Processing technology and application of low-protein and low-lignin cordyceps sinensis dregs

A processing technology and protein technology, applied in the application, tobacco, tobacco treatment and other directions, can solve the problems of reducing the protein and lignin content, feather odor, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A processing technology for low-protein and low-lignin cordyceps medicinal residues, comprising the following steps:

[0024] S1: According to the solid-to-liquid ratio of 1:10-15, crush the cordyceps residues to 40-50 mesh and add distilled water to make the first suspension, add laccase to the first suspension, and heat at 40-50°C Under the condition of water bath for 1-6h; then under the condition of 90-100°C for 10-20min in water bath to inactivate the laccase;

[0025] S2: Continue to add protease to the first suspension, and treat it in a water bath at 40-50°C for 1-6h; filter and dry at 100-110°C for 6-8h, and obtain a low-protein and low-lignin product after drying Cordyceps dregs.

[0026] Before being added to the first suspension, the initial activity of the laccase is 10000±100 U / g, and the initial activity of the protease is 10000±100 U / g. In the first suspension, the enzyme dosage of the laccase is 30-240 U / g, and the enzyme dosage of the protease is 240...

Embodiment 2

[0028] An application of low-protein and low-lignin Cordyceps medicinal residues, wherein the above-mentioned low-protein and low-lignin Cordyceps medicinal residues are refined and added to cigarette paper, and the low-protein and low-lignin insecticide residues The amount of herbal dregs added is 10-20g / m 2 .

[0029] The method of refinement treatment is ball milling for 0.5-1h; the method of adding to cigarette paper is: add water to the low-protein and low-lignin Cordyceps medicinal residues to prepare the second suspension, and then filter the The low-protein and low-lignin cordyceps medicinal residues are loaded on cigarette paper, and finally dried with a roller dryer at 40-60° C. for 20-30 minutes.

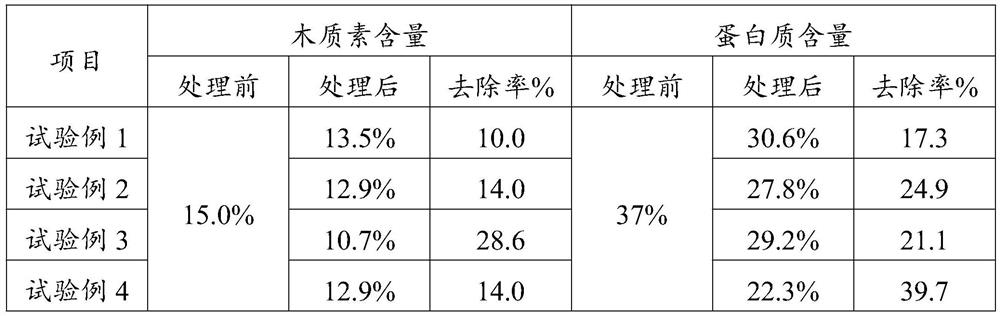

[0030] In order to further illustrate the beneficial effects of the present application, the following will be further described according to specific test examples and comparative examples:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com