Sublevel open-stop and delayed filling mining method

A filling mining and empty field technology, applied in the direction of filling, ground mining, mining equipment, etc., can solve the problems of difficult control of fan-shaped blast holes, loss of difficult-to-recover resources, and large interference in mining.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

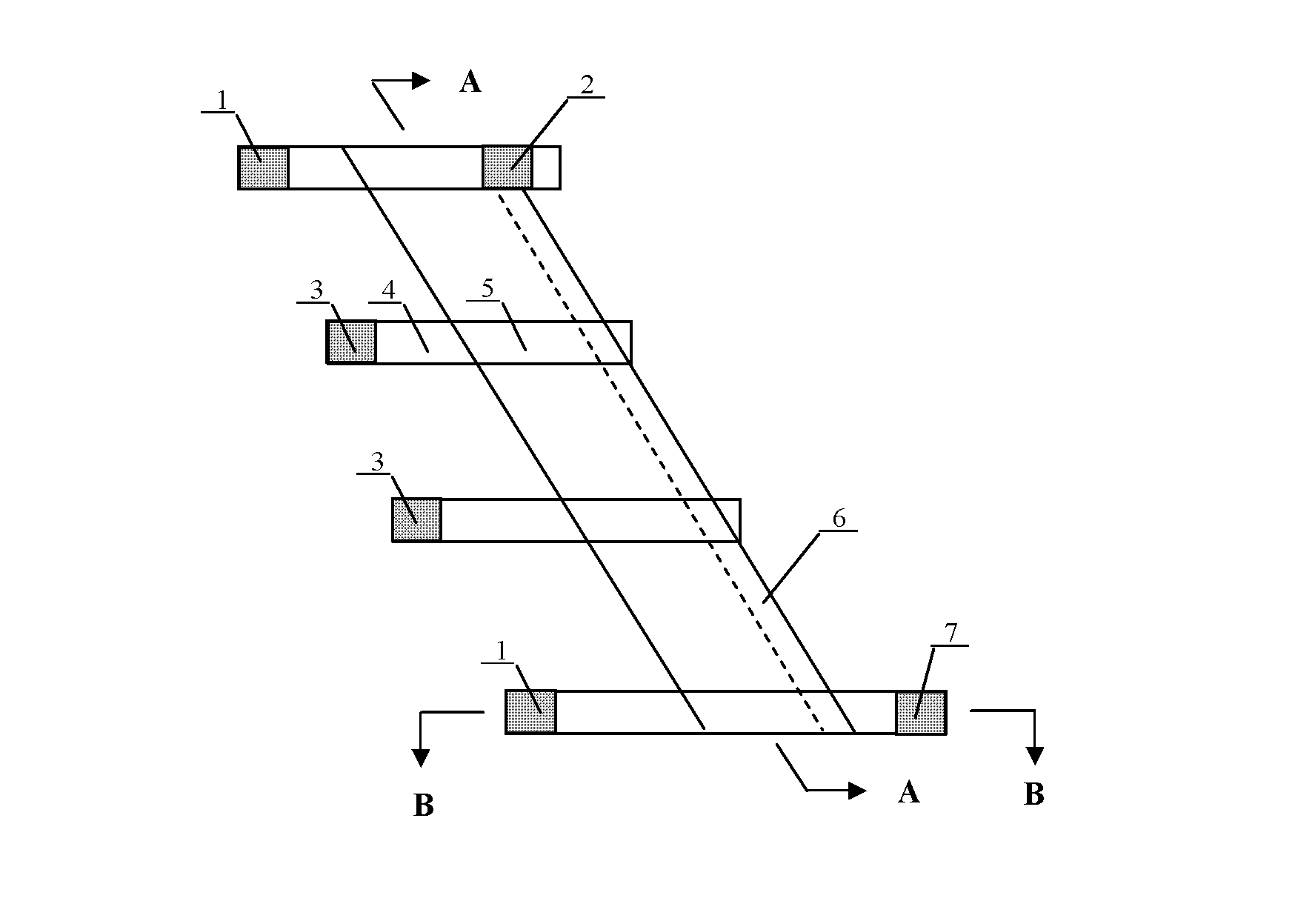

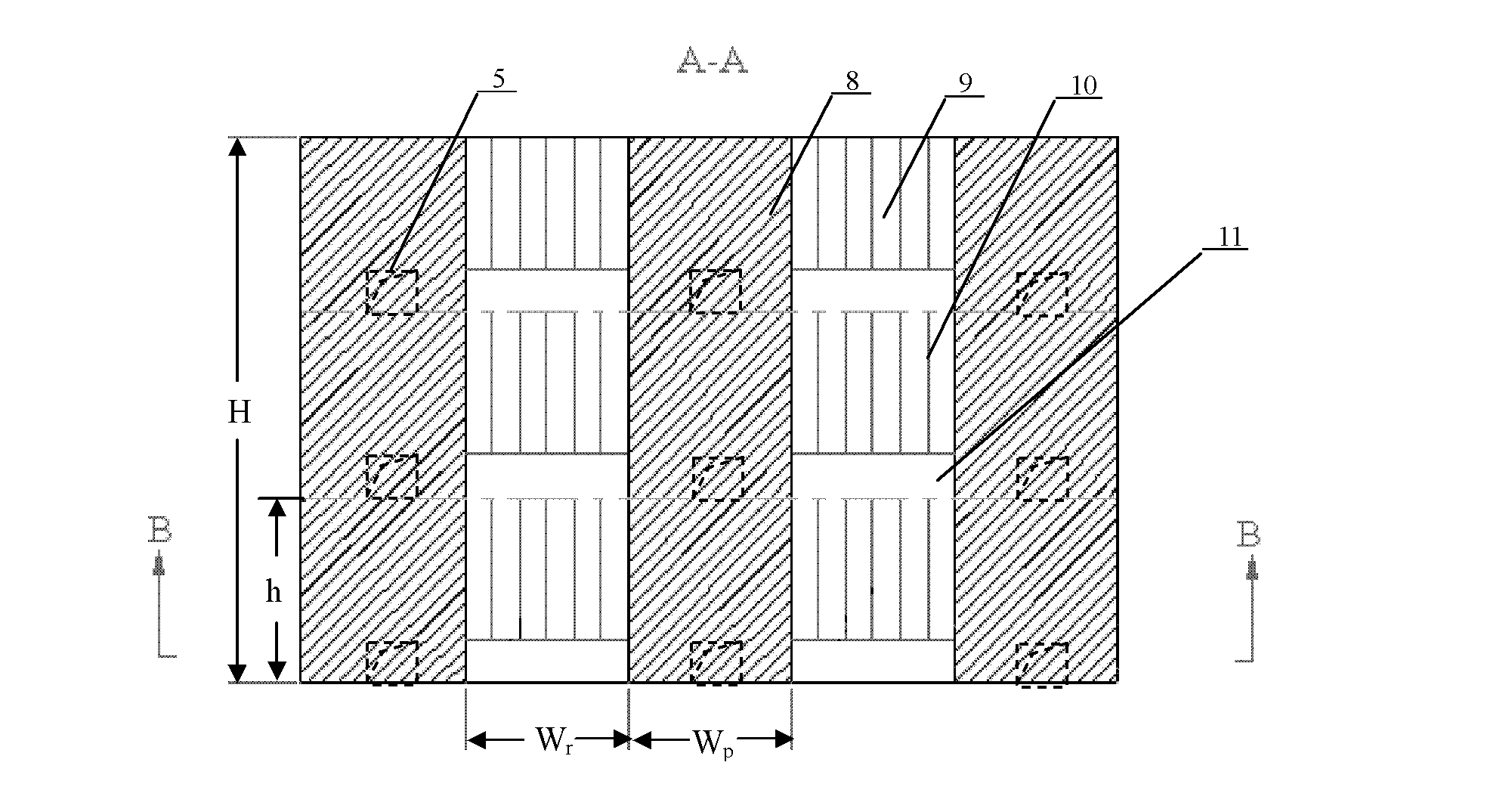

[0025] Such as figure 1 Shown, the sectional view of the middle section of the vertical direction of the ore block in the embodiment of the present invention;

[0026] The two adjacent middle transportation roadways 1 divide the ore block into a middle section. In the embodiment, the middle section is further divided into two subsections through two subsection levels 3. The middle section transportation roadway 1 and the segmented horizontal roadway are arranged along the vein. Outside the vein, along the middle transport roadway 1 and segmented horizontal roadway 3, excavate the connecting road 4 and the cutting cross roadway 5 at certain distances to penetrate the ore body vertically, and excavate and cut the raised shaft (uphill) along the ore body within the boundary of the ore body 6. The cutting patio 6 is connected through the return air tunnel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com