Method of manufacturing reconstituted tobacco through high-quality functional paper-making process

A technology for reconstituted tobacco leaves and a manufacturing method, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of inability to separate enzymes and proteins, and the smoking quality of the reconstituted tobacco leaves is degraded, and achieves improved input-output rate, excellent combustion performance, and improved uniformity. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Tobacco raw materials such as tobacco stems, tobacco sticks, tobacco powder, chips, and low-grade tobacco leaves are mixed in a ratio of 6:1:1:1:1, pretreated with 7 times of water at 50 degrees Celsius for 1 hour, and then the tobacco mixture and water After being squeezed by a pulper, the tobacco extract is sieved, and then enters a horizontal screw discharge sedimentation centrifuge for separation, and then enters a concentration system to concentrate to a specific gravity of 1.250.

[0038] The tobacco pulp after being squeezed by the pulper enters the pulping system, and after high, medium and low consistency refining, screening, and pulping, the beating degree of the tobacco mixed fiber is 35 0 SR, concentration 3.0%. In the process of pulping and papermaking, add wood fiber pulp equivalent to 10% of tobacco mixed fiber pulp in the pulp mixing tank, and add filler calcium carbonate equivalent to 8% of tobacco raw material pulp in the pulp forming tank. The finish...

Embodiment 2

[0041] The difference from Example 1 is that after the tobacco extract is sieved, it enters the flocculation section, the liquid flocculation addition ratio is 0.4%, the solid flocculant addition ratio is 1%, the flocculant treatment time is 20 minutes, the flocculation temperature is 35 degrees, and after flocculation Allow to settle for 20 minutes. The flocculation process module automatically controls the operation. After the flocculation treatment, the tobacco liquid is stably controlled by the flow controller, and then enters the horizontal screw discharge sedimentation centrifuge for separation.

[0042] The same amount of slag from the slag discharge outlet of the horizontal spiral unloading settling centrifuge and the tobacco extract from the discharge outlet of the horizontal screw discharge sedimentation centrifuge in Examples 1 and 2 were collected within 30 minutes, and the test data are shown in Table 1. From Table 1, the slag content of the extract of Example 2 ...

Embodiment 3

[0046] The difference from Example 1 is: when the tobacco pulp after pulping through the pulping machine enters the pulping system, add composite protease and ligninase in the tobacco pulp rough stock tank, wherein the addition ratio of composite protease is at 1.5 %, the addition ratio of ligninase is 1.0%. The slurry temperature is controlled at 30-40 degrees, the pH value is 6.0, and the reaction time is 8 hours.

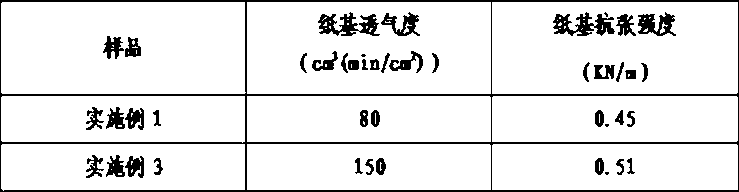

[0047] The reconstituted tobacco leaf paper bases of Examples 1 and 3 were respectively taken to measure the air permeability of the base paper, and the data are shown in Table 2. It can be concluded from Table 2 that the air permeability and tensile strength of the reconstituted tobacco leaf paper base increased significantly after biological enzyme treatment.

[0048] Table 2:

[0049]

[0050] The reconstituted tobacco leaf paper bases of Examples 1 and 3 were respectively taken to measure protein and cellulose, and the data are shown in Table 3. It can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com