Method for improving turbidity of spectinomycin hydrochloride product

A technology of spectinomycin hydrochloride and its products, which is applied in the direction of organic chemistry, can solve the problems of unguaranteed final product quality, unstable product quality, and excessive isomer content, so as to avoid the problem of bacterial contamination of feed liquid and reduce dissolution Dosage, the effect of prolonged storage time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

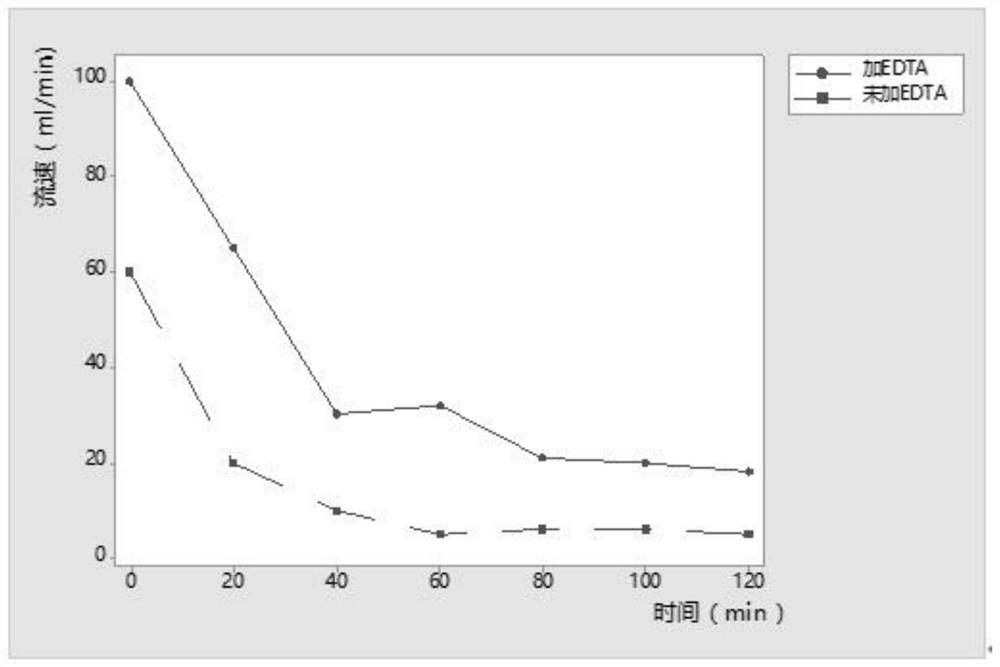

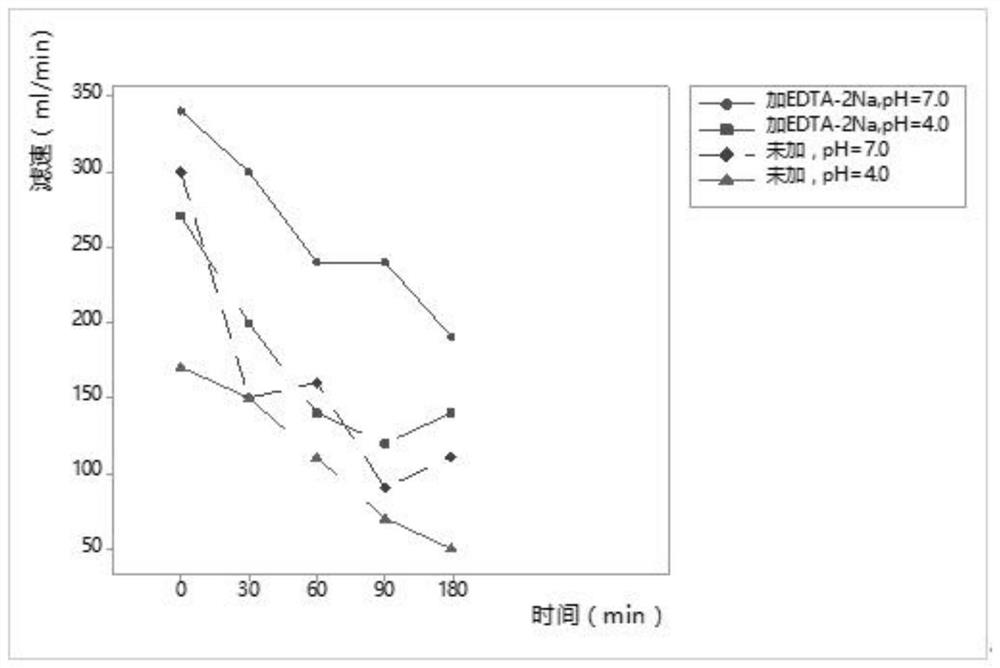

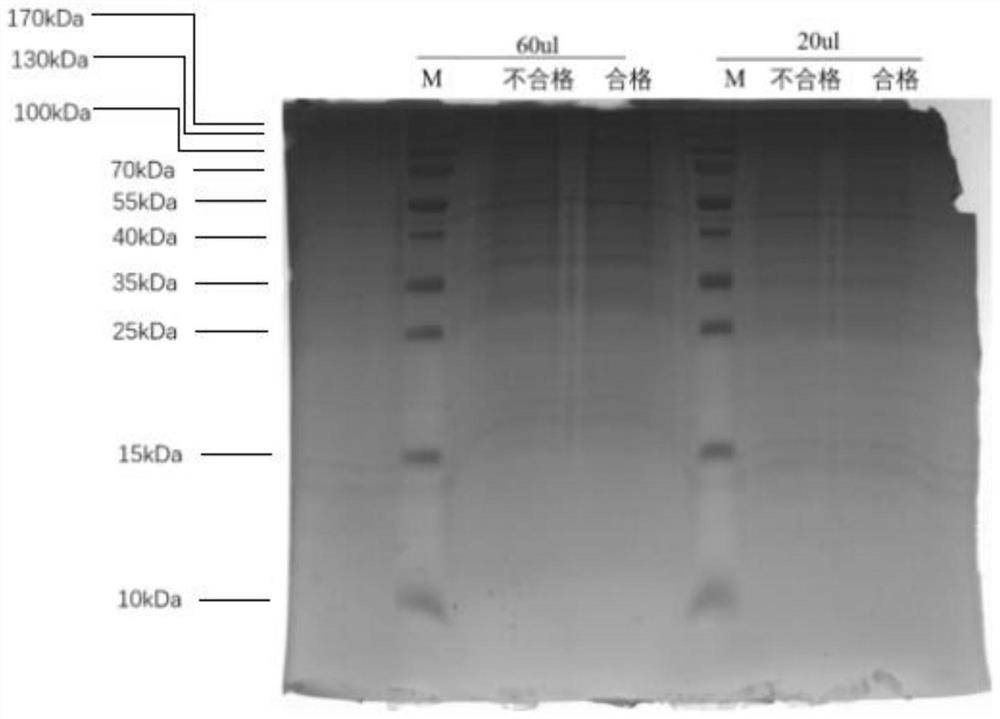

[0024] Embodiment 1: a kind of method for improving the turbidity of spectinomycin hydrochloride product comprises the following steps: coarse filtration: adjust the pH value of spectinomycin hydrochloride fermentation broth to 3.5 with oxalic acid, obtain filtrate through plate and frame filtration; Adsorption: take The above filtrate 1m 3 , titer 3000u / ml, add 0.3kgEDTA-2Na, stir for 0.5h, adjust the pH to 6.5, and then adsorbed by D152 resin, the adsorption flow rate is 0.5BV / h, control the adsorption outlet pH ≥ 7.0 to obtain the adsorption saturated resin; analysis: the adsorption After backwashing with saturated resin water, analyze with 2.0% hydrochloric acid to obtain the analysis solution; decolorization: adjust the pH value of the analysis solution to 6.5, and decolorize with activated carbon to obtain the decolorization solution; The liquid was obtained by ultrafiltration at a pressure of 0.6 MPa to obtain an ultrafiltered clear liquid, and the pH of the obtained cl...

Embodiment 2

[0025] Embodiment 2: a method for improving the turbidity of spectinomycin hydrochloride product, comprising the following steps: coarse filtration: adjust the pH value of spectinomycin hydrochloride fermentation broth to 4.0 with oxalic acid, and obtain the filtrate through plate and frame filtration; adsorption: take The above filtrate 1m 3 , titer 3000u / ml, add 0.6kgEDTA-2Na, stir for 0.5h, adjust the pH to 7.0, and then adsorbed by D152 resin, the adsorption flow rate is 0.5BV / h, control the adsorption outlet pH ≥ 7.0 to obtain adsorption saturated resin; analysis: the adsorption After backwashing with saturated resin water, analyze with 4.0% hydrochloric acid to obtain the analysis solution; decolorization: adjust the pH value of the analysis solution to 7.0, and decolorize with activated carbon to obtain the decolorization solution; Concentration: the above decolorization solution is subjected to ultra-nanofiltration to obtain a concentrated solution, decolorization The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com