Ultrasonic, H2O2 and microchannel advanced oxidation method and device

A technology of H2O2 and microchannel, applied in chemical instruments and methods, separation methods, oxidized water/sewage treatment, etc., can solve the problems of large equipment investment, limited technology application, high treatment cost, etc., and achieve the effect of safe treatment and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

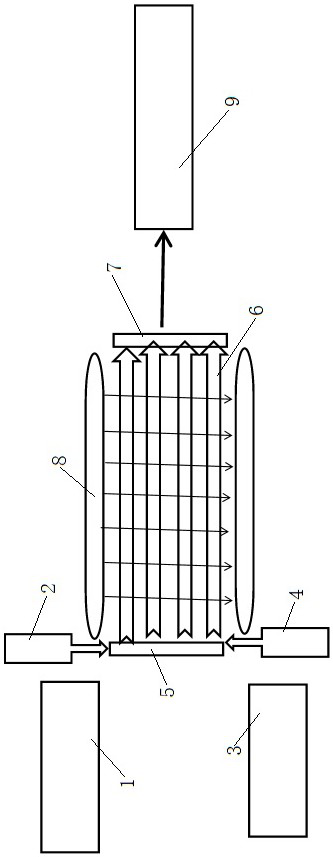

Image

Examples

Embodiment 1

[0059] The wastewater to be treated in this embodiment is chloronitrobenzene wastewater with an initial CODCr value of 11500 mg / L.

[0060] The wastewater to be treated is treated by the aforementioned device, and the operation is as follows.

[0061] 1) The first conveying device sends the waste water to be treated in the organic matter temporary storage device into the water inlet tank of the microchannel reactor, and the second conveying device sends the hydrogen peroxide in the hydrogen peroxide temporary storage device into the water inlet tank of the microchannel reactor, through The flow rate of the first conveying device and the second conveying device is controlled, so that the hydrogen peroxide and the waste water to be treated entering the microchannel reactor are mixed according to a set ratio, and an oxidized intermediate liquid is obtained. In the oxidation intermediate liquid, the amount of hydrogen peroxide added is 15ml / L (wastewater) of 50%H 2 o 2 .

[006...

Embodiment 2

[0069] The wastewater to be treated in this embodiment is molasses alcohol wastewater with a COD value of 36000 mg / l.

[0070] Among them, the concentration of hydrogen peroxide in the oxidation intermediate liquid is 50%H of 45ml / L (waste water). 2 o 2 ; In step 2), the inner diameter of the microchannel is 200 microns, the flow rate of the liquid in the microchannel is 20ml / min, and the power density of the ultrasonic generator is 0.5w / cm 2 , the applied ultrasonic frequency is 30kHz. Other operations are the same as in Example 1.

[0071] The ultrasonic intermediate solution was tested, and the test results were as follows: CODcr was 423mg / L.

Embodiment 3

[0073] The wastewater to be treated in this embodiment is printing and dyeing wastewater, the chroma is 4096 times, and the COD is 10240mg / L.

[0074] Among them, the concentration of hydrogen peroxide in the oxidation intermediate liquid is 50%H of 30ml / L (waste water). 2 o 2 ; In step 2), the inner diameter of the microchannel is 150 microns, the flow rate of the liquid in the microchannel is 25ml / min, and the power density of the ultrasonic generator is 0.5w / cm 2 , the applied ultrasonic frequency is 40kHz. Other operations are the same as in Example 1.

[0075] The ultrasonic intermediate solution was tested, and the test results were as follows: the chroma was 48 times, and the COD was 120mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com