Process for extracting greater than or equal to 98% of ursolic acid from loquat leaf

A technology of loquat leaves and ursolic acid, applied in the directions of steroids, organic chemistry, etc., can solve the problems of small preparation amount, high safety requirements, toxic solvents, etc., and achieve the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

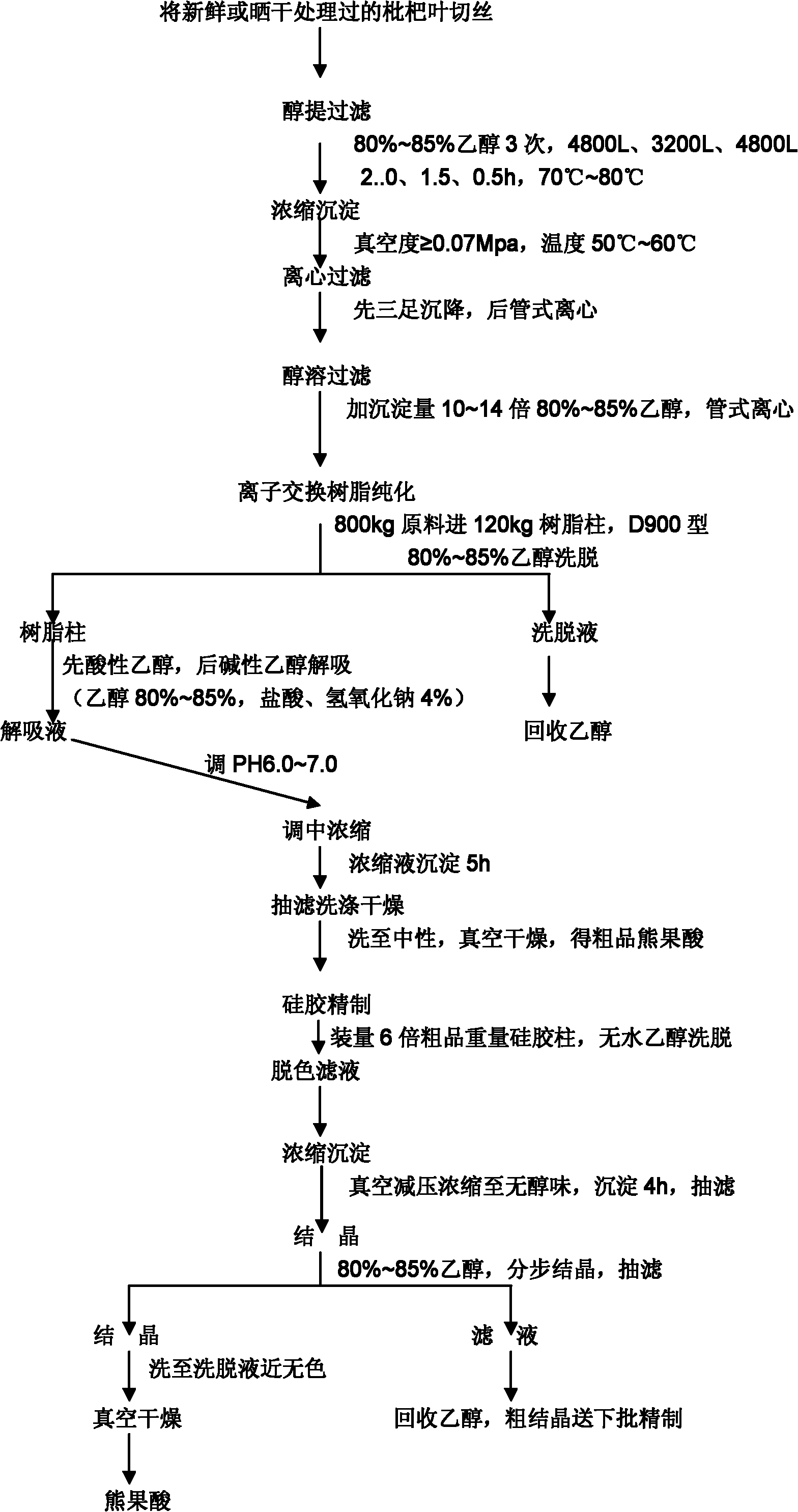

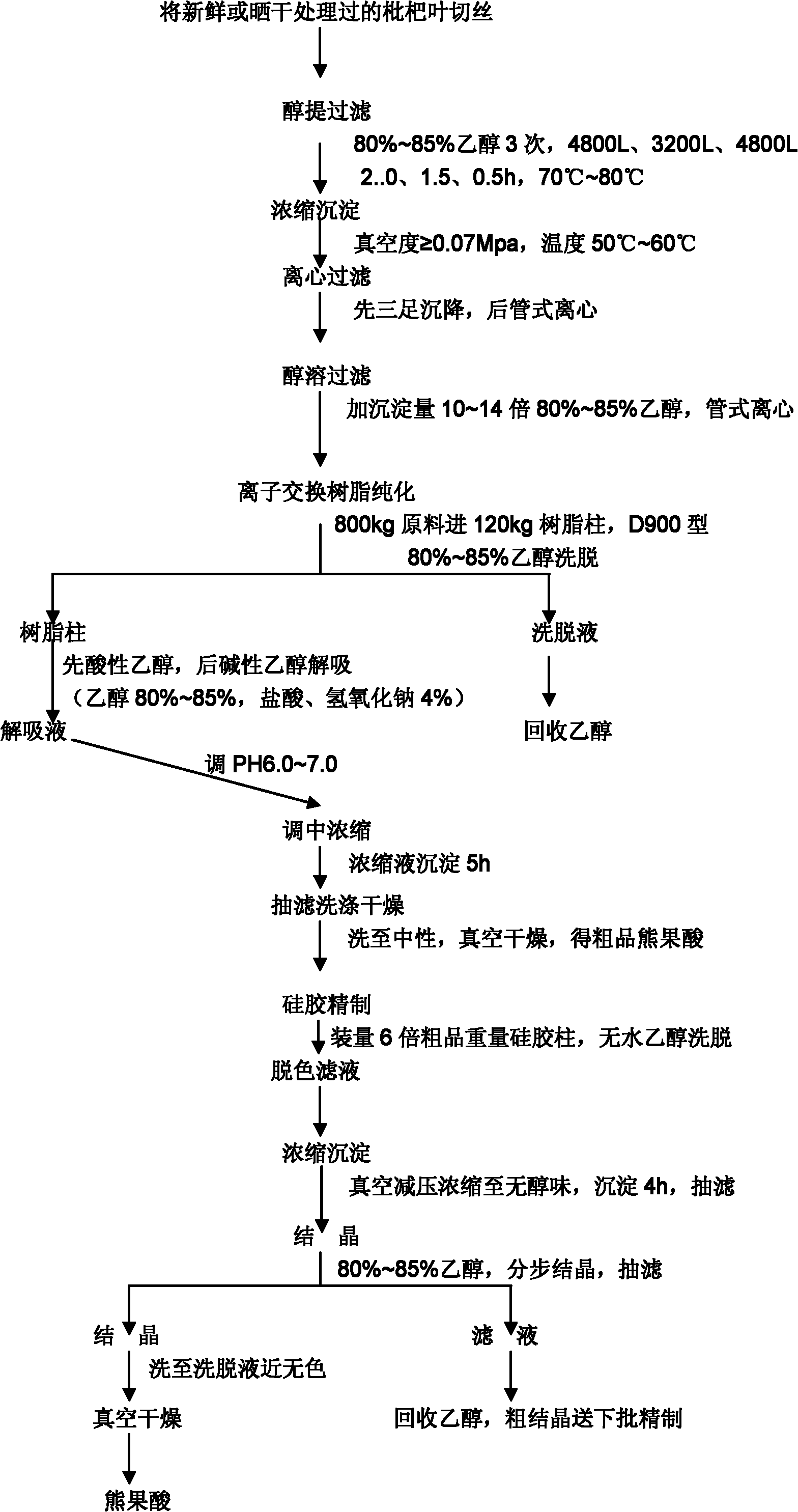

[0039] The process of separating and extracting ≥98% ursolic acid from loquat leaves includes the following steps:

[0040] (1) Cut into shreds: Take 800kg of fresh or sun-dried loquat leaves and cut into shreds with a medicine cutter, with a width of 0.5-2.0cm;

[0041] (2) Alcohol extraction and filtration: Put the shredded loquat leaves into 6cm 3 In the extraction tank, extract with 80% ethanol solution for 3 times. The amount of extraction solvent added is 6, 4, 6 times the weight of the medicinal material, that is, 4800L for the first time, 3200L for the second time, and 4800L for the third time. Extraction time It is 2.0, 1.5, 0.5h, and the extraction temperature is 70℃~80℃. Filter, combine the first two filtrates, and the third filtrates extract as the first extraction of the next batch of materials, and discard the residue;

[0042] (3) Concentrated precipitation: the first 2 combined filtrate was concentrated under vacuum to a material-liquid ratio of 1:0.7~1.2, that is, t...

Embodiment 2

[0056] Repeat Example 1 according to the same steps as described, but: step (2) is to extract 3 times with 85% ethanol; step (5) is to add 10 to 14 times the weight of the precipitate with 85% ethanol solution under constant stirring; Step (6) wash with 85% ethanol until the color of the liquid is extremely light; Step (12) add 85% ethanol with a concentration of 15 times the precipitation weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com