Patents

Literature

187results about How to "Low lignin content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

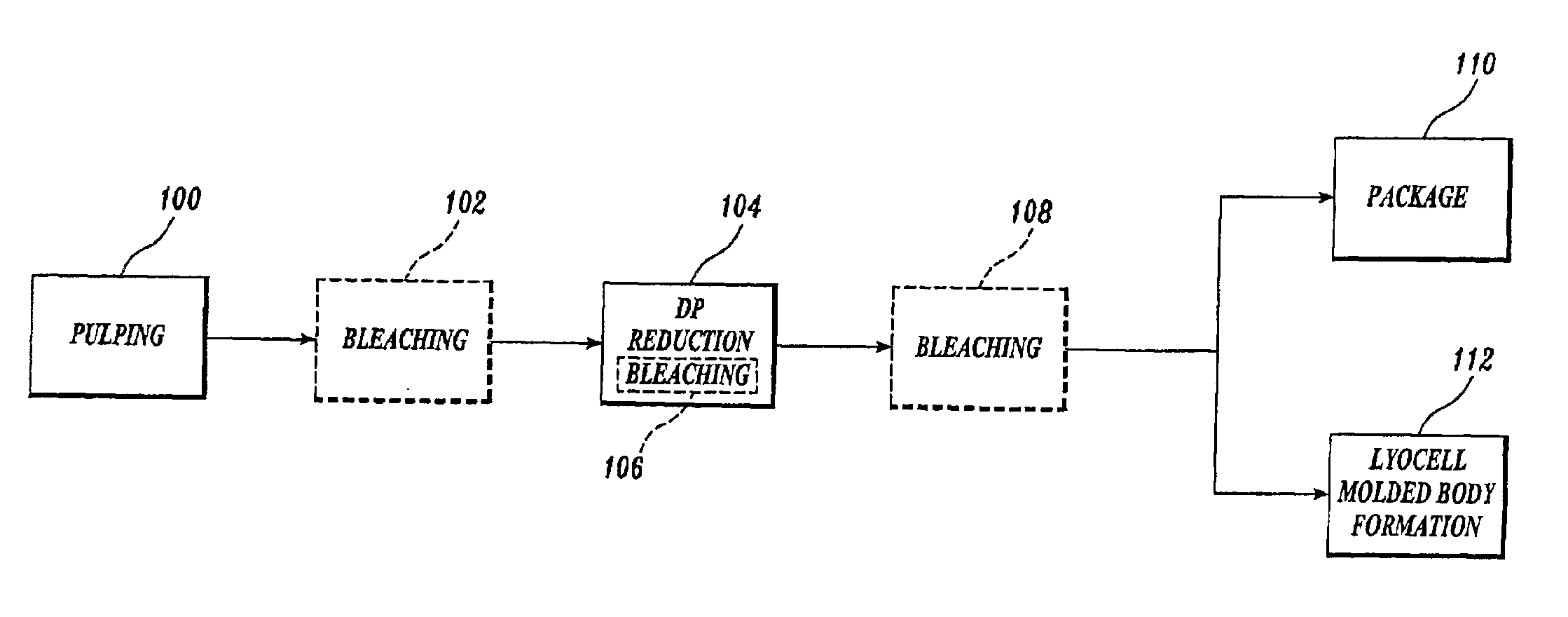

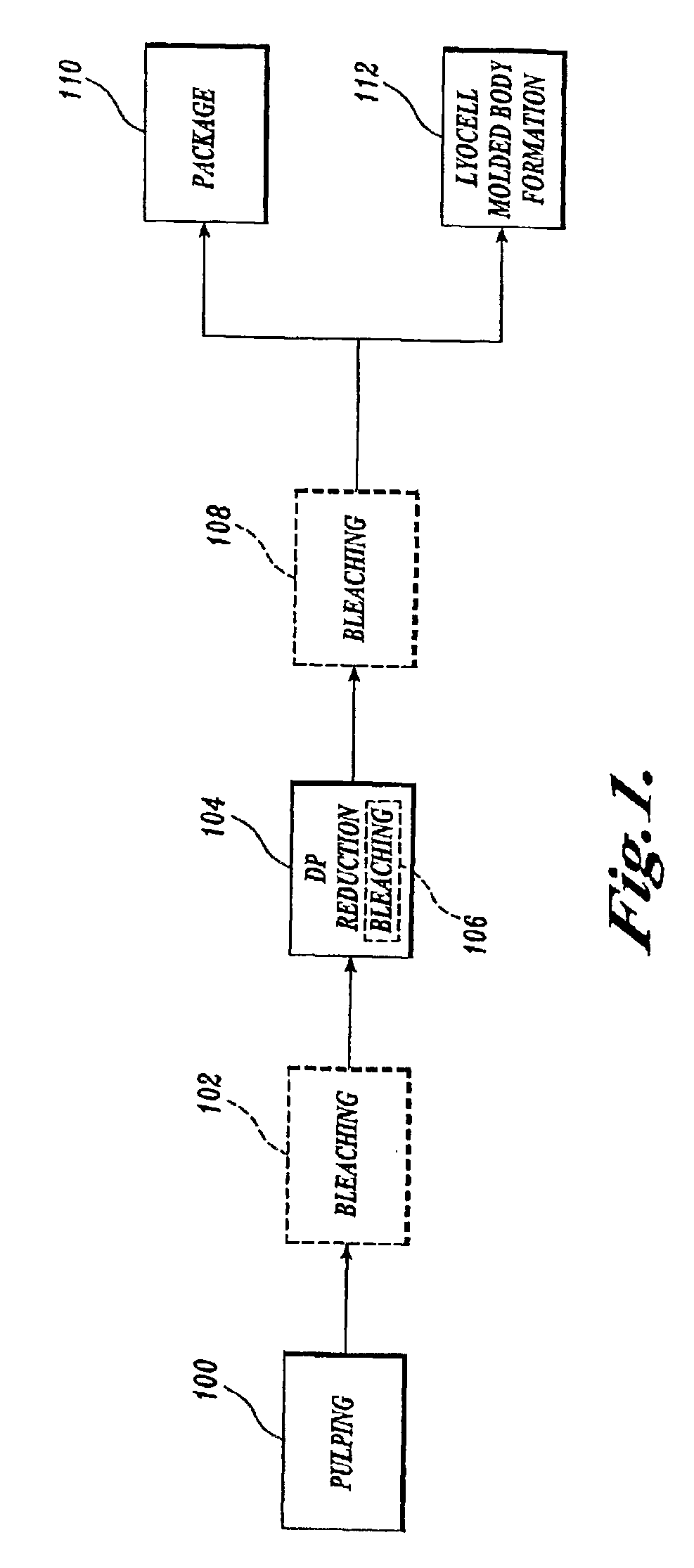

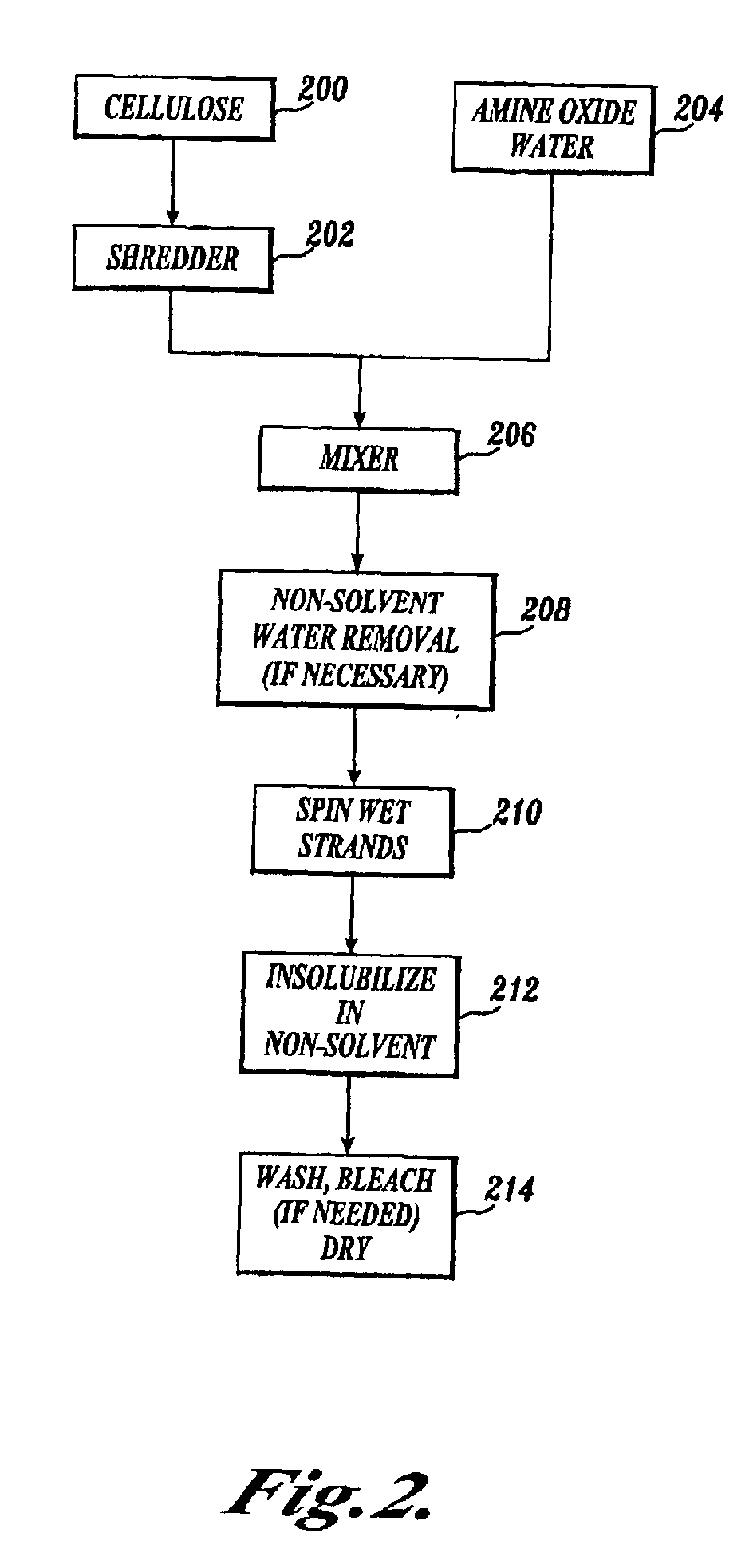

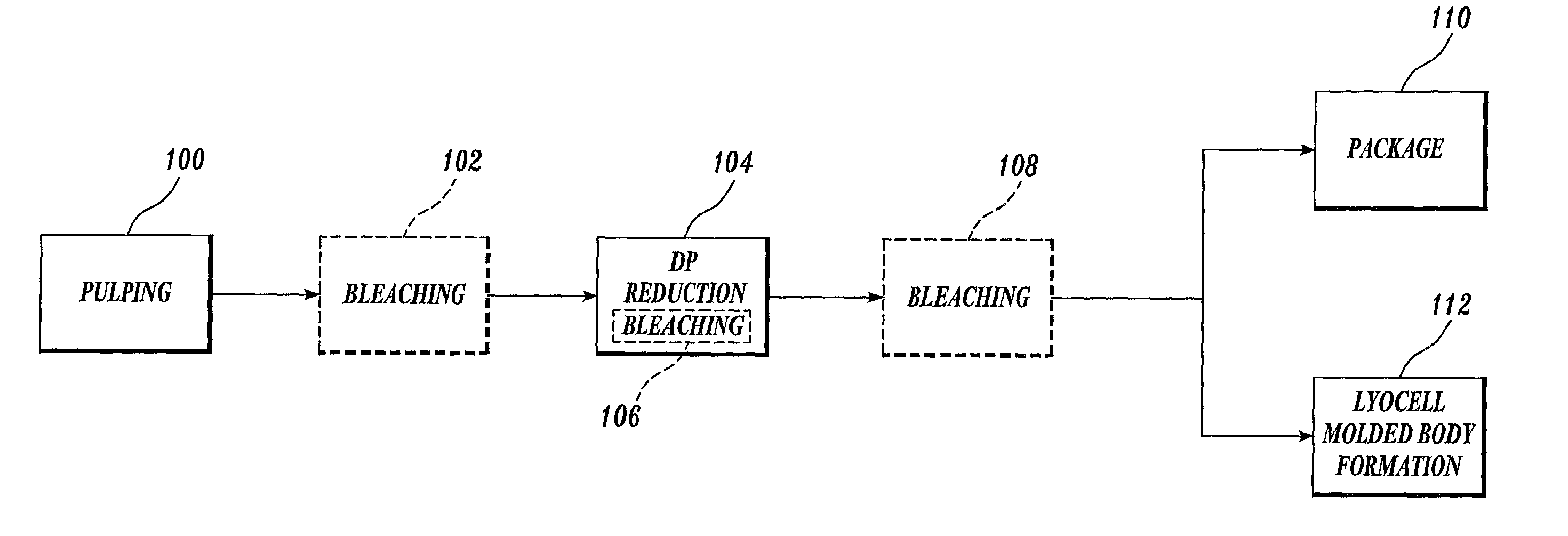

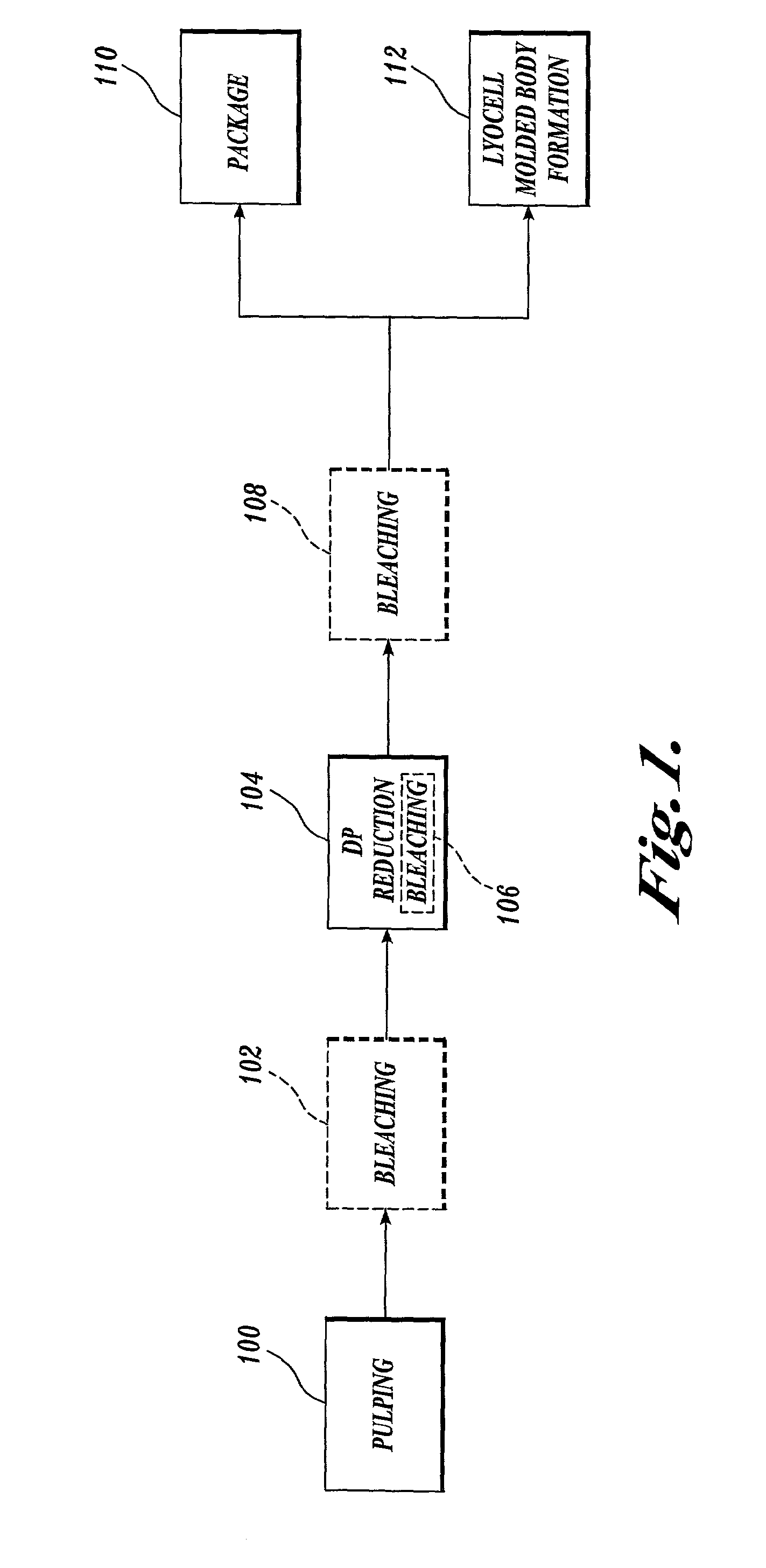

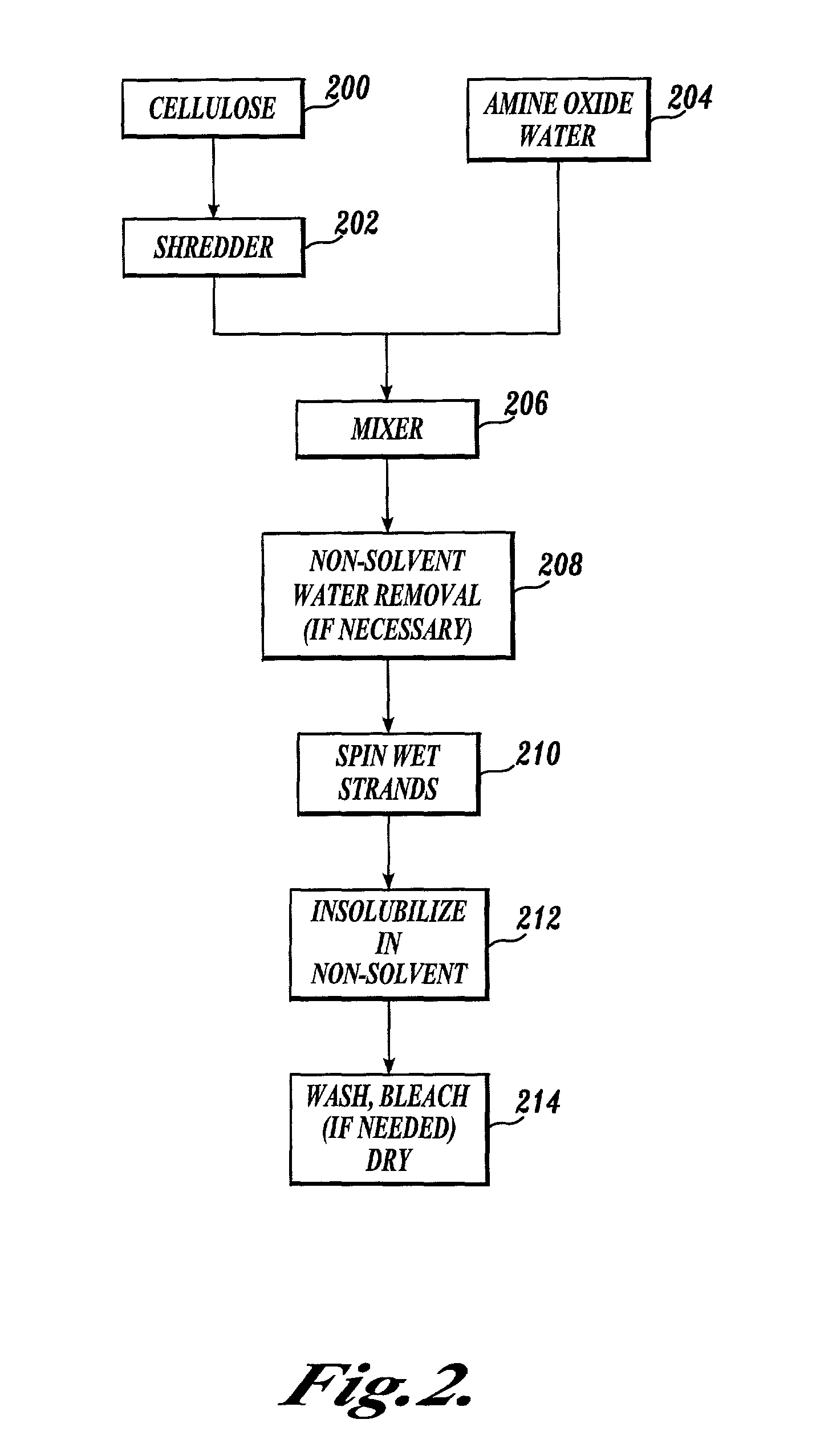

Process for making lyocell fiber from sawdust pulp

InactiveUS6861023B2Reducing average degree of polymerizationReduced hemicellulose contentPulp properties modificationArtificial filaments from cellulose solutionsCopperLyocell

A process for making lyocell fibers including the steps of pulping raw material in a digester to provide an alkaline pulp, wherein the raw material includes sawdust in an amount greater than 0% up to 100%; contacting the alkaline pulp including cellulose and at least about 7% hemicellulose under alkaline conditions with an amount of an oxidant sufficient to reduce the average degree of polymerization of the cellulose to the range of from about 200 to about 1100 without substantially reducing the hemicellulose content or substantially increasing the copper number of the pulp; and forming fibers from the pulp.

Owner:INT PAPER CO

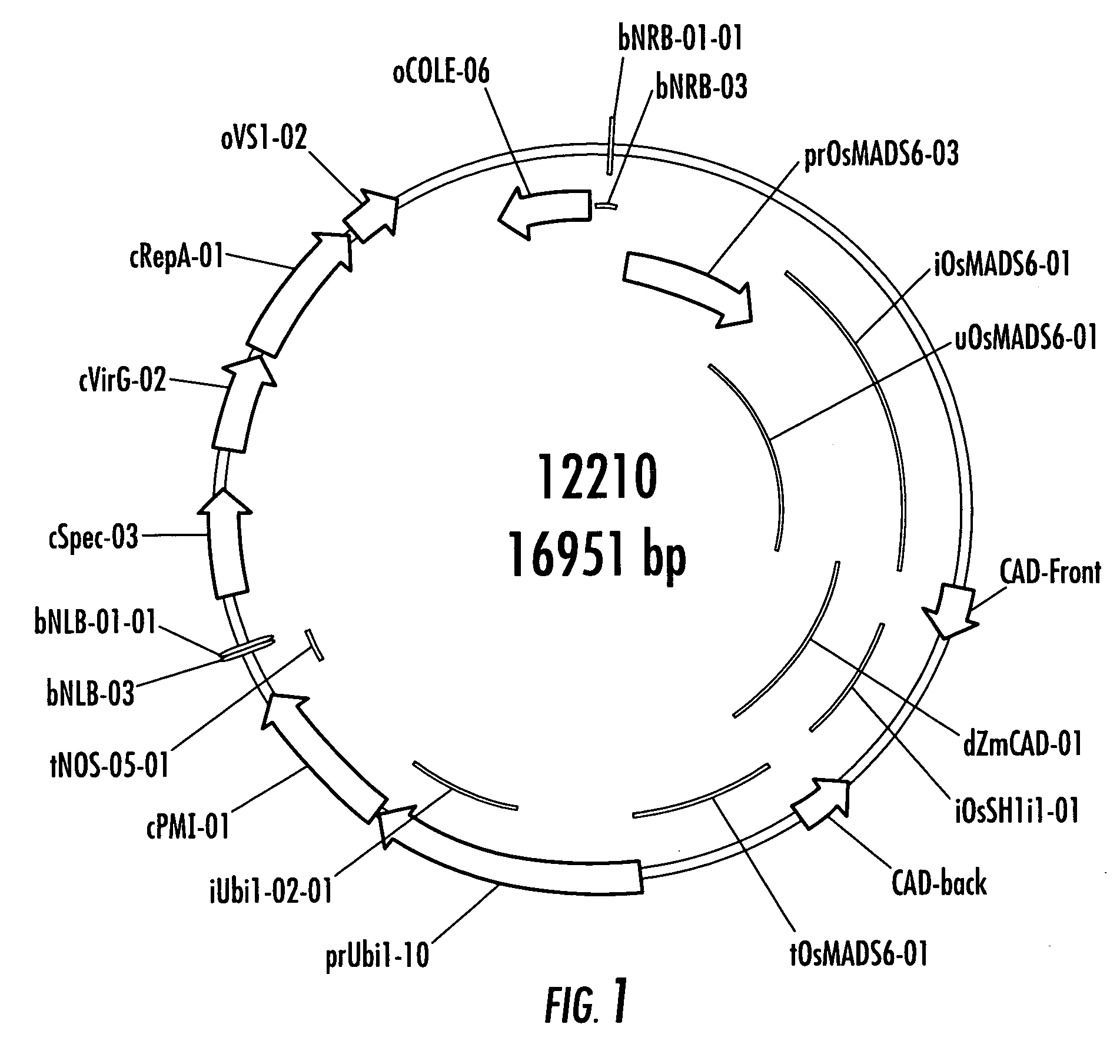

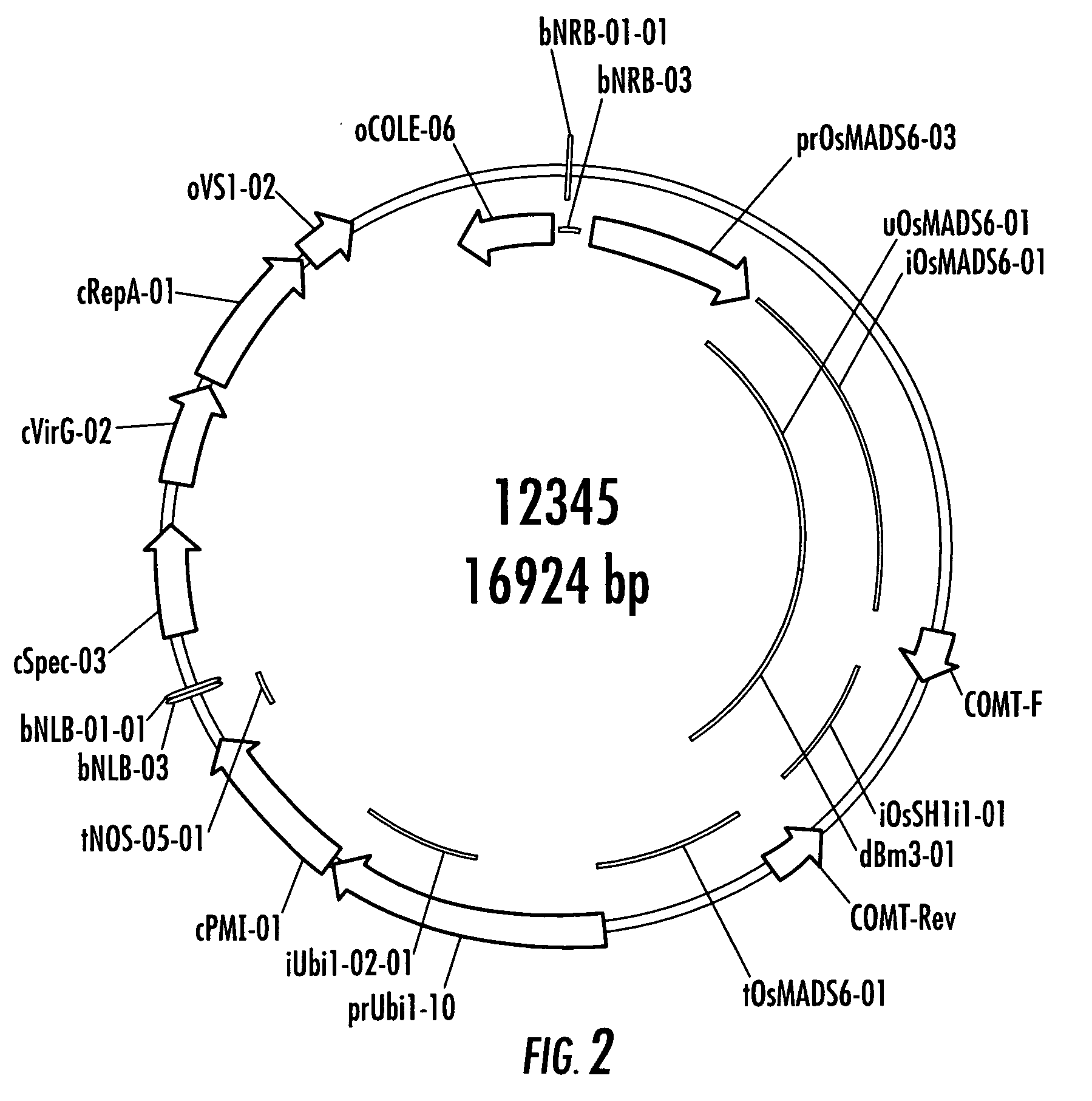

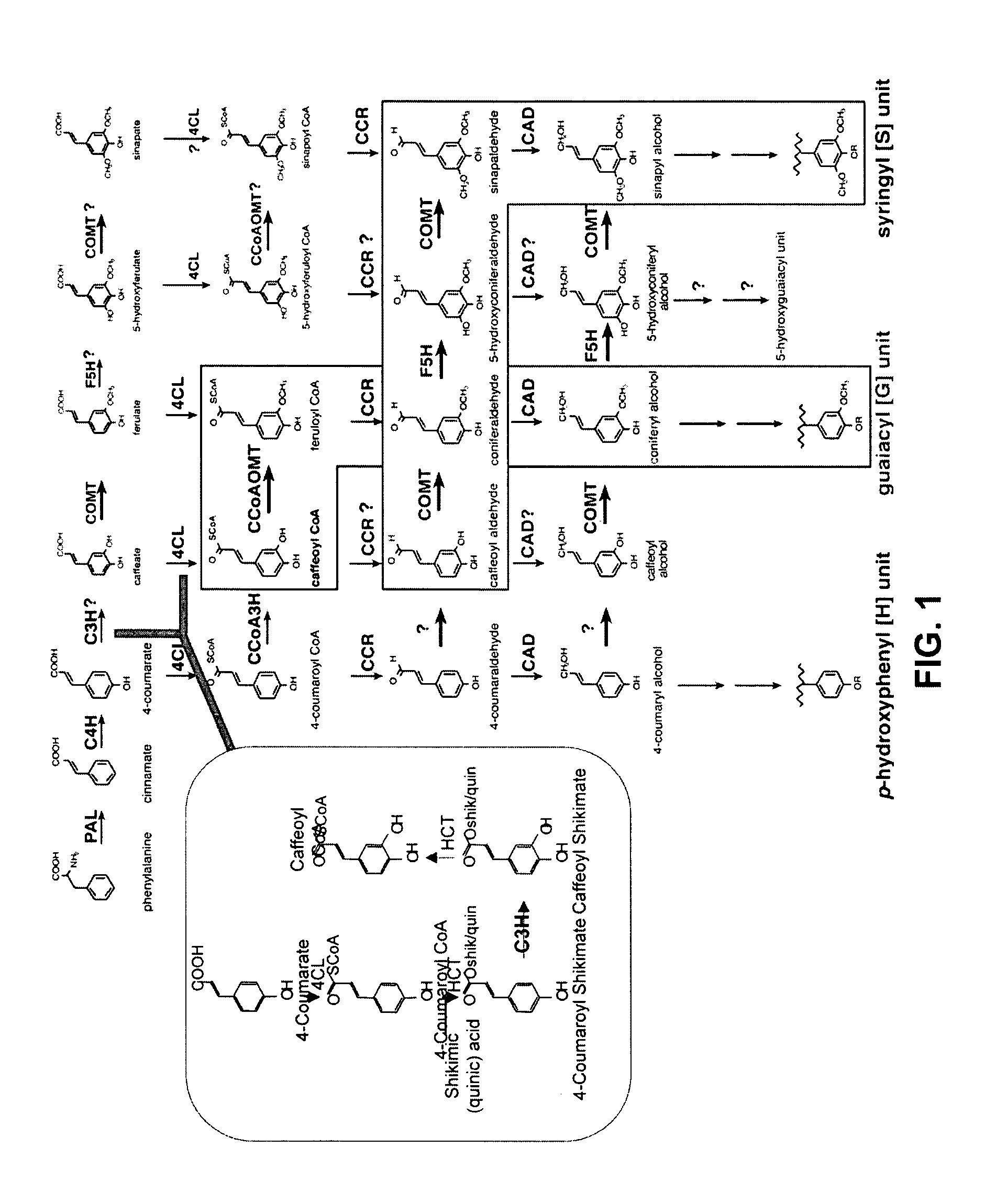

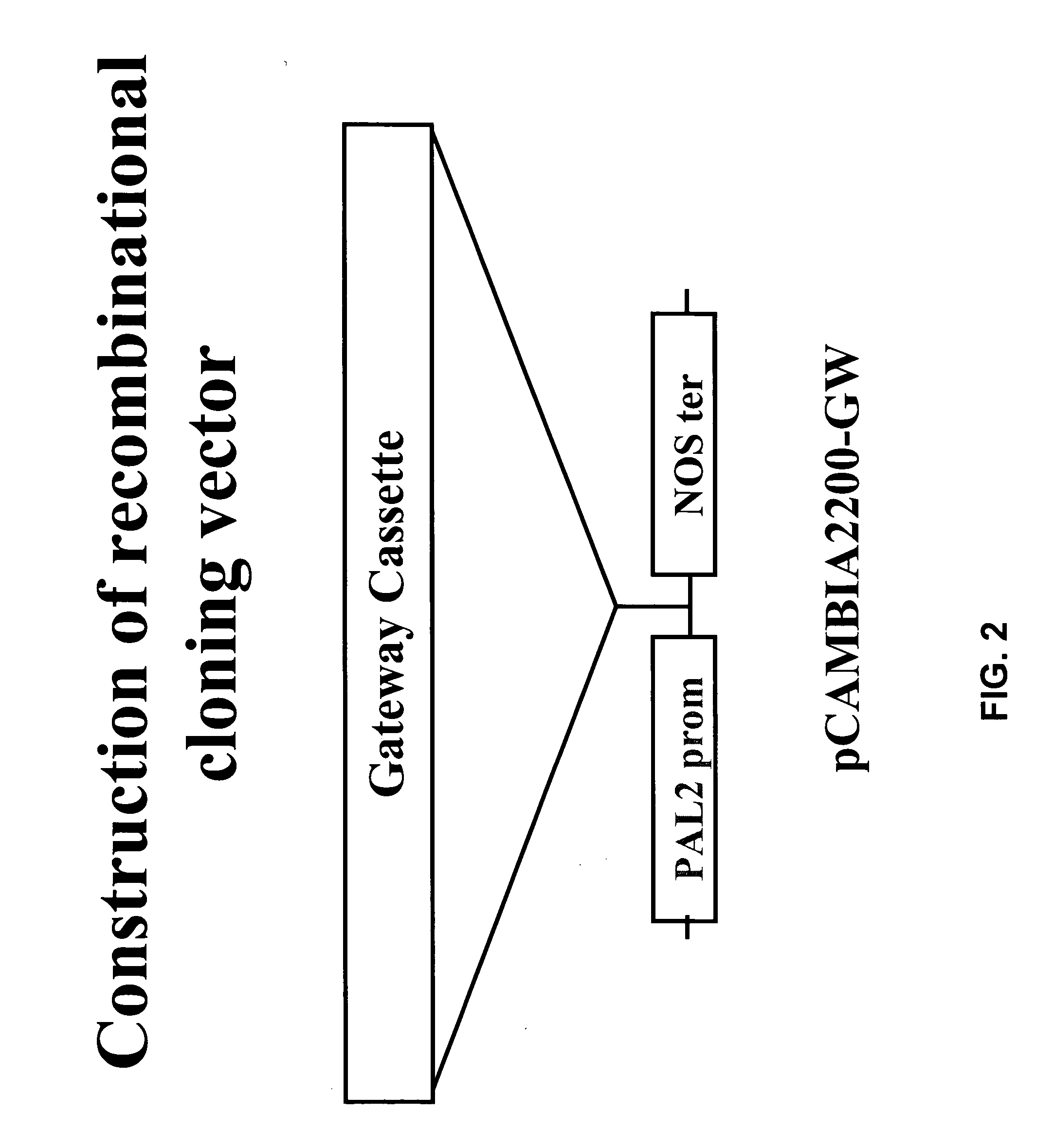

Methods and genetic constructs for modification of lignin composition of corn cobs

InactiveUS20060260011A1Reduce expressionLow lignin contentBiofuelsOther foreign material introduction processesDouble strandedLignin biosynthesis

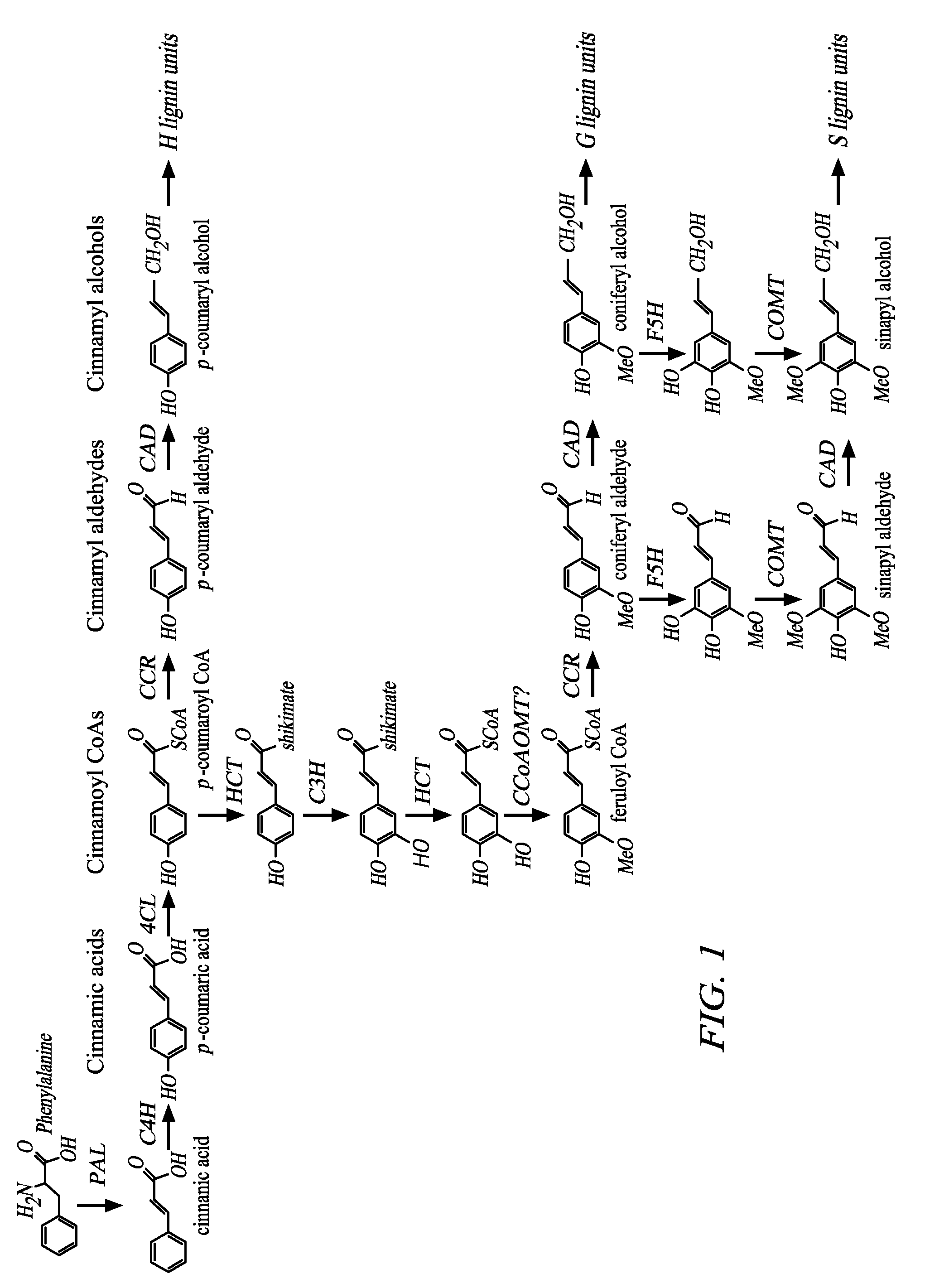

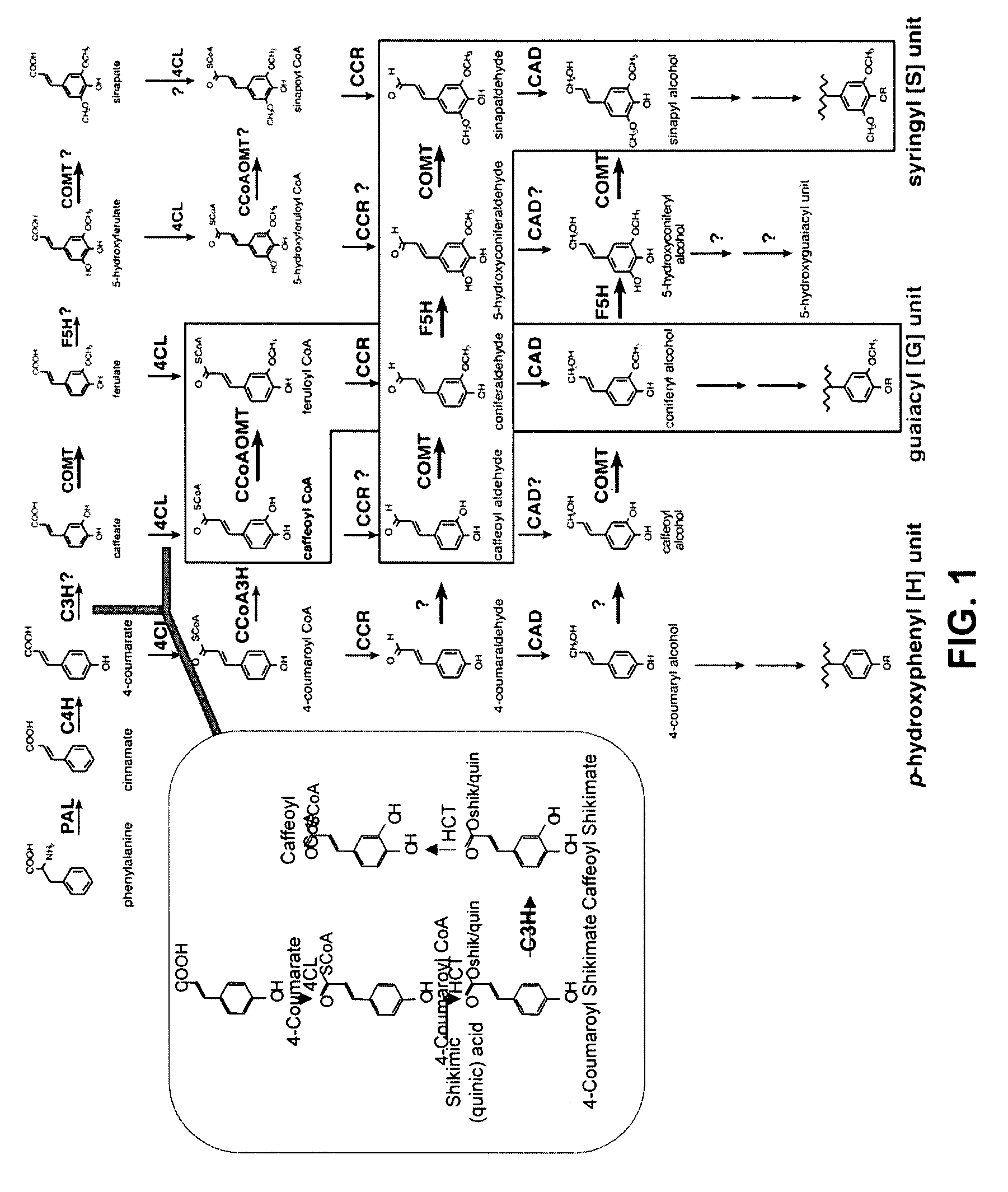

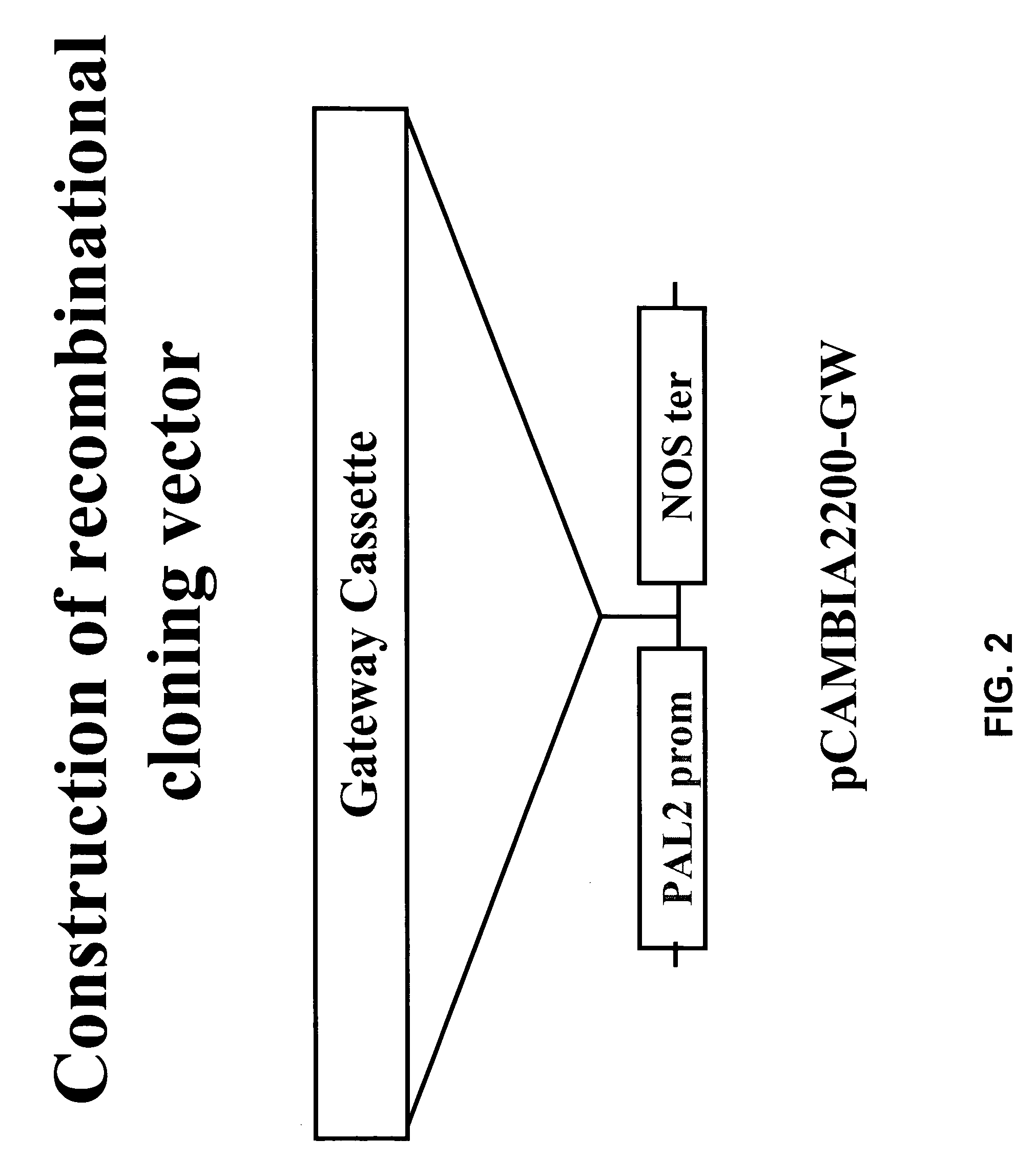

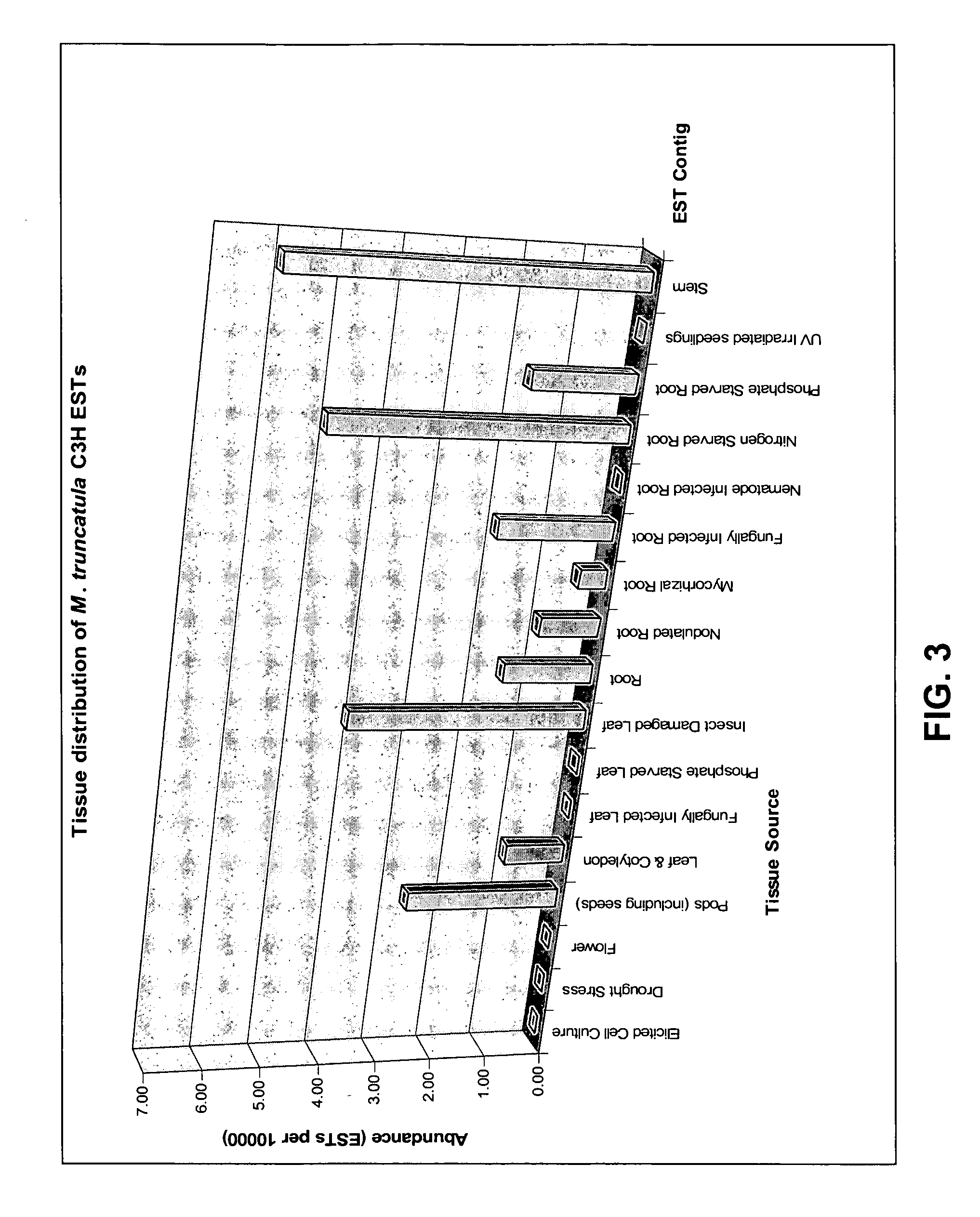

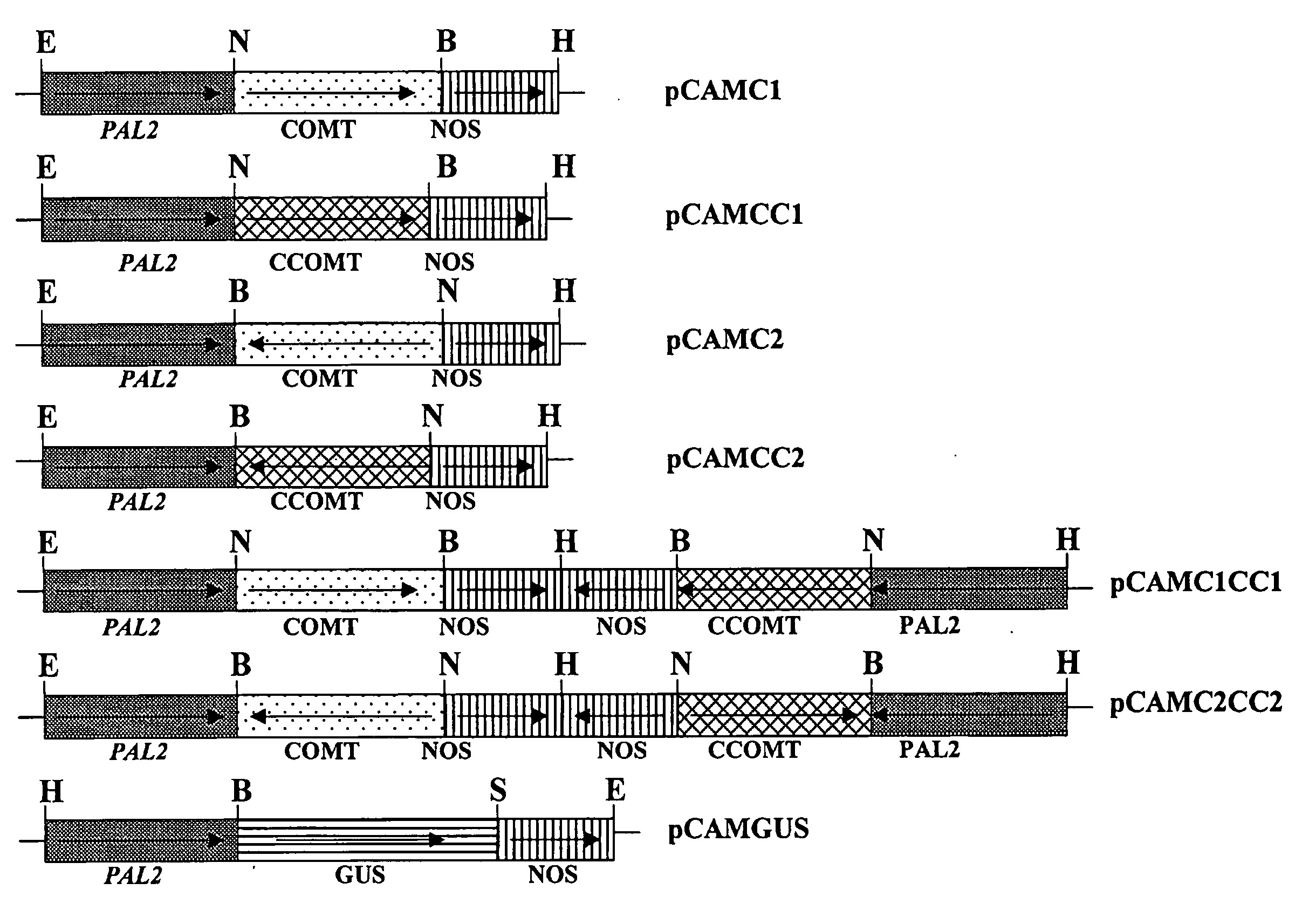

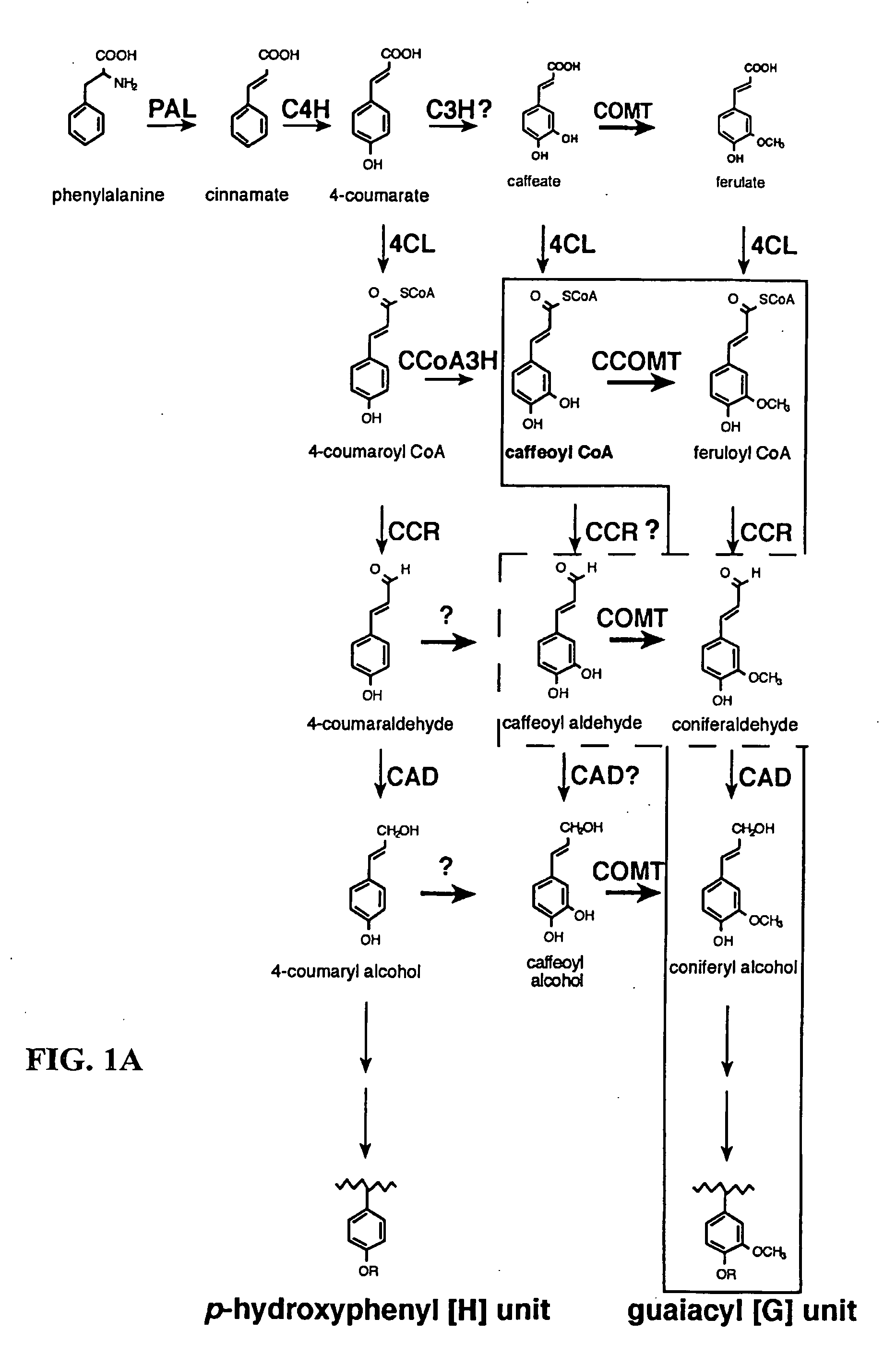

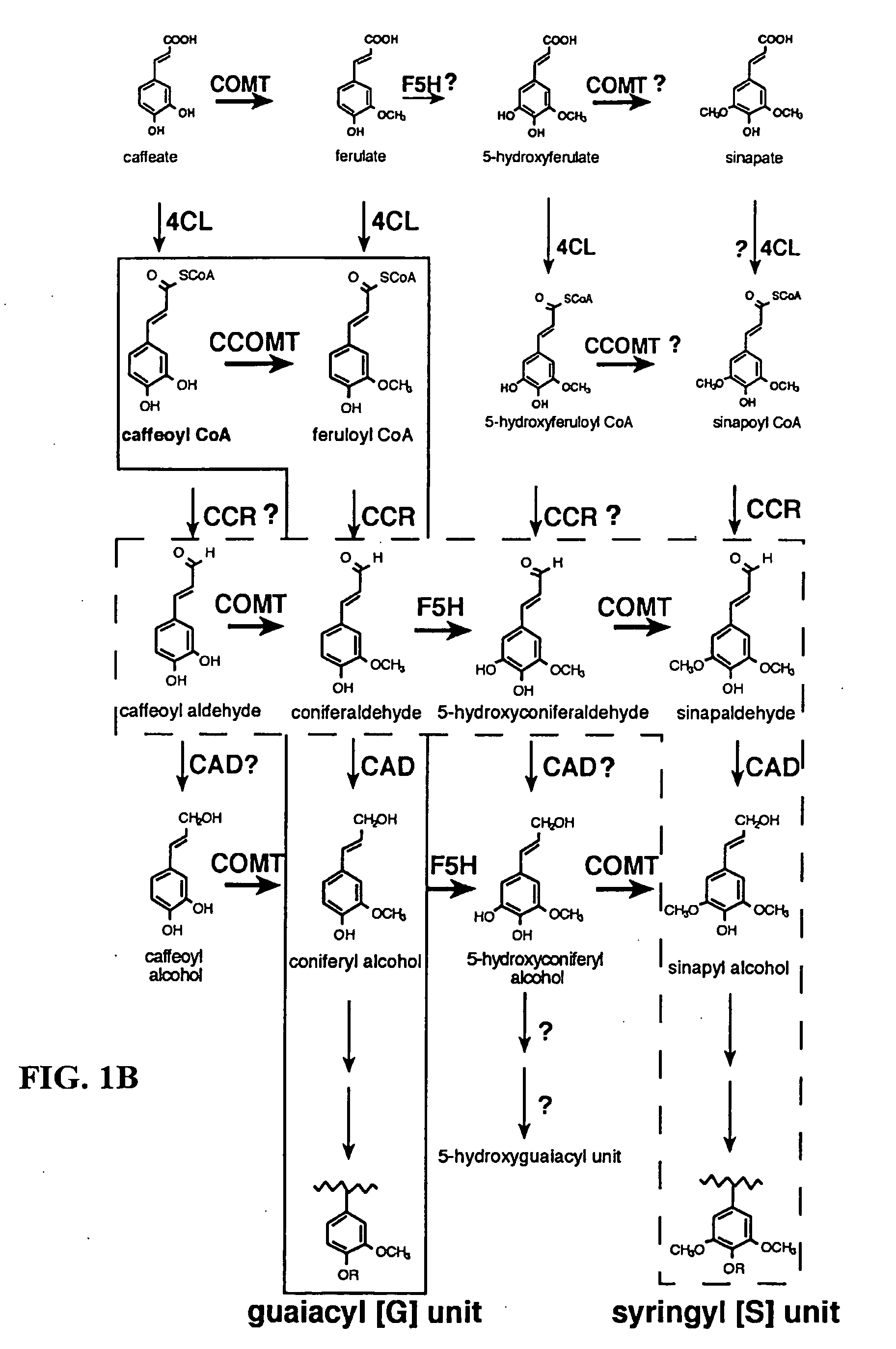

The present invention relates to methods and genetic constructs for the control of expression of enzymes involved in lignin biosynthesis in plants. The method involves the use of double-stranded RNAi to down-regulate or knock out the expression of the CAD and COMT genes. In particular embodiments the method involves the use of cob-specific or cob-preferred promoters for down-regulation of lignin biosynthesis in the cobs of corn plants.

Owner:SYNGENTA PARTICIPATIONS AG

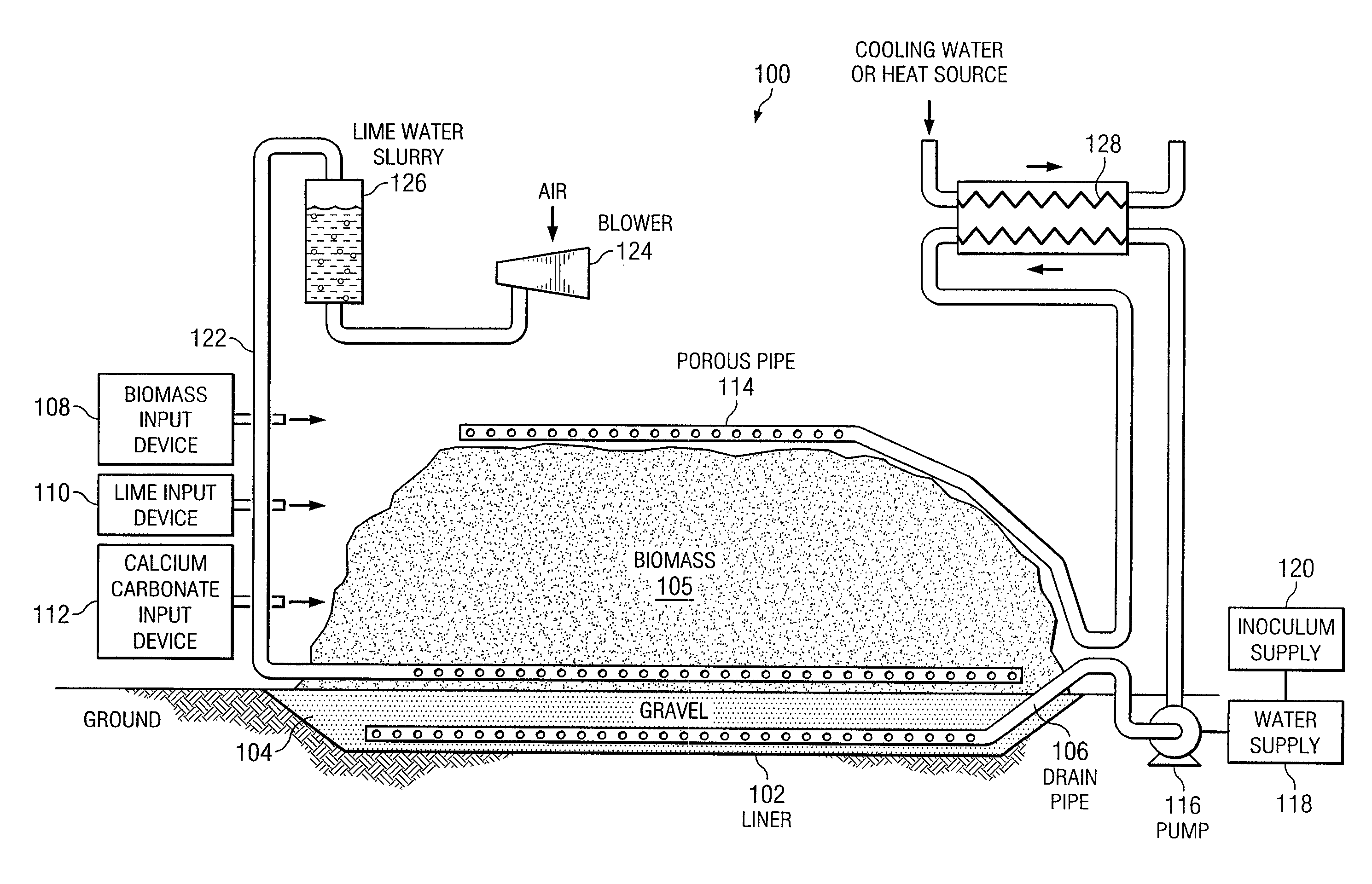

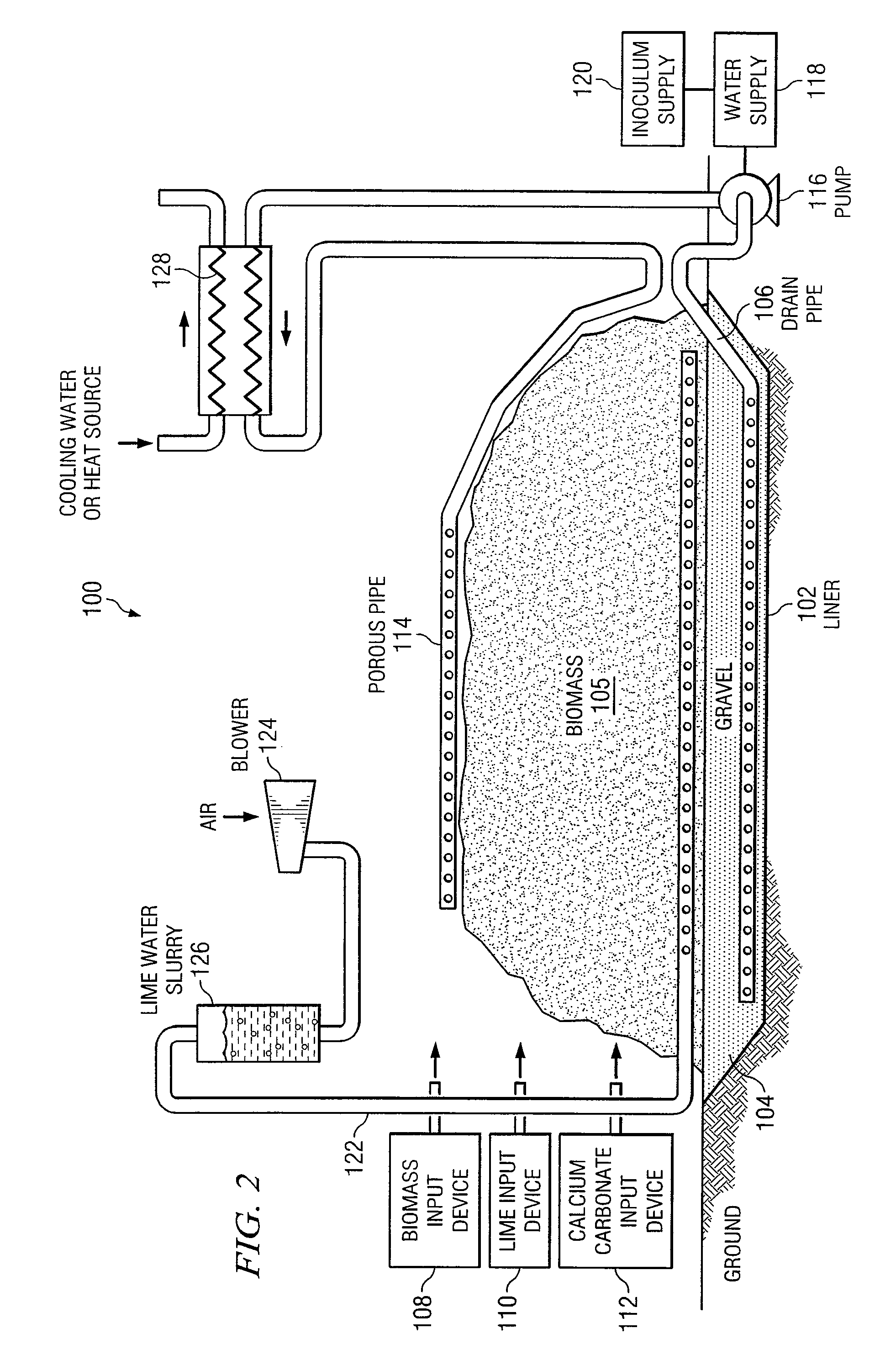

Methods and Systems for Pretreatment and Processing of Biomass

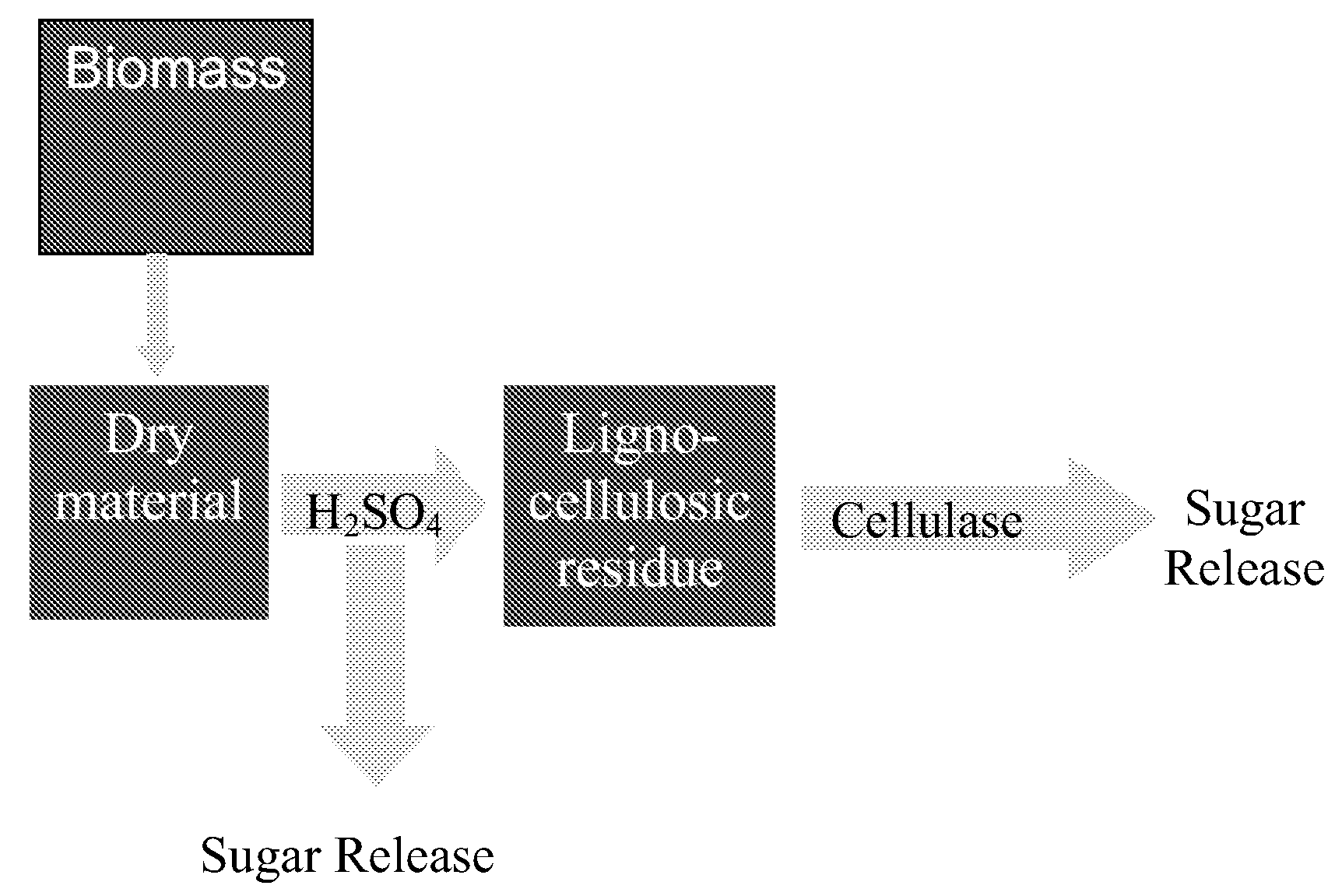

InactiveUS20080121359A1Increasing enzyme digestibilityLow lignin contentBio-organic fraction processingProductsEnzymatic digestionCellulose

According to one embodiment of the invention, a system for processing biomass includes a water-impermeable bottom liner, a gravel layer supported by the bottom liner, a drain pipe disposed within the gravel layer, a biomass input device operable to deliver biomass over the gravel layer to form a biomass pile, a lime input device operable to deliver lime to the biomass for pretreating the biomass, a distribution pipe elevated above the gravel layer, and a pump operable to circulate water through the biomass pile by delivering water to the distribution pipe and receiving water from the drain pipe after it has traveled through the biomass pile.According to another embodiment, a method for biomass pretreatment with alkali, conducted at ambient pressure for approximately 4-16 weeks at temperatures ranging from approximately 25° C. to 95° C. Biomass may be lignocellulosic biomass and may be rendered suitable for enzymatic digestion or pulp production.

Owner:TEXAS A&M UNIVERSITY

Technique for preparing thin slice of tobacco and prepared thin slice of tobacco

InactiveCN101438852ARich aromaImprove combustion qualityTobacco preparationTobacco treatmentPectinaseChemistry

The invention provides a technique for preparing tobacco sheets and the tobacco sheets. The technique comprises the following steps: soaking tobacco materials in water to obtain extract liquid and a water-insoluble solid; carry out enzymatic hydrolysis on the extract liquid by pectinase and / or protease so as to obtain a first water-soluble extract; degrading the protein in the water-insoluble solid by the protease so as to obtain an enzyme-hydrolyzed water-insoluble solid and a second water-soluble extract; placing the enzyme-hydrolyzed water-insoluble solid in acidic alcohol solution so as to acid-degrade lignose, then preparing the separated solid into tobacco sheet bases; and carrying out vacuum concentration on the first and the second water-soluble extracts and applying the first and the second water-soluble extracts to the tobacco sheet bases to prepare the tobacco sheets. The technique can effectively reduce the content of water-soluble pectin and water-insoluble protease, and reduce the unique lignin flavor in the tobacco sheets by the chemical degradation of the lignose.

Owner:HUABAO FLAVOURS & FRAGRANCES CO LTD +1

Process for making composition for conversion to lyocell fiber from sawdust

InactiveUS7090744B2Reduce the degree of polymerizationReduce contentPulp properties modificationMonocomponent cellulose artificial filamentCopperHemicellulose

A process for making a composition for conversion to lyocell fiber where the process comprises pulping a raw material in a digester to provide an alkaline pulp, wherein the raw material comprises sawdust in an amount greater than 0 % up to 100 %; and contacting the alkaline pulp comprising cellulose and at least about 7 % hemicellulose under alkaline conditions with an amount of an oxidant sufficient to reduce the average degree of polymerization of the cellulose to within the range of from about 200 to about 1100, without substantially reducing the hemicellulose content of the pulp or substantially increasing the copper number.

Owner:INT PAPER CO

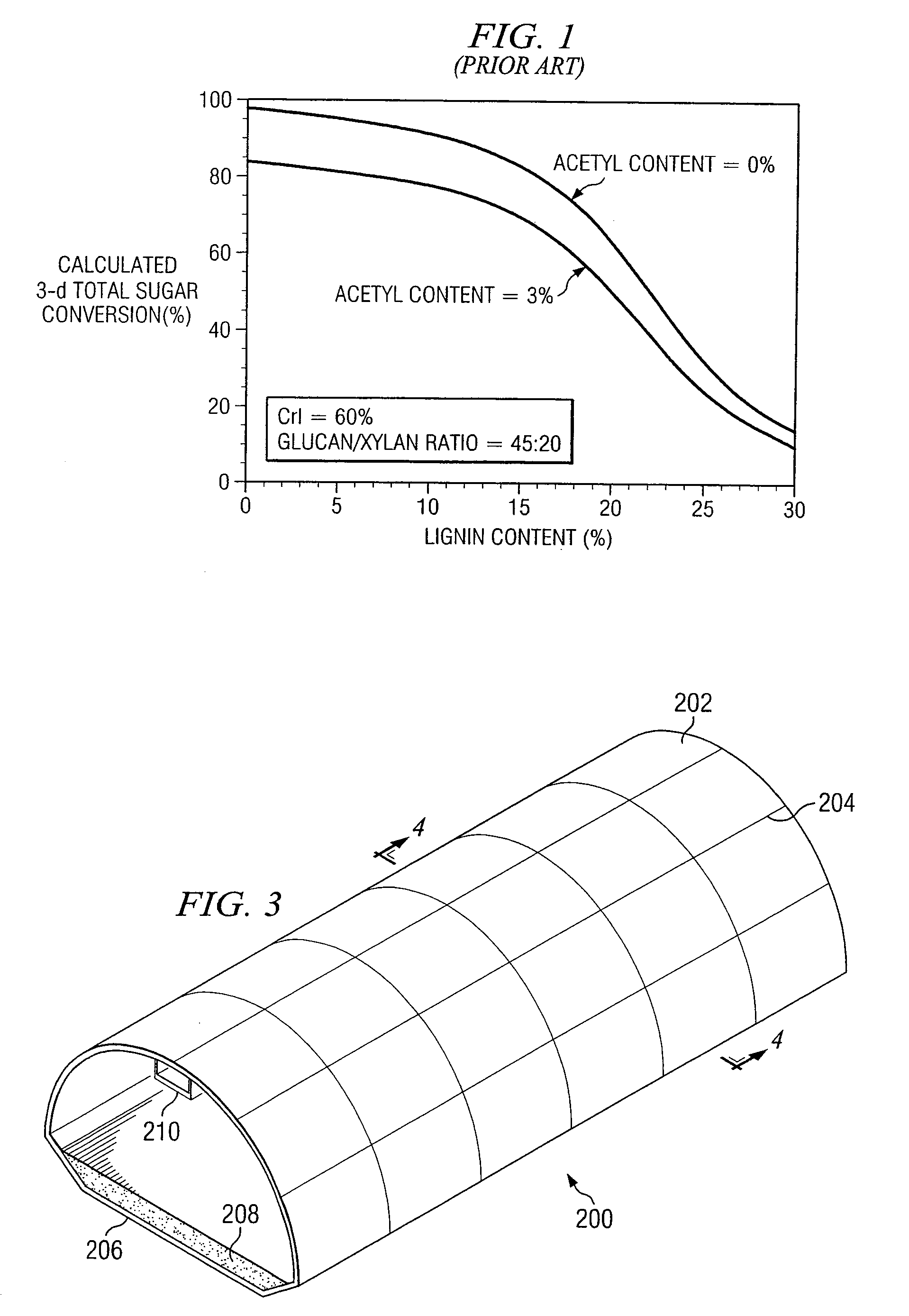

Biofuel production methods and compositions

ActiveUS20080274528A1Increase productionSmooth transitionSugar derivativesBiofuelsBiofuel cropLignin biosynthesis

The invention provides methods for increasing the level of fermentable carbohydrates in a biofuel crop plant such as alfalfa or switchgrass, by modification of the lignin biosynthetic pathway. Also provided are plants prepared by the methods of the invention. Methods for processing plant tissue and for producing ethanol by utilizing such plants are also provided.

Owner:NOBLE RES INST LLC

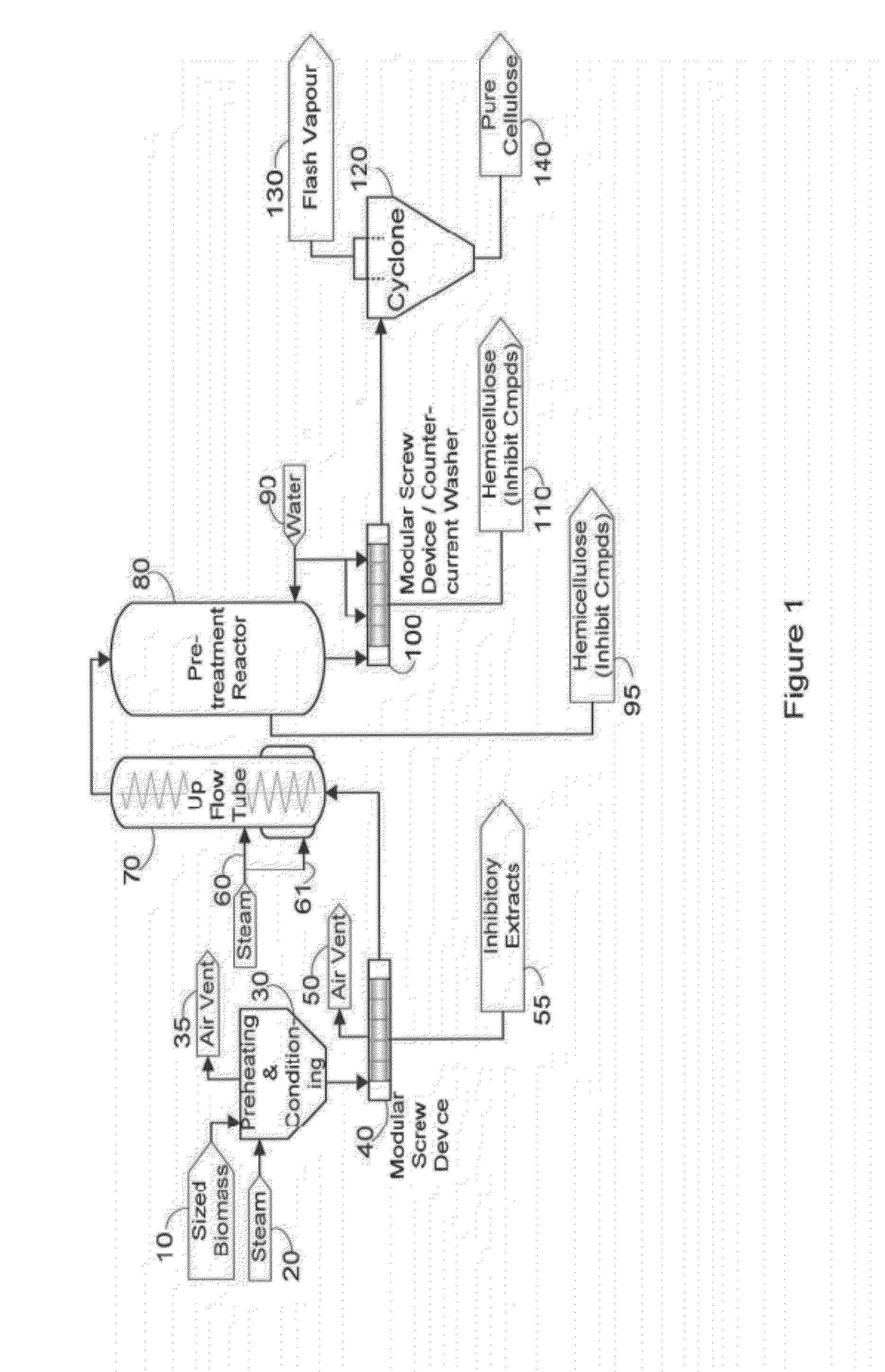

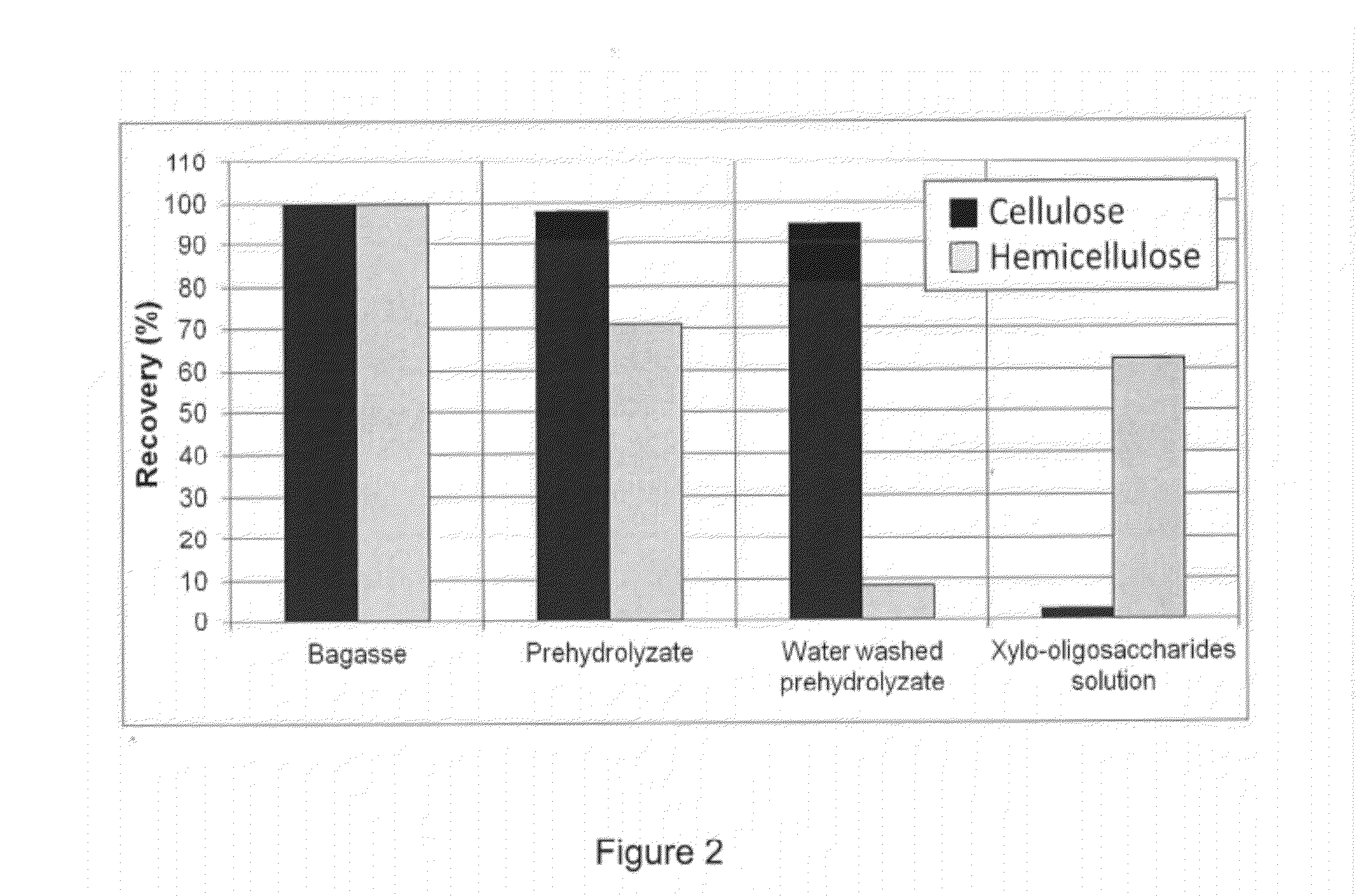

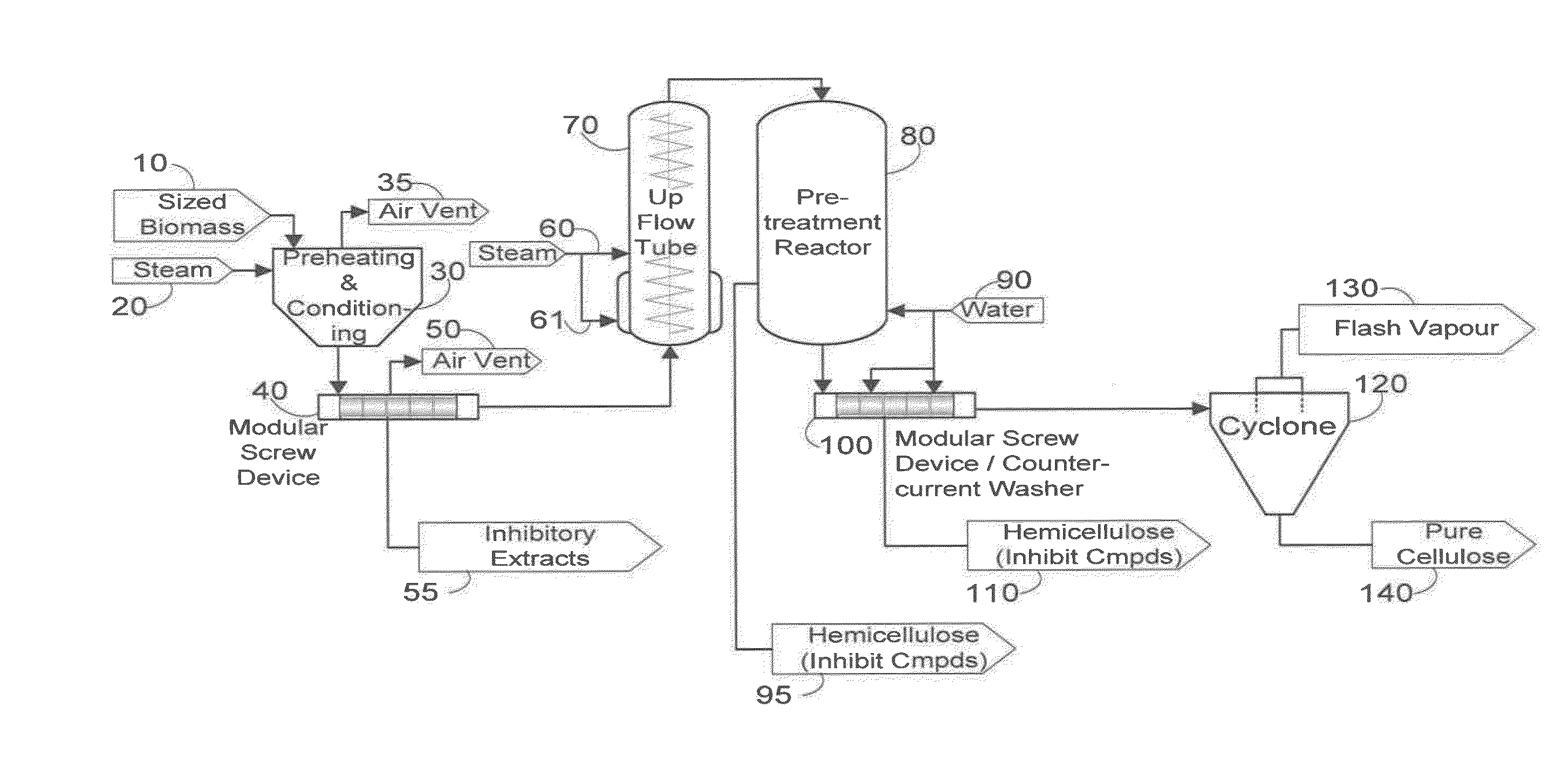

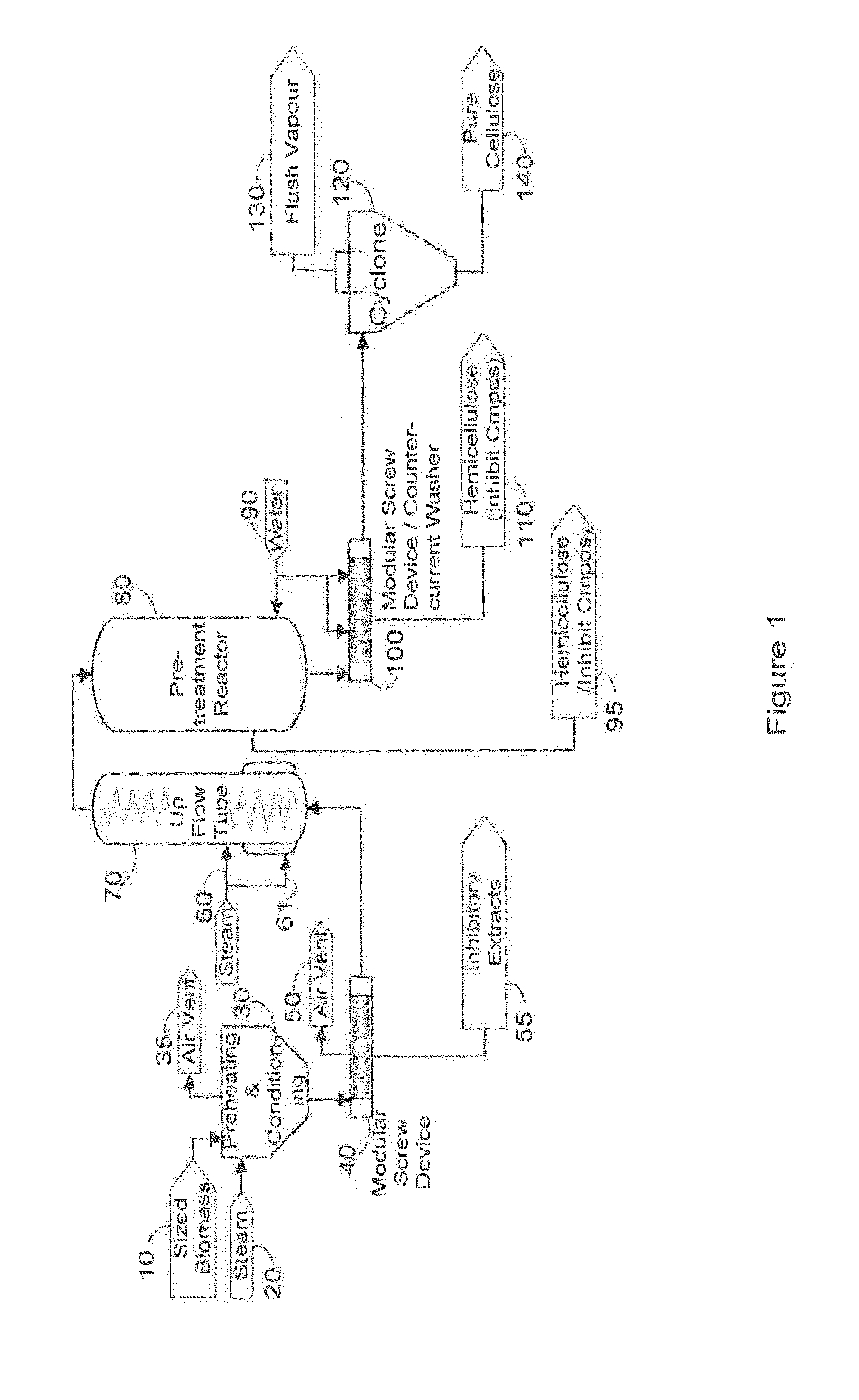

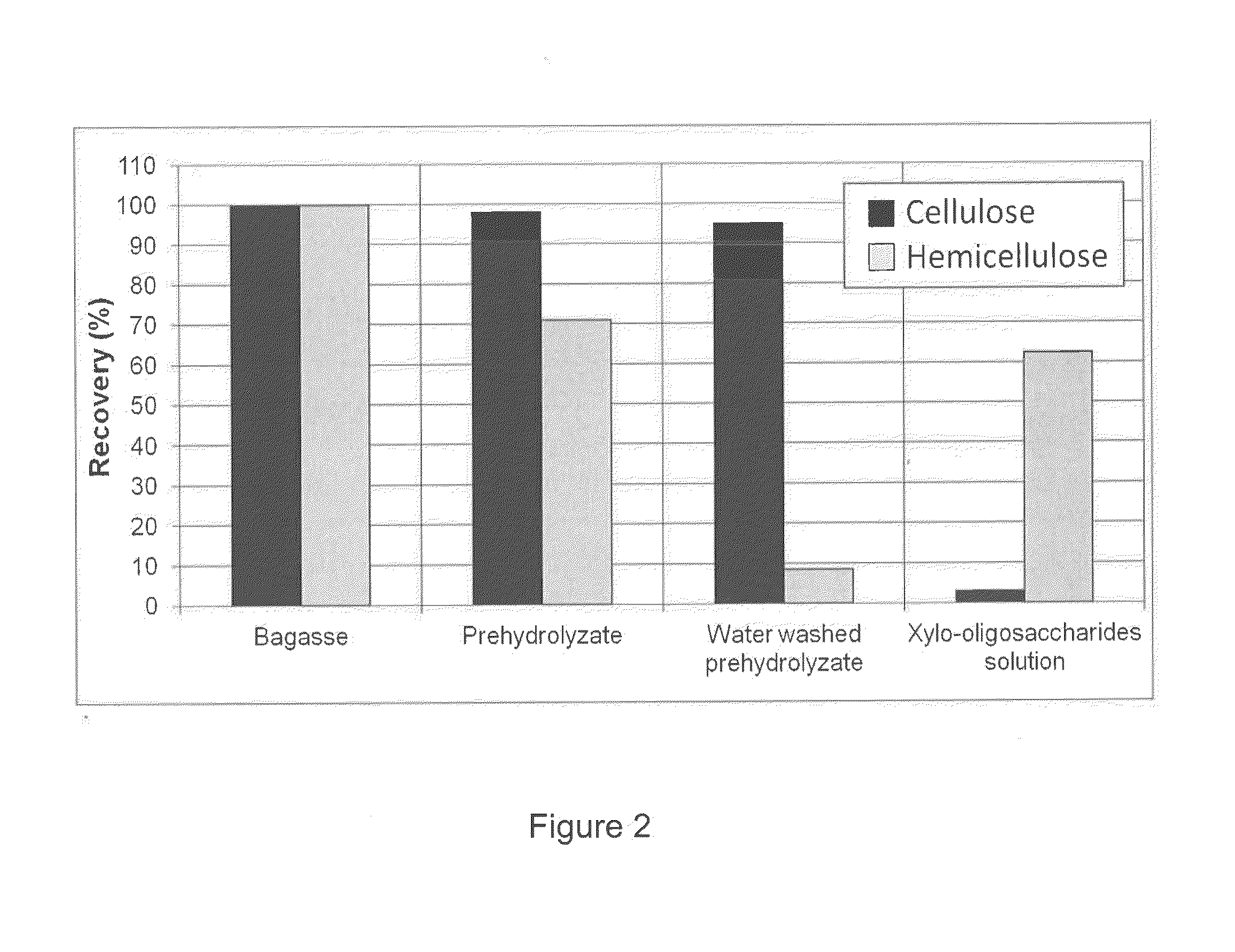

Bagasse fractionation for cellulosic ethanol and chemical production

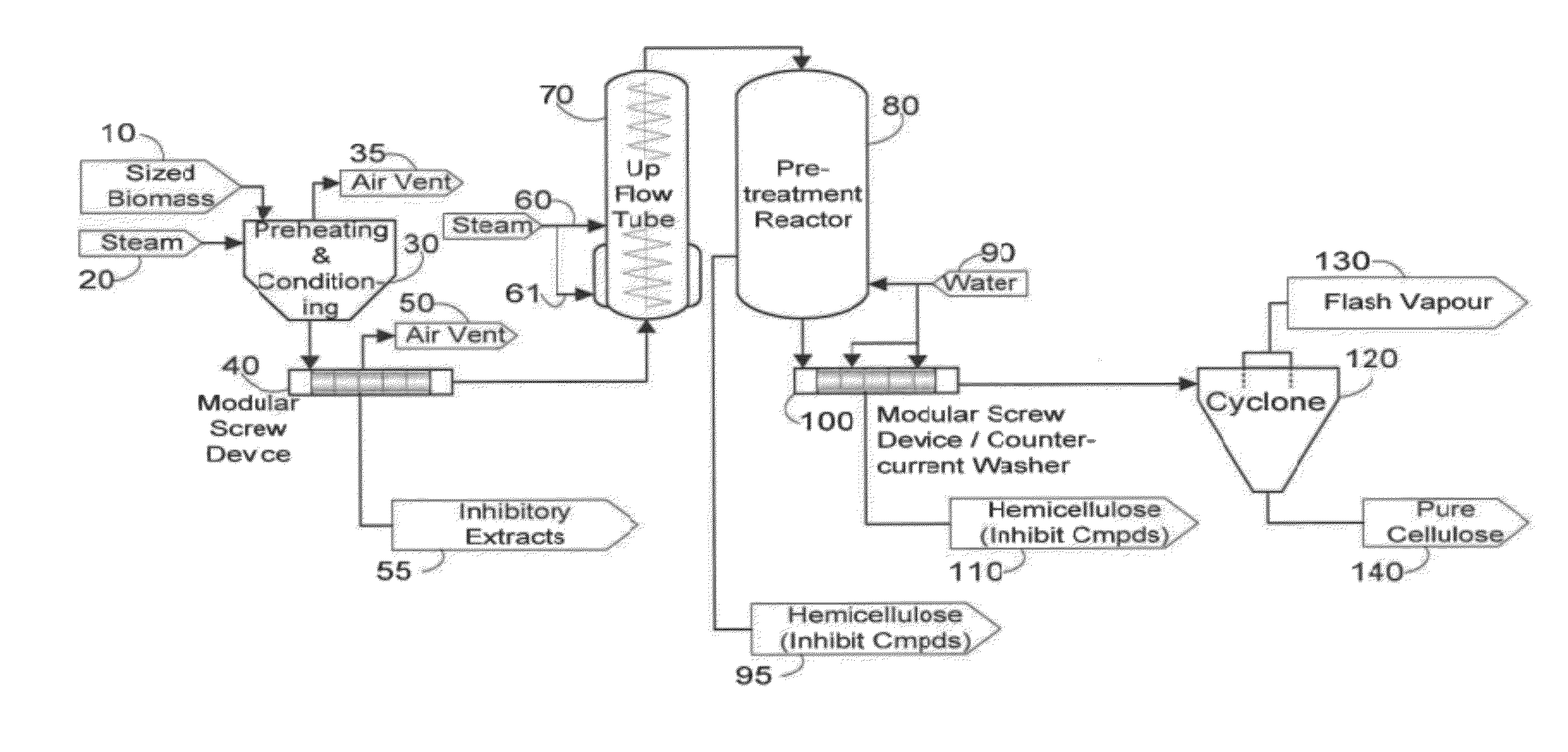

InactiveUS20120111514A1Reduce contentHigh lignin contentPretreatment with water/steamPretreatment with alkaline reacting compoundsEnzymatic hydrolysisFractionation

A process is defined for the continuous steam pretreatment and fractionation of bagasse to produce a concentrated cellulose solid stream that is sensitive to enzymatic hydrolysis. Valuable chemicals are recovered by fractionating the liquid and vapor stream composed of hydrolysis and degradation products of the hemicellulose. Cellulosic derived glucose is produced for fermentation to biofuels. A hemicellulose concentrate is recovered that can be converted to value added products including ethanol.

Owner:GREENFIELD SPECIALTY ALCOHOLS

Short-flow environmentally-friendly production method for jute fibers

ActiveCN102031568AShort production processEfficient removalYarnFibre treatment to obtain bast fibreChemical oxygen demandImpurity

The invention relates to a short-flow environmentally-friendly production method for jute fibers. The method is characterized in that: the principle of deep oxidation is adopted, and jute bast is subjected to identical bath degumming and bleaching. The method comprises the following steps of: 1) performing impurity removal and washing on the jute bast; 2) performing first identical bath degumming and bleaching by using 5 to 6 g / l of nano argil preparation, 6 to 7 g / l of caustic soda, 1 to 3 g / l of soda ash and 8 to 10 g / l of hydrogen peroxide; 3) performing second identical bath degumming and bleaching by using 4 to 5 g / l of nano argil preparation, 4 to 6 g / l of caustic soda, 1 to 3 g / l of soda ash and 8 to 12 g / l of hydrogen peroxide; 4) washing after degumming and bleaching; and 5) dehydrating, shaking, softening and drying the washed jute fibers. Compared with the prior art, the method has the advantages that: 1) the production process flow is shortened by adopting a deep oxidation method; 2) the produced jute fibers have good softness and high whiteness; and 3) the process wastewater is little and has low chromaticity, and the discharge of wastewater chemical oxygen demand (COD) is greatly reduced.

Owner:郑州银泰企业管理咨询有限公司

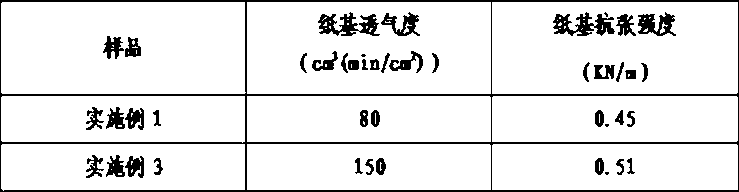

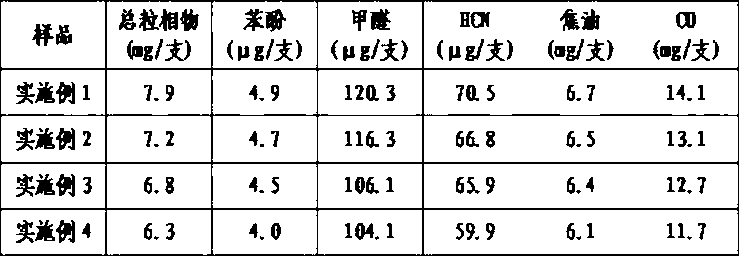

Method of manufacturing reconstituted tobacco through high-quality functional paper-making process

The invention relates to a method of manufacturing reconstituted tobacco through a high-quality functional paper-making process. The method of manufacturing the reconstituted tobacco through the high-quality functional paper-making process is characterized by comprising the following steps: a. waste tobacco materials are extracted after being fully infiltrated in hot water, the mixture of each waste tobacco material and water enters a slurry-squeezing machine to be squeezed into slurry, and solid and liquid are separated; b. crude extract liquid enters a concentrating system and is concentrated after passing through a straight-line vibration screen and a horizontal screw decanter centrifuge, and solid-liquid separation is conducted on the crude extract liquid; c. after the slurry is squeezed through the slurry-squeezing machine, the mixture of waste tobacco materials and water enters a crude extract tobacco slurry pool, and biological enzyme processing is conducted on the tobacco slurry after compound proteases and lignin enzymes are added to the crude extract slurry pool or follow-up slurry pools. According to the method of manufacturing the reconstituted tobacco through the high-quality functional paper-making process, the content of injurious components in raw tobacco materials such as proteins, amino acids, pectins, lignin and cellulose in the reconstituted tobacco can be selectively reduced so as to reduce the number of injurious components released when the reconstituted tobacco is combusted, a large amount of zymoprotein is not left in a finished reconstituted tobacco product, and meanwhile tobacco macromolecule substances are degraded through enzymes or are separated through flocculating agents.

Owner:杭州利群环保纸业有限公司

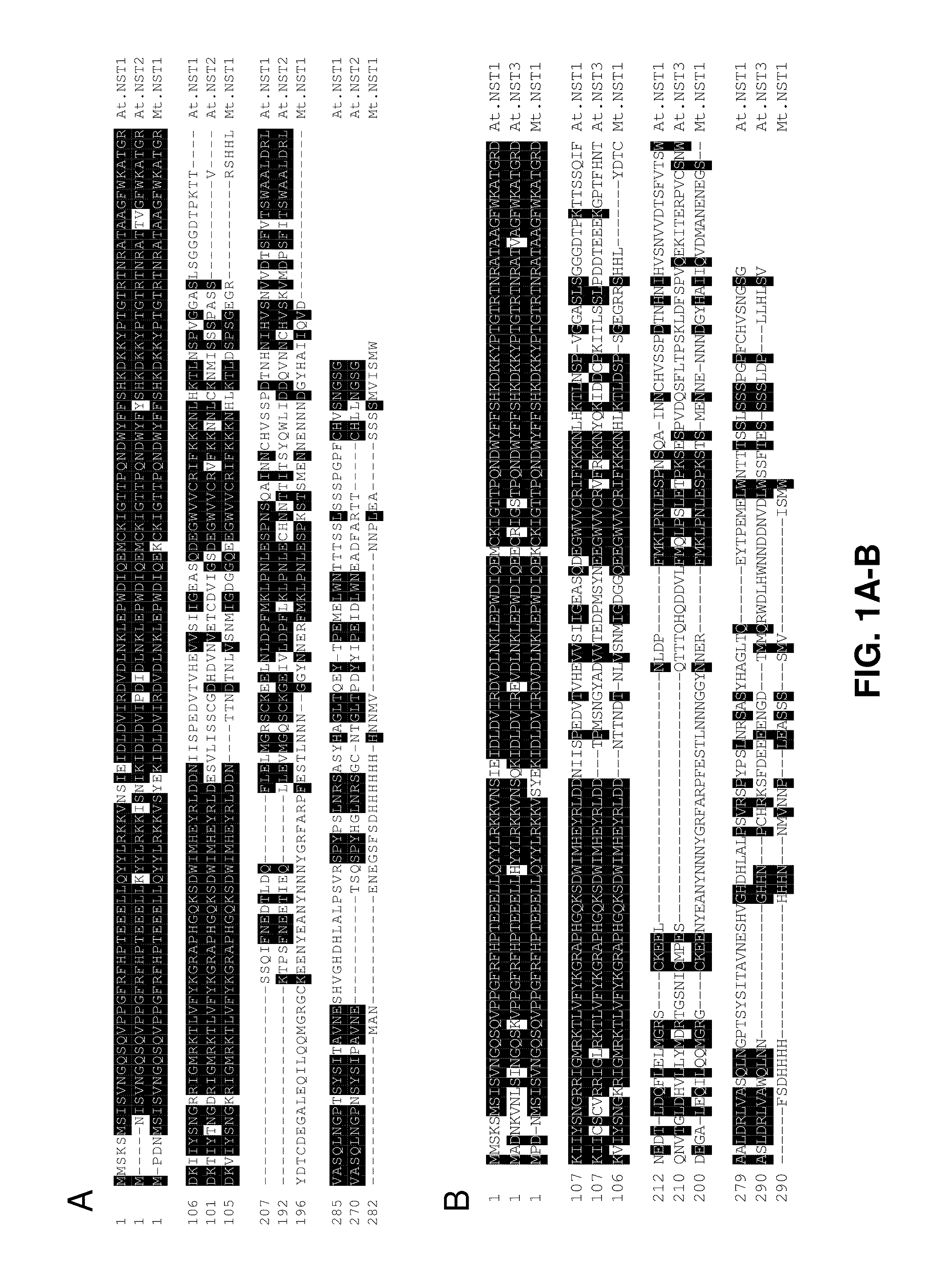

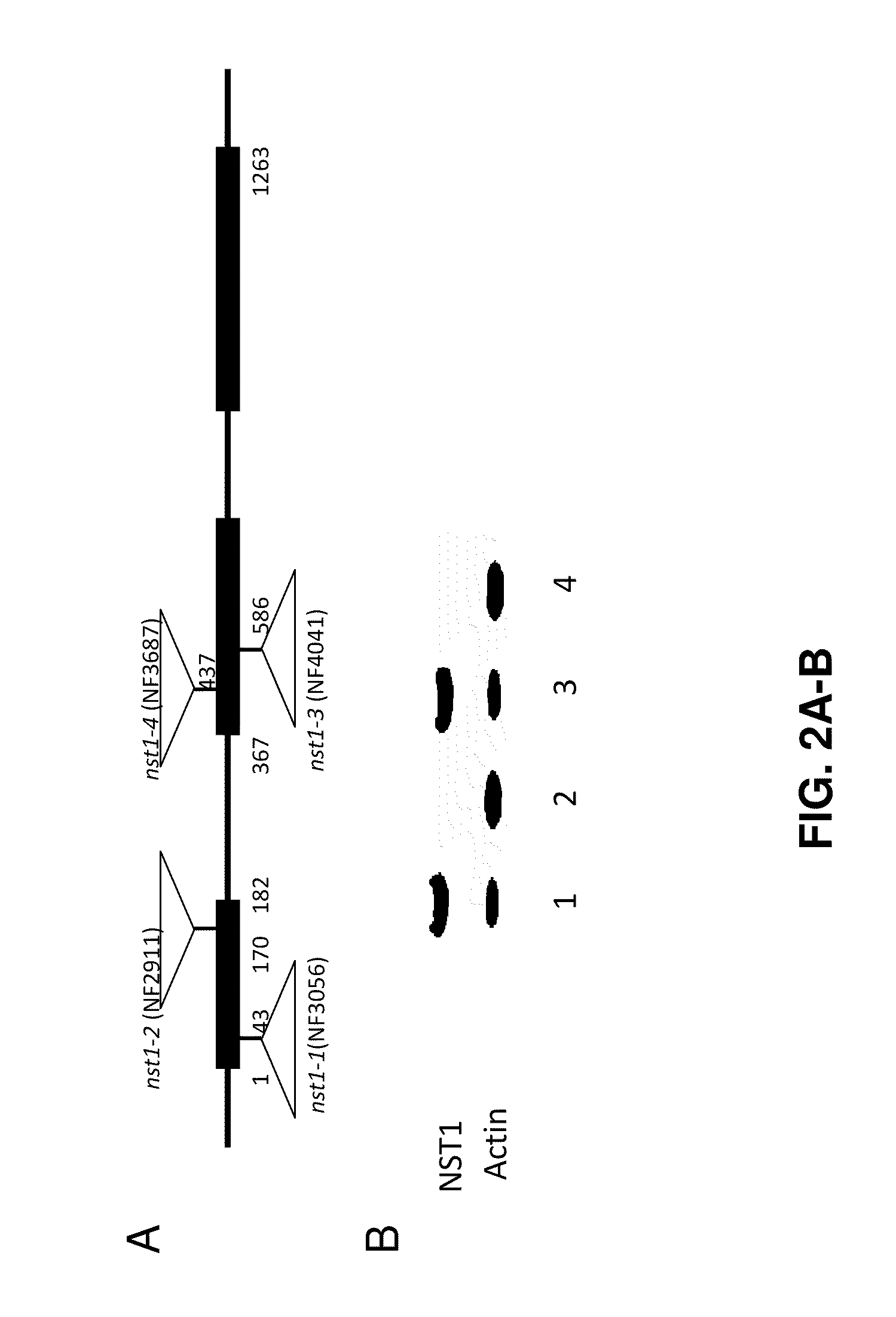

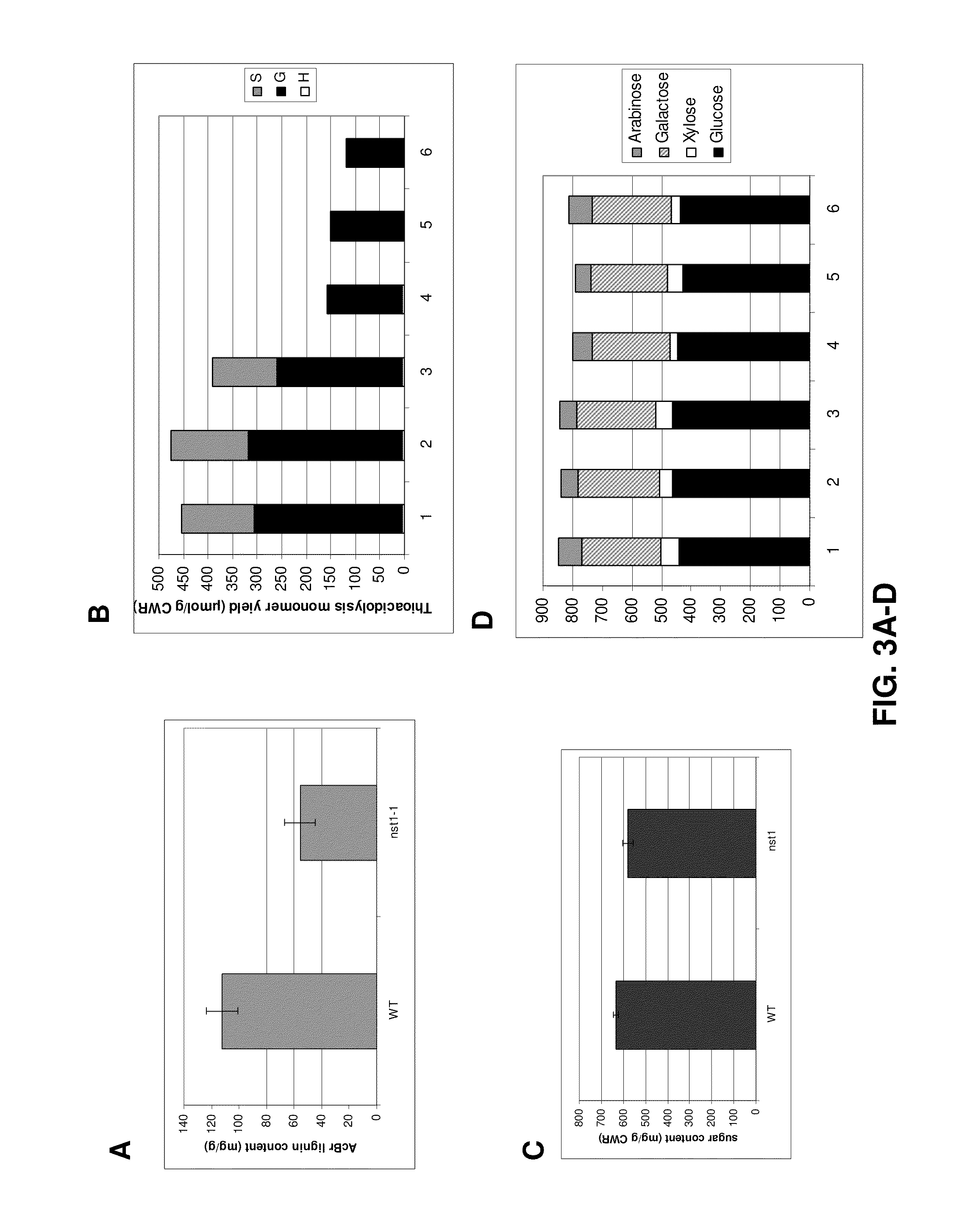

Plants with modified lignin content and methods for production thereof

ActiveUS20110010790A1Improve digestibilityLow lignin contentOxygen compounds purification/separationFermentationAnimal ForagingPlant tissue

The invention provides methods for decreasing lignin content and for increasing the level of fermentable carbohydrates in plants by down-regulation of the NST transcription factor. Nucleic acid constructs for down-regulation of NST are described. Transgenic plants are provided that comprise reduced lignin content. Plants described herein may be used, for example, as improved biofuel feedstock and as highly digestible forage crops. Methods for processing plant tissue and for producing ethanol by utilizing such plants are also provided.

Owner:NOBLE RES INST LLC

Natural plant fibre extraction by alkali oxidation

InactiveCN1818157AReduce the probability of residual glueLow lignin contentFibre treatment to obtain bast fibreChemistryNatural fiber

The invention provided an alkaline extracting method of the natural plant fiber. The process is: the material->acid etch->washing->alkaline with oxygen->strike the fiber->washing by the water->washing by the acid->washing by the water->dehydration->shake the fiber->oil feed->dehydration->air dry or oven dry. The fiber can be protected by adding the assistant Mg<2+>, the stability of the H2O2 in the alkali and the chemical assistant, also the nucleophilic reaction of the H2O2 to lignine can reach the best efficient. It can be used for extracting the plant fiber of the spinning, weaving and the dressing.

Owner:QINGDAO UNIV

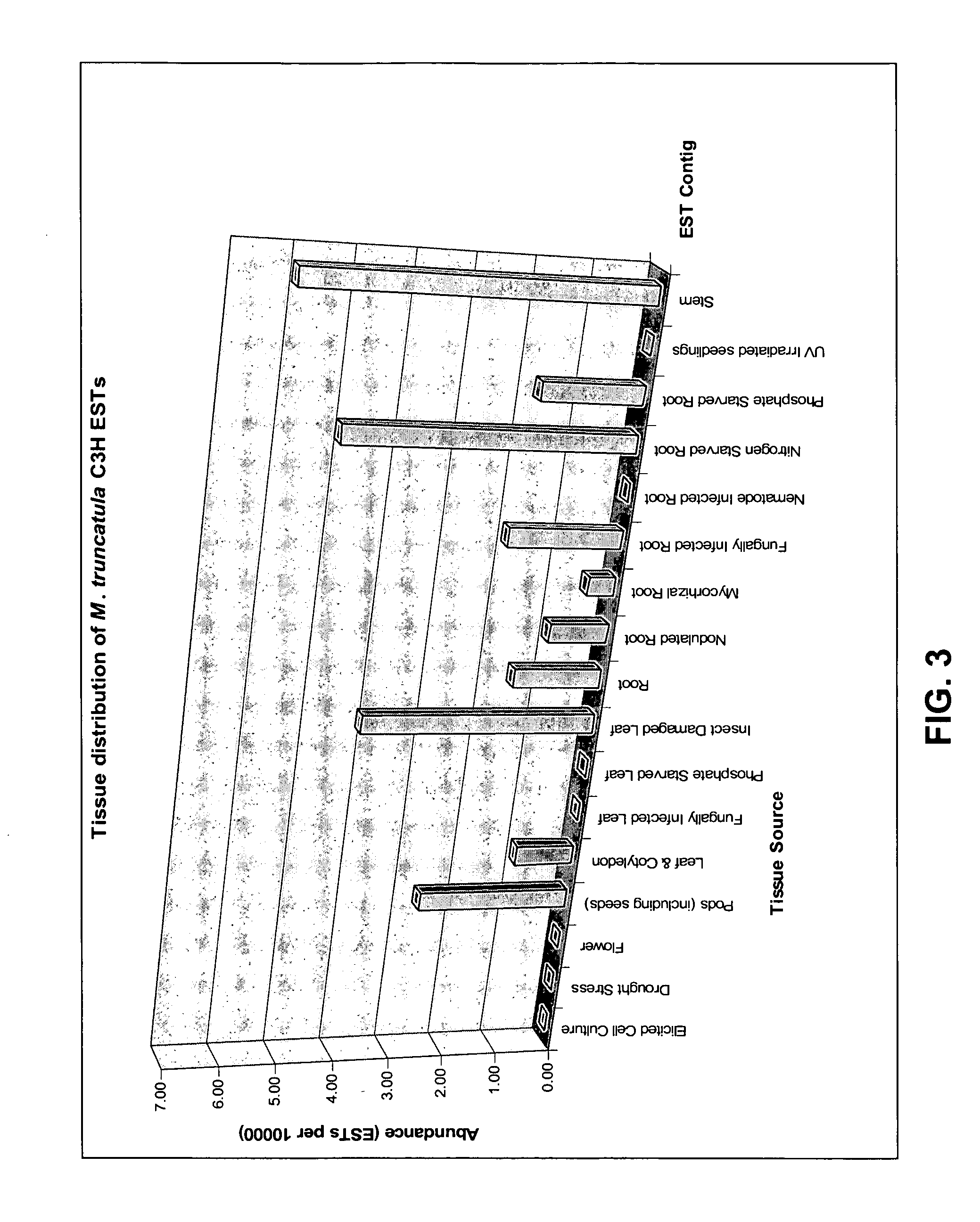

Modification of lignin biosynthesis

ActiveUS7663023B2Raise the ratioLow lignin contentClimate change adaptationOther foreign material introduction processesBiotechnologyLignin biosynthesis

Owner:NOBLE RES INST LLC

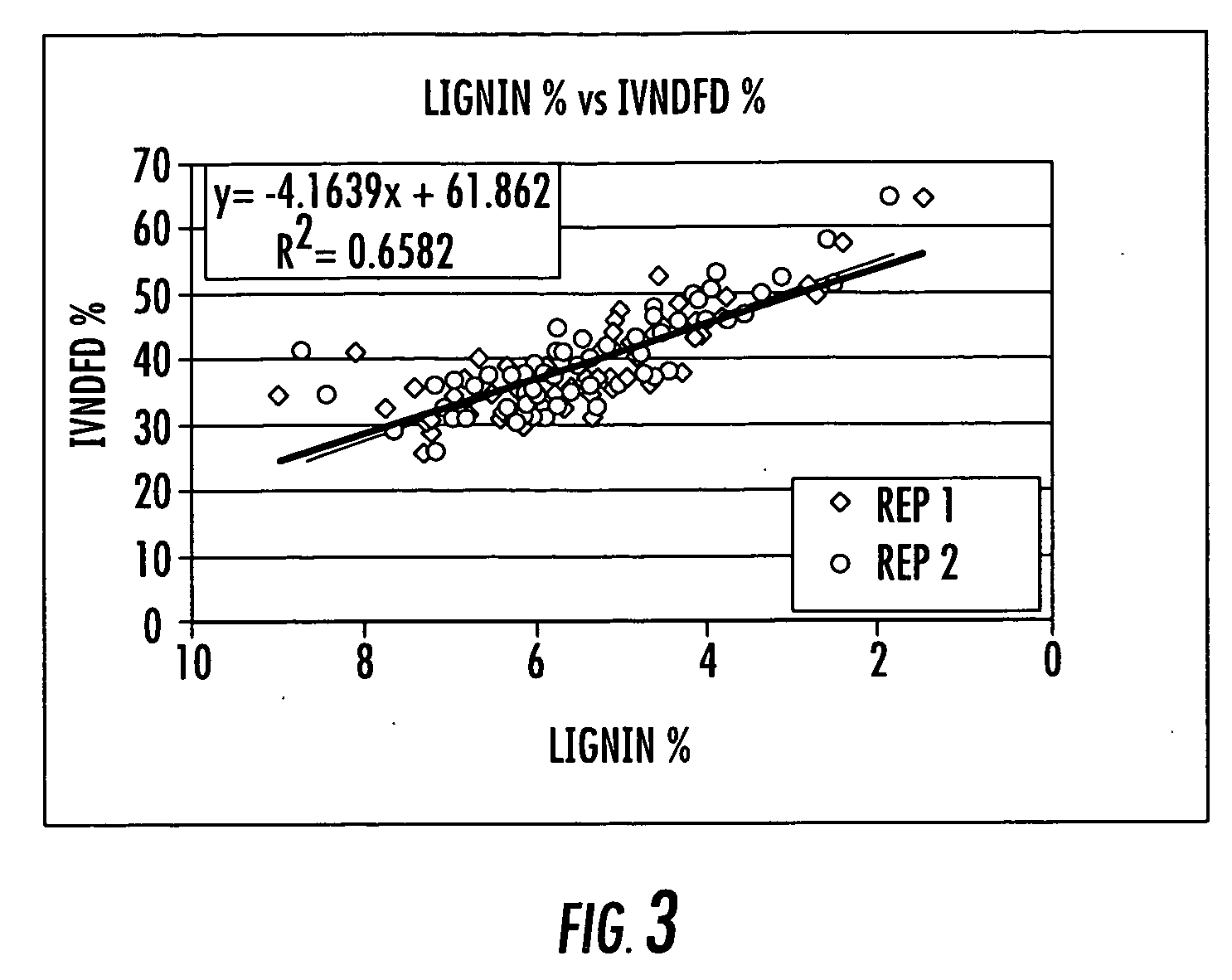

Method for modifying lignin composition and increasing in vivo digestibility of forages

InactiveUS20090044294A1Improve digestibilityLow lignin contentTransferasesOther foreign material introduction processesAntisense OrientationOpen reading frame

Methods for transforming forage legumes or woody plants with a DNA construct comprising at least one open reading frame encoding for a caffeoyl CoA 3-O-methyltransferase enzyme or a Medicago sativa caffeic acid 3-O-methyltransferase enzyme or a fragment thereof in either a sense or antisense orientation under a lignification-associated tissue specific promoter have been found, resulting in the down-regulation of the corresponding homologous gene either through antisense inhibition or sense suppression, as well as reduced lignin content and modified lignin composition in the transgenic plants. The expression of the caffeoyl CoA 3-O-methyltransferase transgene produces an increased syringyl lignin to guaiacyl lignin ratio in the transformed plant, and greatly improved forage digestibility.

Owner:NOBLE RES INST LLC

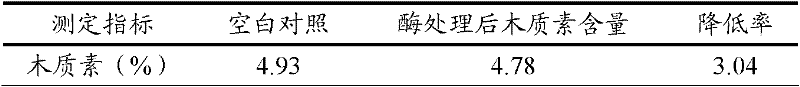

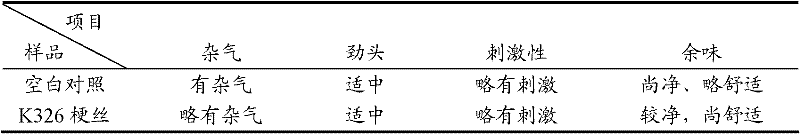

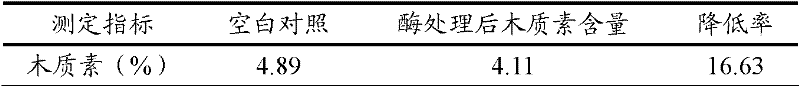

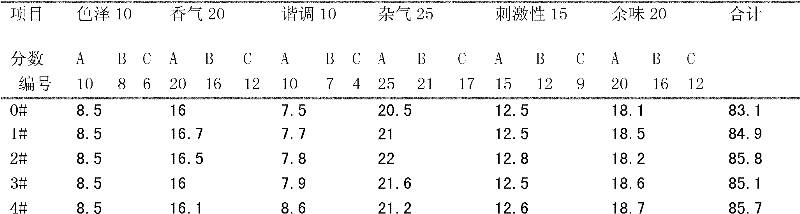

Method for reducing content of lignin in peduncle shred of tobacco

The invention relates to a method which adopts lignin-degradation complex enzyme to treat a peduncle shred of tobacco so as to reduce the content of lignin in the peduncle shred of the tobacco. The method comprises the steps of heating and sterilizing the peduncle shred of the tobacco in a microwave oven, degrading the lignin by using the complex enzyme, heating to denature the complex enzyme, equalization treatment and the like. The method disclosed by the invention uses the complex enzyme to treat the peduncle shred of the tobacco so as to reduce the content of the lignin in the peduncle shred of the tobacco, and the tobacco products produced by using the peduncle shred of the tobacco with low content of lignin are obviously improved on the aspects of foreign flavor, smoke strength, irritancy and aftertaste.

Owner:GUANGDONG GOLDEN LEAF TECH DEV

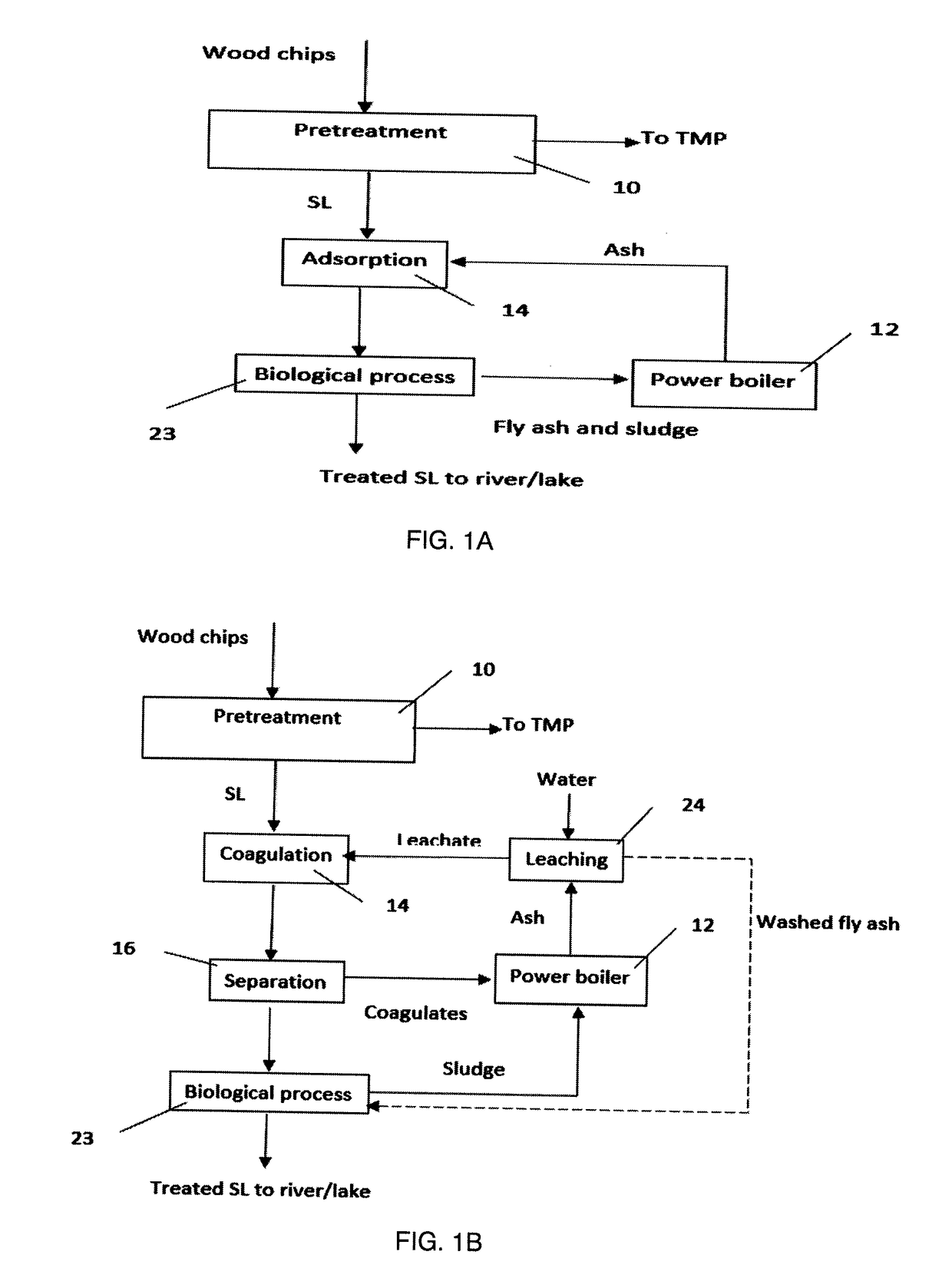

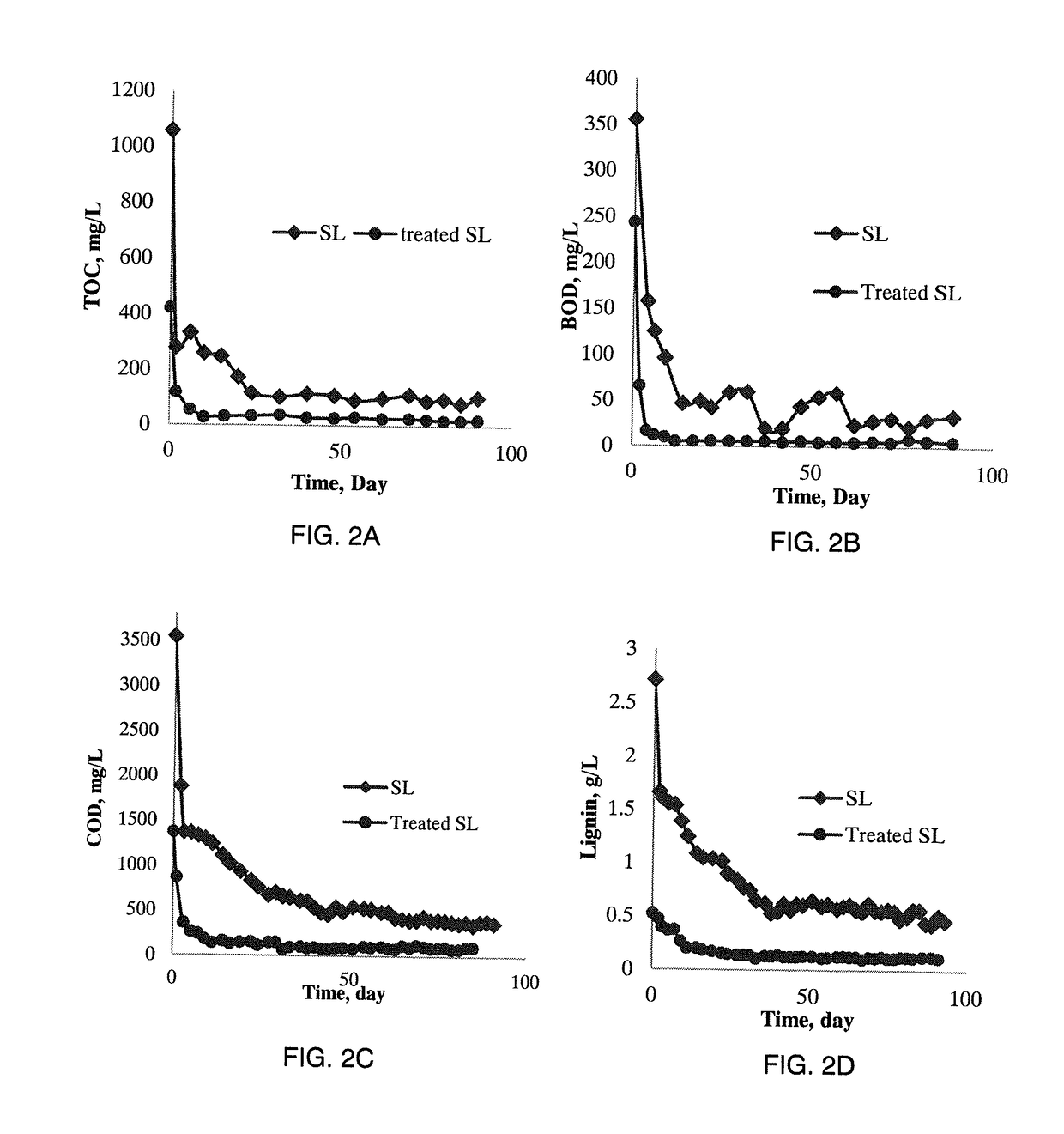

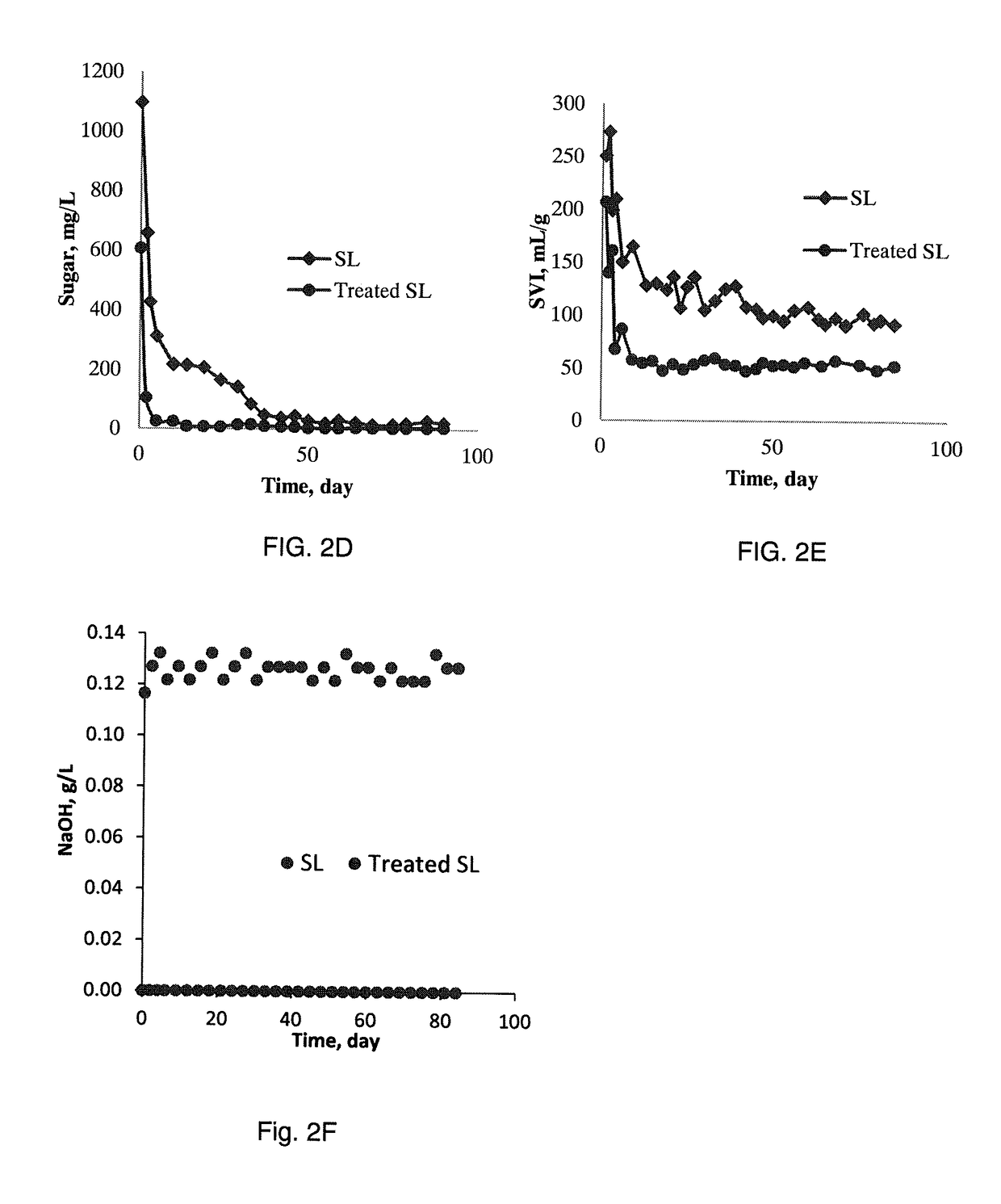

Use of Fly Ash in Biological Process of Wastewater Treatment Systems

ActiveUS20190024309A1Improve settling abilityImprove dewatering performanceOther chemical processesAluminium silicatesLiquid wasteHigh load

The spent liquor (SL) of a thermomechanical pulping (TMP) process introduces a high load to the wastewater system of this process. To reduce this load, fly ash from a biomass boiler is used and the application of fly ash improves the performance of biological process. Three different alternatives are introduced to apply fly ash to treat spent liquor.

Owner:LAKEHEAD UNIVERSITY

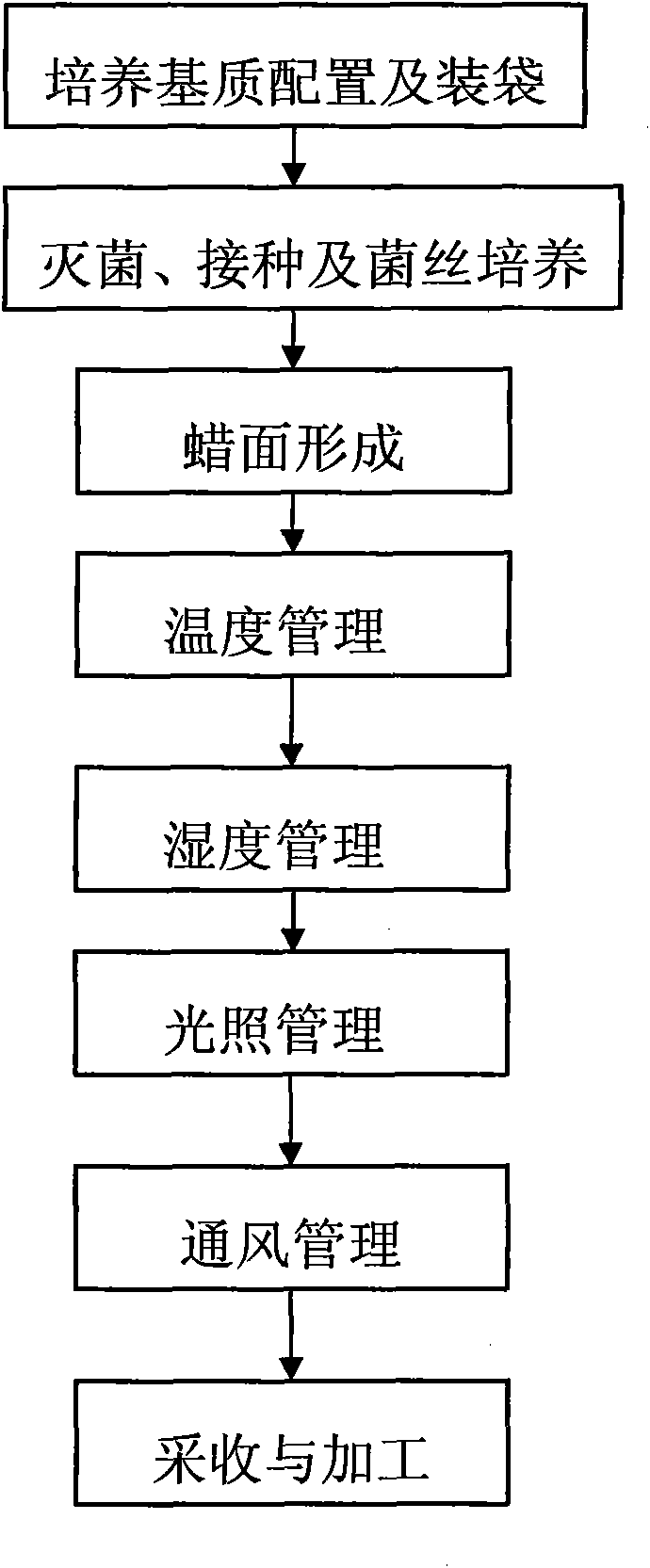

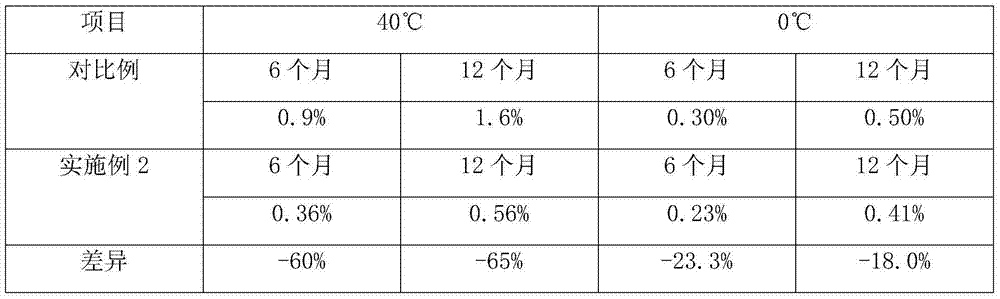

Pholiota nameko(T.Tto)S.Ito et Imai) facility culture substrate prescription and production process thereof

InactiveCN101941866AReduce dosageIncrease nitrogen sourceHorticultureFertilizer mixturesBiotechnologyPholiota

The invention relates to a pholiota nameko(T.Tto)S.Ito et Imai) facility culture substrate prescription and a fruiting condition control process, which belong to the field of edible fungus facility production and provide a pholiota nameko(T.Tto)S.Ito et Imai) facility culture optimal substrate prescription which has abundant nutrition and reasonable proportioning and is more suitable for the facility production requirement (a fruiting cycle lasts for 35 to 40 days) so as to realize year production (nine fruiting cycles can be achieved in one year). The culture substrate prescription of the invention comprises the following components in percentage by weight: 30 percent of beanstalk, 55 percent of hard miscellaneous broad leaf sawdust, 10 percent of bran, 4 percent of rice bran and 1 percent of gypsum; the ratio of materials to water is 1:(1.2-1.3), and a pH value is 6-6.5; the pholiota nameko(T.Tto)S.Ito et Imai) facility culture production condition control concerns the parameters of temperature, humidity, illumination and ventilation process, and a facility pholiota nameko(T.Tto)S.Ito et Imai) production condition control process is provided for realizing the production with high conversion rate and orderliness degree.

Owner:葛树军

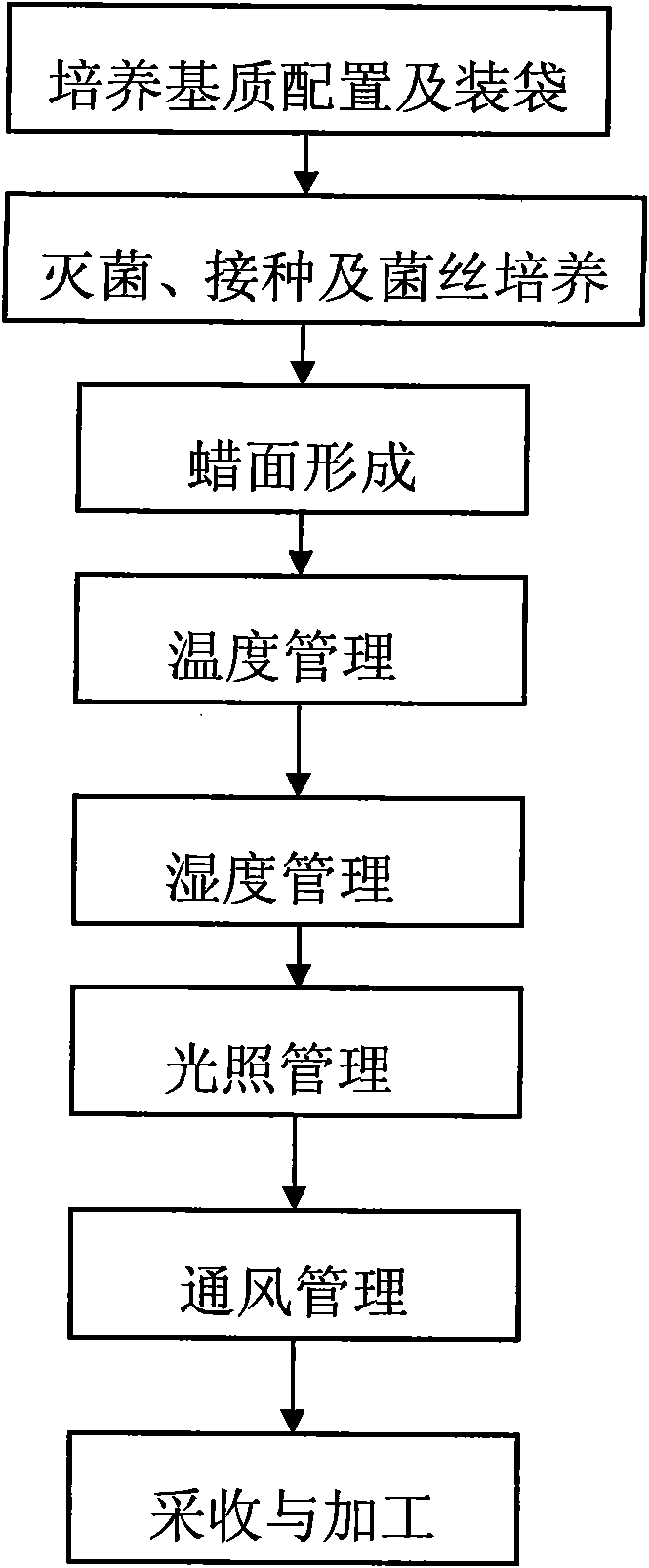

Preparation method of hemp husk fibers

InactiveCN103757964ALow lignin contentLow ash contentCellulosic pulp after-treatmentSpinningPulp and paper industry

The invention discloses a preparation method of hemp husk fibers. Bleached hemp husk fibers which have whiteness exceeding 78% and complete degumming, degreasing, delignification and decoloring are obtained by directly digesting the whole hemp husks or the whole hemp stalks chemically, extruding and washing the whole hemp stalks and directly gas-bleaching the washed strip-shaped hemp husk fibers with ozone. The hemp husk fibers can serve as hemp husk pulp for papermaking after being pulped and cut off, and can serve as hemp husk fibers for spinning after being air-dried. By adopting the preparation method, the hemp stalks and the hemp husks are unnecessary to be sliced, so that the forms of the hemp husk long fibers can be furthest maintained; the aim of bleaching can be achieved by carrying out one-stage bleaching on the hemp husk fibers obtained after digesting with zone; high-concentration shoving and powerful dispersion equipment before conventional ozone bleaching of pulp is not needed; for either the hemp husk pulp for papermaking or the hemp husk fibers for spinning, the preparation method with the characteristics of efficiency, cleanliness, economy, simplicity and directness has important values for processing and utilization of hemp fibers.

Owner:KUNMING UNIV OF SCI & TECH TECH IND SALES MANAGEMENT

Short-flow environment-friendly degumming and bleaching method for hemp fibers

ActiveCN102146589ALow lignin contentEfficient removalVegetable materialFibre treatment to obtain bast fibreState of artChemical oxygen demand

The invention relates to a short-flow environment-friendly degumming and bleaching method for hemp fibers. The method is characterized by performing one-bath degumming and bleaching on hemp bast by adopting a deep oxidation principle and utilizing materials such as a nano-clay preparation, hydrogen peroxide and the like. The method comprises the following steps of: 1) performing impurity-removing washing on the hemp bast for 1 to 3 times by using recycled washing water; 2) performing temperature-rising washing on the hemp bast for 1 to 3 times by using the recycled water again; 3) performing the one-bath degumming and bleaching on the hemp bast by using 3 to 4 g / l nano-clay preparation, 3 to 4 g / l sodium hudroxide, 1 to 2 g / l sodium carbonate and 5 to 10 g / l hydrogen peroxide; 4) washing with water after performing the one-bath degumming and bleaching; and 5) processing the hemp bast into ramie cotton blended yarns after shaking hemp, curing and drying. Compared with the prior art, the method has the advantages that: the processes of embossing the hemp and beating the hemp are saved by adopting a deep oxidation method; the production flow is shortened; and the water dosage is greatly reduced; 2) the whiteness and the softness are high; and 3) the chemical oxygen demand (COD) value of the process waste water is low.

Owner:郑州银泰企业管理咨询有限公司

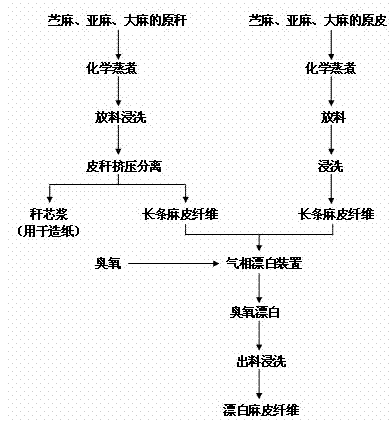

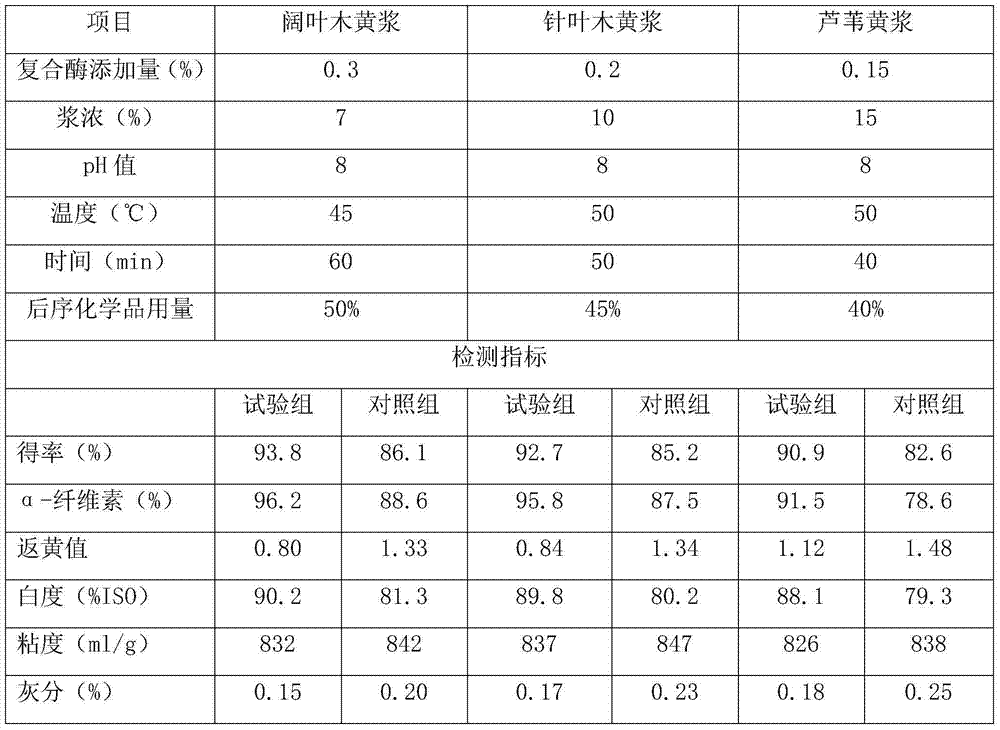

Bleaching compound enzyme for papermaking and preparation method of bleaching compound enzyme

The invention discloses a bleaching compound enzyme for papermaking and a preparation method of the bleaching compound enzyme. The bleaching compound enzyme for papermaking, which has the advantages of complete enzyme system, good bleaching effect, easiness in preservation and good storage stability, is prepared by taking high temperature-resistant alkaline xylanase as main raw material, scientifically compounding a thermophilic bacillus culture, laccase and a medium thereof, dextranase, EDTA (ethylenediaminetetraacetic acid), a protecting agent, an activator, mannose, lipase, tannase, pectase, a whiteness stabilizer, a nonionic surfactant, an antioxidant and the like, completely retaining paper pulp cellulose and simultaneously dissolving out and degrading lignin to the greatest extent. The bleaching compound enzyme disclosed by the invention can significantly improve yield and quality of paper pulp against broad-leaf wood, coniferous wood and reed yellow slurry, and the whiteness is improved by 10.94%, 11.97% and 11.10% respectively; the yellow index is reduced by 39.84%, 37.31% and 24.32% respectively; the amount of conventional chemical products can be saved by 50-60%; and the purposes of reducing cost and protecting an environment are finally achieved.

Owner:黄冈晨鸣浆纸有限公司

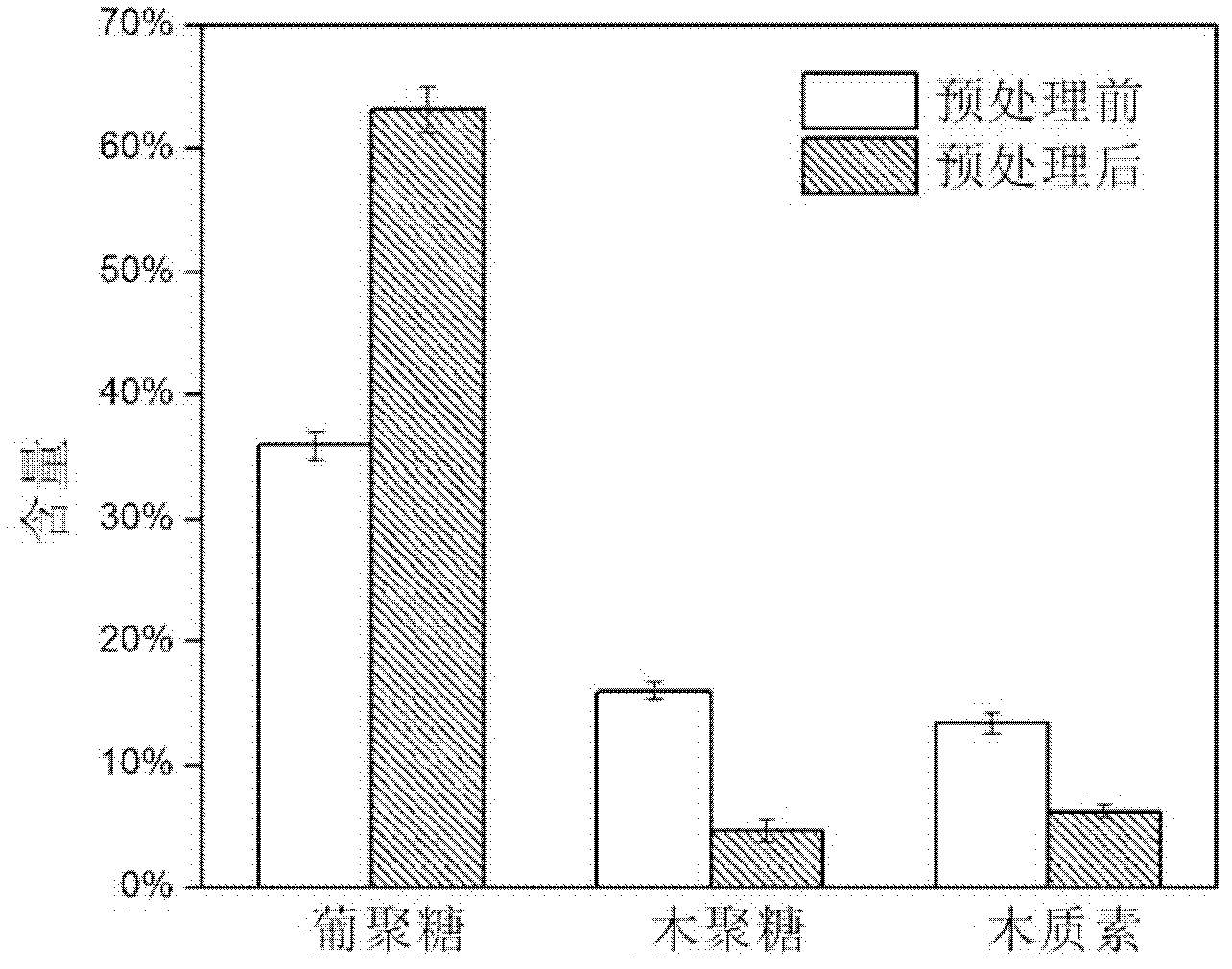

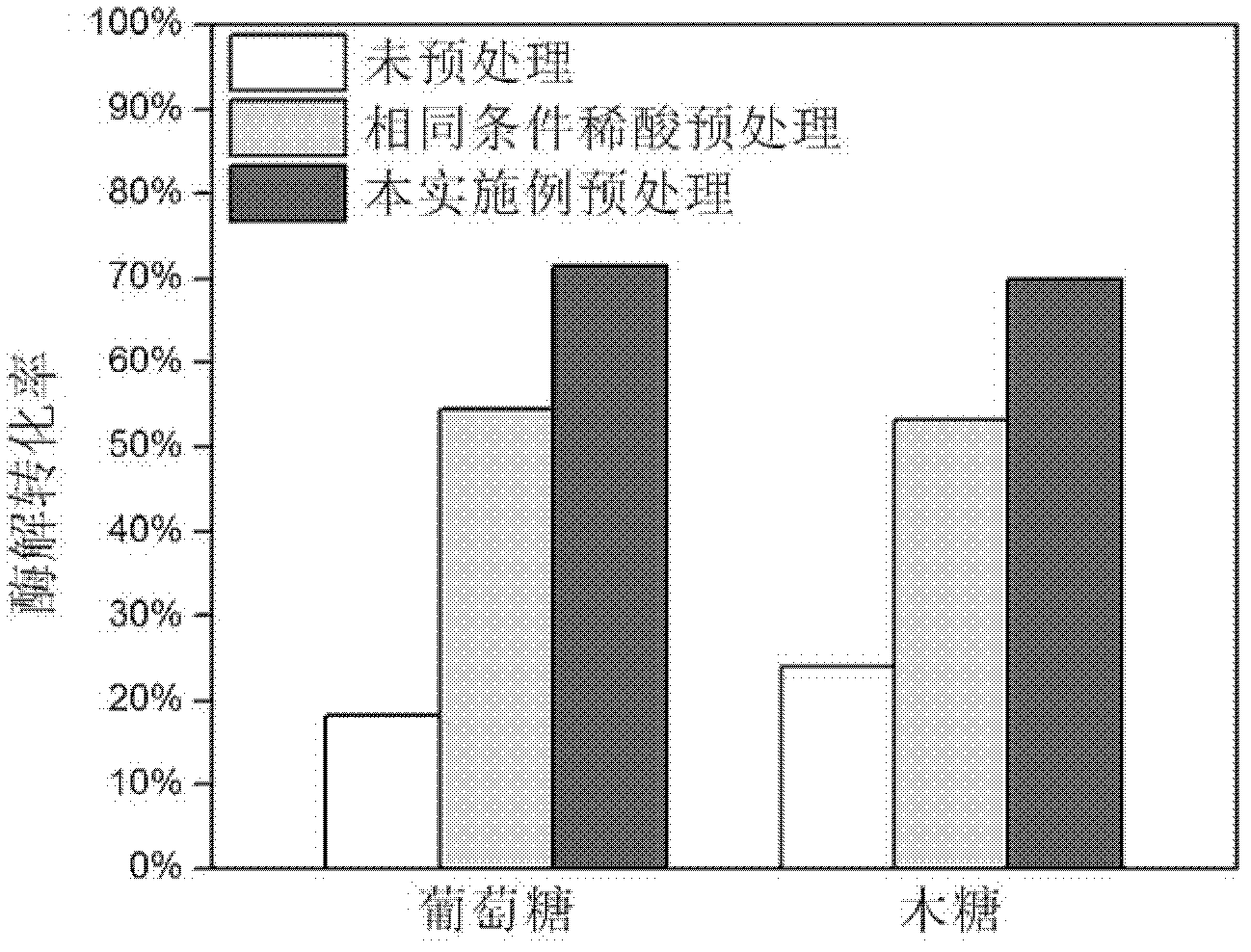

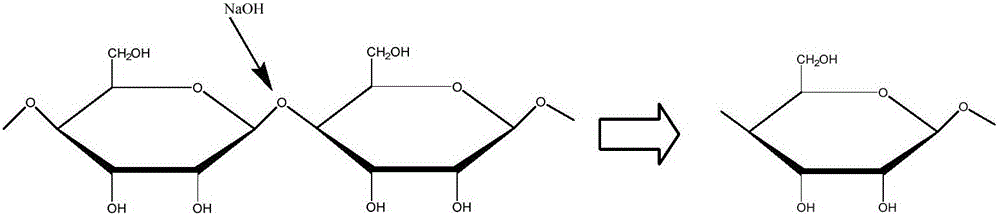

Method for improving lignocellulose enzymolysis and saccharification efficiency

The invention discloses a method for improving lignocellulose enzymolysis and saccharification efficiency, which comprises the following steps: mixing sheared lignocellulose material, ethanol, sulfuric acid and water, and heating in a high-temperature and high-pressure resisting sealed reactor to carry out pretreatment reaction to obtain a mixture; neutralizing the obtained mixture by using an alkali, separating solid from liquid, and distilling the liquid, wherein the component distilled out is ethanol, and the liquid left in a distiller is a solution rich in pentose; drying the solid, adding cellulase and water, and adjusting the pH value, and performing enzymolysis, wherein the liquid re-separated from the solid is the solution rich in the glucose. The method has the advantages that the pretreatment temperature is lower than the pretreatment temperature of the common diluted acid, the content of hemicellulose and lignin in the solid obtained through pretreatment is low, the conversion rate of glucose is high due to enzymolysis, the used ethanol can be recycled, and the fermentation inhibitor in sugar liquid is less pretreated than the common diluted acid.

Owner:TIANJIN UNIV

High-gum-content raw hemp fiber degumming method

The invention discloses a high-gum-content raw hemp fiber degumming method. The method comprises a mechanical decortication and chemical immersion pre-degumming step, a steam explosion degumming step, a lignin oxidation degumming step and an ethanol boiling step. In the invention, based on the prior art, an independent lignin catalytic oxidation step is adopted, and chemical formula and technological conditions of a lignin catalytic oxidizer are improved to control the degradation degree of lignin, so that the lignin is partially degraded into non-water-soluble polyphenol substances, thus skillfully solving the problem that the lignin is sufficiently degraded into water-soluble monophenol and enters production wastewater. The polyphenol substances obtained after the degradation of the lignin are extracted through the subsequent ethanol boiling step, i.e. the polyphenol substances enter an ethanol solution and are subjected to simple distillation and purification to produce useful industrial byproducts. According to the invention, the method has the characteristics of favorable degumming effect, mild process, small fiber damage and the like; and the obtained fiber has high strength, favorable whiteness and high comprehensive quality.

Owner:QINGDAO UNIV

Bagasse fractionation for cellulosic ethanol and chemical production

InactiveUS20160069020A1Quantity minimizationMinimize water usagePretreatment with water/steamBiofuelsBiofuelFractionation

A process is defined for the continuous steam pretreatment and fractionation of bagasse to produce a concentrated cellulose solid stream that is sensitive to enzymatic hydrolysis. Valuable chemicals are recovered by fractionating the liquid and vapor stream composed of hydrolysis and degradation products of the hemicellulose. Cellulosic derived glucose is produced for fermentation to biofuels. A hemicellulose concentrate is recovered that can be converted to value added products including ethanol.

Owner:GREENFIELD SPECIALTY ALCOHOLS

Method for comprehensively utilizing xanthoceras sorbifolia shells

InactiveCN101899475AEasy to separatePromote conversionBio-organic fraction processingClimate change adaptationBiodieselMethanation

The invention provides a method for comprehensively utilizing xanthoceras sorbifolia shells. The method comprises the following steps of: performing steam explosion pretreatment on the xanthoceras sorbifolia shells to obtain a slurry material; transforming hemicellulose and partial cellulose sugar into biological natural gas through acidification and methanation by adopting a microorganism transformation principle; extracting and separating enzymatic hydrolysis lignin contained in residues of the xanthoceras sorbifolia shells, wherein the enzymatic hydrolysis lignin can be effectively taken as a modifier for a high polymer material; and converting cellulose in the residues from which the lignin is extracted into bioethanol so as to reasonably and effectively utilize three natural major high polymer components in the xanthoceras sorbifolia shells, namely the hemicellulose, the lignin and the cellulose. The utilization problem of the xanthoceras sorbifolia shells after biodiesel is extracted from xanthoceras sorbifolia nuts in the prior art is solved, major biomass components contained in the xanthoceras sorbifolia shells are utilized reasonably and effectively, the produced biological natural gas and the bioethanol are clean renewable energy sources, and another product, namely, the enzymatic hydrolysis lignin can replace partial petrochemical materials and is used for modifying the high polymer material. Recycling and comprehensive utilization of xanthoceras sorbifolia shell waste can contribute to lowering the cost of the biodiesel, saving energy, reducing emission and bringing high social benefit; and processing technology for comprehensively utilizing the xanthoceras sorbifolia shells is simple and easy to implement and has good effect.

Owner:FUZHOU UNIV

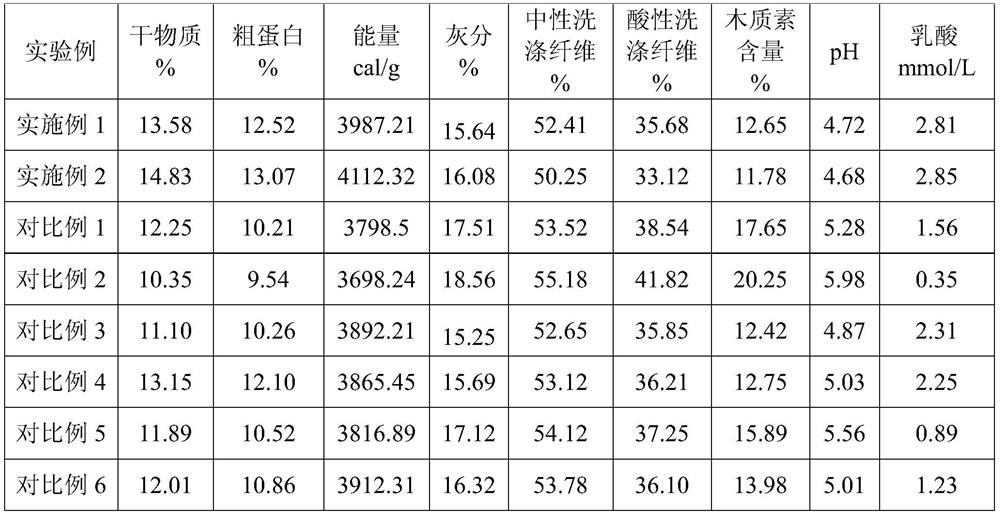

Processing method of ramie and pennisetum purpureum mixed silage

PendingCN112006157AMake up for the defect that silage is difficultIncrease dry matterFood processingAnimal feeding stuffBiotechnologyPennisetum purpureum

The invention provides a processing method of ramie and pennisetum purpureum mixed silage, and belongs to the field of feed additives. The processing method comprises the following specific steps: mixing 60%-80% of pennisetum purpureum and 20%-40% of ramie to obtain silage; then spraying fermentation liquor to the silage, spraying an additive at the same time, and then performing fermentation. Thefermentation liquor comprises compound bacteria, compound enzyme and water, and the compound bacteria comprise lactobacillus plantarum, lactobacillus buchneri, pediococcus pentosaceus and bacillus subtilis; the compound enzyme comprises cellulase, xylanase and laccase; and the additive comprises calcium propionate, molasses, urea, ethanol and water. According to the processing method of the silage, ramie and pennisetum purpureum mixed silage is adopted, nutrients are complemented, the fermentation liquid and the additive are combined for fermentation, the defect that ramie and pennisetum purpureum silage is difficult to silage is overcome, the dry matter and crude protein content and lactic acid bacteria of the silage are increased, and the crude ash content, the acid washing fiber content, the lignin content and the pH value are reduced.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION BUFFALO INST

Method for reducing content of lignin in papermaking tobacco sheets

InactiveCN102631023ALow lignin contentImproved taste qualityTobacco treatmentIron organic compoundsDry weightCitric acid

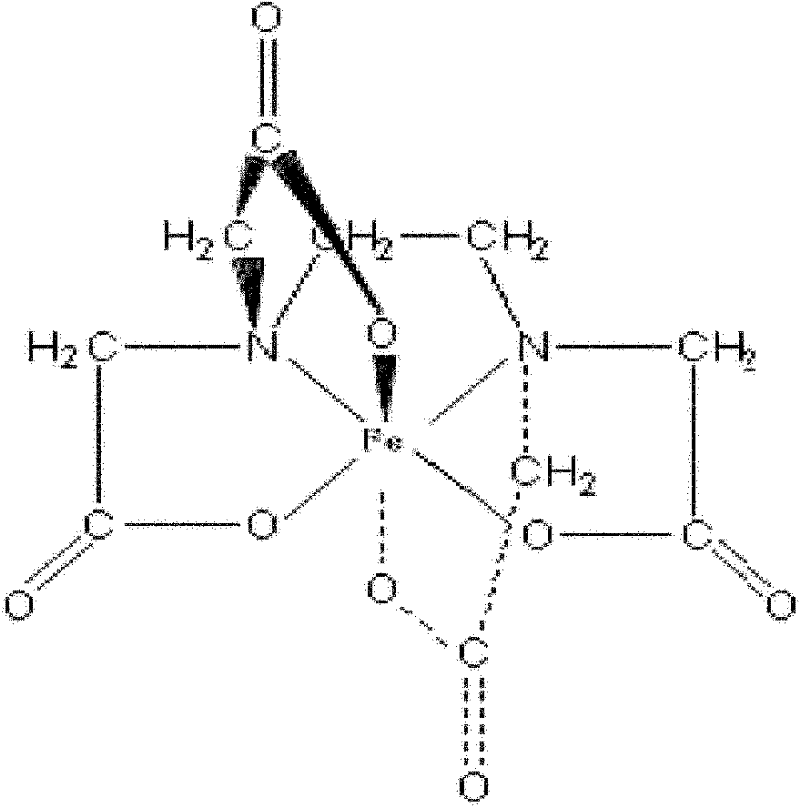

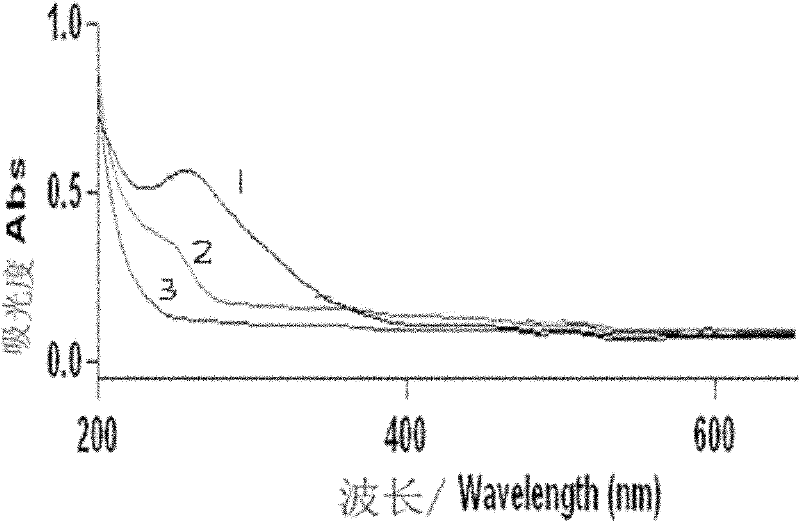

The invention discloses a method for reducing the content of lignin in papermaking tobacco sheets, belonging to the technical field of cigarette tobacco sheets. The method comprises the following step: at the tobacco raw material pulping state of the papermaking tobacco sheet production process, adding mimic enzyme according to a proportion of 1-6.5% of the dry weight of tobacco pulp material, wherein the temperature of the tobacco pulp material during the addition of the mimic enzyme is 25-40 DEG C, and after the addition, the temperature is kept for 20-40 minutes. The mimic enzyme formula comprises the following components by weight percent: 10-35% of FeSO4.7H2O, 5-20% of citric acid, 2-15% of oxalic acid and 20-60% of water. The mimic enzyme is obtained by the following steps: firstly adding the FeSO4.7H2O in the water at the temperature of 25-45 DEG C; then adding citric acid and oxalic acid; and mixing uniformly. The method provided by the invention is simple to operate and marked in effect, and is capable of decreasing the content of the lignin in the papermaking tobacco sheets and enhancing the smoking quality.

Owner:HUBEI XINYE TOBACCO SLICE DEV

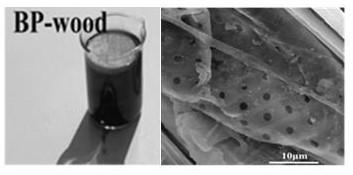

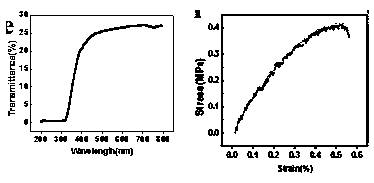

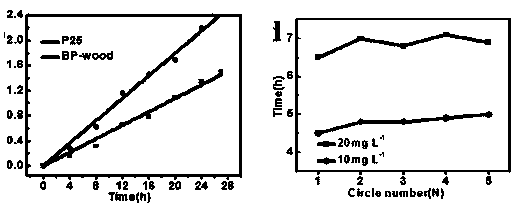

Recyclable high-efficiency photocatalytic degradation material and preparation method thereof

ActiveCN109603919AIncrease profitLow lignin contentWater/sewage treatment by irradiationWater treatment compoundsPhotocatalytic degradationBiomass

The invention discloses a recyclable high-efficiency photocatalytic degradation material and a preparation method thereof. The preparation method comprises the following steps: A, performing bleachingon biomass; B, preparing a titanium dioxide nanoparticle suspension; and C, performing surface treatment. According to the method provided by the invention, a steam process or solution immersion is adopted to remove lignin in a biomass material to obtain bleached biomass, photocatalyst nanoparticles such as titanium dioxide are uniformly dispersed on the obtained bleached biomass, and an originalskeleton is retained; the bleaching method provided by the invention has the advantages of greenness, high efficiency, a simple process, a high utilization rate of raw materials and good equipment universality, and facilitates large-scale production; and the surface and interior of the obtained bleached wood can uniformly load titanium dioxide nanoparticles to obtain a three-dimensional porous bleached biomass / titanium dioxide composite photocatalytic material, and the composite photocatalytic material can be floated, transmit ultraviolet visible light, be recyclable and be applied in a large-scale industrialized manner.

Owner:SOUTHWEST FORESTRY UNIVERSITY

Modification of lignin biosynthesis

ActiveUS20070079398A1Decrease lignin contentImprove digestibility and other characteristicClimate change adaptationOther foreign material introduction processesLignin biosynthesisLignin degradation

Owner:NOBLE RES INST LLC

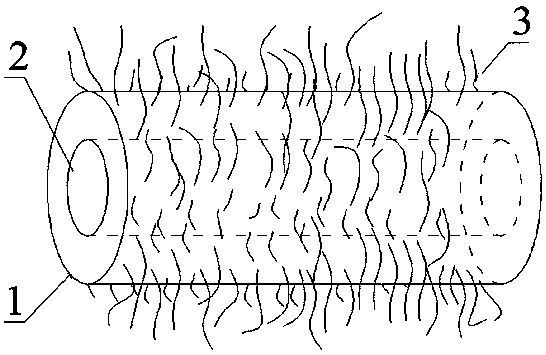

Water treatment filler capable of removing ammonia nitrogen and total nitrogen in wastewater synchronously

ActiveCN107720978AImprove ammonia nitrogen removal performanceImprove surface roughnessTreatment with aerobic and anaerobic processesSustainable biological treatmentChemistryCalcium carbonate

The invention discloses water treatment filler capable of removing ammonia nitrogen and total nitrogen in wastewater synchronously. The filler is of a cylindrical embedding-sleeving structure as a whole and is divided into an outer sleeving layer and an inner embedding layer. The outer sleeving layer is formed by foaming and blending outer sleeving layer materials, and the outer sleeving layer materials comprise low-density polyethylene (LDPE), basalt fiber and nano calcium carbonate powder. The inner embedding layer is blended by inner embedding layer materials, and the inner embedding layermaterials comprise polybuthylenesuccinate (PBS) and modified bamboo powder. By the adoption of the embedding-sleeving structure, the outer sleeving layer is provided with a pore structure which can allow microorganisms to gather together and a trichoid structure which extends outwards, under the aerobiotic and high-hydraulic-shearing condition, a surface turbulence environment is formed, and the inner embedding layer is in an alternating oxygen-enriched-microaerobic-anaerobic environment. The water treatment filler can synchronously remove ammonia nitrogen and total nitrogen, the running costof the filler is low, the volume load of unit nitrogen of wastewater treatment facilities can be increased in situ, and the selection contradiction of technological parameters of synchronously removing nitrogen and phosphorous in the running process of an actual technology can be effectively avoided.

Owner:ZHEJIANG UNIV

Beef fodder with bagasse and moso bamboo leaves as main raw materials and preparing method thereof

InactiveCN105685499AChange internal structureLow lignin contentFood processingAnimal feeding stuffPre treatmentFodder

The invention discloses beef fodder and a preparing method thereof. The beef fodder comprises bagasse, moso bamboo leaves, molasses, probiotics and traditional Chinese medicine additives. A continuous steam explosion technology is adopted to process bagasse in a puffing mode, then biological fermentation is conducted, and beef fodder is prepared. The preparing technology is simple, moso bamboo leaves, abandoned molasses and bagasse are recycled, preprocessed and subjected to biological fermentation, the palatability of the animal fodder is greatly improved, the nutrient-rich fodder is provided for cud chewers, the fodder is safe and free of toxin and can be stored for a long time, it is ensured that the fodder can be supplied all year around, and the problem that green grass fodder is in shortage in winter is solved.

Owner:GUANGXI STATE FARMS JINGUANG DAIRY IND CO LTD +1

Chinese yew pulp and preparation method thereof

ActiveCN102605667AAlleviate shortagesLow lignin contentNatural cellulose pulp/paperPretreatment with alkaline reacting compoundsLignin peroxidaseManganese peroxidase

The invention discloses Chinese yew pulp and a preparation method thereof. Chinese yew stalks are used as raw materials, shredded by a rolling and grinding shredding machine and then added into the potassium hydroxide solution for pre-impregnation, water is squeezed out after pre-impregnation, complex enzyme comprising lignin peroxidase and manganese peroxidase according to the mass ratio of 5:1-4 is added into the solution, the Chinese yew stalks are soaked for 30-40h at the temperature of 35-50 DEG C, alkali cooking is performed after defibrination, total chlorine free bleaching is performed after shoving, cleaning, screening and impurity removal, and then paper is manufactured with pulp after acid treatment, washing and desanding, so that the Chinese yew pulp is prepared. A using approach with a high added value is provided for the Chinese yew stalks, the application field of the Chinese yew stalks is widened, a low-pollution mature production process is provided for preparing dissolving pulp and regenerated cellulose fibers with the Chinese yew stalks, and shortage of regenerated cellulose fiber raw materials at present is relieved.

Owner:潍坊欣龙生物材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com