Fusel oil molecular sieve gas phase dewatering method and separating and purifying method

A purification method and fusel oil technology are applied in the field of fusel oil molecular sieve gas phase dehydration method and separation and purification, which can solve the problems of corroding separation equipment, affecting the purity and yield of rectified products, and achieving the effect of increasing product yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

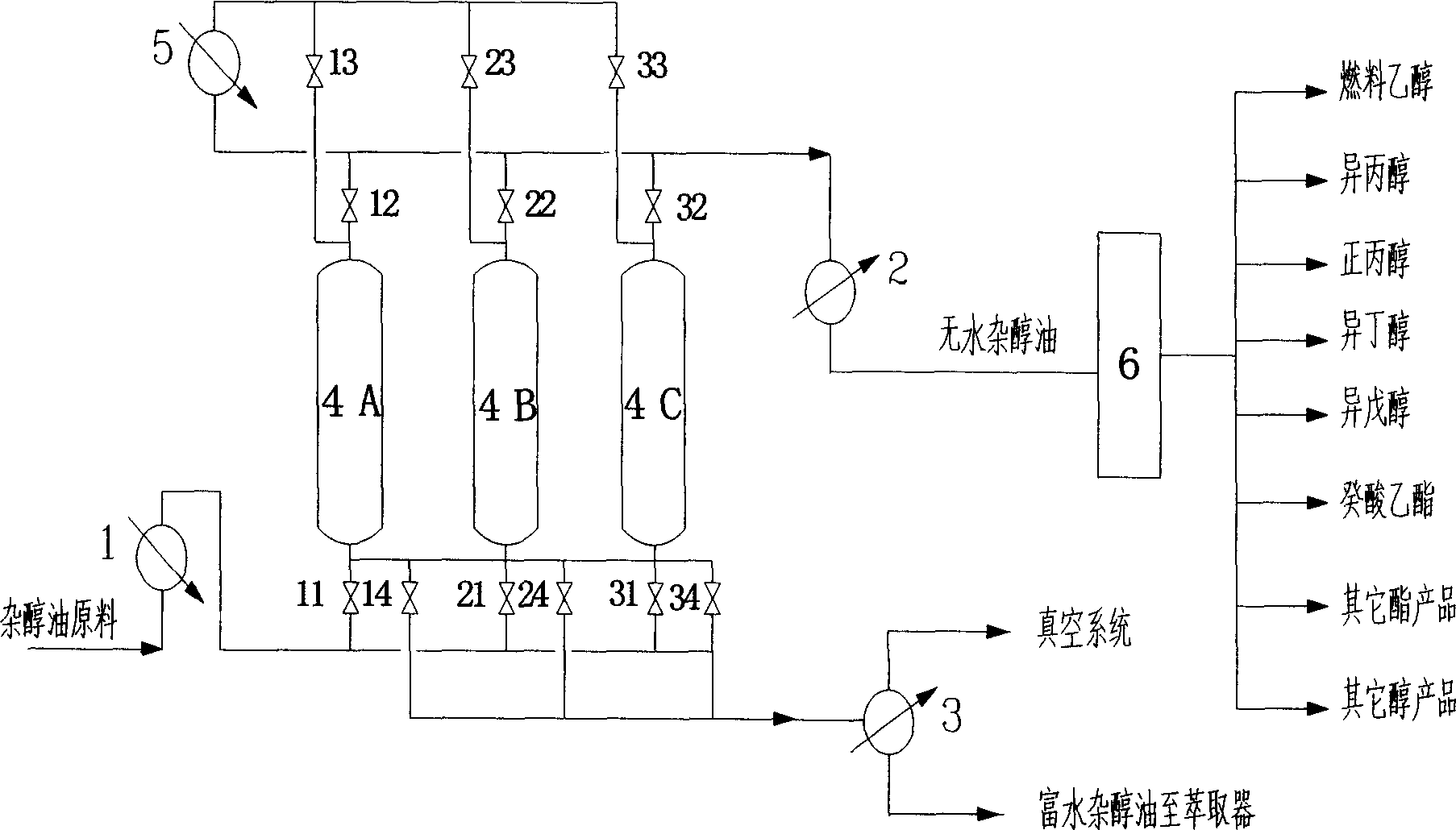

[0032] like figure 1 As shown, the production process of the new fusel oil separation and purification process is mainly composed of raw material preheater 1, adsorption condenser 2, desorption condenser 3, adsorber 4A, adsorber 4B, adsorber 4C, heater 5 and rectification purification device 6 and other operating unit equipment. 200 grams of 3A molecular sieves are installed in the adsorber, and the space velocity is 0.24h -1 .

[0033] The fusel oil raw material with a water content of 15% is heated to 250° C. through a raw material heater, so that the raw material is in a gaseous state. It is sent to the adsorber 4A through the valve 11. At this time, the valve 14 and the valve 13 are in the closed state. The water in the fusel oil raw material is adsorbed by the adsorbent installed in the adsorber 4A, and the anhydrous fusel oil enters the adsorption condenser through the valve 12 to condense 2 to obtain anhydrous fusel oil. The gauge pressure of the operating pressure...

Embodiment 3

[0039] Same as Example 2, the difference is that the water content of the raw material fusel oil is 1%, and the space velocity is 1.0h-1 , the adsorption operating pressure is gauge pressure 0.6Mpa, and the adsorption temperature is 300 degrees; after the adsorption treatment in an adsorption tower, the water content in the fusel oil is 0.1%.

Embodiment 4

[0041] Same as Example 1, the difference is that two adsorption towers are used to operate, the water content of the raw material fusel oil is 10%, and the space velocity is 0.6h -1 , the adsorption operating pressure is 0.2Mpa gauge pressure, the adsorption temperature is 220 degrees; After treatment, the water content in the fusel oil was 0.15%. The switching time between the adsorption and desorption operations of the two adsorption towers is 25 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com