Method for cutting and pre-breaking top coal to improve mining efficiency by utilizing water power

A technology of hydraulic cutting and mining rate, which is applied in hydraulic mining, earth square drilling, special mining, etc., can solve the problems of coal seam top-coal caving difficulties and low mining rate, so as to improve the top-coal mining rate and mining construction progress, and speed up The effect of mining speed and reducing the lumpiness of falling coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

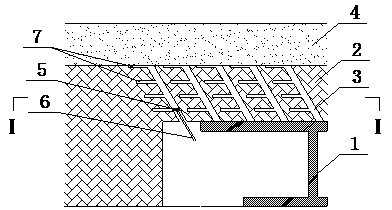

[0015] As shown in the accompanying drawings: the present invention utilizes hydraulic cutting to pre-break the top coal to improve the operating steps of the mining rate method as follows:

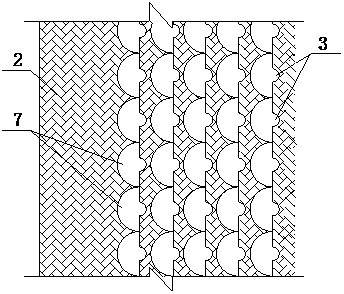

[0016] ①Use a drilling rig to drill an advanced borehole 3 to the interface between the coal body 2 and the rock formation 4 in the roof coal body 2 in front of the hydraulic support 1;

[0017] ② Pull out the drill pipe, extend the high-pressure water pipe 6 with the high-pressure nozzle 5 installed at the front end into the bottom of the advanced drilling hole 3, open the valve, and make the high-pressure water jet flow to the coal body 2 with a pressure of 20MPa~30MPa and a flow rate of 50~70L / min. Carry out hydraulic cutting along the horizontal direction, and rotate the high-pressure water pipe 6 at a constant speed, so that the high-pressure water jet cuts a semicircular transverse slit 7 in the coal body 2 along the mining direction, and rotate the high-pressure water pipe 6 repeate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com