Car shell model manufacturing tool

A technology for making tools and models, which is applied in the field of car shell model making tools, can solve the problems of reducing the reuse efficiency of oil sludge, and achieve the effect of improving operation efficiency and recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further detailed explanation through specific implementation mode below:

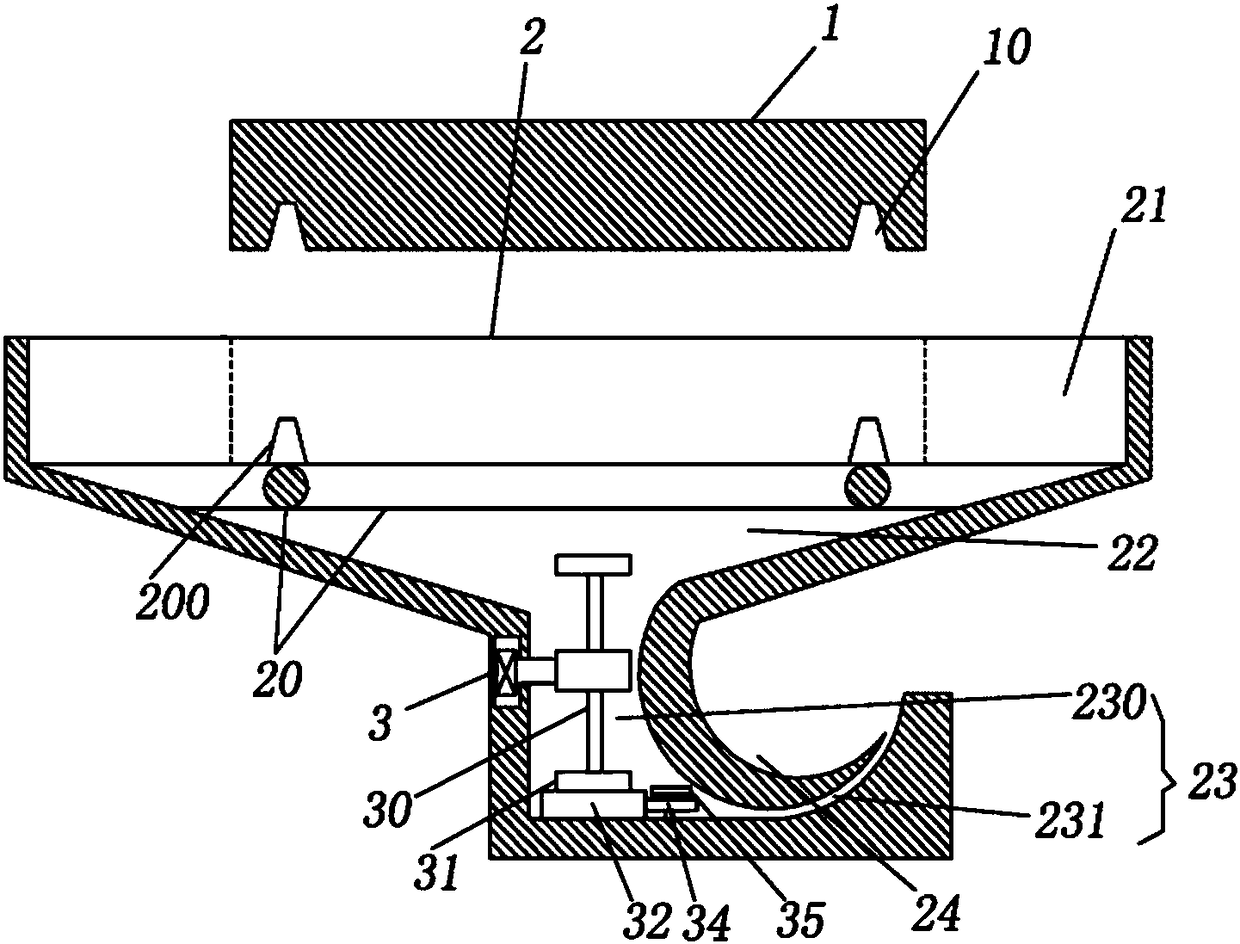

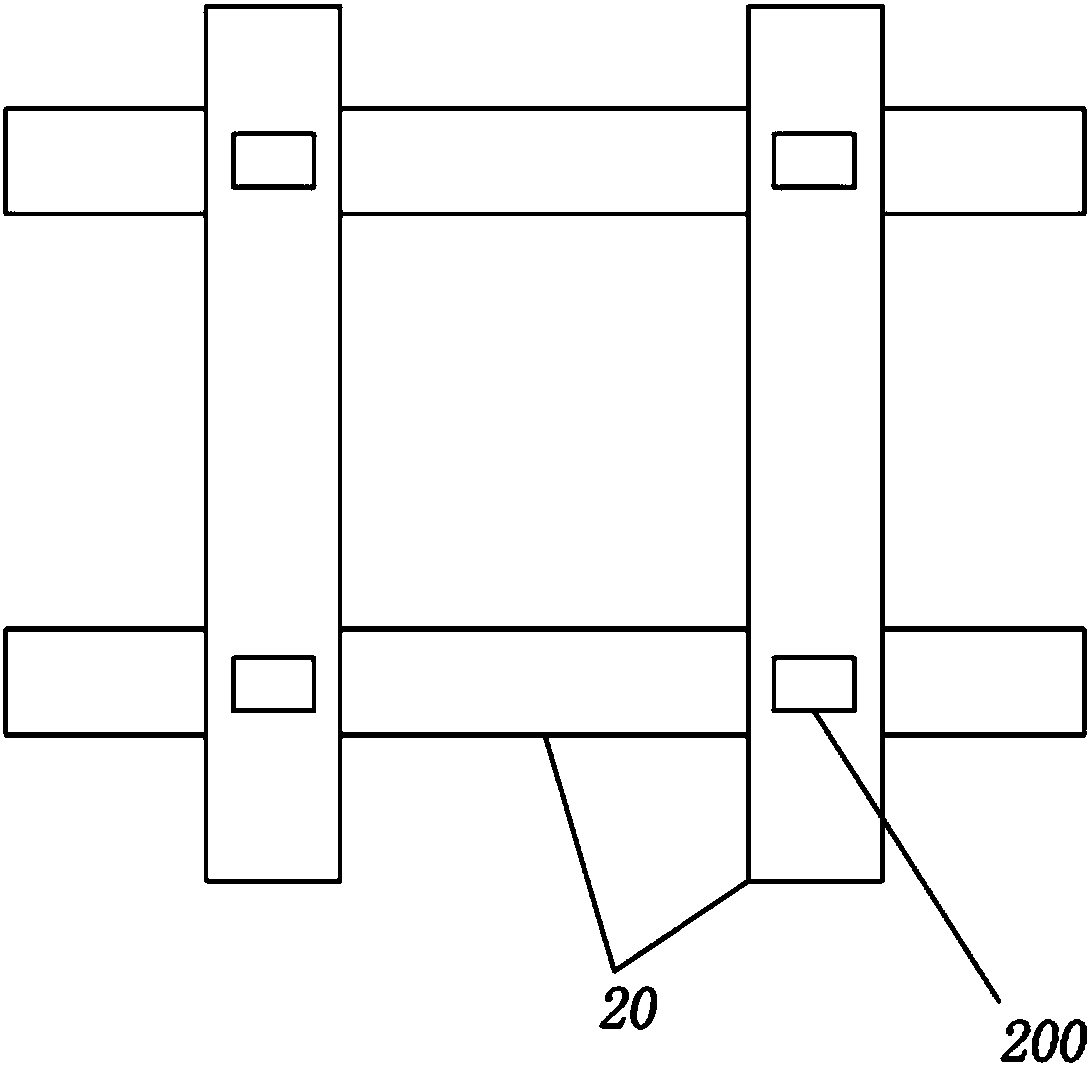

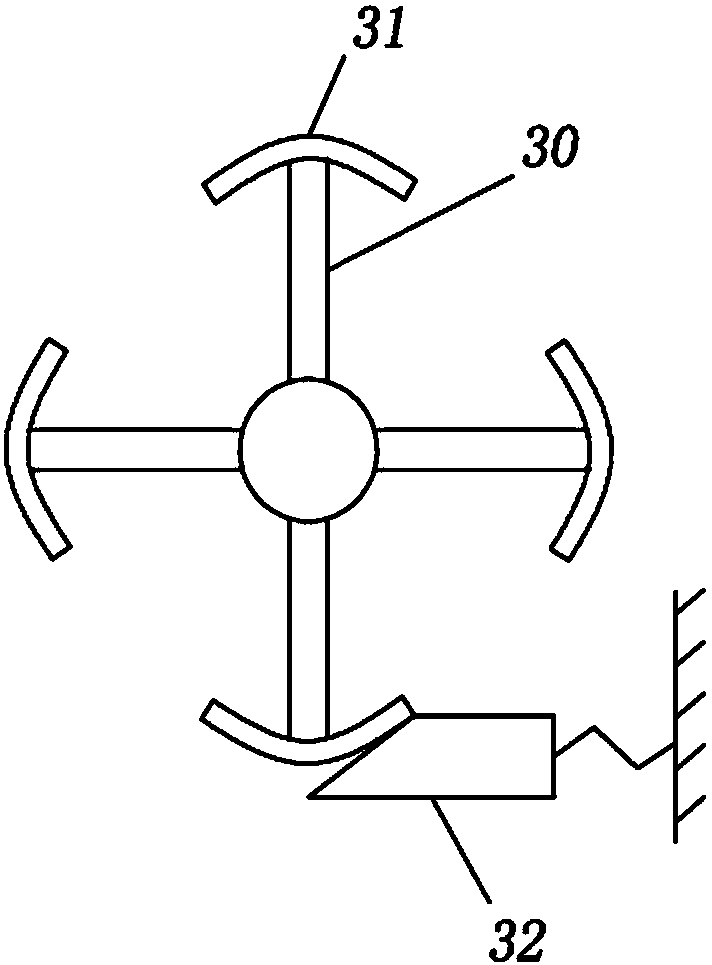

[0018] The reference signs in the drawings of the description include: workbench 1, groove 10, recovery box 2, support frame 20, bump 200, blanking chamber 21, receiving chamber 22, returning chamber 23, crushing chamber 230, forming Cavity 231 , collecting tank 24 , motor 3 , crushing rod 30 , extruding part 31 , wedge block 32 , ratchet 33 , ratchet wheel 34 , extruding disc 35 .

[0019] The embodiment is basically as figure 1 Shown: the car shell model making tool, including a workbench 1, and a recycling box 2 with a hollow design.

[0020] The top of the recovery box 2 has an opening, preferably the top of the recovery box 2 is in the shape of a box, and the top of the workbench 1 and the recovery box 2 form a frame-shaped blanking cavity 21 .

[0021] The middle part of the recovery box 2 has a material receiving cavity 22 communicated with the blanking cavity 21; the cross-sectional are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com