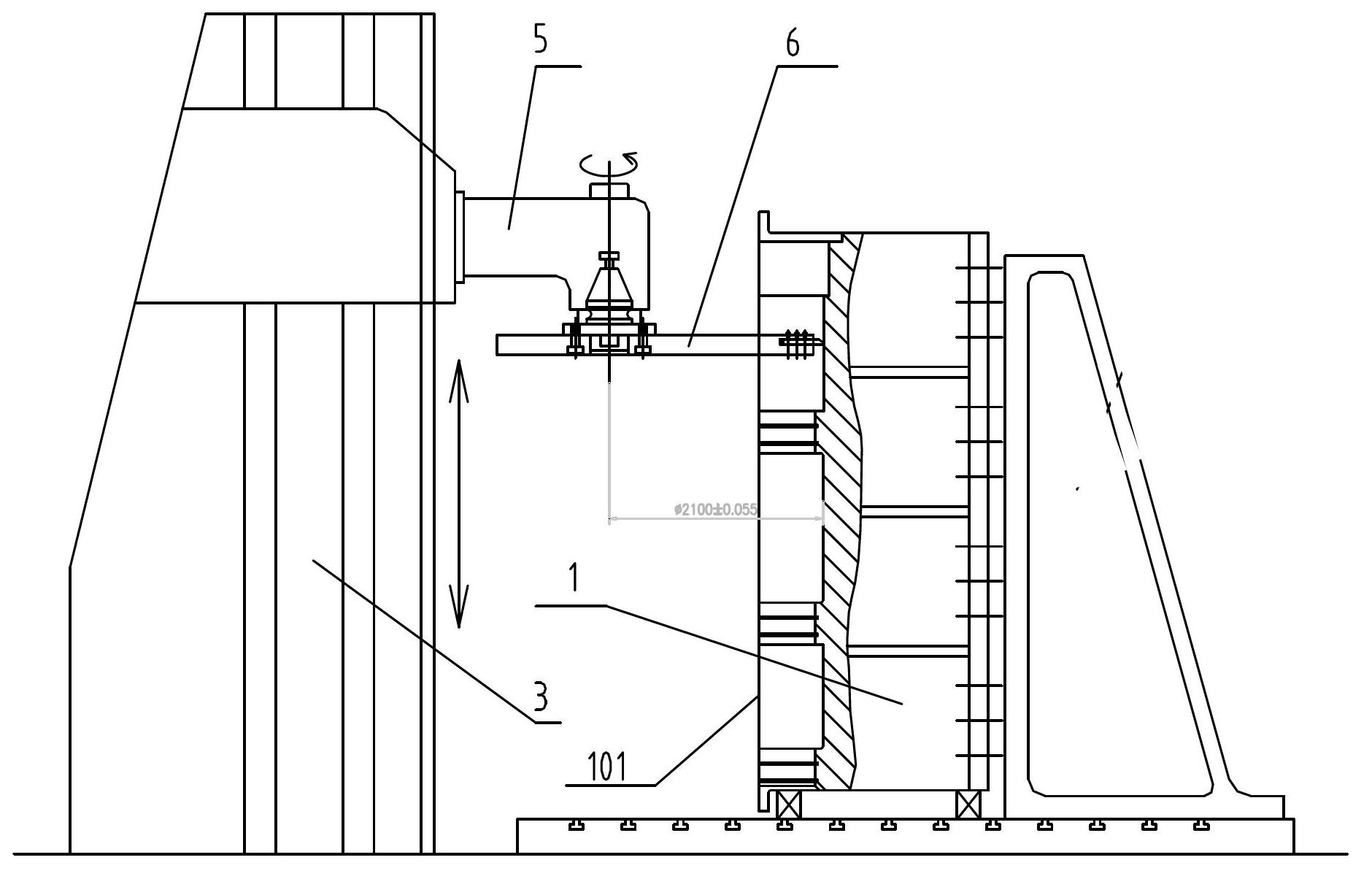

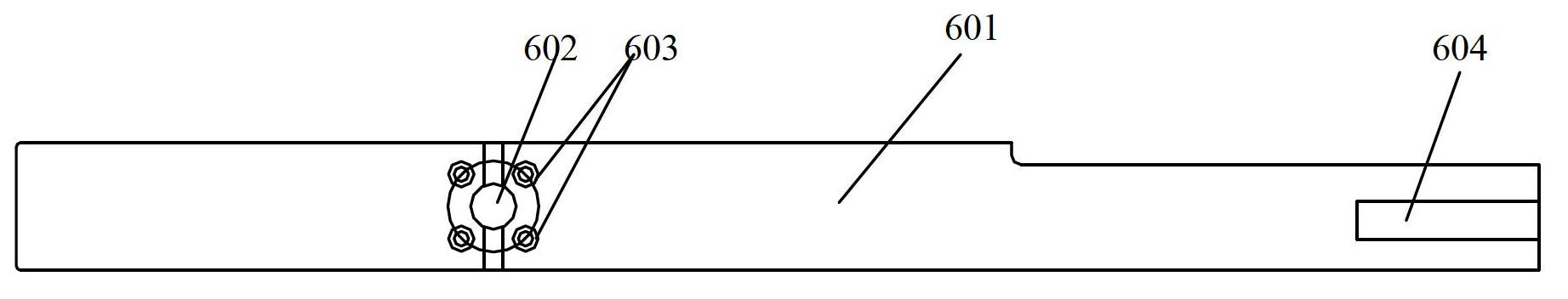

[0025] The present invention is described in further detail below in conjunction with accompanying drawing:

[0026] The processing method of this kind of large-scale box hole system proposed by the present invention breaks the thinking of the traditional processing technology, which is to carry out boring processing on the upper box body 2 and the lower box body 1 of the large-scale box body in the state of separately existing respectively , The clamping method during processing ensures that the centerline of the main shaft of the boring machine 3 and the axis of the hole system are perpendicular to each other, and the vertical milling head 5 is used to process the hole system. see figure 2 , the processing method specifically includes the following steps:

[0027] 1) First process the horizontal datum for clamping on the side of the upper box 2 or the lower box 1;

[0028] 2) Install the upper box 2 or the lower box 1 on the ground platform of the horizontal floor boring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com