Production method for making pineapple fruit wine

A production method, pineapple technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, preparation of alcoholic beverages, etc., can solve the problem of high content of methanol and fusel oil, high activity of bromelain, incomplete clarification of glue, etc. problems, achieve high clarity, reduce protein and pectin content, reduce fusel oil and methanol production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

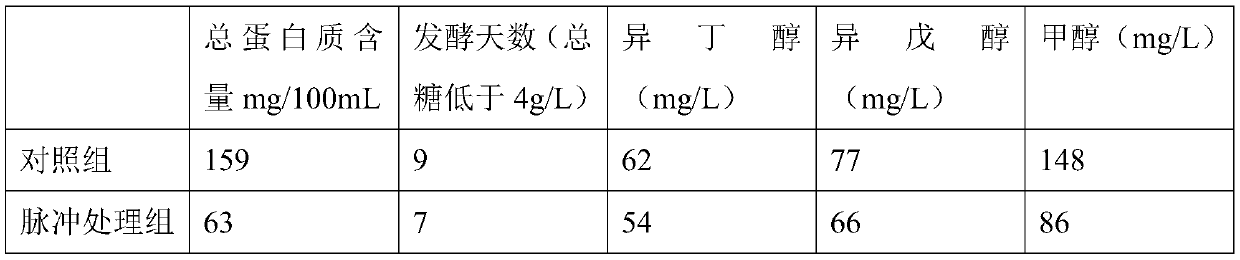

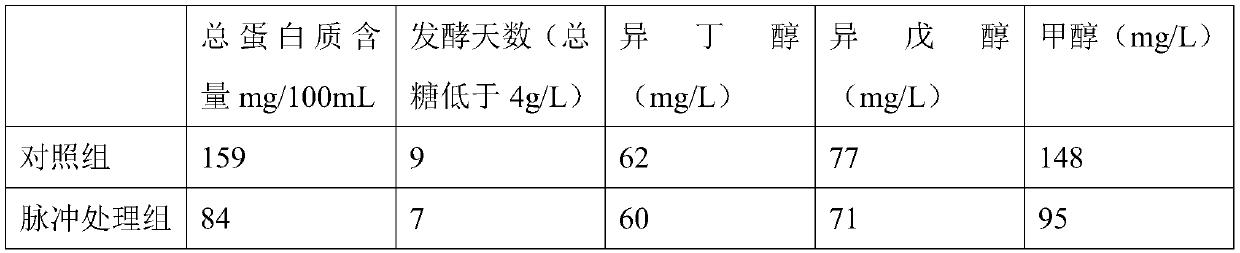

Embodiment 1

[0044] A production method for brewing pineapple wine, comprising the steps of:

[0045] 1) Juice treatment: Squeeze fresh pineapple fruit to extract juice, add 60mg / L sulfur dioxide (added in the form of sulfurous acid), adjust the pH to 3.4 with tartaric acid, add food-grade NaCl to adjust the conductivity to 4000uS / cm, and preheat the juice To 30°C, keep the constant temperature for 3 minutes, pump into the high-intensity electric pulse electric field treatment chamber under the condition of flow rate 120mL / min, the parameters are: field strength 10kV / cm, frequency 1000Hz, pulse width 5μs, waveform is unipolar square wave, pulse equipment The continuous pulse electric field treatment equipment produced by Guangzhou Xin'an Food Technology Co., Ltd. was used, and the treatment time was 1.5 minutes.

[0046] 2) Stand still at low temperature: place the processed pineapple juice at 4° C. for 20 hours, and take the supernatant juice.

[0047] 3) Ingredient adjustment: adjust th...

Embodiment 2

[0059] A production method for brewing pineapple wine, comprising the steps of:

[0060] 1) Juice treatment: Squeeze fresh pineapple fruit to extract juice, add 90mg / L sulfur dioxide (added in the form of sulfurous acid), adjust the pH to 3.5 with tartaric acid, add food-grade NaCl to adjust the conductivity to 4500uS / cm, and preheat the juice to 38°C, keep the constant temperature for 5 minutes, and pump it into the high-intensity electric pulse electric field treatment chamber at a flow rate of 150mL / min. The parameters are: field strength 12kV / cm, frequency 1200Hz, pulse width 10μs, waveform is unipolar square wave, pulse equipment The continuous pulse electric field treatment equipment produced by Guangzhou Xin'an Food Technology Co., Ltd. was used, and the treatment time was 2 minutes.

[0061] 2) Stand still at low temperature: place the processed pineapple juice at 2° C. for 15 hours, and take the supernatant juice.

[0062] 3) Adjustment of ingredients: adjust the sug...

Embodiment 3

[0068] A production method for brewing pineapple wine, comprising the steps of:

[0069] 1) Juice treatment: Squeeze the fresh pineapple fruit, add 80mg / L sulfur dioxide, adjust the pH to 3.5 with tartaric acid, add food-grade NaCl to adjust the conductivity to 4200uS / cm, preheat the juice to 35°C, and keep the temperature for 4 minutes , pumped into the high-intensity electric pulse electric field treatment chamber at a flow rate of 130mL / min, the parameters are: field strength 11kV / cm, frequency 1100Hz, pulse width 15μs, waveform is unipolar square wave, pulse equipment adopts Guangzhou Xinan Food Technology Co., Ltd. The continuous pulse electric field treatment equipment produced by the company has a treatment time of 2 minutes.

[0070] 2) Stand still at low temperature: place the processed pineapple juice at 0° C. for 10 h, and take the supernatant juice.

[0071] 3) Ingredient adjustment: adjust the sugar content of pineapple to 220g / L.

[0072] 4) Fermentation: Take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com