Graphite/silicon carbide compact composite material preparation method

A composite material and silicon carbide technology, which is applied in the field of preparing graphite/silicon carbide dense composite materials, can solve problems such as short cycle time, purity of graphite parts and coating bonding force, and achieve short cycle time, solve the problems of purity and coating bonding force Problems, the effect of low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A preparation method of graphite / silicon carbide dense composite material, comprising the steps of:

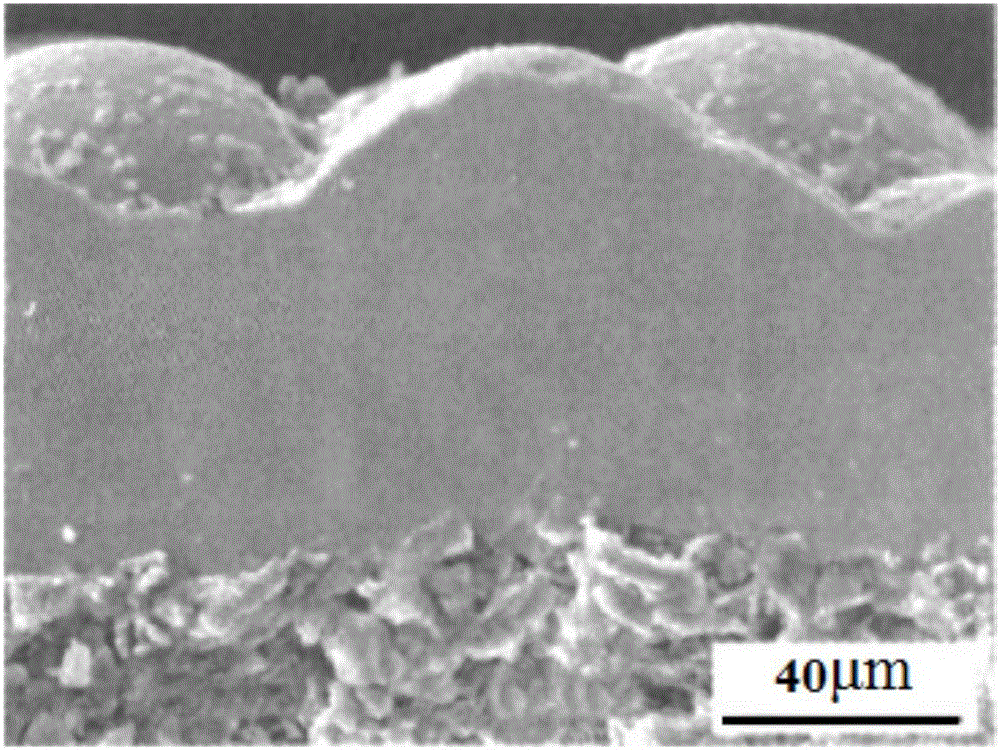

[0022] (1) After ultrasonically cleaning the graphite parts, brush the slurry made of certain silicon carbide particles, the strength of the silicon carbide particles ranges from 1-20 μm, and the slurry is composed of silicon carbide particles, graphite glue, and diluent in a mass ratio of 3:3: 1 is mixed and evenly painted on the surface of graphite parts, and then transferred to a drying oven for at least 90 ° C for more than 2 hours to form a dense silicon carbide particle layer on the surface of graphite parts. The thickness of the coating is 60 μm, and a graphite piece coated with a silicon carbide particle layer is obtained, which is then sent as a substrate into a CVD reactor to deposit a silicon carbide coating.

[0023] (2) CVD deposition process conditions:

[0024] 1) Lower the bottom flange, open the furnace tube, and put in the base material;

[0025] 2) ...

Embodiment 2

[0034] A preparation method of graphite / silicon carbide dense composite material, comprising the steps of:

[0035] (1) After ultrasonically cleaning the graphite parts, brush the slurry made of certain silicon carbide particles. The strength of the silicon carbide particles ranges from 1-20 μm. The slurry is composed of silicon carbide particles, graphite glue, and diluent in a mass ratio of 3:4: 1 is mixed and evenly painted on the surface of graphite parts, and then transferred to a drying oven for at least 90 ° C for more than 2 hours to form a dense silicon carbide particle layer on the surface of graphite parts. The thickness of the coating is 80 μm, and a graphite piece coated with a silicon carbide particle layer is obtained, which is then sent as a substrate into a CVD reactor to deposit a silicon carbide coating.

[0036] (2) CVD deposition process conditions:

[0037] 1) Lower the bottom flange, open the furnace tube, and put in the base material;

[0038] 2) Lift...

Embodiment 3

[0047] A preparation method of graphite / silicon carbide dense composite material, comprising the steps of:

[0048] (1) After ultrasonically cleaning the graphite parts, brush the slurry made of certain silicon carbide particles. The strength of the silicon carbide particles ranges from 1-20 μm. The slurry is composed of silicon carbide particles, graphite glue, and diluent in a mass ratio of 4:3: 1 is mixed and evenly painted on the surface of graphite parts, and then transferred to a drying oven for at least 90 ° C for more than 2 hours to form a dense silicon carbide particle layer on the surface of graphite parts. The thickness of the coating is 30 μm, and a graphite piece coated with a silicon carbide particle layer is obtained, which is then sent as a substrate into a CVD reactor to deposit a silicon carbide coating.

[0049] (2) CVD deposition process conditions:

[0050] 1) Lower the bottom flange, open the furnace tube, and put in the base material;

[0051] 2) Lift...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com