Patents

Literature

89 results about "Fusel alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fusel alcohols or fuselol, also sometimes called fusel oils in Europe, are mixtures of several alcohols (chiefly amyl alcohol) produced as a by-product of alcoholic fermentation. The word Fusel [ˈfuːzl̩] is German for "bad liquor".

Method for reducing acid and removing fusel oil of plum wine

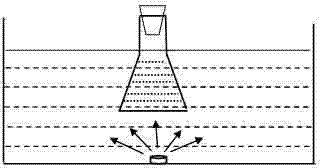

The invention discloses a method for reducing acid and removing fusel oil of a plum wine, belonging to the field of improvement of fruit wine quality. According to the method, an immersion type plum wine is used as a raw material, anion-exchange resin is adopted to reduce acid and ultrasonic waves are adopted to remove fusel oil, so that the problems of high acidity and easy drunkenness of the immersion type plum wine are solved. The flow of reducing acid of the plum wine comprises the steps of pretreating with resin, mixing the plum wine with resin for adsorption acid reduction, filtering and regenerating the resin; the flow of removing the fusel oil comprises the steps of filling the plum wine into a glass ware, putting the glass ware into an ultrasonic treatment field, treating for 10-50 minutes under different powers, taking the glass ware out, and placing for 15 days. The maximum reduction amplitude of the acid reaches 28%, and the maximum reduction amplitude of the fusel oil reaches 20%. The method disclosed by the invention adopts the anion-exchange resin to reduce the acid, so that the effect is good, no impurity is introduced, and the flavor of the wine is well preserved; through continuous alternate treatment with low and medium frequency ultrasonic waves, the fusel oil content can be reduced, and the maturation of the wine can be accelerated. The method for reducing the acid and removing the fusel oil of the plum wine is favorable for quick maturation of a newly-prepared immersion type plum wine.

Owner:GUANGDONG JIAHAO FOOD +1

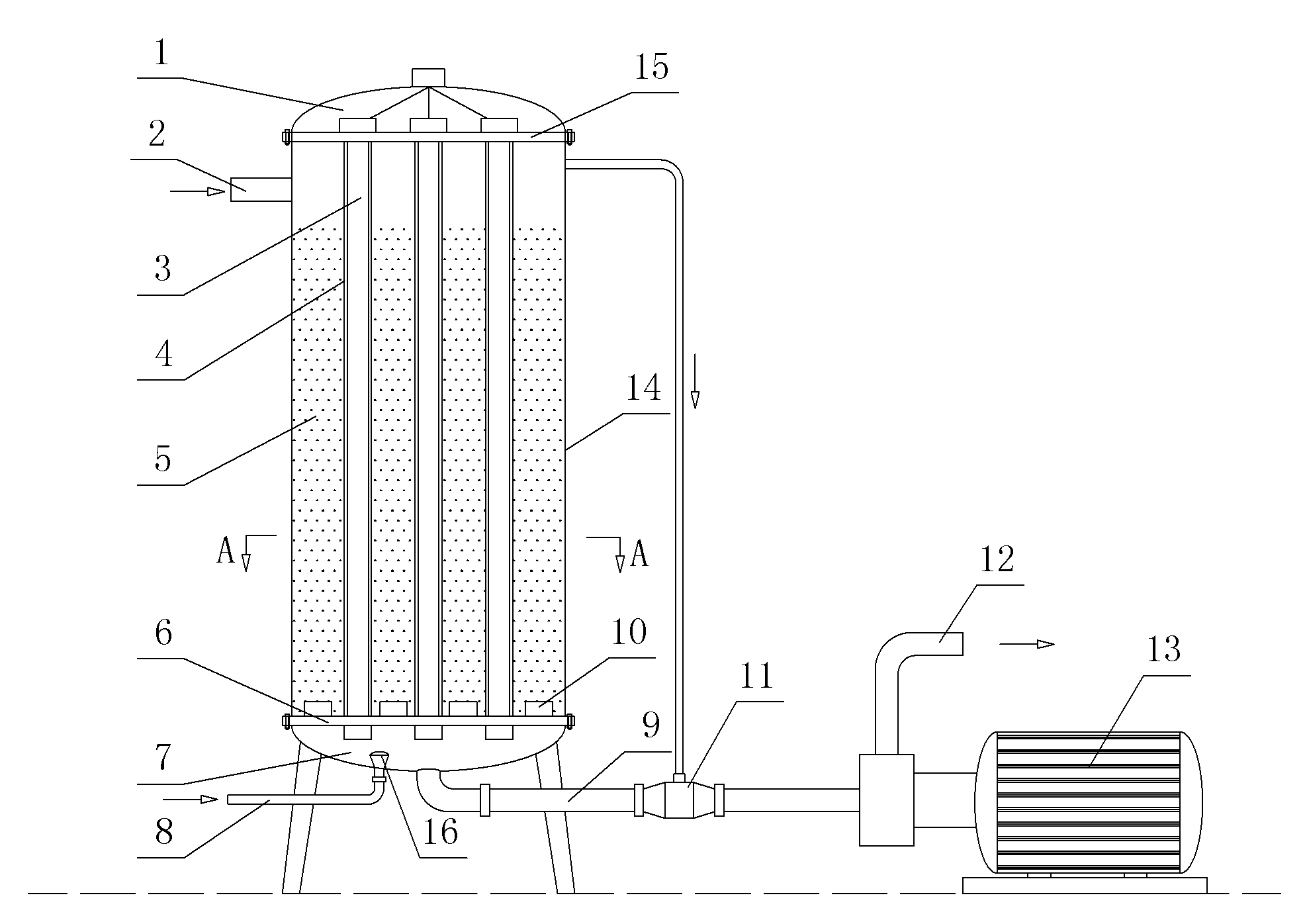

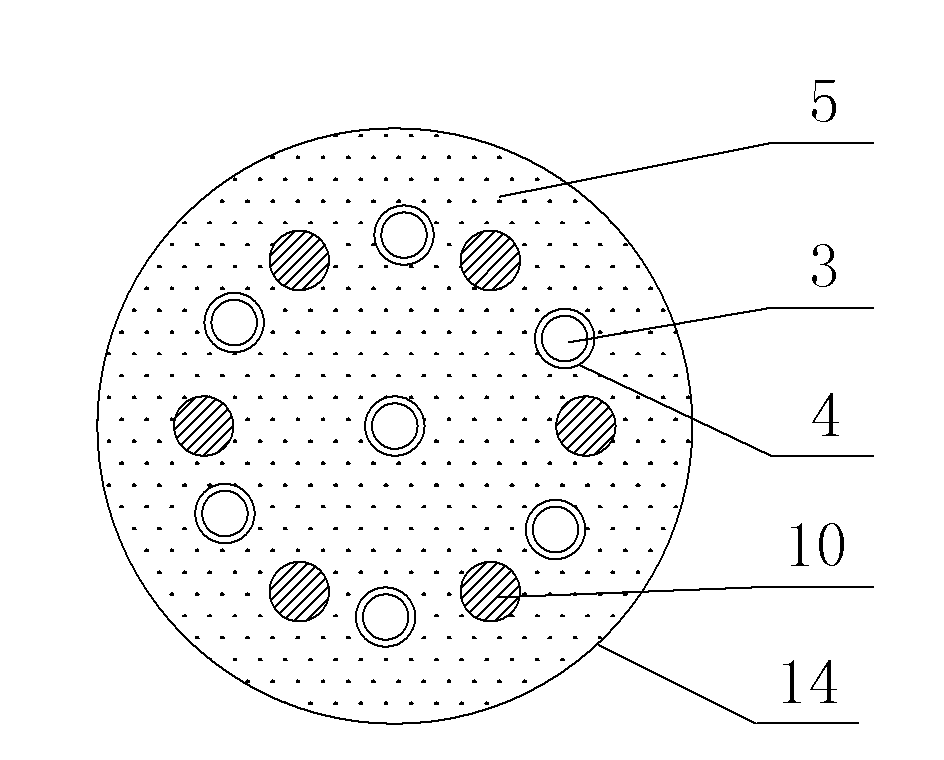

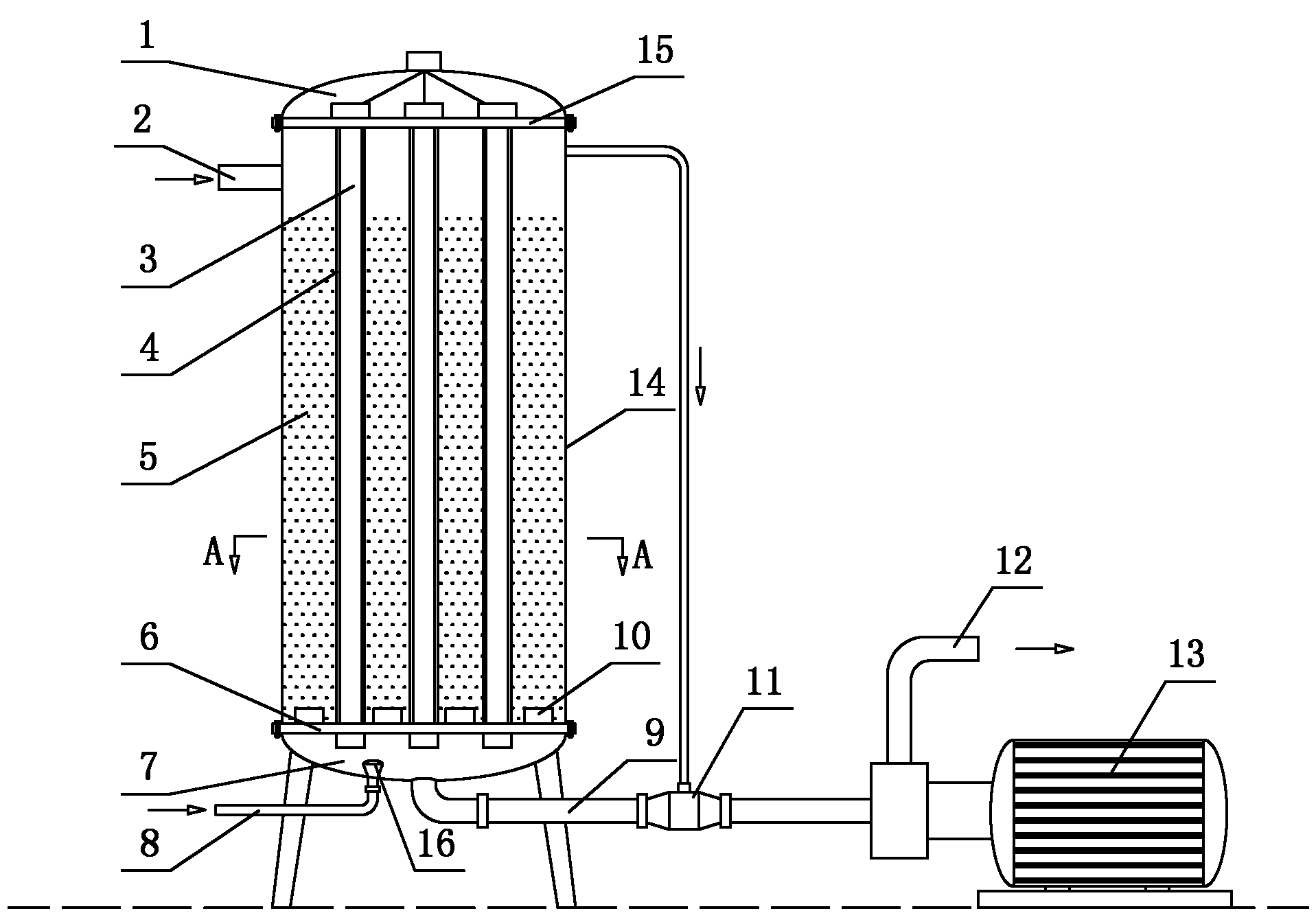

Method and device for purifying vinosity

InactiveCN101948732AImprove inner qualityReduce flow rateAlcoholic beverage preparationUltraviolet lightsSolid particle

The invention discloses a method for purifying vinosity, comprising an oxidation reduction reaction which is carried out on the surfaces of solid particles attached with TiO2 photochemical catalyst layers under the irradiation of ultraviolet light after the body is mixed with oxygen or ozone. The invention also discloses a device for realizing the method for purifying the vinosity. In the invention, multiple groups of ultraviolet light sources are evenly arranged at each part of a reaction chamber to directly irradiate the body and the surface of the photocatalyst; the ultraviolet light can efficiently decompose unsaturated compounds in the body, such as aldehydes, fusel oil, sulfide and other harmful components under the action of catalyst, eliminates impurities and peculiar smell in thewine, eliminates spicy, stimulated and bran taste of green wine, eliminates the off-flavor of edible alcohol, and deeply promotes the inherent quality of the wine.

Owner:李建东

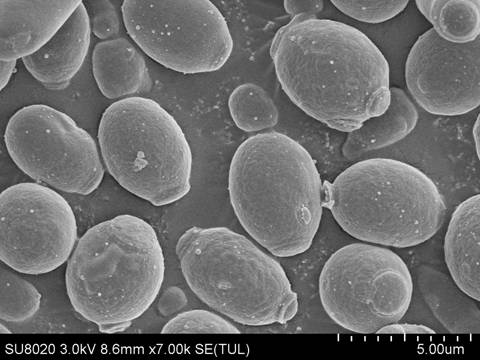

Low yield fusel oil yeast and application thereof to lowing of content of fusel oil in Xiaoqu raw wine

The invention discloses low yield fusel oil yeast. According to the invention, the classification and the name of the low yield fusel oil yeast are Saccharomyces cerevisiae Y19, the low yield fusel oil yeast is preserved in the China typical model cultivation center, the preservation date is march 19, 2013, and the preservation number is CCTCC NO.M2013091; the low yield fusel oil yeast is used for manufacturing the aromatic Xiaoqu raw wine, and compared with a conventional fermentation method, the content of the fusel oil is lowered by 24.7%; the manufactured aromatic Xiaoqu raw wine has pure aroma, typical style, harmonious aroma and clear aftertaste, tastes spongy and sweet, and is fresh; a person can not get dunk after drinking the wine.

Owner:JING BRAND

Method for promoting aging of fruit-type white spirit under actions of infrared assisted ultrasonic and pulse electric field

InactiveCN104560587ATypical fruit aromaSoft tasteAlcoholic beverage preparationBiotechnologyFruit juice

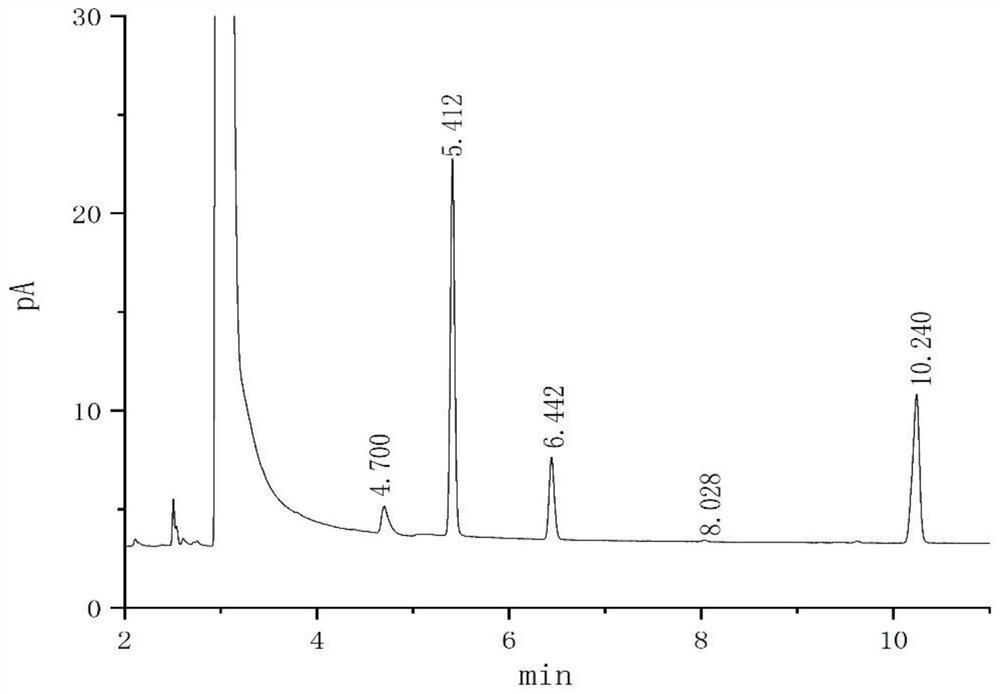

The invention discloses a method for promoting aging of fruit-type white spirit under actions of infrared assisted ultrasonic and a pulse electric field, which comprises the following steps: fermenting full fruit juice, distilling to obtain fruit-type white spirit, treating under the actions of infrared rays and ultrasonic for 5-15 minutes while controlling the temperature at 40-60 DEG C, ultrafiltering with an ultrafiltration membrane with the pore size of 0.02-0.05 mu m to obtain an ultrafiltrate, treating the ultrafiltrate under the action of a pulse electric field with the electric field intensity of 30-50 kV / cm, quickly cooling the liquor subjected to electric field treatment to 0-5 DEG C, keeping for 12-20 hours, and heating to normal temperature to obtain the fruit-type white spirit with soft mouthfeel. The fruit-type white spirit treated by the method has typical fruit odor and soft and thick mouthfeel; and the content of ethyl acetate, ethyl propionate, ethyl lactate, ethyl laurate, phenethyl alcohol and other aroma substances is enhanced by 50-70% as compared with the untreated white spirit, the heady fusel oil component is reduced by 40-60%, and all the components are close to the indexes of the 5-year-aged white spirit. The method has the advantages of time saving, labor saving and low cost.

Owner:HUIZHOU UNIV +1

Method for processing methanol rectified raffinate

InactiveCN101717163AA considerable amount of recyclingSave resourcesFatty/oily/floating substances removal devicesOrganic compound preparationExtractive distillationFusel alcohol

The invention discloses a method for processing methanol rectified raffinate. The method comprises the following steps of: separating out the methanol, the alcohol and the fusel oil by a distillation method on the basis of the principle that water, methanol, alcohol, fusel oil, high carbon chain wax oil, and the like have different boiling points and volatility at the same temperature to; separating out the paraffinoil on the basis of the characteristic that water and parainoil can not be dissolved mutually and the density difference between the water and paraffinoil is large; filtering out insoluble suspended solids by a sand filtration method; and finally obtaining recovery liquid which is used for a synthetic relief gas washing tower or extractive distillation. The method for processing methanol rectified raffinate not only eliminates pollutant but also changes waste material into things of value, thereby not only being environmentally-friendly but also having certain economic benefit.

Owner:SHANXI LANHUADANFENG CHEM

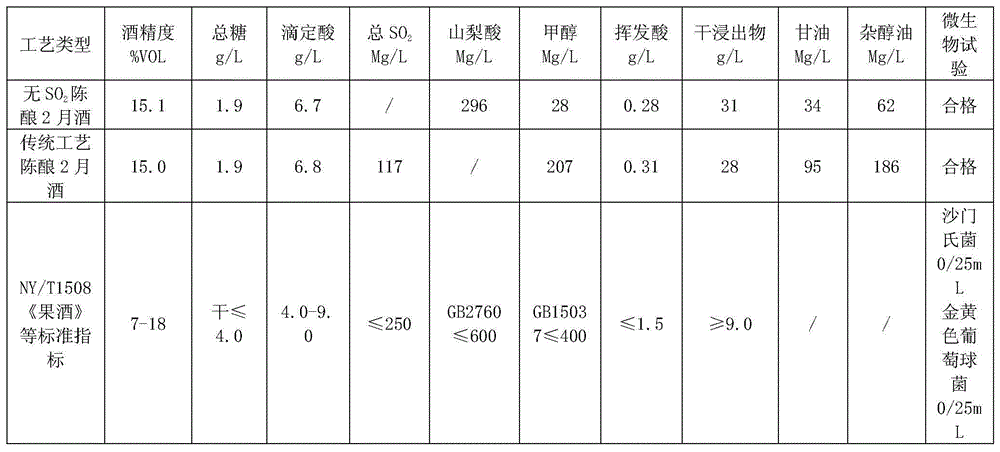

Sulfur-dioxide-free full juice fermented kiwifruit wine and production process thereof

ActiveCN104130904AGuaranteed normal fermentationInhibit G+ bacteriaAlcoholic beverage preparationVitamin CFruit juice

The invention provides a sulfur-dioxide-free full juice fermented kiwifruit wine and a production process thereof, belonging to fermented fruit wines and production technologies thereof. The production process comprises the steps of crushing and juicing, adjusting the acidity of the juice, removing turbidity, resisting bacteria and adjusting the sugar content, preparing mother liquor of the wine, blending and fermenting the juice, ageing the wine base and transiting and storing. The kiwifruit wine has the beneficial effects that an innovative process of replacing SO2 with a composite of six non-toxic materials such as antibacterial and oxidation-resistant D-erythorbic acid, nisin, sorbic acid, chitosan, vitamin C and ethanol materials (refined alcohols and the like) is adopted; compared with traditional processes, in the production process, the operation of adding toxic gaseous and liquid SO2 step by step is safer and more convenient; the production process is an innovation of popularizing the traditional processes of wines for more than a hundred years to make wine with other fruit raw materials; the kiwifruit wine produced by the technology does not contain SO2 and has the advantages that the content of methanol is reduced by about 90%, the content of fusel oil is reduced by about 65% and the harmful ingredients such as bioamine, sulfate, methanol, fusel oil and the like are controlled compared with the fruit wines produced by the traditional processes.

Owner:万源市大面山酒业有限公司

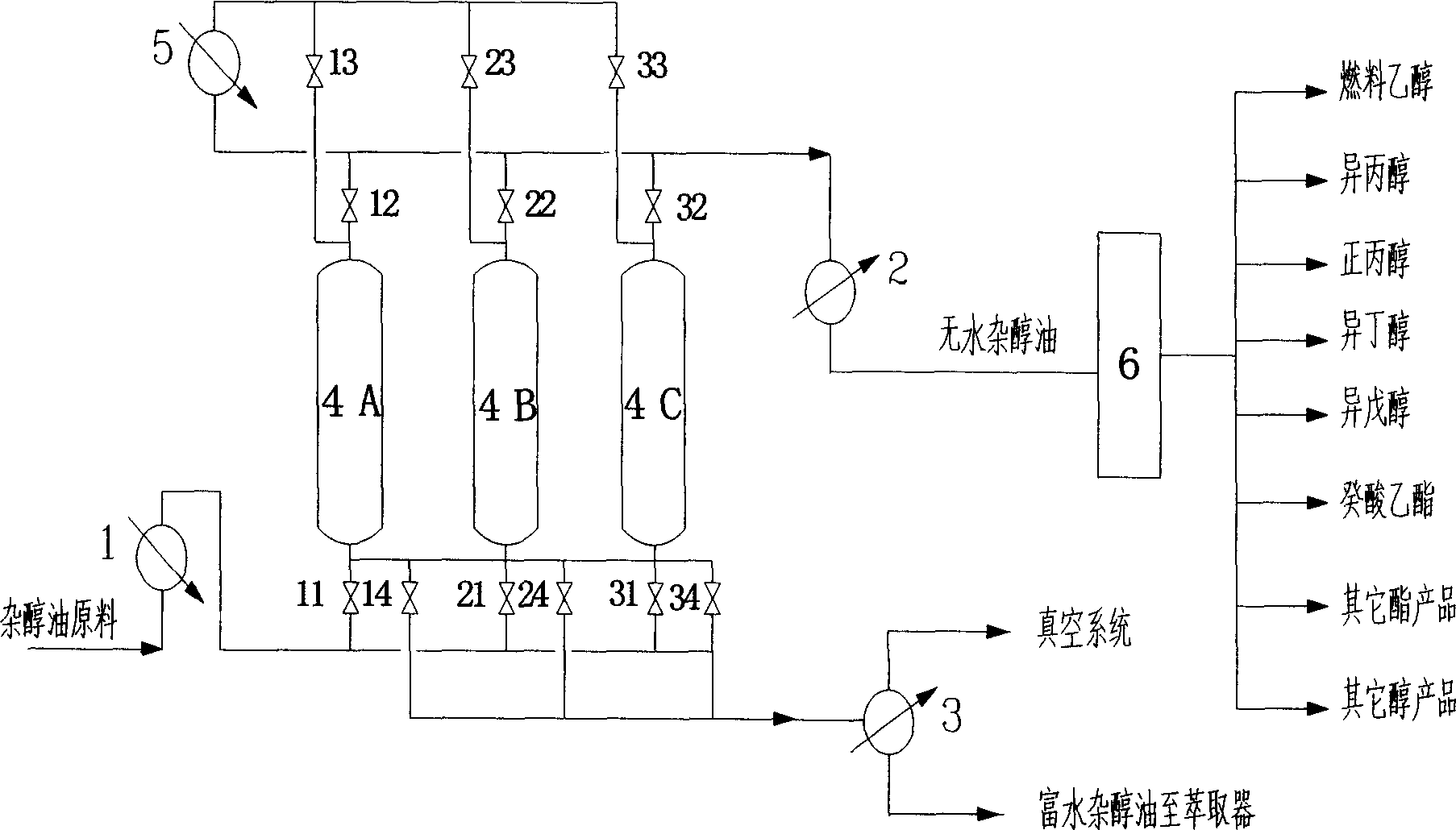

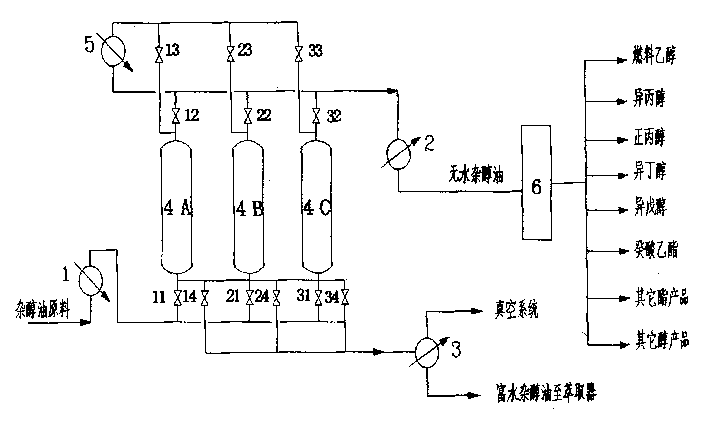

Fusel oil molecular sieve gas phase dewatering method and separating and purifying method

InactiveCN1458260ASolve can't get alcoholAddressing Purity IssuesIon-exchange process apparatusBy-product recoveryGas phaseFusel alcohol

The present invention proposes the technological scheme of separation and purifying fusel oil through combining molecular sieve vapor phase dewatering and rectification. Fuel oil fraction gas containing water is introduced to adsorbing apparatus for selective adsorption of fusel alcohol and water at operation gage pressure of 0-0.6 MPa and temperature 190-300 deg.c; and after water is adsorbed bythe adsorbent, various alcohols and esters are condensated to obtain qualified fuel alcohol product. The through dewatering of the fusel oil material can solve the difficult problem that water and various alcohols form azeotrope to lower the yield of separated fuel oil products. The thorough dewatered fuel oil in further rectified and separated intermittently or continuously to obtain fuel alcohol, isopropyl alcohol, isobutyl alcohol, isoamyl alcohol, ethyl caprate and other products.

Owner:TIANJIN UNIV

Wild blueberry white spirit and preparation method thereof

The invention relates to a wild blueberry white spirit and a preparation method thereof. The wild blueberry white spirit contains the following raw materials: blueberry, pectinase, yeast, hide trimmings, preserved distilled liquor and gelatin, wherein high-quality wild blueberries produced in Da Hinggan Ling are used as raw material, are rich in nutritional ingredients, not only have a favorable nutritional health care function, but also have the effects of preventing cranial nerves from aging, strengthening heart, resisting cancer, softening blood vessels, enhancing immunity of human bodies and the like. The wild blueberry white spirit is brewed from blueberries, belongs to fruit white spirit and is prepared by direct fermentation and distillation of fructose in the blueberries without a starch convertion process in grain white spirit or addition of auxiliary materials; and few harmful ingredients, such as fusel oil, are contained in the brewed blueberry white spirit; therefore, the damage to the human body is greatly reduced.

Owner:大兴安岭依莓酒业有限公司

Method of accelerating liquor aging process

InactiveUS20090186143A1Accelerated agingReduce manufacturing costAlcoholic beverage preparationOrganic acidManufacturing cost reduction

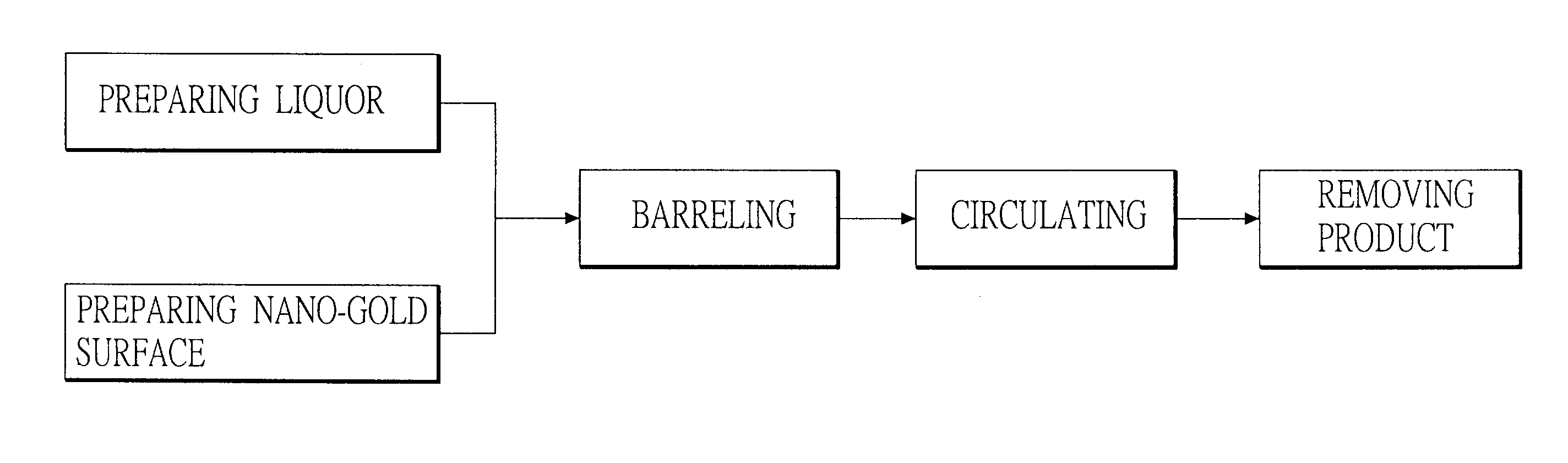

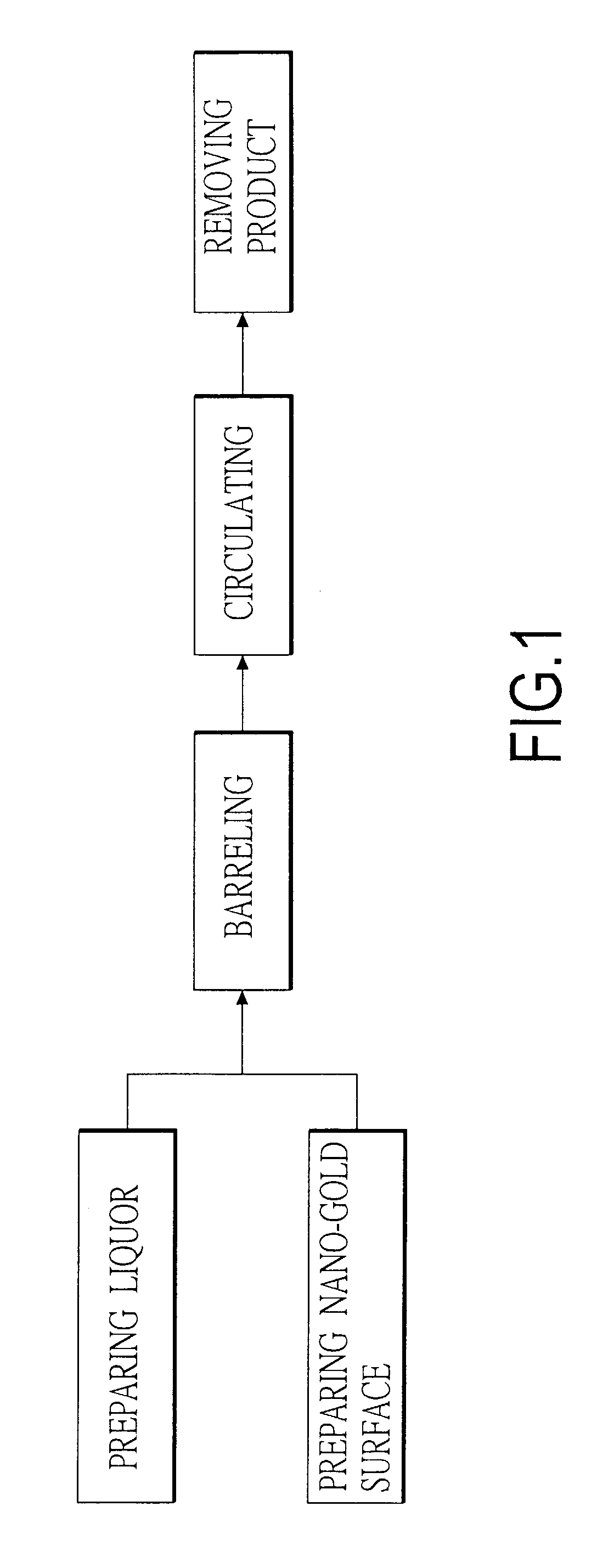

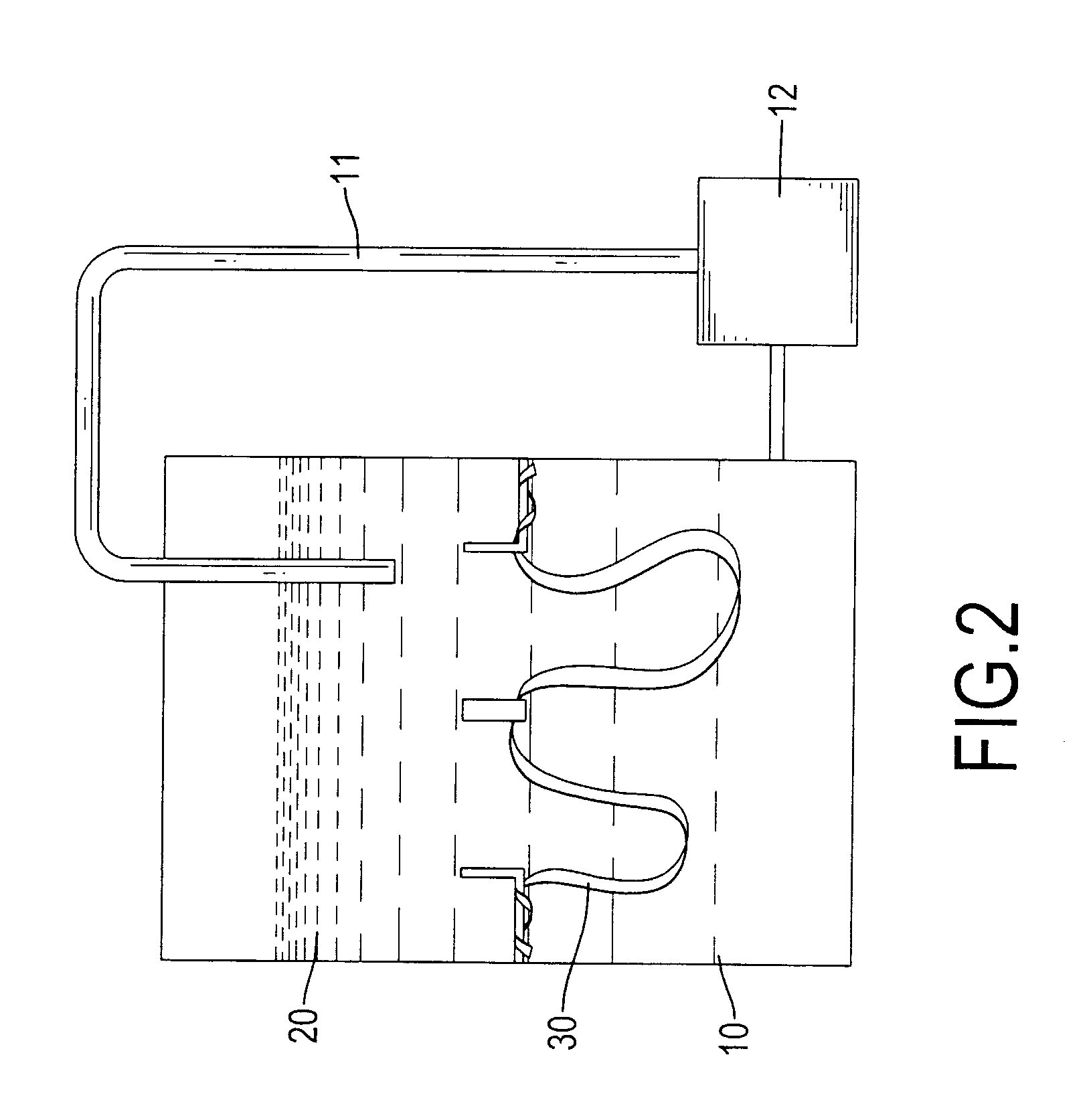

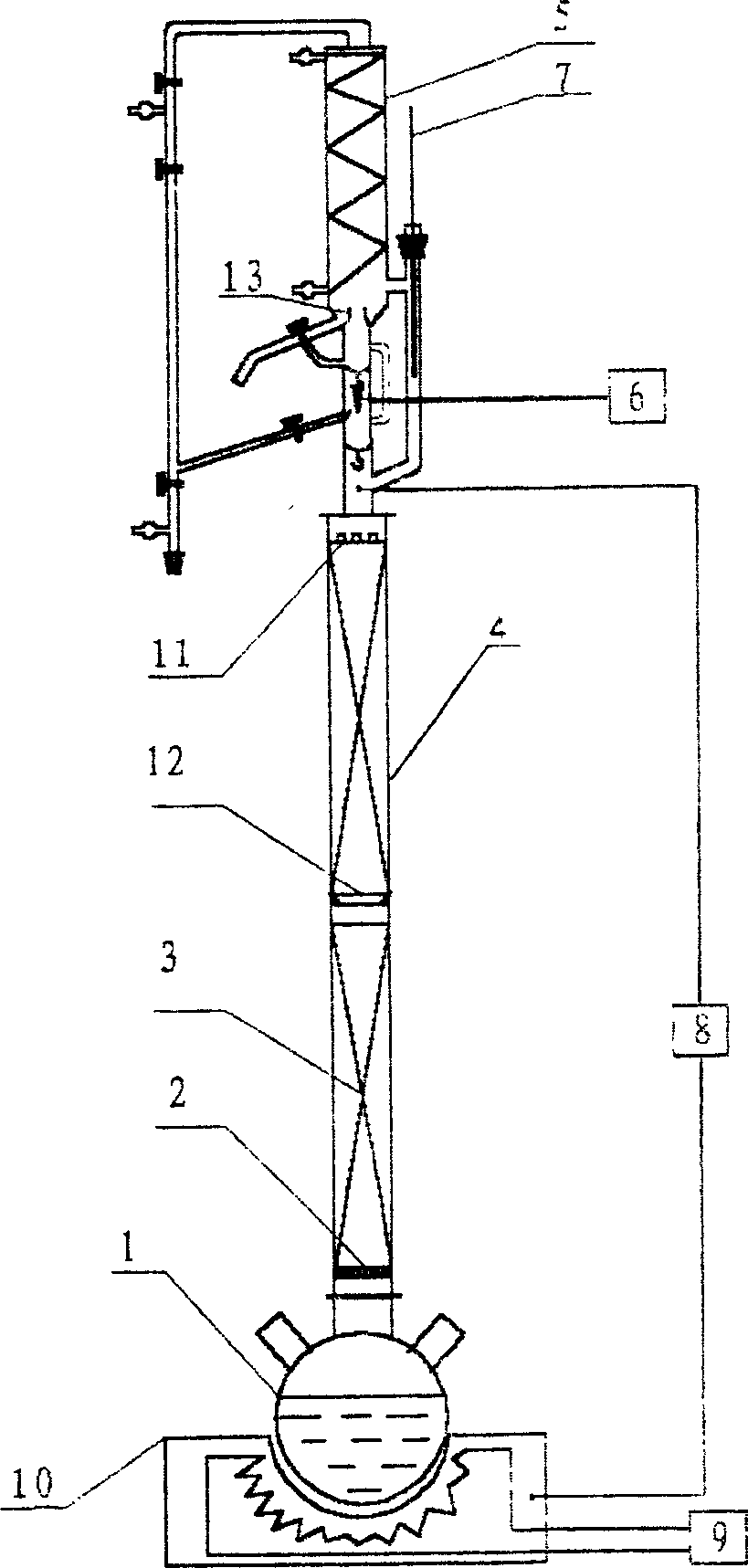

A method of accelerating liquor aging process includes acts of preparing a liquor having by-products, preparing a nano-gold surface by sputtering gold nanoparticles onto a substrate, barreling the liquor and the nano-gold surface into a barrel, circulating the liquor and removing a product of artificially aged liquor. The liquor is circulated by a pump for increased rate of diffusion and incidences of collision between the by-products and nano-gold surface. The gold nanoparticles serve as a catalyst to promote oxidation of by products including formaldehyde, acetaldehyde and fusel alcohols in the liquor into organic acids and esterification of organic acids to accelerate the liquor aging process of the. After the product is removed, the nano-gold surface can be recycled. The gold nano-particles do not aggregate or precipitate in the liquor, therefor, perform more predictably so reduce manufacturing costs and improve consistency of manufacture.

Owner:KO CHUAN TAO

Method for simultaneously separating and purifying racemic optical amyl alcohol, optical active amyl alcohol and isoamyl alcohol from fusel oil or mixed amyl alcohol and its equipment

InactiveCN1443739ATake advantage ofReduce energy consumptionOrganic compound preparationHydroxy compound preparationIt equipmentIsoamyl alcohol

The present invention adopts single tower, on the basis of general precision rectification process adds flooding operation, its total reflux is implemented at twice, reflux ratio of 4-80, and betweentwo stages of total reflux the light component can be fractionized out from top of tower and the water content is removed. It provides the equipment for implementing the above-mentioned method. It istechnically characterized by adopting high-effective precision rectification filling material and electromagnetic needle pendulum reflux ratio control instrument, height of filling layer is 140-150 cm, its complete condenser is water-splitting complete condenser, and upper portion of filling layer and its middle portion are respectively equipped with returned liquor distributor and oblique cone ring baffle.

Owner:SICHUAN UNIV +1

Method for accelerating aging of rum by means of micro-oxygenation and oak chip addition

InactiveCN105602816ARemarkable aging aromaSoft and mellow wineAlcoholic beverage preparationFlavorAccelerated aging

The invention discloses a method for accelerating aging of rum by means of micro-oxygenation and oak chip addition. According to the method, rum brewed by fermenting molasses is subjected to micro-oxygenation treatment and oak chip addition treatment, and the main physicochemical property, a fragrant substance and sense flavor of the stored rum are detected regularly. Esters of the rum treated through the method are increased, wood fragrance is remarkable, the rum has a special fragrance type and an outstanding style, in the drinking process, the rushed and spicy mouthfeel is avoided, and after drinking, fragrance lingers in a wine glass. By means of the method, fusel alcohol content is reduced, the content of the esters and high alcohols is increased, the aging period is shortened effectively, and the effect of fast aging is achieved.

Owner:GUANGXI UNIV

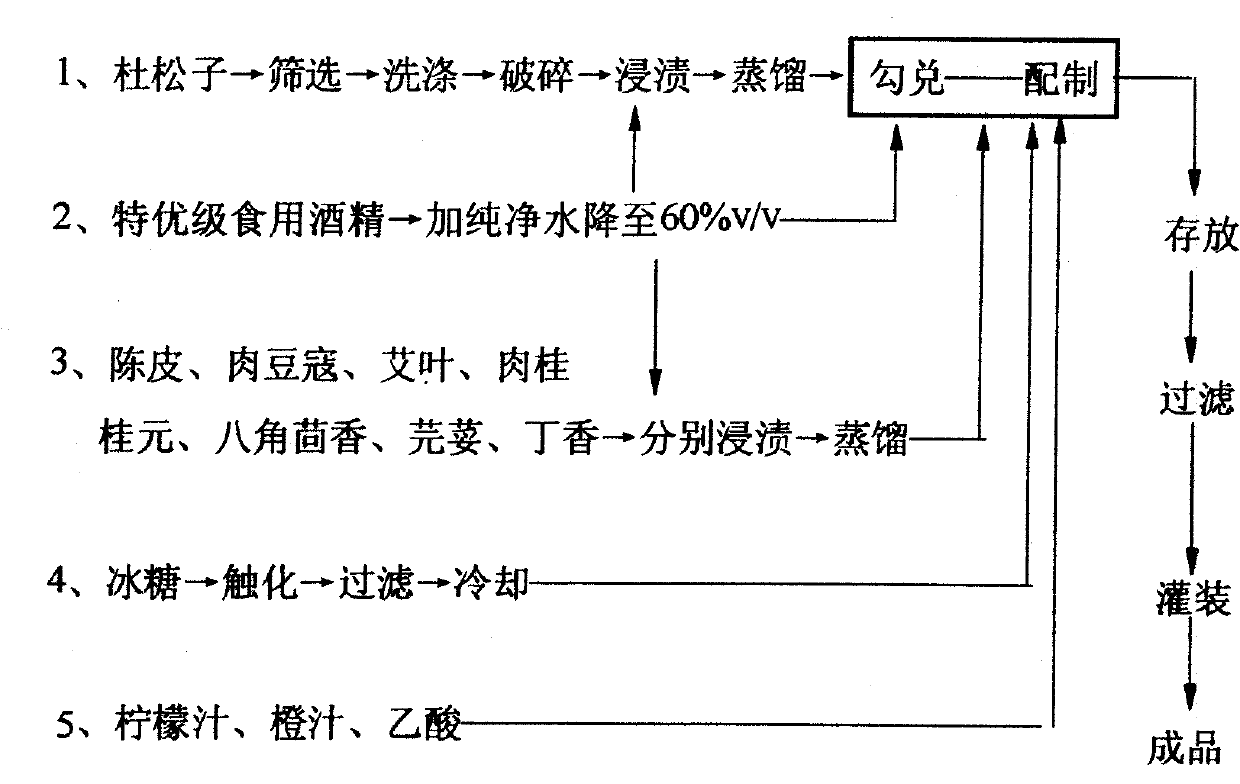

Distilled prepared wine-gin flzz with foreign wine (dry gin) flavor characteristics

InactiveCN102408971ANo precipitationNo suspended matterAlcoholic beverage preparationBiotechnologyJuniperus communis Fruit

The invention relates to distilled prepared wine-gin flzz with foreign wine DRY or GIN (dry gin) flavor characteristics, which is characterized in that juniper fruits serving as wild resources in China are used as main fragrance sources, and aroma and flavor-producing Chinese herbal medicine and the like are used as auxiliary fragrance sources. The gin flzz is prepared by using superior edible alcohol as wine bases through pretreatment, impregnation distillation, flavoring blending and storage filtering. The distilled prepared wine-gin flzz with foreign wine DRY or GIN (dry gin) flavor characteristics has the advantage of no methanol or fusel oil checking is obtained.

Owner:李良

Waxberry fruit wine and processing method thereof

InactiveCN104327997AEffective control of methanolEffective control of fusel oil contentAlcoholic beverage preparationMicroorganism based processesBiotechnologyFruit wine

The invention discloses waxberry fruit wine and a processing method thereof. The processing method comprises the following steps: performing raw material treatment on fresh waxberry fruits, juicing, separating, adjusting the components, performing double-yeast fermentation, sterilizing in ultra-high pressure, naturally aging, accelerating aging in a high-voltage pulse electric field, performing cold treatment, and filtering, thereby obtaining the waxberry fruit wine. The waxberry fruit wine disclosed by the invention is rich and thick in waxberry fruit wine fragrance, and good in taste, the light transmittance of the waxberry fruit wine is greater than 88%, the total ester content of the waxberry fruit wine is 2.98-3.12mg / L, the total amount of fusel oil of the waxberry fruit wine is 175.68-185.36mg / L, and the waxberry fruit wine is free of methanol; and moreover the full processing process is performed in a non-thermal processing manner, the production period is short, beneficial significance is achieved for increasing the additional values of a waxberry processed product, and the product is good in market prospect.

Owner:FUJIAN AGRI & FORESTRY UNIV

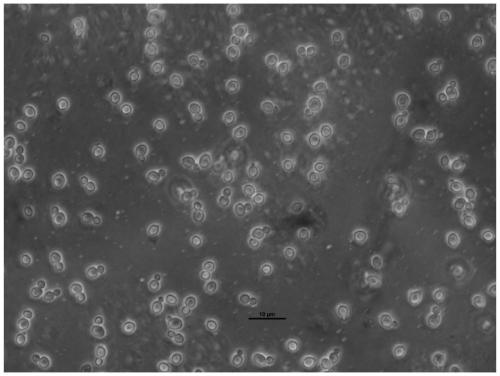

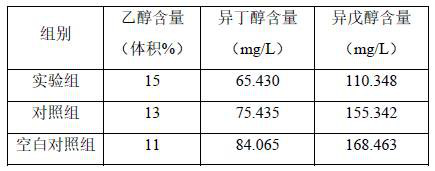

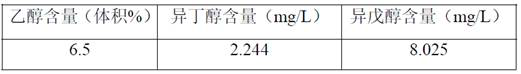

Saccharomyces cerevisiae with low fusel oil yield and application thereof

ActiveCN111484941AReduce contentQuality improvementFungiMicroorganism based processesBiotechnologyFusel alcohol

The invention discloses Saccharomyces cerevisiae Y276 and application thereof. The preservation date of the Saccharomyces cerevisiae Y276 is December 27, 2019, and the preservation number of the Saccharomyces cerevisiae Y276 is CCTCC NO: M2020080. The saccharomyces cerevisiae strain disclosed by the invention is obtained by separating and purifying soy sauce flavor type fermented grains from Jianpai Maotai Town Liquor Co., Ltd. The fusel oil in the faint scent Xiaoqu liquor can be reduced by 25.7%, the strain can be matched with other strains such as rhizopus to prepare mixed koji for brewingof the Xiaoqu faint scent liquor, and the effects of reducing the fusel oil in Xiaoqu raw liquor and improving the quality of the Xiaoqu raw liquor are achieved.

Owner:JING BRAND

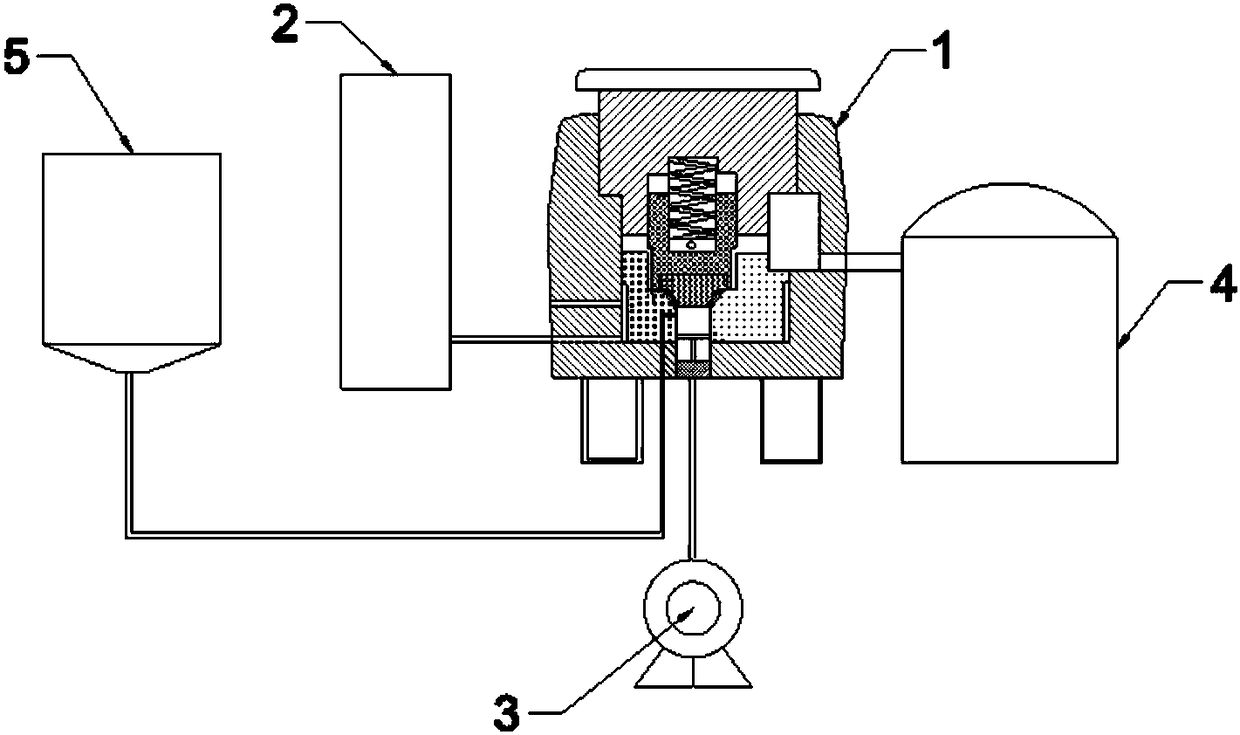

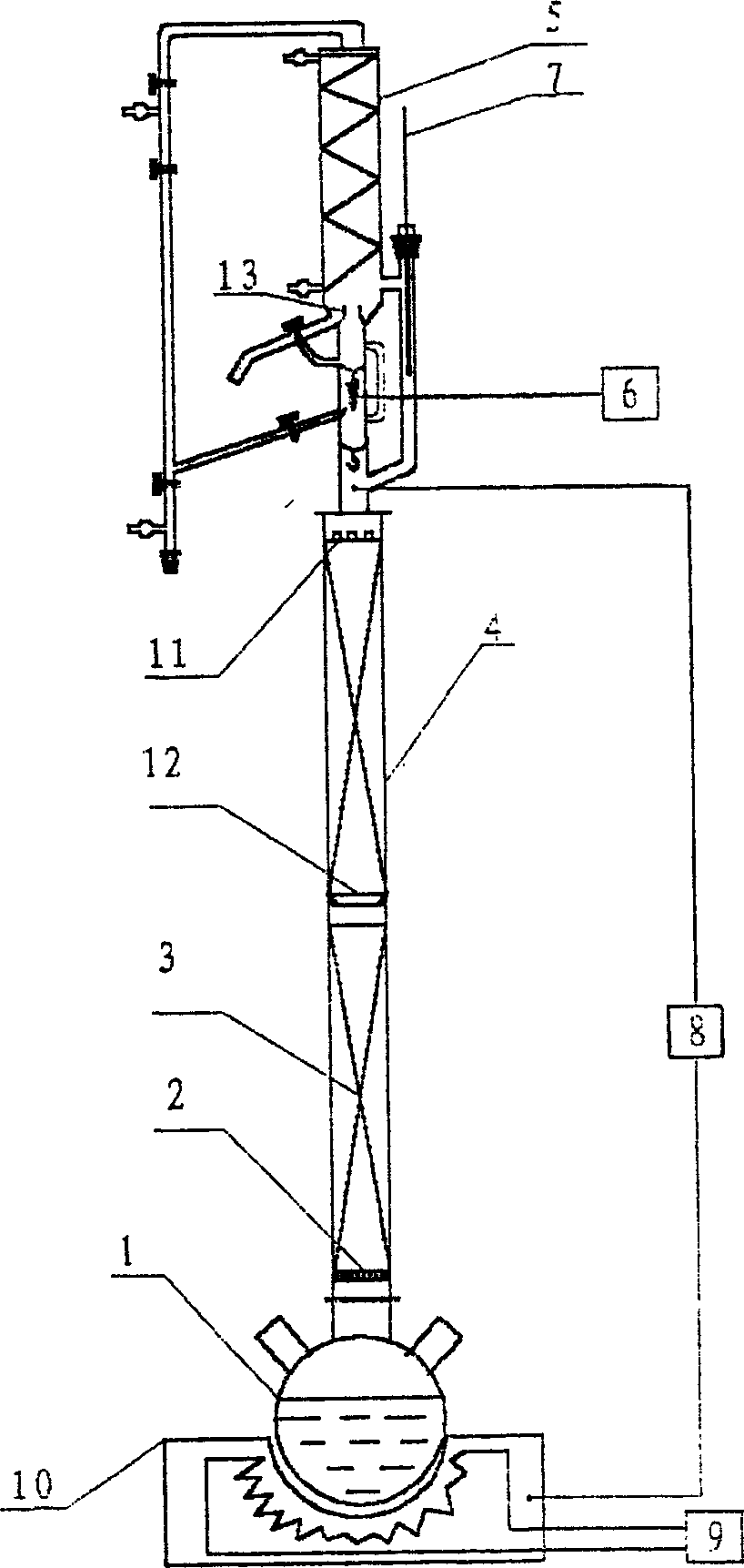

Preparation method of small-molecular wine and production system thereof

InactiveCN108373959AShorten the aging time of cellarGreat tasteAlcoholic beverage preparationCavitationEngineering

The invention discloses a preparation method of small-molecular wine and a production system thereof. The preparation method and the production system disclosed by the invention have the beneficial effects that ultrahigh-pressure micro jet equipment adjusts the throttling area by changing a trapezoidal ring-shaped gap between a valve core and a valve seat to generate ultrahigh-speed jet, and afterlarge pressure drop is formed in a reaction cavity, static pressure up to 200MPa-600MPa is formed; due to instantaneous conversion of the kinetic energy and the actions of high-speed impact, oscillation, expansion and cavitation and the like of fluid, a large shearing force is generated; hydrogen-bond combination, hydrophobic bonding and ion combination in macromolecular three-dimensional structures are damaged, so that free micromolecules in 0.1-10 nanometers are formed; under the action of Vander Wale force, intermolecular self assembly is finished, so that a relatively-stable polybasic micromolecular cmopound is formed; in the process, the content of fusel oil with larger molecular weight is obviously reduced, and the efficiency of conversion and association from macromolecular acid, alcohol, ester, aldehyde and ketone compounds to fatty acid, lipopeptid, polyol and aromatic hydrocarbon and the like is greatly improved, so that the mouth feel and the quality of the wine body can beimproved to a greater extent in a shorter time.

Owner:贵州瑞诚新材料技术有限公司

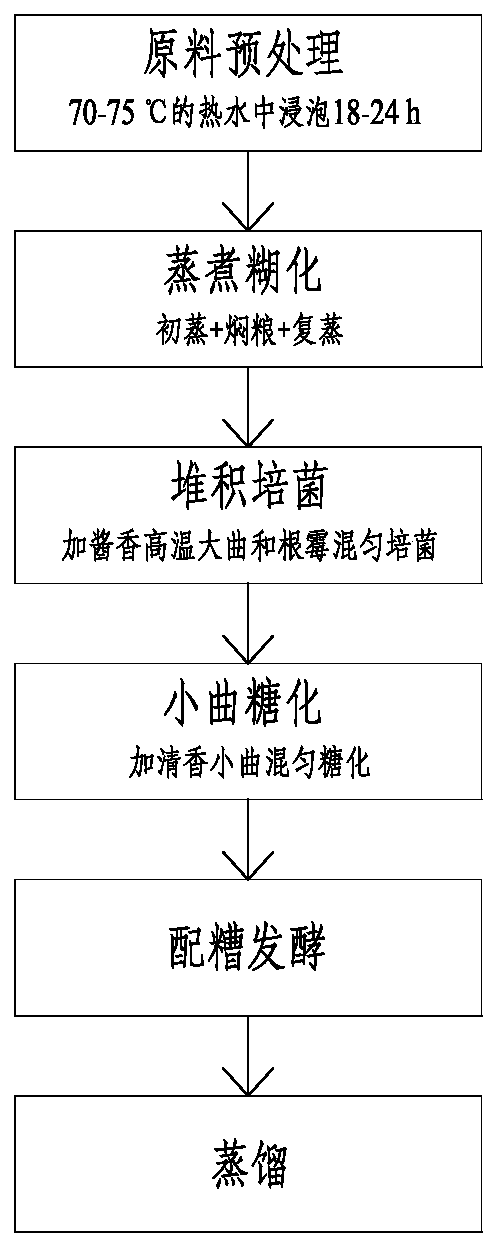

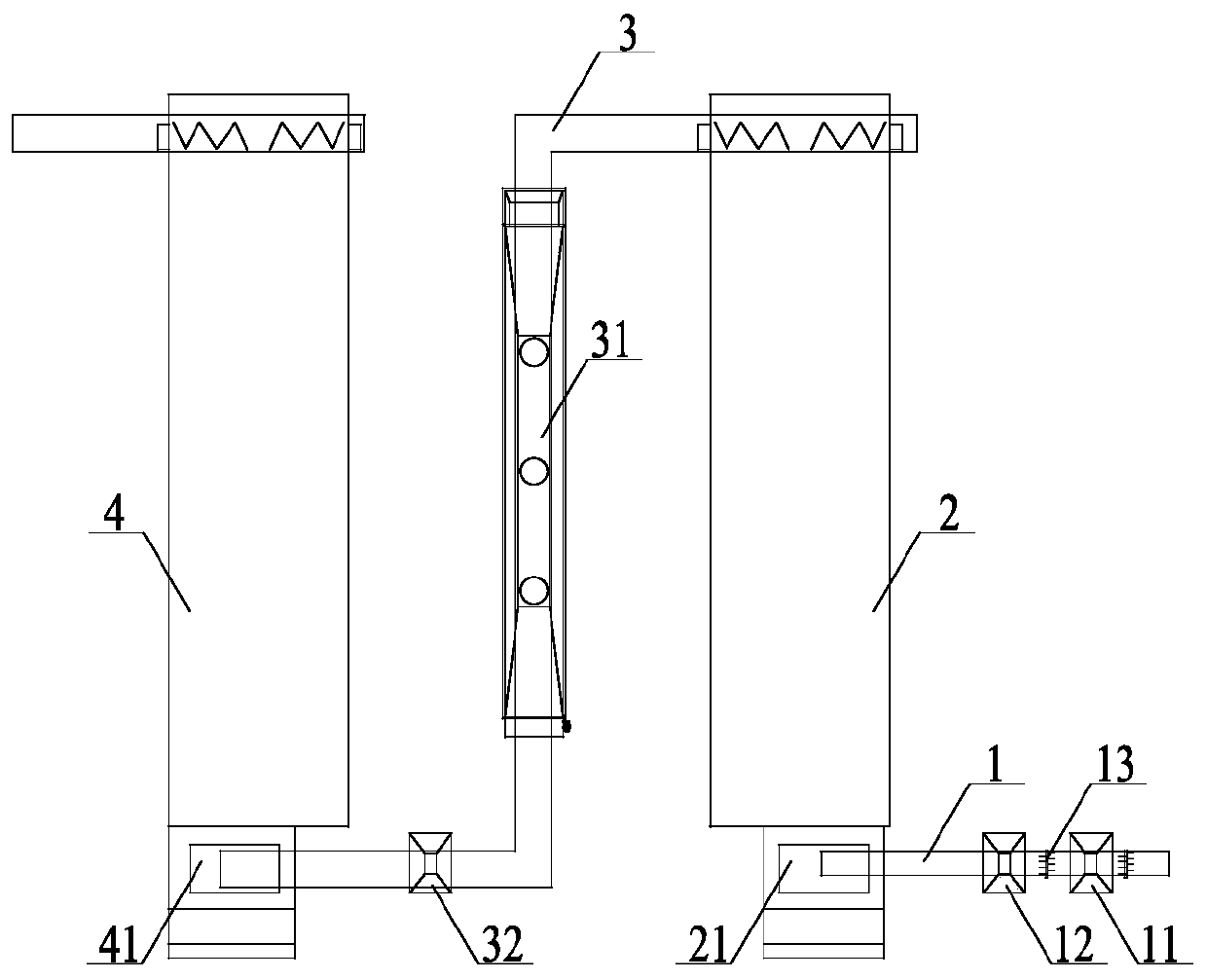

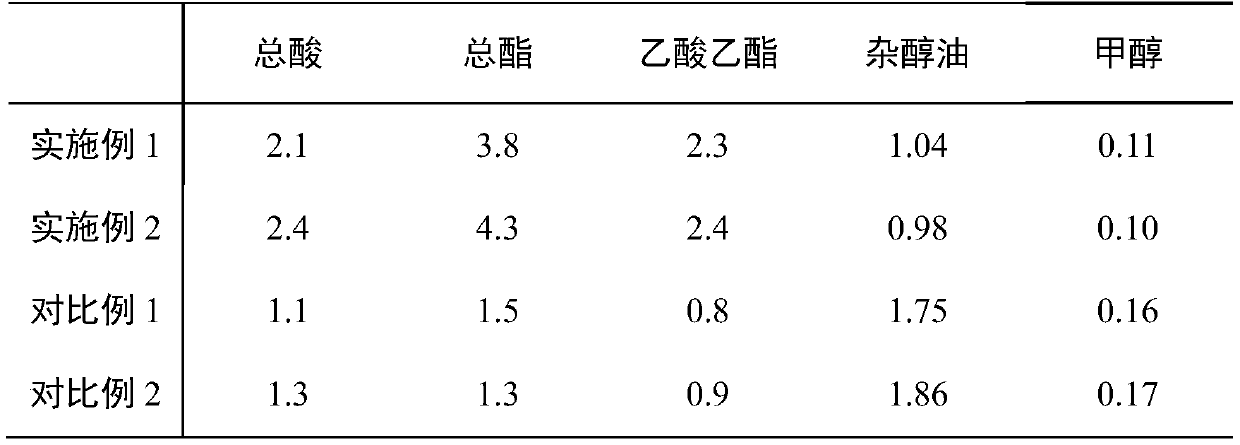

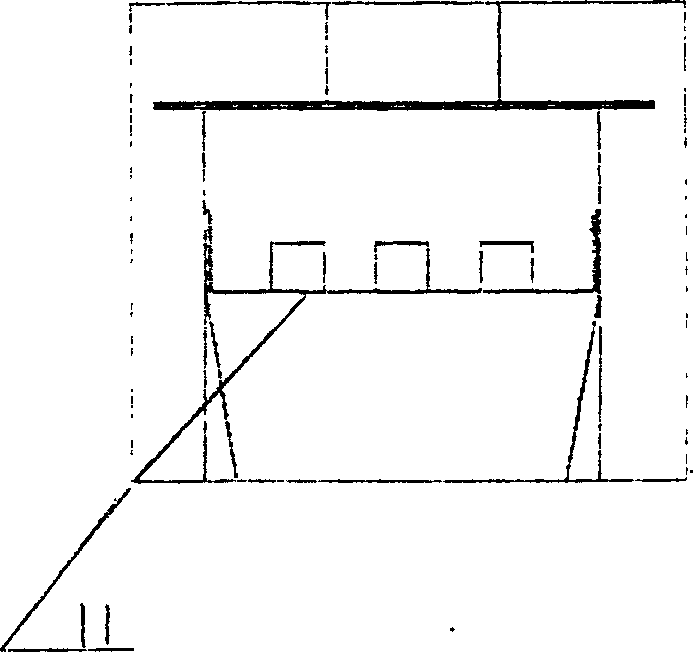

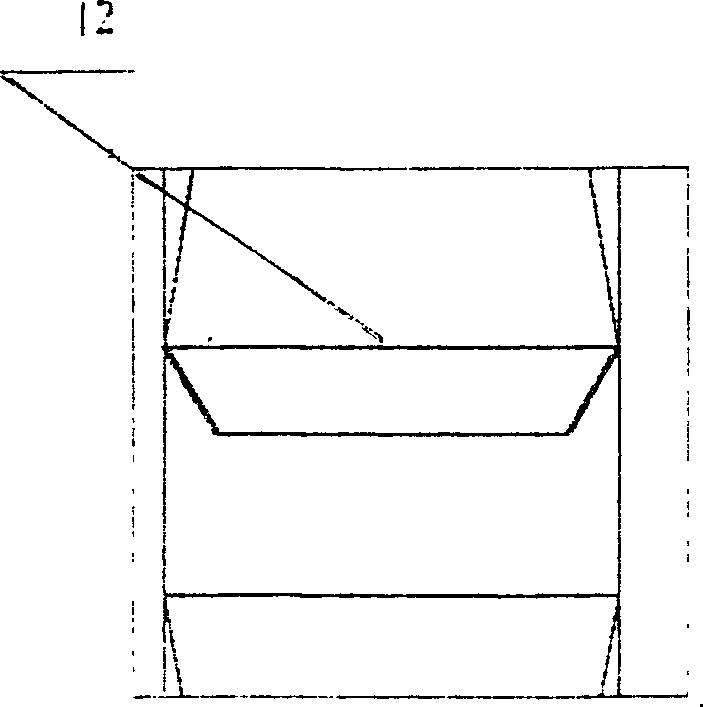

Brewing method of compound Xiaoqu liquor and bacterium cultivation saccharification system adopted by same

PendingCN111518648AGreat tasteReduce contentBioreactor/fermenter combinationsBiological substance pretreatmentsChaptalizationFusel alcohol

The invention discloses a brewing method of compound Xiaoqu liquor and a bacterium cultivation saccharification system adopted by the same. The brewing method comprises the steps of sorghum cooking, stacking bacterium cultivation, Xiaoqu saccharification, distiller grain mixing and fermentation and distillation. The stacking bacterium cultivation specifically is that: Maotai-flavor high-temperature Daqu a weight of which is 3 to 7 weight percent of a dry weight of a raw material and rhizopus a weight of which is 1 to 3 weight percent of the dry weight of the raw material are added into cookedsorghum; and after uniform mixing, stacking bacterium cultivation is carried out. Xiaoqu saccharification specifically is that: fen-flavor Xiaoqu a weight of which is 0.4 to 0.6 weight percent of thedry weight of the raw material is added into fermented grains obtained after the stacking bacterium cultivation is completed; and after uniform mixing, Xiaoqu saccharification is carried out. The bacterium cultivation saccharification system comprises a cooked grain inlet box plate chain, a stacking box, a distiller grain conveyor and a saccharification box. According to the brewing method disclosed by the invention, total acid, total ester and ethyl acetate content of the brewed product can be effectively increased, content of fusel oil is reduced, a fragrant aroma is given, the taste is increased, and liquor quality of the produced liquor is promoted; the bacterium cultivation saccharification system is reasonable in design, can continuously complete the stacking bacterium cultivation and Xiaoqu saccharification processes and ensures product quality.

Owner:JING BRAND

Gorgon fruit decoction dreg wine and brewing method thereof

PendingCN111518657AGood alcohol rateImprove wine qualityAlcoholic beverage preparationBiotechnologyPropanol

The invention provides gorgon fruit decoction dreg wine and a brewing method thereof. The brewing method comprises the following steps: taking gorgon fruit decoction dregs as raw materials, and brewing by adopting a Xiaoqu liquor solid-state fermentation process, wherein the fermentation period is adjusted to be 10-12 days. According to the invention, the Xiaoqu liquor solid-state fermentation process is adopted, the fermentation period is adjusted to be 10-12 days, the contents of acetaldehyde, methanol and ethyl acetate in the key indexes of wine quality chromatography are in a superior range, the content of n-propanol is in a first-level range, and the content of fusel oil is in a first-level range; and meanwhile, the wine yield in the fermentation period is ideal, namely, raw wine withhigh wine yield and high wine quality is brewed by taking the gorgon fruit decoction dregs as raw materials, the economic value of the gorgon fruit decoction dregs is greatly improved, and the wine varieties in the market are enriched.

Owner:JING BRAND

New technology for preparing ester spices by using fusel oil enzyme method and natural ester spices

InactiveCN102559784AImprove conversion rateMeet the requirements of friendly productionFermentationChemical synthesisFusel alcohol

The invention discloses a new technology for preparing ester spices by using a fusel oil enzyme method and natural ester spices, and relates to a new technology for preparing natural ester spices by catalysis of lipase under the non-aqueous phase condition by using fusel oil and acetic acid as main raw materials and the natural ester spices. The fusel oil is a byproduct of fermentation alcohol, mainly contains isoamyl alcohol, isobutyl alcohol, n-propanol and the like, is mainly used for refining chemical products by extraction or manufacturing ester spices by using catalysis of concentrated sulfuric acid, and does not meet the requirement for environment-friendly production. A non-aqueous phase enzymatic transformation technology and an ultrasonic field reinforcing technology are integrated in the new technology, the fermentation-derived fusel oil and the acetic acid are used as the main raw materials, and the natural ester spices of isoamyl acetate, isobutyl acetate, propyl acetate and the like are prepared by non-aqueous phase transformation of the lipase; and the reaction conditions are mild, the defects of high energy consumption, serious pollution and the like in chemical synthesis are overcome, and nature and eating safety of the spices are enhanced. The ester spices can be widely applied to preparation of essence for wine, food essence, daily use chemical essence and the like.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

Method for simultaneously separating and purifying racemic optical amyl alcohol, optical active amyl alcohol and isoamyl alcohol and its equipment

InactiveCN1181026CTake advantage ofReduce energy consumptionOrganic compound preparationHydroxy compound preparationIt equipmentIsoamyl alcohol

The present invention adopts single tower, on the basis of general precision rectification process adds flooding operation, its total reflux is implemented at twice, reflux ratio of 4-80, and between two stages of total reflux the light component can be fractionized out from top of tower and the water content is removed. It provides the equipment for implementing the above-mentioned method. It is technically characterized by adopting high-effective precision rectification filling material and electromagnetic needle pendulum reflux ratio control instrument, height of filling layer is 140-150 cm, its complete condenser is water-splitting complete condenser, and upper portion of filling layer and its middle portion are respectively equipped with returned liquor distributor and oblique cone ring baffle.

Owner:SICHUAN UNIV +1

Recovery method and recovery equipment of distillation waste liquid latent heat of alcohol plant

InactiveCN102921181AGuaranteed stabilityProduct stabilityFlash distillationLiquid wasteRecovery method

The invention provides a recovery method and equipment of distillation waste liquid latent heat of an alcohol plant. High-temperature waste liquid exhausted by the tower bottom of a rectifying tower is guided into a flash evaporation balancer, steam is generated by the self-evaporating effect of the high-temperature waste liquid, and the generated steam is used as heat energy of the process of aldehyde tower rectifying, crude wine preheating or fusel oil tower concentrating of the alcohol plant. According to the recovery method and the equipment of the distillation waste liquid latent heat of the alcohol plant, latent heat recovery rate of the alcohol plant can be improved, the steam can be saved by 1.5t / h, energy consumption of a production enterprise is lowered, and the purpose of energy saving and emission reduction is achieved.

Owner:广西农垦思源酒业有限公司

Saccharomyces cerevisiae, microbial inoculum, application thereof, white spirit, yellow rice wine and brewing methods of white spirit and yellow rice wine

The invention relates to the field of microorganisms, and discloses Saccharomyces cerevisiae, a microbial inoculum, an application thereof, white spirit, yellow rice wine and brewing methods of the white spirit and the yellow rice wine. The preservation number of the saccharomyces cerevisiae is CGMCC No. 20591. The yeast strain is used for producing strong-fragrance raw wine, the fusel oil contentis obviously reduced, the ethanol content is increased, and the produced strong-fragrance raw wine is harmonious in fragrance, mellow, sweet and refreshing in taste and free of headache after being drunk.

Owner:COFCO NUTRITION & HEALTH RES INST +1

Novel biodiesel with low cold filter plugging point and preparation method thereof

InactiveCN105087170AImprove cold flow propertiesImprove miscibilityFatty acid esterificationFatty acids production/refiningPetrochemicalOil and grease

The invention provides a novel biodiesel with a low cold filter plugging point and a preparation method thereof. Natural grease or waste grease are mixed with fusel oil, a catalyst is added, wherein the mol ratio between fusel oil and grease is 1:1-8:1, the catalyst amount needed in a reaction is 0.2-20%, the reaction is carried out for 0.5-20 hours at 20-200 DEG C, and a mixed liquor is obtained; the mixed liquor is washed with water and centrifuged, and an oil phase product crude fusel ester and a water phase impurity are obtained; the crude fusel ester is distilled, fusel and refined fusel ester are obtained, and the refined fusel ester is the biodiesel with a low cold filter plugging point. According to the invention, natural grease or waste grease and fusel oil are used as raw materials for reacting and preparing the biodiesel, the low temperature fluidity of the product is substantially improved, and the cold filter plugging point is decreased by 5-15%. According to the invention, the product can be mixed with petrochemical diesel oil and biodiesel with a high cold filter plugging point, and thereby improving low temperature properties of the biodiesel with the high cold filter plugging point, and expanding the usage scope of the biodiesel with the high cold filter plugging point.

Owner:BEIJING UNIV OF CHEM TECH +1

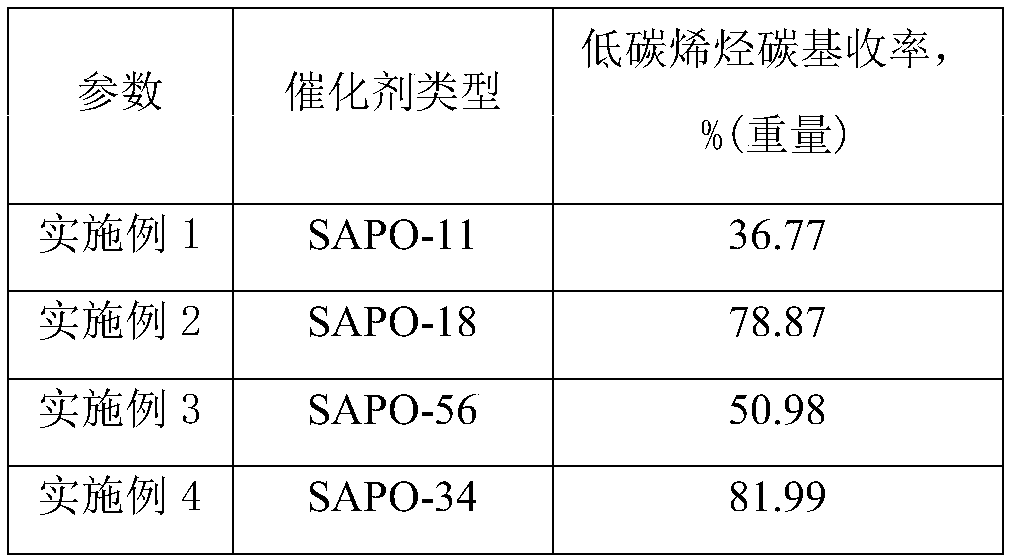

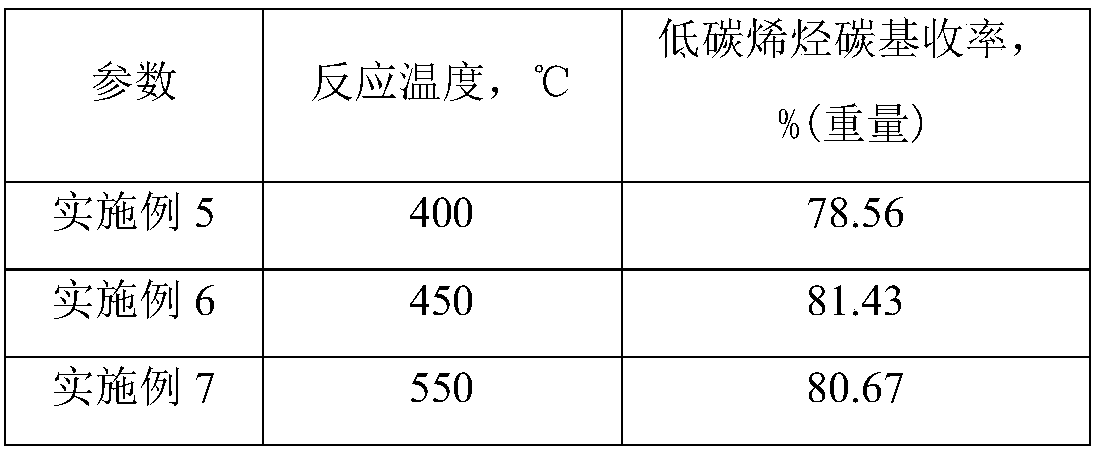

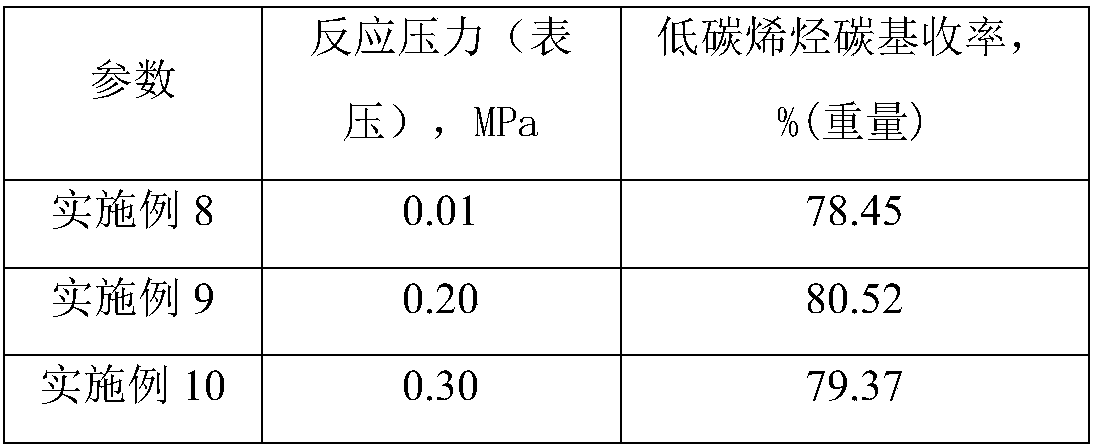

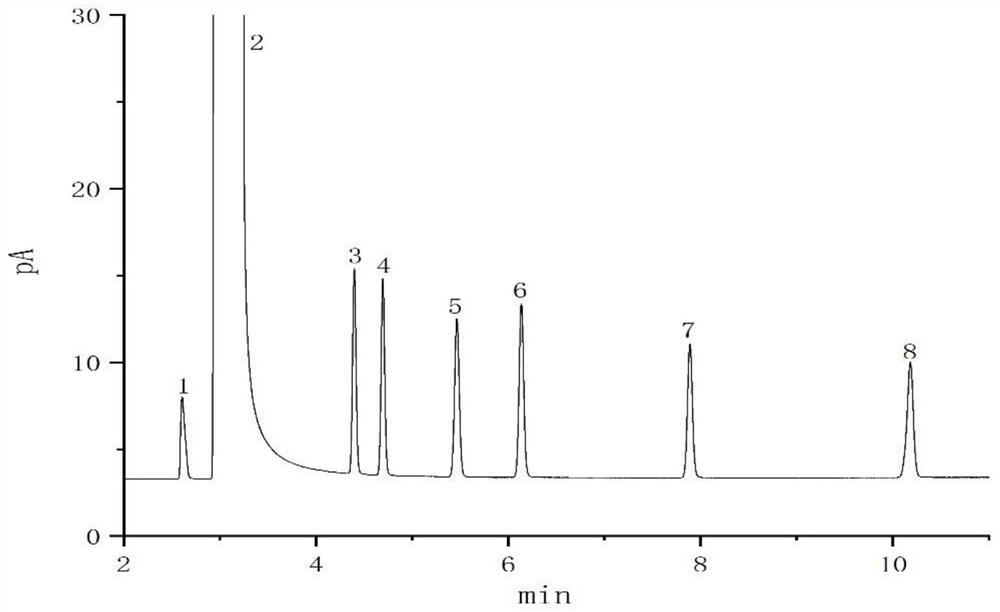

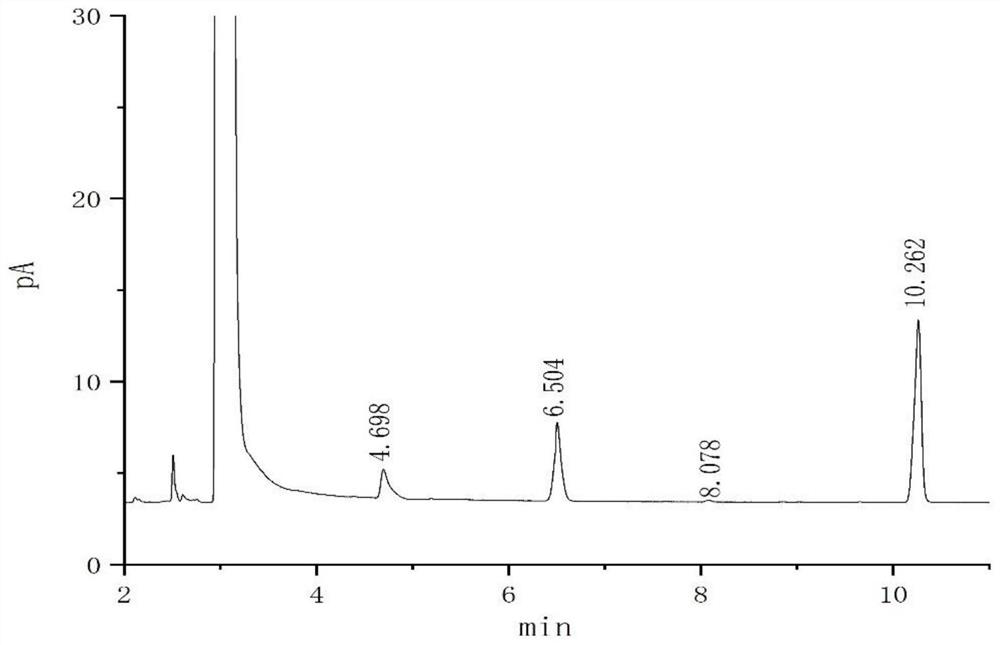

Method for producing low-carbon olefins

ActiveCN110452087ASolve the impactDoes not affect activityMolecular sieve catalystCatalystsMolecular sieveFluidized bed

The invention relates to a method for producing low-carbon olefins. The method is mainly used for solving the problems of a low-carbon olefin production process that the yield of a target product is relatively low, the influence caused by raw material impurities is relatively large, and the operation cycle is short. According to the method, crude methanol serves as a raw material and is in contactwith an aluminosilicophosphate molecular sieve catalyst in a fluidized-bed reactor under effective conditions to produce a product containing the low-carbon olefins, the catalyst is deactivated and then enters a fluidized bed regenerator for regeneration through a regeneration pipe chute, and the regenerated catalyst is degassed in a degassing tank and then returns to the fluidized-bed reactor through a regeneration pipe chute; the crude methanol has a methanol purity higher than 90% and contains impurities, the impurities comprise fusel alcohol and heavy carbon hydrocarbons, and the mass content of the impurities is lower than 2%; the method is characterized in that the crude methanol raw material is subjected to flash vaporization by a flash evaporation tank and then enters the fluidized-bed reactor, and the impurities are withdrawn from the bottom of the flash evaporation tank and then are fed into the degassing tank; through adopting the technical scheme, the above problems are better solved; and the method can be applied to industrial production of the low-carbon olefins.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for removing fusel oil in yellow rice wine

PendingCN112159747AEfficient removalPreserve the flavorAlcoholic beverage preparationBiotechnologySpecific adsorption

The invention discloses a method for removing fusel oil in yellow rice wine. The method comprises the following steps of: (1) filtering the yellow rice wine by using an ultrafiltration membrane, and collecting filtrate; and (2) adding specific adsorption resin into the filtrate in the step (1), adsorbing for 1-4 hours, and filtering by using a filtering net, thereby removing the fusel oil in the yellow rice wine. By adopting a low-temperature ultrafiltration membrane separation technique and combining the specific resin adsorbing the fusel oil in the yellow rice wine, the problem that people easily get drunk after drinking the yellow rice wine is solved to a great extent, meanwhile the flavor and the taste of the yellow rice wine are maintained, and the method is simple to operate and canbe applied to yellow rice wine production on a large scale.

Owner:SHENZHEN ANGEL DRINKING WATER IND GRP +1

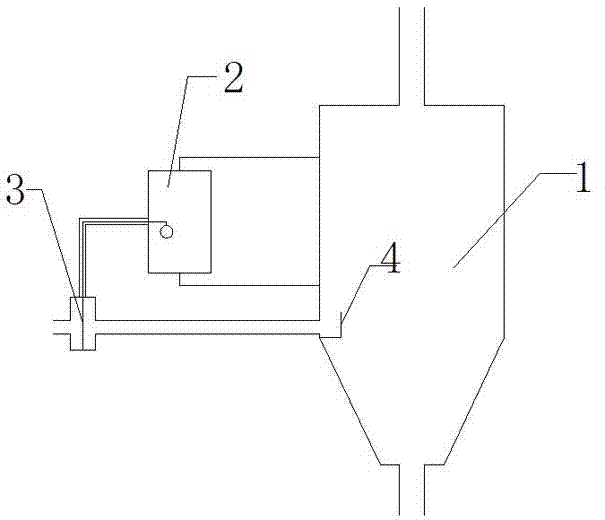

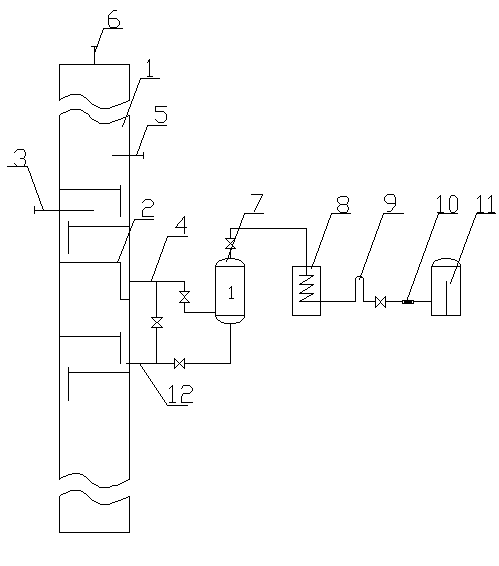

Device for extracting fusel oil by alcohol distillation

The invention relates to a device for extracting fusel oil by alcohol distillation. The device comprises an alcohol refining tower, a fusel oil separator, a raw material inlet, a finished product outlet, a fusel oil collecting point and a low boiling point impurity collecting point, wherein the raw material inlet is formed in the middle-lower part of the alcohol refining tower; the finished product outlet is formed in the middle-upper part of the alcohol refining tower; the low boiling point impurity collecting point is arranged on the top of the alcohol refining tower; the fusel oil collecting point is formed above the raw material inlet; the fusel oil separator is connected with the fusel oil discharge point; the fusel oil separator is sequentially connected with a cooler, an observation cover, an emulsifier and a separator through a pipeline in sequence; the bottoms of the fusel oil separator and the alcohol refining tower are communicated. The device is capable of thoroughly separating and collecting unstable alcohol and distilling and extracting the fusel oil.

Owner:JINJIANG TAIXING CHEM IND CO LTD

Method for producing whiskey by three times of distillation of beer malt

PendingCN111718827ARich aroma of wheatFixing an Easy HangoverBeer fermentationAlcoholic beverage preparationBiotechnologyAlcohol content

The invention provides a method for producing whiskey by three times of distillation of beer malt. The method comprises the following steps of (1) producing raw distilled wine; (2) carrying out distillation for the first time; (3) carrying out distillation for the second time; (4) carrying out distillation for the third time; (5) discharging wine; and (6) carrying out aging. The continuous three-time distillation process is adopted; in the distilled whiskey, distillate is higher in alcohol content, the fusel oil content reaches 50-100 mg / L, and the wheat fragrance is strong; the problems thatat present, after the whiskey is drunk, hangover, headache and physical discomfort are likely to happen are solved; and the taste is purer.

Owner:YANTAI GISBELLE WINE

Yeast with low fusel oil production and its application in reducing the content of fusel oil in Xiaoqu Yuanjiu

The invention discloses low yield fusel oil yeast. According to the invention, the classification and the name of the low yield fusel oil yeast are Saccharomyces cerevisiae Y19, the low yield fusel oil yeast is preserved in the China typical model cultivation center, the preservation date is march 19, 2013, and the preservation number is CCTCC NO.M2013091; the low yield fusel oil yeast is used for manufacturing the aromatic Xiaoqu raw wine, and compared with a conventional fermentation method, the content of the fusel oil is lowered by 24.7%; the manufactured aromatic Xiaoqu raw wine has pure aroma, typical style, harmonious aroma and clear aftertaste, tastes spongy and sweet, and is fresh; a person can not get dunk after drinking the wine.

Owner:JING BRAND

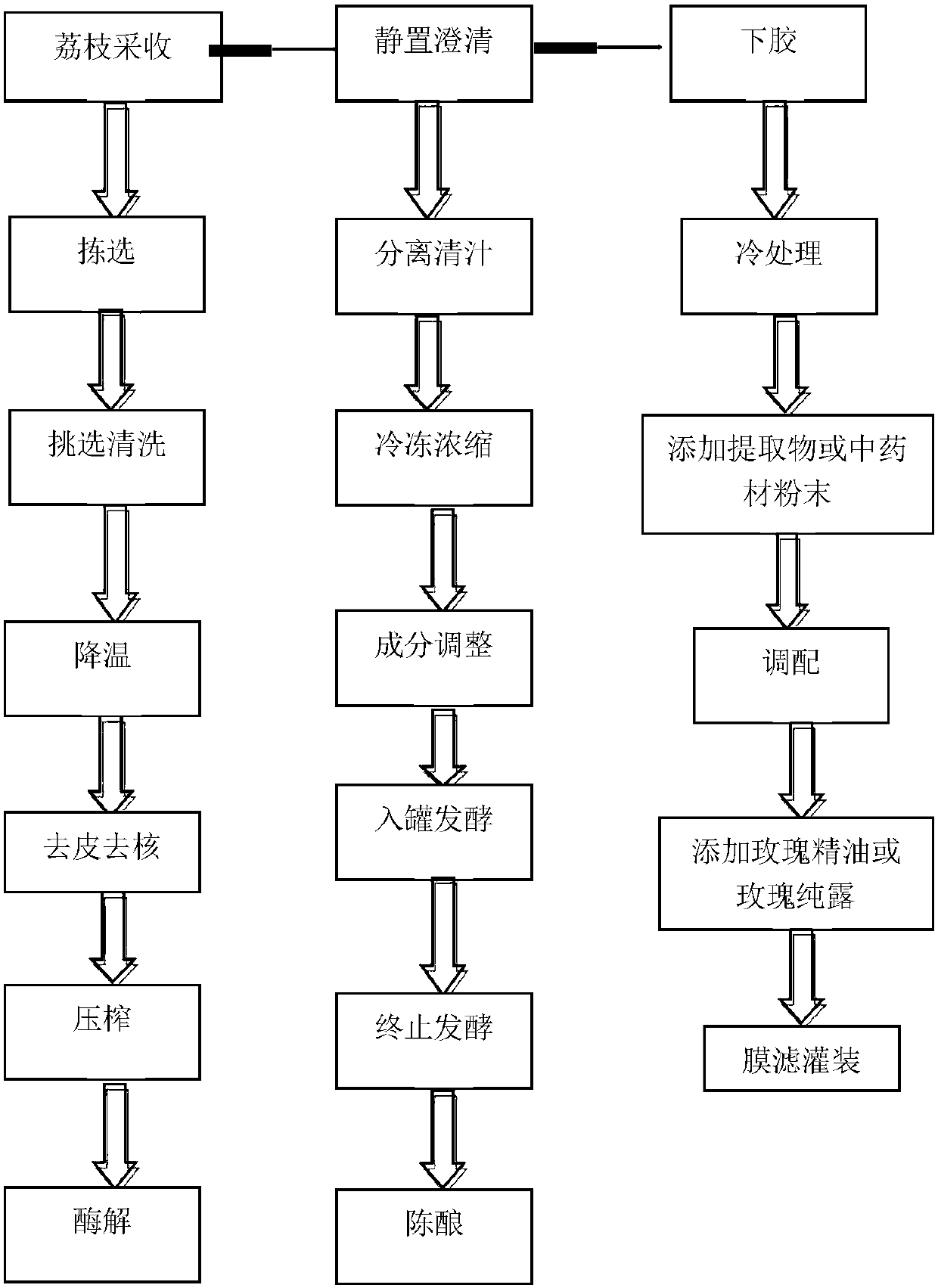

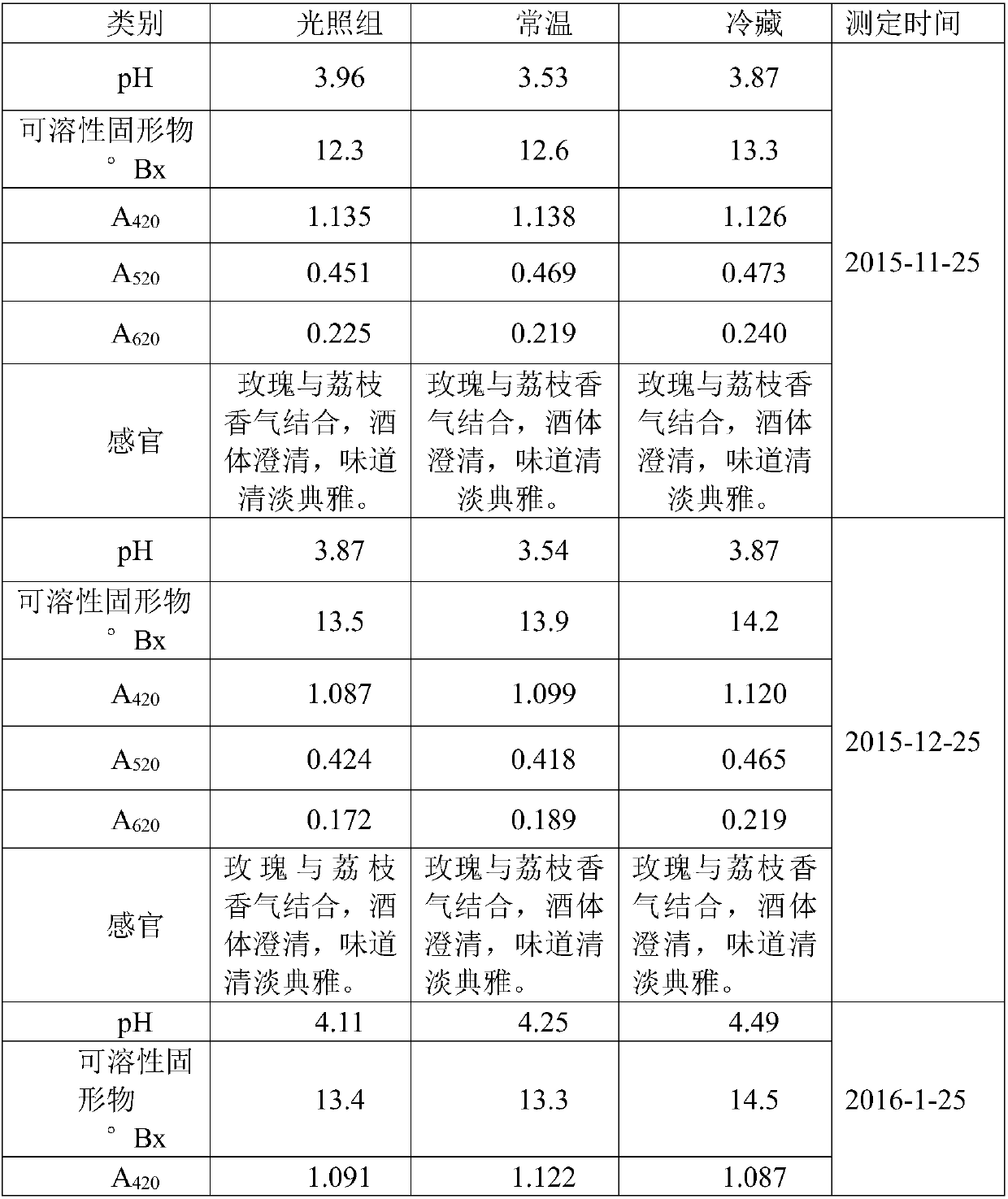

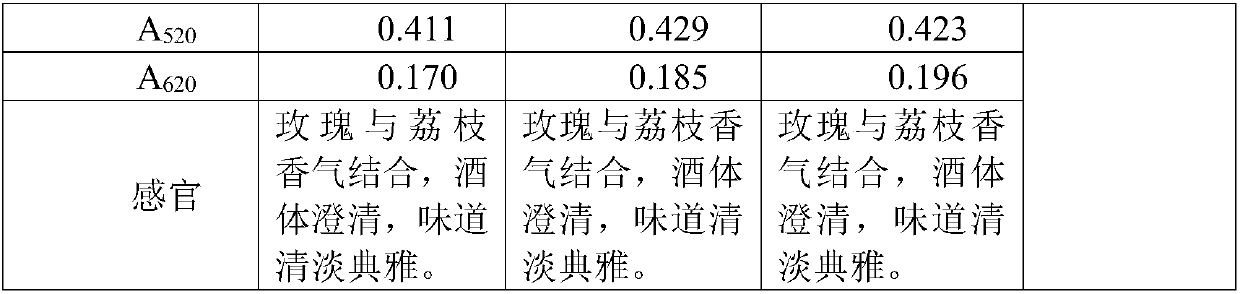

Lychee rose wine as well as preparation method and application in tonifying qi and blood and resisting oxidation

ActiveCN107557254ASweet tasteUnique flavorDigestive systemAlcoholic beverage preparationCold treatmentAdjuvant

The invention relates to lychee rose wine as well as a preparation method and an application thereof. According to the lychee rose wine, lychee base wine, which is prepared by conducting scientific fermentation on lychee, is blended with red wine and white wine, and with the lychee serving as a monarch which is added with finely selected fruit of Chinese wolfberry, red jujube, radix glycyrrhizae,radix ginseng and apple powder and is assisted by a blending agent and a proper amount of adjuvants, the lychee rose wine is prepared by the method comprising the following steps: 1) harvesting, sorting, selecting and cleaning, cooling, peeling off and depitting, and squeezing the lychee, and conducting enzymatic hydrolysis; 2) standing by and conducting clarifying, separating clear juice, freezing and concentrating the clear juice, adjusting components of the juice, conducting fermentation in a tank, ending the fermentation, conducting aging, implementing fining and implementing cold treatment, so that the lychee base wine is obtained; 3) adding the fruit of Chinese wolfberry, the red jujube, the radix glycyrrhizae, the radix ginseng and the apple powder; and 4) conducting blending, filtering obtained liquid by virtue of a membrane, and filling and sealing the liquid, so that the lychee rose wine is obtained. The lychee rose wine prepared by the invention is clear and transparent in wine body and low in content of volatile acid, and the lingering bitterness of the wine body is obviously reduced and the wine body is good in taste; the wine is low in content of fusel oil; and the wine has such functions of resisting oxidation and the like, and the wine is suitable for tonifying qi and blood, promoting blood circulation and removing toxins. The lychee rose wine provided by the invention, which is applicable to preparation of various health-care wine drinks, has a broad market prospect.

Owner:ZHUZHOU QIANJIN PHARMA

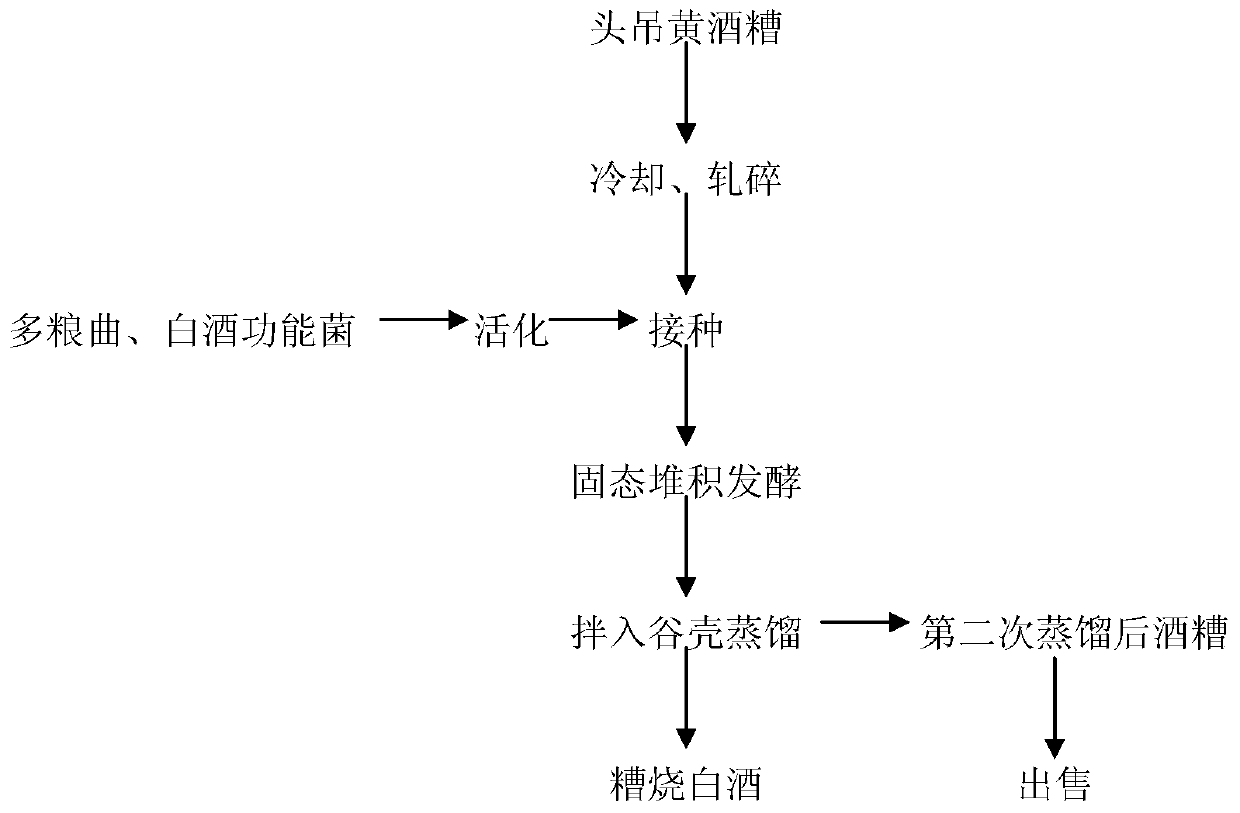

Process for producing lees-burnt baijiu by using first-stage yellow wine lees

The invention discloses a process for producing lees-burnt baijiu by using first-stage yellow wine lees, and belongs to the technical field of wine brewing. The process comprises the following steps:carrying out direct or solid-state stacking fermentation on the yellow wine lees which are obtained by brewing, squeezing and separating according to the conventional yellow wine production process; distilling remaining lees (commonly known as the first-stage yellow wine lees) after processing of the lees-burnt baijiu; after cooling and crushing the remaining lees, uniformly inoculating multi-grain distiller's yeast and baijiu functional bacteria into the remaining lees; meanwhile, adjusting the water content; and after carrying out solid-state stacking fermentation for 5-10 days, carrying outdistilling to obtain the lees-burnt baijiu. Results show that the lees-burnt baijiu produced by the process has the yield about 8% (converted into 50% vol of alcoholic strength); compared with first-stage lees-burnt baijiu (baijiu obtained after distilling the yellow wine lees for the first time), the lees-burnt baijiu has the advantages of high total ester, low fusel oil, light after-bitterness,soft and sweet mouthfeel and the like; and the utilization rate of raw materials is improved, and moreover, the protein content in the yellow wine lees is improved by 3 to 5 percent; and if the yellow wine lees is used as a feed raw material, the selling price can also be further increased.

Owner:绍兴国家黄酒工程技术研究中心有限公司 +1

A kind of bayberry fruit wine and processing method thereof

InactiveCN104327997BSmooth and thorough fermentationPlay the role of reducing acid and increasing flavorAlcoholic beverage preparationMicroorganism based processesBiotechnologyFruit wine

The invention discloses a red bayberry fruit wine and a processing method thereof. The fresh red bayberry fruit is processed through raw material processing, juice extraction and separation, component adjustment, double yeast fermentation, ultra-high pressure sterilization, natural aging, aging by high-voltage pulse electric field, cold treatment and filtration. Obtain the red bayberry fruit wine. The obtained red bayberry fruit wine of the present invention has a strong fragrance and good taste, its light transmittance is more than 88%, the total ester content is 2.98-3.12 mg / L, the total amount of fusel oil is 175.68-185.36 mg / L, and does not contain methanol; and The whole process of processing is non-thermal processing, and the production cycle is short, which has positive significance for increasing the added value of waxberry processed products, and the market prospect of the products is good.

Owner:FUJIAN AGRI & FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com