Rock roadway deep-hole multi-wedge straight-hole internal subsection micro-difference cutting blasting method

A deep hole and multiple technology, applied in the field of rock roadway blasting, can solve the problems of long throwing distance of gangue, damage and damage of surrounding rock, bulging belly, etc., and achieve small gangue lumps, small destructiveness of surrounding rock and large cavity space big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

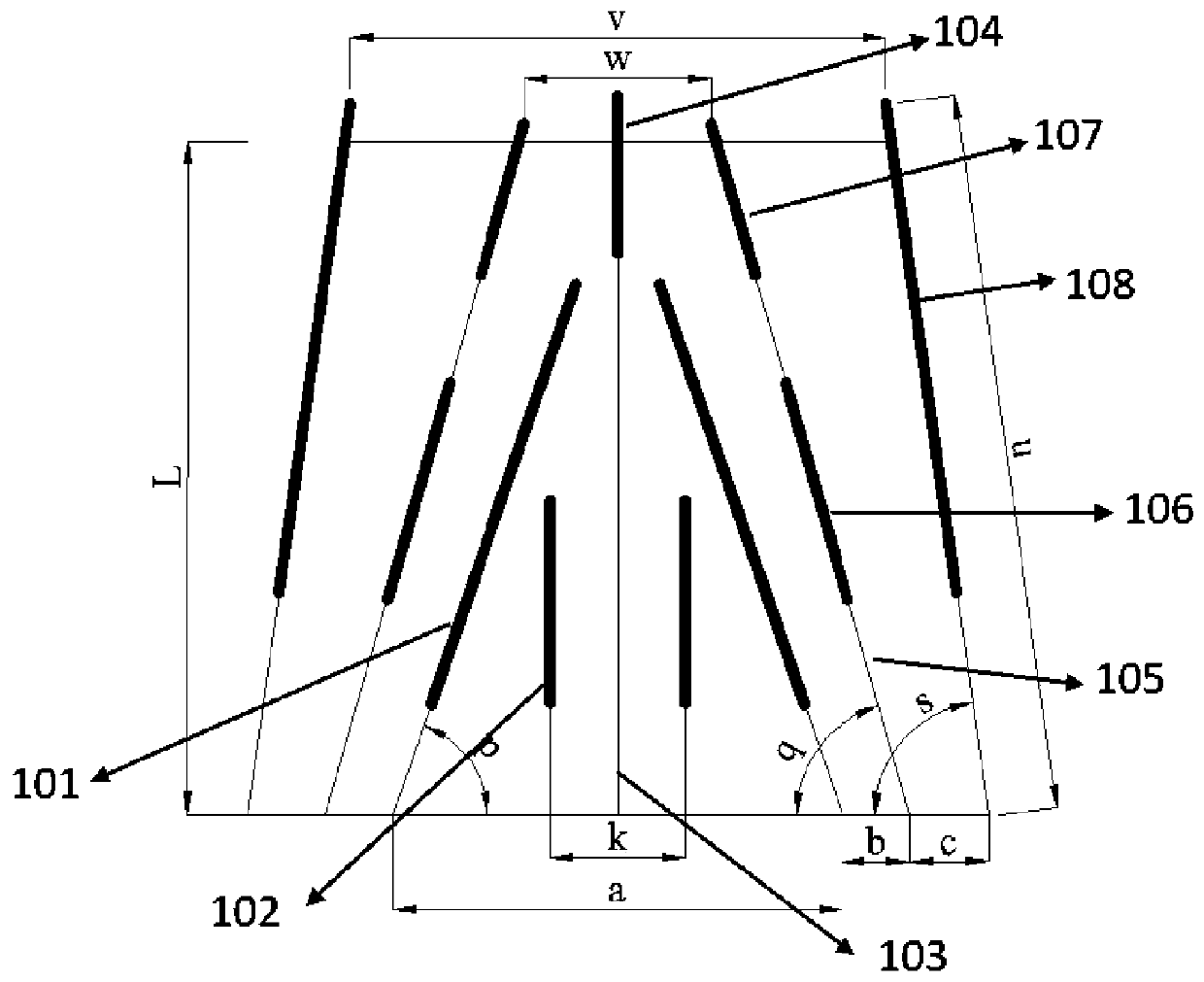

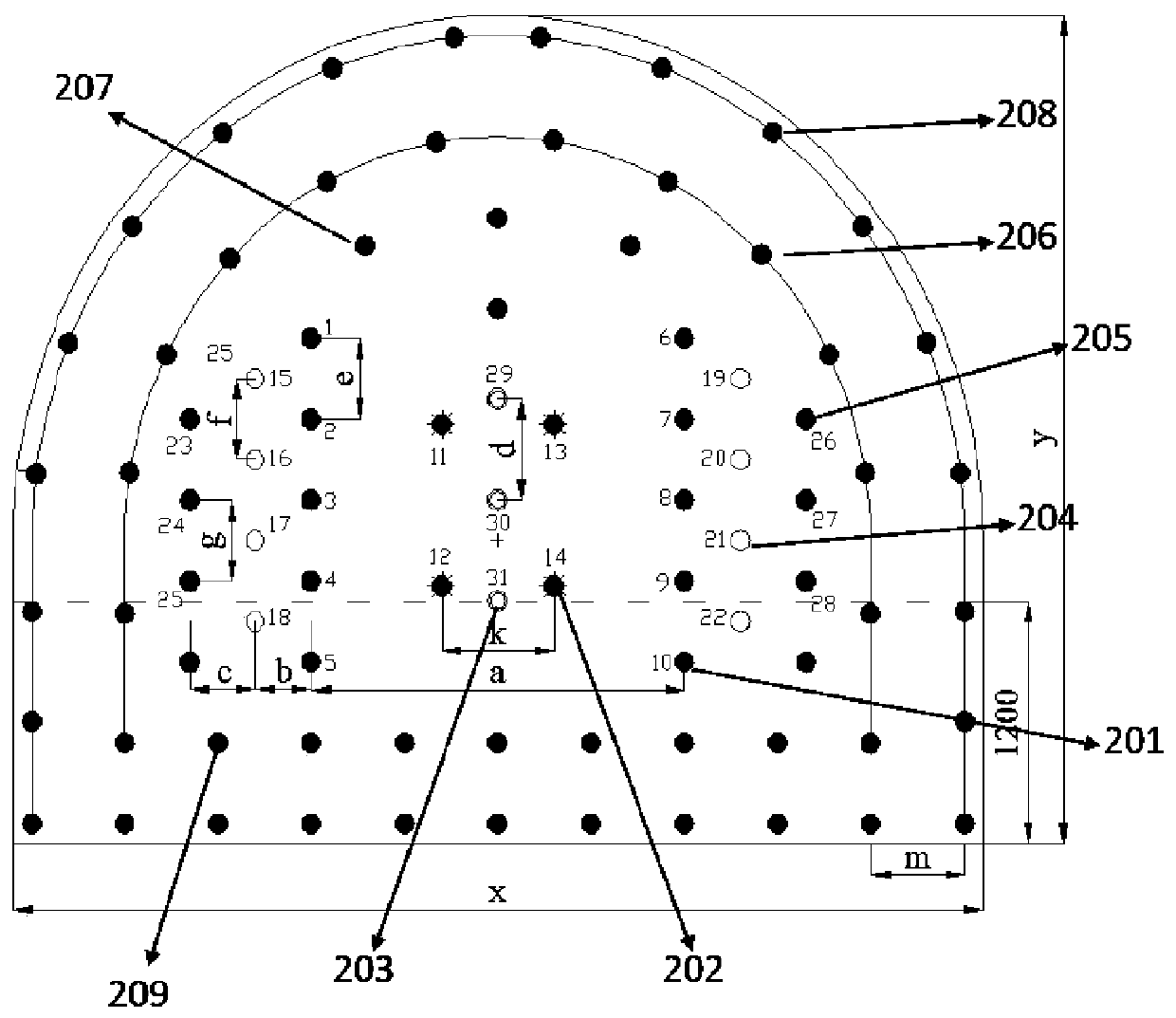

[0073] It is studied to transport the horizontal roadway in mining area 7-1 of Hengyuan Coal and Electricity Coal and Electricity Coal in Northern Anhui. The transportation level road adopts the shape of straight wall and semi-circular arch, supported by anchor net and cable spraying, the gross section width is 5240mm, the gross section height is 4120mm, the net section width is 5100mm, and the net section height is 4050mm. The surrounding rock is white sandstone, with well-developed joints and bedding, and local sections are complete, with a hardness coefficient of f=10-13, which belongs to the hard sandstone layer.

[0074] The original construction plan adopts the drilling and blasting method. The specific method is to blast the entire section of the transport levelway at one time and blast the holes in groups. The group blasting adopts two sets of charges, each group is detonated once, that is, the first charge blasts the floor 1.2m upwards, and the second charge blasts the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com