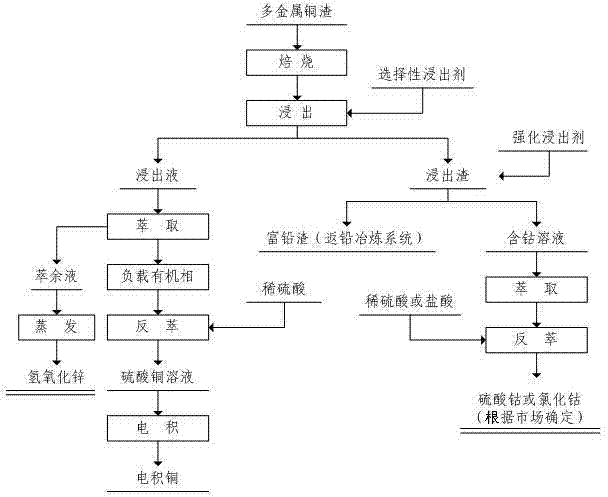

Method for producing electrodeposited copper from polymetallic copper slag

A multi-metal, copper electrodeposited technology, applied in the improvement of process efficiency, photographic technology, instruments, etc., can solve the problem of not fully reflecting the economic benefits of valuable metals, difficult to control the quality of copper sulfate, and failing to reach high-quality products, etc. problems, to achieve the effect of high added value of products, elimination of secondary pollution, and high recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Send 5kg of multi-metallic copper slag containing Cu7.56%, Co2.8%, Zn2.6%, Pb7.8%, Ni0.3%, and 6% moisture into the laboratory for φ0.5×3.2m rotation In the kiln, the oxygen is 3.5m 3 min -1 kg -1 For copper slag, the roasting temperature is controlled at 600°C, and the roasting time is 2 hours. The roasted ore is not cooled and spirally added to the leaching tank. The selective leaching agent is a solution with an initial mass fraction of 5%, and the liquid-solid weight ratio is 2:1. The leaching temperature 35°C, leaching time 6 hours, filtering to obtain leaching solution and leaching residue, the solute components and weight ratio of the leaching agent are: ammonia water (NH 3 ·H 2 O): 25%, ammonium persulfate ((NH 4 ) 2 S 2 o 8 ): 60%, ammonium chloride (NH 4 Cl): 15%, copper leaching rate 98%, zinc leaching rate 95%, cobalt leaching rate 0.1%, lead leaching rate 0.02%, nickel leaching rate 0.08%, the leaching solution uses LIX841 and 260# kerosene mixed or...

Embodiment 2

[0022] Send 5kg of multi-metallic copper slag containing Cu10.06%, Co5.4%, Zn1.8%, Pb15.3%, Ni0.1%, and 8% water into the laboratory for φ0.5×3.2m rotation In the kiln, the oxygen is 6.5m 3 min -1 kg -1 Copper slag, the roasting temperature is controlled at 800°C, the roasting time is 4h, the roasted ore is not cooled and spirally added to the leaching tank, the leaching agent is a solution with an initial mass fraction of 10%, the liquid-solid weight ratio is 4:1, and the leaching temperature is 45°C , the leaching time was 8 hours, filtered to obtain the leaching solution and leaching residue, the solute component and weight ratio of the leaching agent were: ammonia water (NH 3 ·H 2 O): 35%, ammonium persulfate ((NH 4 ) 2 S 2 o 8 ): 50%, ammonium chloride (NH 4 Cl): 15%, copper leaching rate 98.5%, zinc leaching rate 96.8%, cobalt leaching rate 0.08%, lead leaching rate 0.03%, nickel leaching rate 0.06%, the leaching solution is mixed with M5640 and 260# kerosene to ...

Embodiment 3

[0024] The solute components and weight ratio of the selective leaching agent are: ammonia water (NH 3 ·H 2 O): 35%, ammonium persulfate ((NH 4 ) 2 S 2 o 8 ): 60%, ammonium chloride (NH 4 Cl): 5%; the solute components and weight ratio of the mechanical strengthening leaching agent are: sulfuric acid (H 2 SO 4 ): 10%, ammonium persulfate (H 3 N 1 / 2 h 2 o 5 S 2 ): 50%, ammonium nitrite (NH 4 NO 2 ): 40%, the initial mass fraction of the selective leaching agent is a solution of 20%, the concentration of the strengthening leaching agent is 15%, and the remaining steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com