Water treatment filler capable of removing ammonia nitrogen and total nitrogen in wastewater synchronously

A technology for water treatment and ammonia removal, applied in the field of water treatment, can solve the problems of unsatisfactory mechanical strength and cost control, single function, etc., and achieve the effect of improving ammonia nitrogen removal performance, improving surface roughness, and facilitating rapid film hanging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

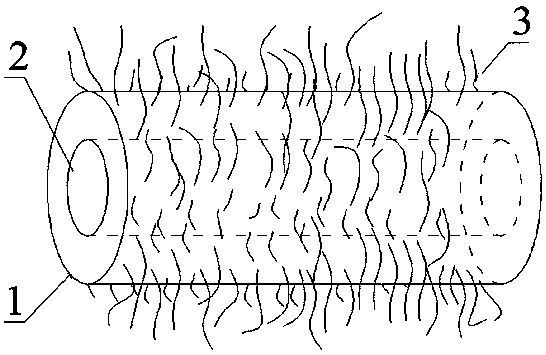

[0027] Such as figure 1 As shown, the filler is divided into outer layer 1 and inner layer 2. The overall shape is cylindrical, the surface is coated with fibers 3, the overall diameter of the filler is 8mm, the height is 10mm, and the inner layer has a diameter of 4mm and a height of 10mm. The outer layer material of the filler is 64 parts of low-density polyethylene LDPE, 15 parts of nano-calcium carbonate powder, 15 parts of basalt fiber, 2 parts of coupling agent (silane coupling agent), and 3 parts of foaming agent (azodicarbonamide) , Foaming aid (urea) 1 part. The inner layer material adopts 46 parts of polybutylene butyrate (PBS), 50 parts of 400 mesh modified bamboo powder, 3 parts of coupling agent (monoalkoxy pyrophosphate), heat stabilizer (hypophosphorous acid) 1 serving.

[0028] Table 1 is the effect of this embodiment packing treatment synthetic waste water:

[0029] .

Embodiment 2

[0031] The filler is divided into outer layer and inner layer. Its overall shape is cylindrical, the surface is coated with fibers, the overall diameter of the filler is 8mm, the height is 10mm, and the diameter of the inner layer is 4mm, and the height is 10mm. The material of the jacket layer is 75 parts of low-density polyethylene LDPE, 10 parts of nano-calcium carbonate powder, 10 parts of basalt fiber, 2 parts of coupling agent (silane coupling agent), 2.5 parts of foaming agent (azodicarbonamide). Foaming agent (urea) 0.5 part. The inner layer material adopts 51 parts of polybutylene butyrate (PBS), 45 parts of 400 mesh modified bamboo powder, 3 parts of coupling agent (monoalkoxy pyrophosphate), heat stabilizer (hypophosphorous acid) 1 serving.

[0032] Table 2 is the effect of this embodiment packing treatment actual pharmaceutical waste water:

[0033] .

Embodiment 3

[0035] The filler is divided into outer layer and inner layer. Its overall shape is cylindrical, the surface is coated with fibers, the overall diameter of the filler is 8mm, the height is 10mm, and the diameter of the inner layer is 4mm, and the height is 10mm. The material of the jacket layer is 55 parts of low-density polyethylene LDPE, 17 parts of nano-calcium carbonate powder, 20 parts of basalt fiber, 2.5 parts of coupling agent (silane coupling agent), and 4.5 parts of foaming agent (azodicarbonamide). Foaming agent (urea) 1 part. The inner layer material adopts 65 parts of polybutylene butyrate (PBS), 31 parts of 400 mesh modified bamboo powder, 3 parts of coupling agent (monoalkoxy pyrophosphate), heat stabilizer (hypophosphorous acid) 1 serving.

[0036] Table 3 is the effect that this embodiment filler handles actual pig farm wastewater:

[0037] .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com