Recovery method and recovery equipment of distillation waste liquid latent heat of alcohol plant

A recycling method and technology of alcohol plant, applied in flash evaporation and other directions, can solve the problems of wasting cooling water, wasting latent heat of high-temperature waste liquid, destroying the ecological environment, etc., and achieve the effect of reducing energy waste, stable steam generation and full utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

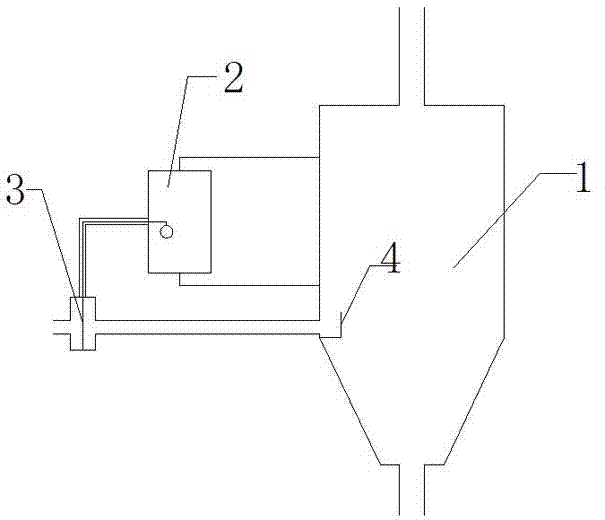

[0014] The waste liquid discharged from the bottom of the rectification tower enters the valve 3 through the pipeline, and the up and down movement of the connecting rod of the valve 3 adjusts the flow rate of the waste liquid leaving the valve 3, and enters the flash tank from the side bottom of the tank of the flash evaporator 1. During the process of the flash evaporator 1, encountering the baffle plate 4 provided in the flash evaporator 1, the high-temperature waste liquid scatters to the space above the baffle plate, and the capacity expansion effect is very obvious. The pipe at the top of the steamer 1 is discharged from the heat energy used for the preheating of the mash and crude wine and the heat energy of the fusel oil tower. The waste liquid that does not generate steam drops downward and is discharged from the pipe at the bottom of the flasher 1 and flows into Sewage treatment pond. Through the method and device of the present invention, the waste heat can be fully...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com