Patents

Literature

60results about How to "No suspended matter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

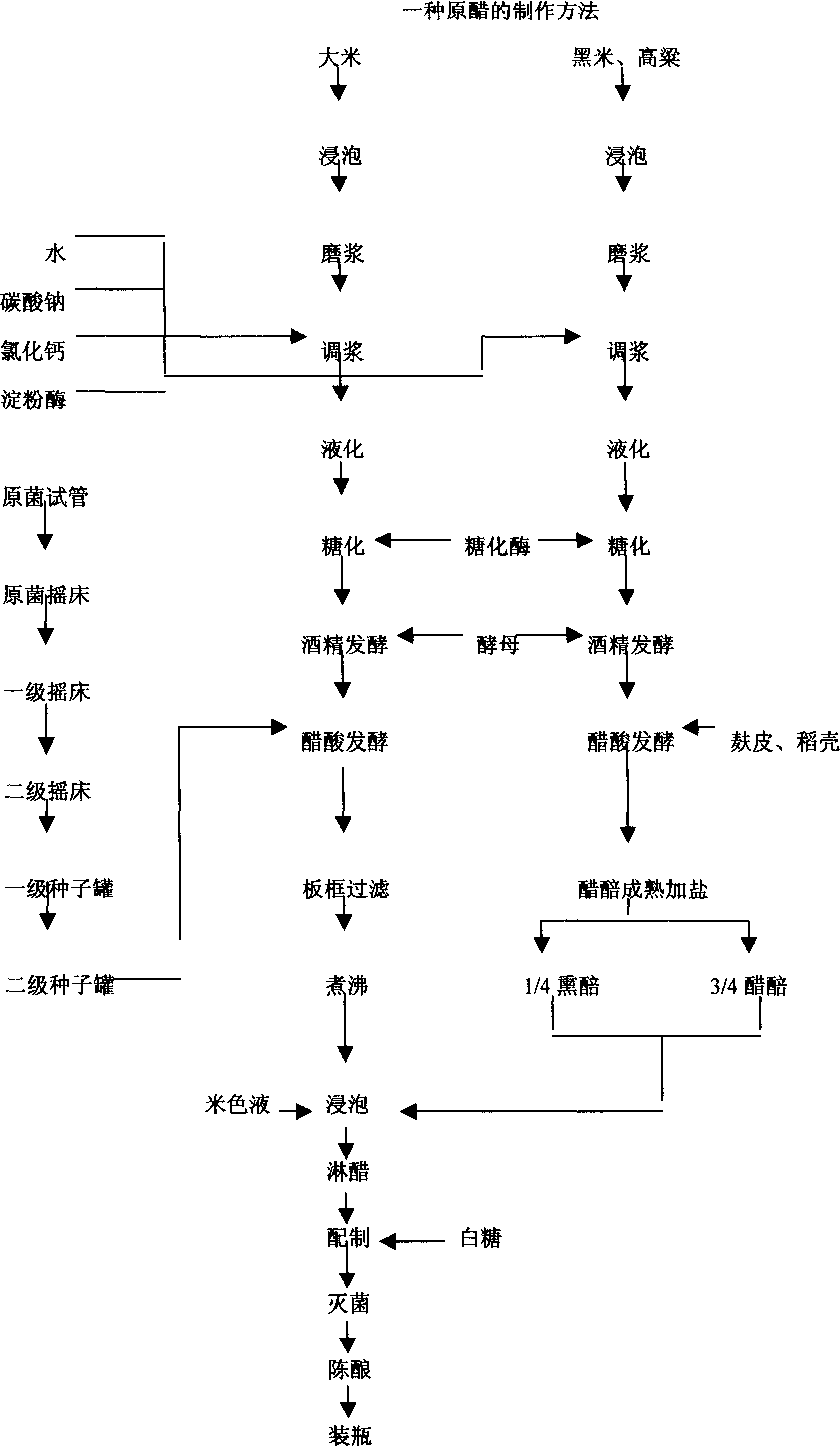

Vinegar making process

The present invention discloses vinegar making process, in which rice, sodium carbonate, salt, calcium chloride, alpha-amylase, sugar, saccharifying enzyme, yeast, water and rice hull or wheat bran in certain weight proportion are used as material. The made vinegar is brown, bight, fragrant, mildly sour and slightly sweet, and has total acid amount account with acetic acid not less than 4.0 g each 100 ml.

Owner:陈松

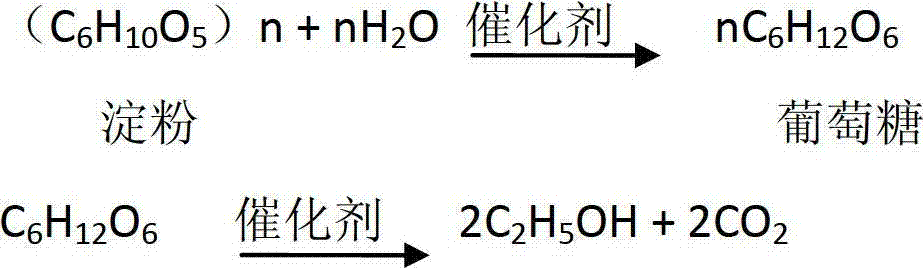

Multi-grain fen-flavor liquor and preparation method thereof

InactiveCN102978064ANo suspended matterNo precipitationAlcoholic beverage preparationPolygonum fagopyrumAcetic acid

The invention discloses a multi-grain fen-flavor liquor and a preparation method thereof and belongs to the technical field of wine brewing. The problem that fen-flavor Xiaoqu wine is not enough in flavor and mellowest taste in the prior art is solved. The multi-grain fen-flavor liquor consists of the following components in parts by weight: 65-75 percent of tartary buckwheat, 1-10 percent of rice, 2-12 percent of sticky rice, 3-13 percent of sorghum, 1-10 percent of corn, 1-8 percent of pea and 1-7 percent of lima bean. The invention also provides a method for preparing the multi-grain fen-flavor liquor. The liquor is brewed by seven grains, so that the liquor is high in content of ethyl acetate and ethyl lactate, extremely low in fusel oil content, strong in fen-flavor and excellent in mellowest taste.

Owner:宣汉巴人地窖酒厂

Method for preparing instant black tea powder

The invention discloses a method for preparing instant black tea powder. The method comprises the steps of withering fresh tea, freezing, rolling and cutting, crushing through ultrasonic wave, fermenting, extracting, filtering, concentrating and drying. Through the freezing treatment, the tea cell walls show brittle state; the tea cell walls are effectively impacted and broken completely by rolling, cutting and processing through ultrasonic wave, so that effective components such as amino acid, microelements and the like encircled in the tea cell walls are effectively leached at a quick leaching speed efficiently; the prepared instant black tea can be dissolved in water with a temperature higher than 5 DEG C; liquor color is clear, transparent and fragrant and the taste is sweet. The method for preparing instant black tea powder is simple, easy to operate, low in cost and applicable to industrial mass production.

Owner:董倩

Technique for producing waxberry brandy

InactiveCN101033440AUnique richUnique alcohol and styleAlcoholic beverage preparationDistillationBottle

This invention relates to a production technology of waxberry aquavit including: selecting and cleaning fresh waxberries, squeezing the fruits to juice, controlling the temperature for biology ferment, rough distillation, fine distillation, storage and aged brewing, preparing it, filtering and freezing and filling them into bottles and checking.

Owner:韩昌盛

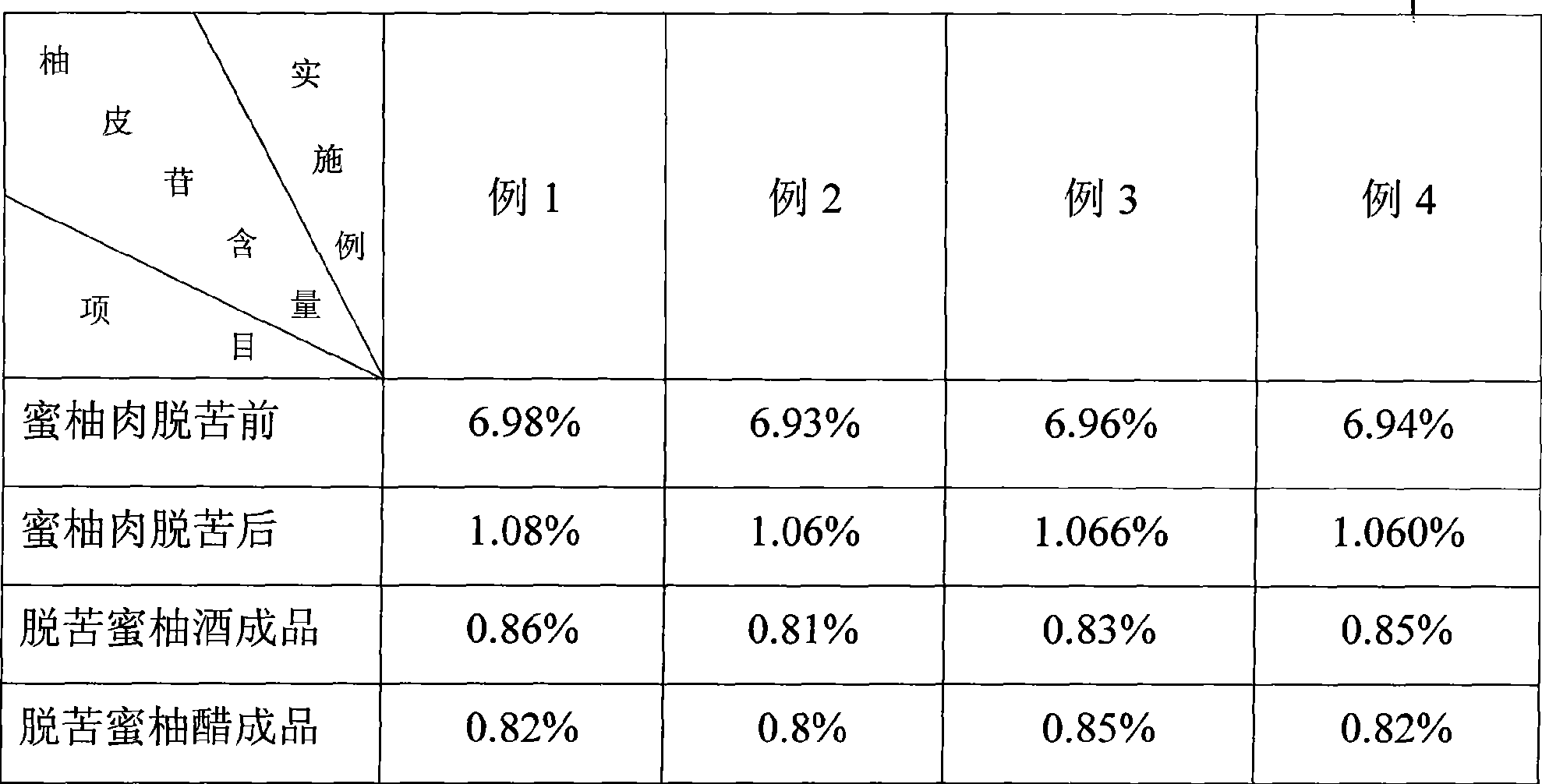

Production method of debittering honey pomelo fermentation product

InactiveCN101381663AReduce contentClear and transparent colorAlcoholic beverage preparationVinegar preparationZymogenNaringin

The invention discloses a method for producing a fermented product of debitterized honey pomelos. A honey pomelo pulp raw material is washed and disinfected, and is debitterized under thermal insulation for 2 to 4 hours at a temperature of between 55 and 66 DEG C by soy milk with the weight ratio of between 1 to 2 and 3, the debitterized honey pomelo pulp is pulped by adding enzyme and is enzymolyzed by heating to obtain juice of the enzymolyzed and debitterized honey pomelo, the juice of the enzymolyzed and debitterized honey pomelo is sterilized; the sugar and acid degree of the enzymolyzed and debitterized honey pomelo is adjusted; and zymogen is added into the enzymolyzed and debitterized honey pomelo for fermentation to obtain a semi-finished product of the fermented product of the debitterized honey pomelos; and the semi-finished product is put into a tank for aging and afterripening to obtain a finished product. When alcohol active dry microzyme is added for fermentation, debitterized honey pomelo wine is obtained; and when acetic acid bacteria is inoculated for fermentation after the alcohol active dry microzyme is added for fermentation, debitterized honey pomelo vinegar is obtained. The method utilizes phytoenzyme contained in the soy milk to effectively reduce the content of bitter principle-naringin in the honey pomelo pulp raw material, and the measurement shows that the contents of naringin are low in the honey pomelo pulp raw material after the debitterization and the fermented products of the debitterized honey pomelos prepared by the honey pomelo pulp raw material. The debitterized honey pomelo wine produced by the method has natural colour and luster and fragrance of honey pomelos, and the produced debitterized honey pomelo vinegar is clear and transparent, and has the fragrance of vinegar and honey pomelos.

Owner:FUJIAN NANHAI FOOD

Method for brewing oil-tea wine by using bio-enzymes

ActiveCN103981054ARaw materials are uniqueWith aromaMicroorganism based processesAlcoholic beverage preparationCamellia oleiferaDecomposition

The invention discloses a method for brewing an oil-tea wine by using bio-enzymes. The method comprises the following steps: (1) cleaning and impurity removal; (2) crushing and sieving; (3) mixing; (4) high-temperature enzyme deactivation; (5) multi-enzyme decomposition; (6) carbohydrate supplementation; (7) fermentation; (8) distillation; and (9) aging and packaging. The method disclosed by the invention is simple in process, less in investment, low in energy consumption, and easy to operate. The oil-tea wine prepared by using the method is bright and transparent, mellow and exquisite in taste and typical in style, and has no suspended matters and precipitates.

Owner:HUNAN ACAD OF FORESTRY

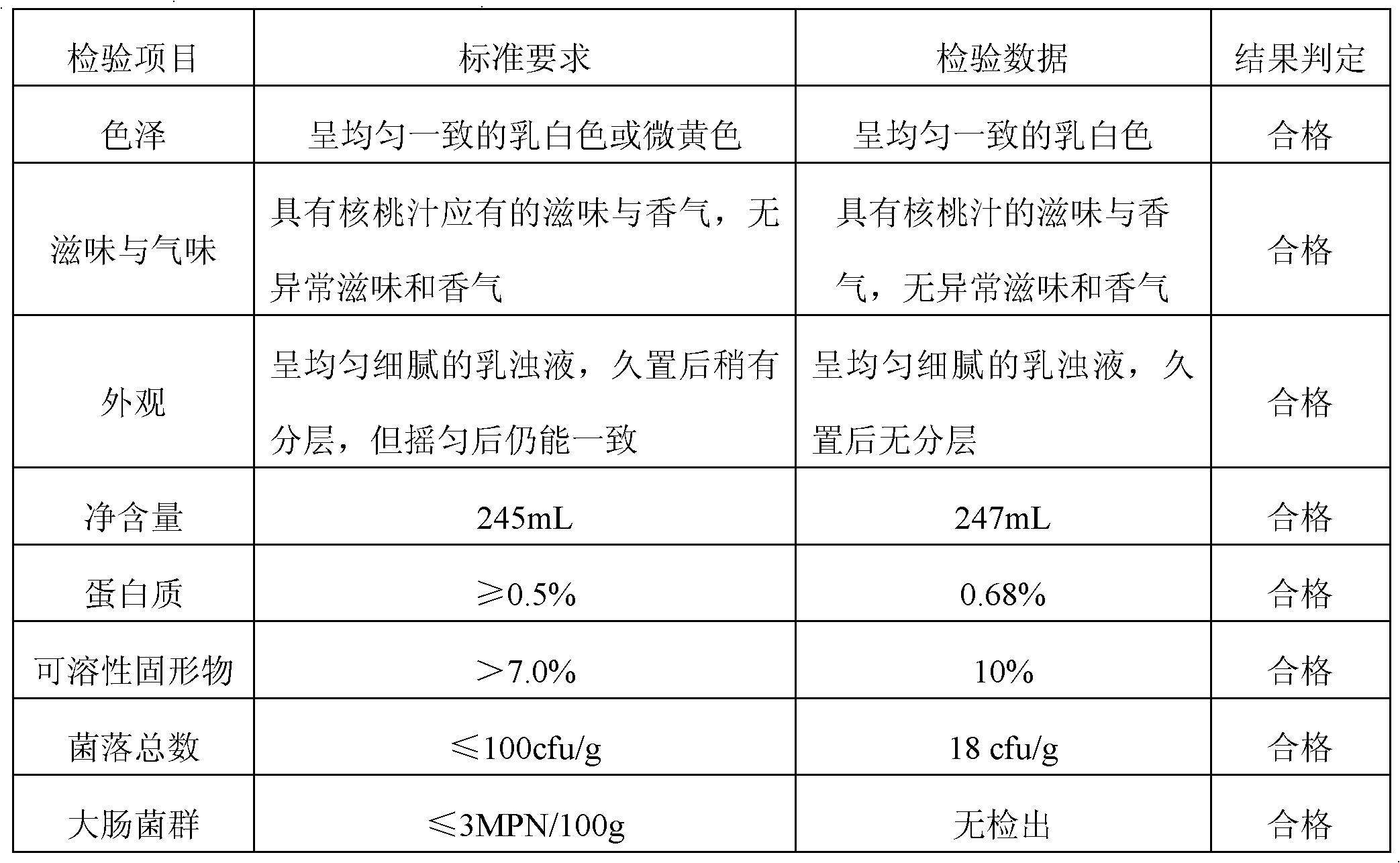

Walnut protein drink and preparation method thereof

The invention belongs to the technical field of plant protein drinks and in particular relates to a walnut protein drink and a preparation method thereof. The walnut protein drink provided by the invention is composed of water, walnut kernels, a food stabilizer, sodium bicarbonate, xanthan gum, sodium erythorbate, nisin and cane sugar. The preparation method comprises the following specific steps of: removing walnut skins on the surfaces of the walnut kernels; preparing the walnut kernels into pulp and pumping into a mixing cylinder; adding the food stabilizer, sodium bicarbonate, the xanthan gum, sodium erythorbate, the nisin, the cane sugar and hot water into a sugar melting pot; uniformly mixing and pumping into the mixing cylinder; and finally, adding a certain amount of water into the mixing cylinder, and sterilizing and packaging after adjusting the pH value. The walnut protein drink provided by the invention has high plant protein content, uniform material juice and good mouth feel and does not contain suspended matters.

Owner:南红强

Preparation method of jackfruit white spirit

InactiveCN102559441AIncrease economic value addedAroma harmonyMicroorganism based processesAlcoholic beverage preparationPectinaseFiltration

The invention relates to a preparation method of jackfruit white spirit, which comprises the following steps: performing antioxidating process for pulp and fruit silk of the jackfruit, mixing with water, mashing, pressing, adding potassium metabisulfite, pectinase and citric acid into scum juice, performing enzymolysis, adjusting sugar content of the jackfruit slurry, adding alcohol dry yeast andammonium dibasic phosphate into the jackfruit slurry and fermenting, filtering 2-4% of the mash obtained from fermentation, performing crude distillation and rectification for the rest of the mash, blending distilled liquor with the fermented mash and performing cold-heat treatment, adding oak pieces and ageing, and performing fine filtration and aseptic canning to obtain the finish product as jackfruit white spirit. The invention uses pulp and fruit silk of the jackfruit as raw materials, and adopts fermenting method which combines open type and closed type steps, stirring and standing stepsand artificial ripening process and oak pieces ageing. Jackfruit white spirit thus obtained has a natural harmonious fragrance of jackfruit liquor and oak and a soft mouthfeel, which increases the economic added value of the jackfruit and has practical significance.

Owner:海南省农垦科学院

Method for producing fruit wine

The invention relates to a method for producing fruit wine. The method comprises the following steps of: pulping fruit pulp, squeezing, adding potassium metabisulfite, pectinase and citric acid, performing enzymolysis, adding white granulated sugar to adjust sugar content, and adding high-activity dried yeast and diammonium hydrogen phosphate to perform primary fermentation; filtering mash obtained through primary fermentation and separating, and performing closed fermentation on filtrate; and clarifying fermentation liquor and separating, performing cold and heat treatment, filtering and mixing, adding oak chips for ageing, and performing precision filtering and high-temperature instant sterilization to obtain a fruit wine finished product. The fruit wine which is prepared from the fruit pulp by an open and closed combined and stirring and standing combined fermentation method through cold and heat treatment is clear and bright, and has mellow and fine and smooth taste, and tannin and pigment of oak are dissolved in the fruit wine, so the fruit wine has elegant and harmonious tropical fruit fragrance and oak fragrance, and has the characteristics of rich nutrition, high stability, no suspended matter or precipitate, long quality guarantee period and the like.

Owner:海南省农垦科学院

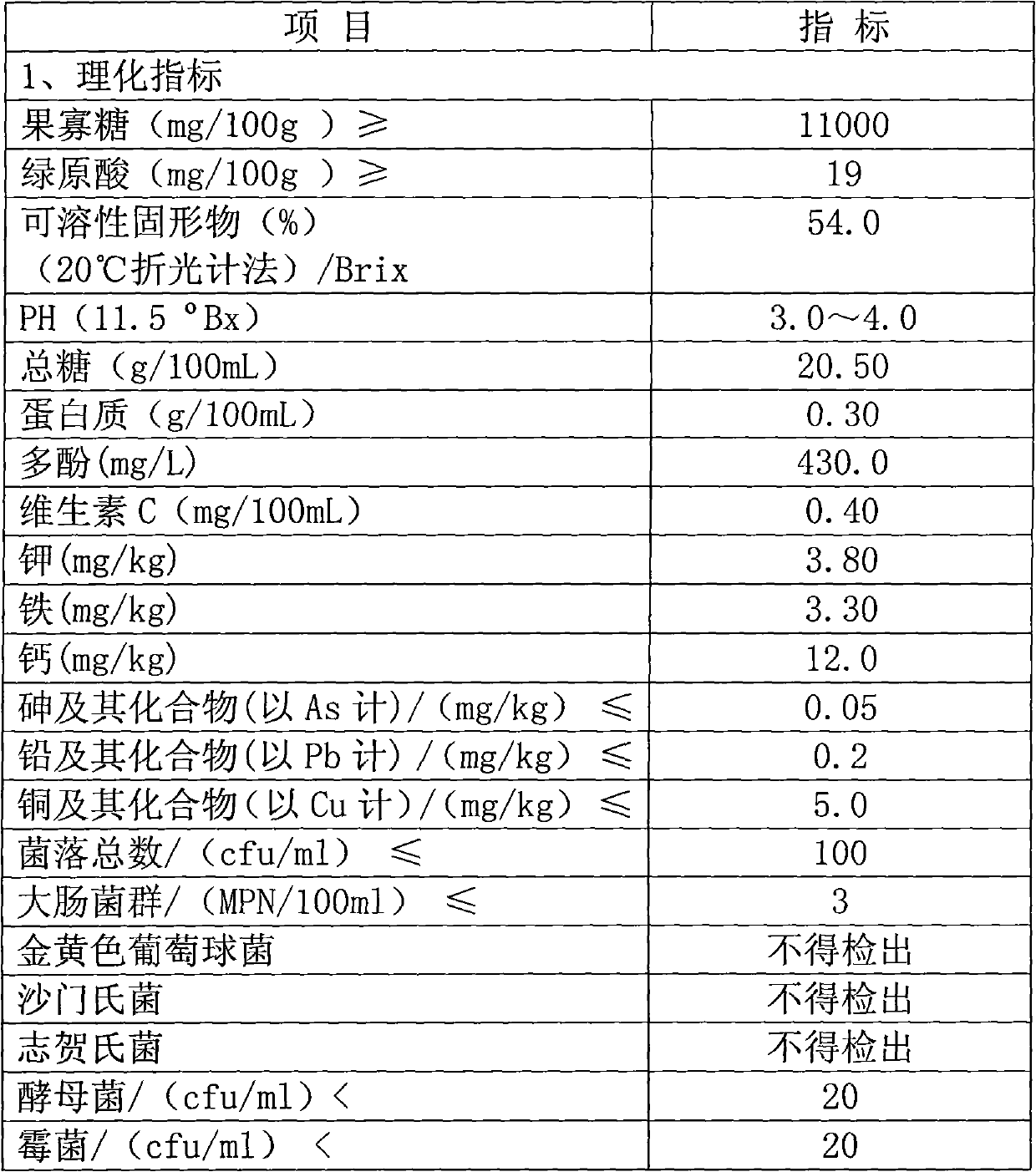

Double-component yacon fruit juice and preparation method thereof

The invention provides yacon fruit juice and a preparation method thereof. The yacon fruit juice contains fructooligosaccharide and chlorogenic acid, wherein the content of the fructooligosaccharide is not less than 11,000mg / 100g, and the content of the chlorogenic acid is not less than 19mg / 100g. The preparation method for producing the yacon fruit juice comprises that yacon tubers are prepared into a yacon fruit juice product by cleaning, peeling, crushing, color protection, juicing, enzyme treatment, adsorption, filtration, centrifugation, blending, high-temperature sterilization and filling. The yacon fruit juice keeps the nutrient components of the fructooligosaccharide and the chlorogenic acid, ensures that the contents of the fructooligosaccharide and the chlorogenic acid do not decline along with prolonging of storage time, and also keeps the unique flavor of yacon fruits. The guarantee period of the product is 1 year, and the yacon fruit juice has no sediment or suspension and does not change color in the guarantee period.

Owner:贵阳高新创嘉创业服务有限公司

Method for preparing sweet potato yellow wine containing anthocyanidin

ActiveCN102344872ARetain nutritionReserved functionAlcoholic beverage preparationAdditive ingredientSweetness

The invention relates to a method for preparing sweet potato yellow wine containing anthocyanidin, which comprises the following steps of: crushing purple sweet potatoes into particles, adding water, adjusting the acidity by using citric acid, digesting the purple sweet potatoes at high temperature, and adding a saccharifying and fermenting agent to saccharify and ferment the purple sweet potatoes for 45-50 h to obtain fermented purple sweet potatoes, adding water and uniformly mixing the fermented purple sweet potatoes with water; adding rice liquor to ferment the mixture in a sealed way after fermentation; and squeezing, clarifying, decocting and filling the wine mash fermented in a sealed way to obtain the sweet potato yellow wine containing anthocyanidin. The method has simple process, the purple sweet potatoes are used as a main raw material, the obtained sweet potato yellow wine effectively preserves the nutritional and functional ingredients of the purple sweet potatoes, has bright red and transparent color, elegant wine aroma, soft and smooth taste, proper sourness and sweetness and typical flavor of potato wine, does not contain suspended matter and is free from extraneous odor, and the value of agricultural and sideline products is increased.

Owner:HAINAN UNIVERSITY

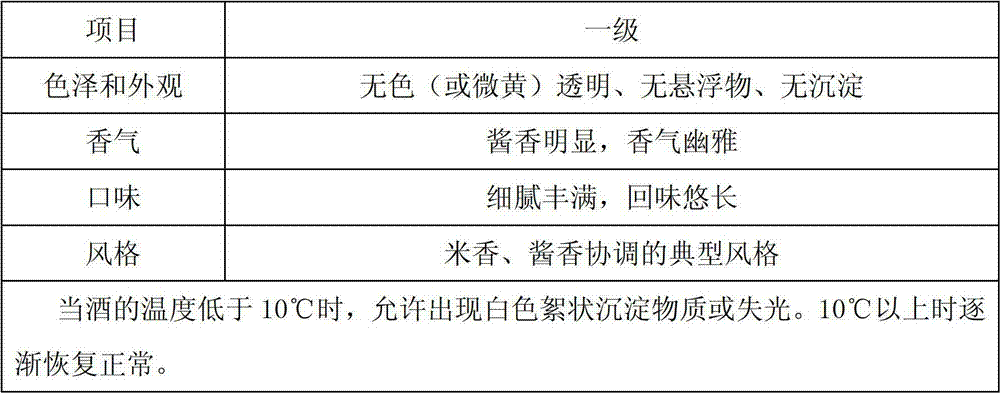

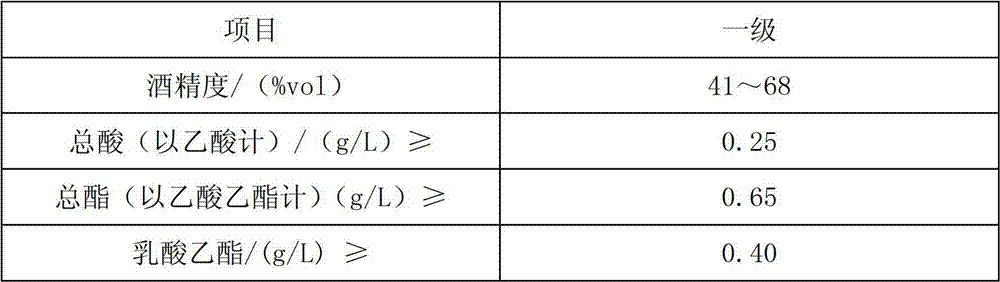

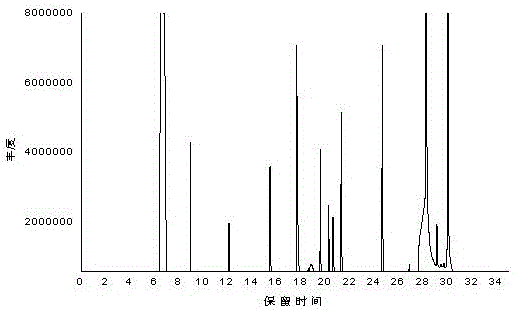

Sticky-rice-flavor-type liqueur brewing method

ActiveCN102732406AThe sauce is outstandingElegant aromaAlcoholic beverage preparationEthyl lactateEthyl hexanoate

The invention discloses a sticky-rice-flavor-type liqueur brewing method, and aims to provide a brewing method for a sticky-rice-flavor-type liqueur mainly prepared from ethyl lactate, ethyl acetate and ethyl hexanoate. The sticky-rice-flavor-type liqueur brewing method technically comprises the following steps in sequence: 1) weighing raw materials and auxiliary materials; 2) steaming sticky rice; 3) scattering yeast; 4) saccharifying the raw and auxiliary materials; 5) ageing and fermenting the saccharified raw and auxiliary materials; 6) distilling the resultant; and blending and preparingthe sticky-rice-flavor-type liqueur, wherein in the step one, raw and auxiliary materials are weighed, and the sticky rice, the bran yeast and the high temperature yeast are weighed in a weight ratioof 95:(1.8-2.2):(2.8-3.2). The sticky-rice-flavor-type liqueur brewing method disclosed by the invention belongs to the technical field of liqueur brewing.

Owner:MEIXIAN LIANQUAN LIQUOR BREWING

Method for preparing blending liquid by utilizing yellow water, and application of blending liquid

ActiveCN105087339ARealize solid-liquid separationHigh mechanical strengthAlcoholic beverage preparationFlavorNanofiltration

The invention belongs to the field of preparation of daqu liquor, and in particular relates to a method for preparing blending liquid by utilizing yellow water, and an application of the blending liquid. The method comprises the following steps: adding a suitable amount of attapulgite into fresh yellow water, stirring under room temperature for 4-8 h, standing, clarifying, centrifuging, intercepting filter residues, and taking the clear liquid, thus obtaining first-grade clear liquid; carrying out microfiltration on the first-grade clear liquid by adopting a 0.2 Mu m inorganic ceramic membrane for removing the residual attapulgite particles, intercepting filter residues, and taking the clear liquid, thus obtaining second-grade clear liquid; and carrying out nanofiltration on the second-grade clear liquid by adopting an organic membrane with the molecular cut off being 300, intercepting filter residues, and taking the clear liquid, and thus obtaining the colorless and transparent blending liquid. The method is simple, convenient and effectively; the attapulgite is mainly used for absorbing macromolecular impurities, the colloid property of yellow water is destroyed, the viscosity is reduced, the blockage for the membrane during the follow-up membrane filtration processes is alleviated, the clarified yellow water is rapidly decolored and concentrated by utilizing the microfiltration using the inorganic ceramic membrane and the nanofiltration using the organic membrane, and finally the colorless and transparent blending liquid with special flavor is obtained.

Owner:LUZHOU GUOZHIRONGYAO LIQUOR IND CO LTD

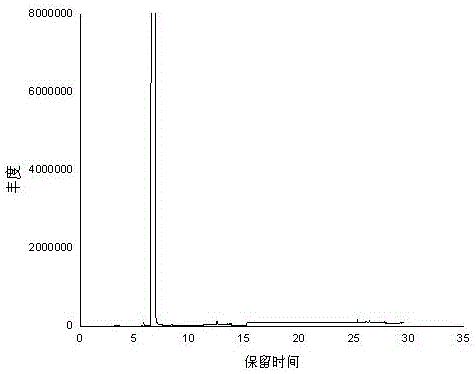

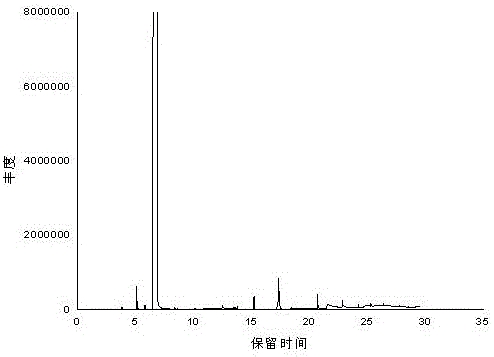

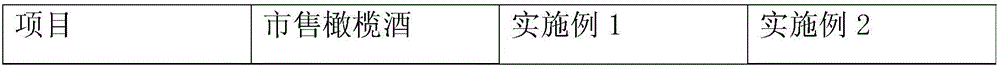

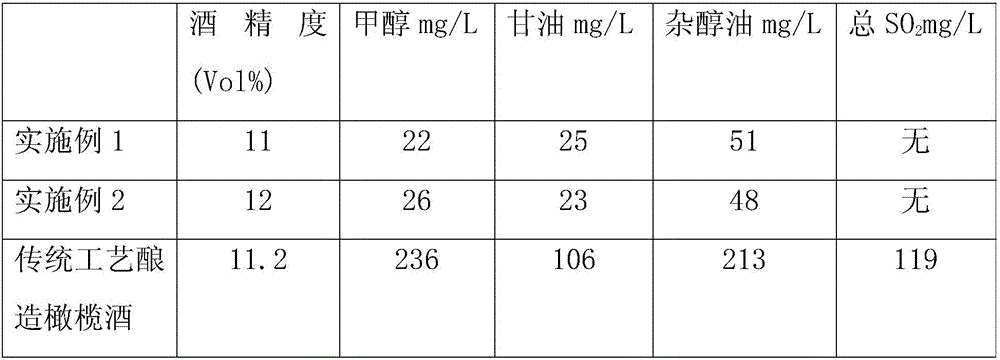

Brewing method of olive fruit fermented wine

InactiveCN106497729AInhibit coloringSweet tasteMicroorganism based processesAlcoholic beverage preparationHydroxytyrosolOrganic acid

The invention provides a brewing method of olive fruit fermented wine. The brewing method includes the steps of 1), pretreatment of olive fruit; 2), enzyme deactivation; 3), bitterless treatment; 4), primary fermentation; 5), secondary fermentation; 6), ageing; 7), canned sterilization. An existing olive wine brewing technology is substantially improved, alcoholic strength of the brewed olive wine is 10%Vol-12%Vol, total sugar content is 2-18g / L, total acid is 0.30-0.60g / L and volatile acid is 0.05-0.1g / L; the fermented wine has the advantages of low content of bacteria, good quality, natural color, lime green, clarification, coexistence of bouquet and fruity and sweet and mellow taste; in addition, the olive fruit fermented wine is rich in organic acid, amino acid, vitamins and minerals and has functions of clearing away heat and toxic materials, eliminating phlegm and regulating qi, moistening lung and nourishing yin and the like, and as is detected, the content of hydroxytyrosol in the olive fruit fermented wine can reach 380mg / mL.

Owner:德保县广鑫贸易有限公司

Tomato and apple fermented wine and brewing method thereof

InactiveCN102391929AKeep natural propertiesAvoid destructionMicroorganism based processesAlcoholic beverage preparationVitamin CLycopene

The invention discloses tomato and apple fermented wine and a brewing method thereof, and the brewing method is characterized by comprising the following steps: mixing tomato which is pressed to making juice or pulped with apple according to the weight ratio of 5-6: 1, adjusting components, and then taking high-temperature wine-brewing yeast as a strain for performing fermentation in the dark at the temperature of 25-32 DEG C till the content by weight of total sugar in wine liquid is below 0.3%; and as for the prepared tomato and apple fermented wine, the alcohol degree by volume is 10-12%, the total acid according to tartaric acid accounts for 5-7g / L, and the tomato and apple fermented wine contains 180-300mg / L of vitamin C, 3-6mg / L of lycopene, 620-650 mu mol / L of glutamic acid, 28-32 mu mol / L of aspartic acid, 40-45 mu mol / L of lactamine, 23-26 mu mol / L of glycine, 17-20 mu mol / L of valine, 13-16 mu mol / L of lysine, 1.9-2.3 mu mol / L of tyrosine, 11-15 mu mol / L of serine, 7.5-7.9 mu mol / L of leucine, 5.6-6.0 mu mol / L of phenylalanine, 12-15 mu mol / L of histidine and 11-14 mu mol / L of isoleucine; and the tomato and apple fermented wine has the peculiar fruity flavors of the tomato and the apple.

Owner:HEFEI UNIV OF TECH

Natural red date vinegar and manufacturing process thereof

Natural red date vinegar is disclosed. The natural red date vinegar comprises following raw materials by weight: 1-6 parts of red date vinegar normal juice, 3-10 parts of white granulated sugar, 3-8 parts of honey, and 0-0.15 part of a food additive. The natural red date vinegar is characterized in that: the natural red date vinegar normal juice is prepared by alcoholic fermentation and acetic fermentation, wherein SO2 is fed into red date primary pulp for pretreatment, and after enzymolysis is performed by utilization of pectinase, the alcoholic fermentation and the acetic fermentation are performed.

Owner:KAIPING OASIS FOOD

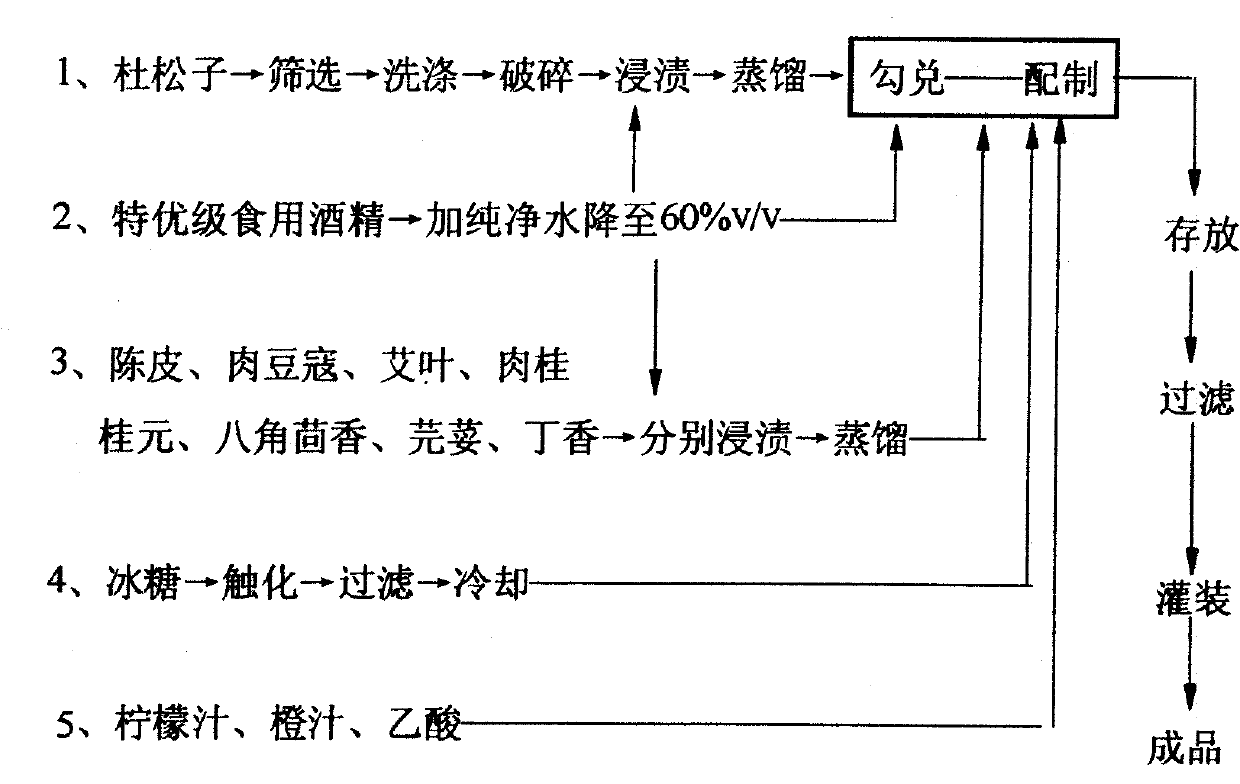

Distilled prepared wine-gin flzz with foreign wine (dry gin) flavor characteristics

InactiveCN102408971ANo precipitationNo suspended matterAlcoholic beverage preparationBiotechnologyJuniperus communis Fruit

The invention relates to distilled prepared wine-gin flzz with foreign wine DRY or GIN (dry gin) flavor characteristics, which is characterized in that juniper fruits serving as wild resources in China are used as main fragrance sources, and aroma and flavor-producing Chinese herbal medicine and the like are used as auxiliary fragrance sources. The gin flzz is prepared by using superior edible alcohol as wine bases through pretreatment, impregnation distillation, flavoring blending and storage filtering. The distilled prepared wine-gin flzz with foreign wine DRY or GIN (dry gin) flavor characteristics has the advantage of no methanol or fusel oil checking is obtained.

Owner:李良

Soda water beverage and preparation method of same

InactiveCN106360200AExtended shelf lifeImprove nutritional qualityFood ingredient as taste affecting agentNatural extract food ingredientsNutrientSodium bicarbonate

The invention discloses a soda water beverage. Each 1000 L of the soda water beverage comprises, by weight, 0.10-0.20 kg of sodium bicarbonate, 0.2-0.4 kg of citric acid, 0.10-0.20 kg of vitamin C, 0.01-0.02 kg of sucralose and 8-20 kg of calamansi juice. The soda water has long shelf life and abundant nutrients, and satisfies demands of common people, and has great advantages on improving body immunity and enhancing body physique.

Owner:贵州北极熊实业有限公司

Blueberries wine

InactiveCN101003773AStrong nutritional and health effectsEnhance polysaccharide nutritionWine preparationBiologyRenal Failures

This invention discloses a blueberry grape wine, which is produced from natural blueberry. The wine has fruit and wine fragrance, and good taste. The wibe cab supplement multiple vitamins and trace elements for human bodies, thus can improve immunity and fitness. The wine has obvious preventative and healthcare functions on neurasthenia, cardiovascular diseases, and renal failure.

Owner:薛晓波

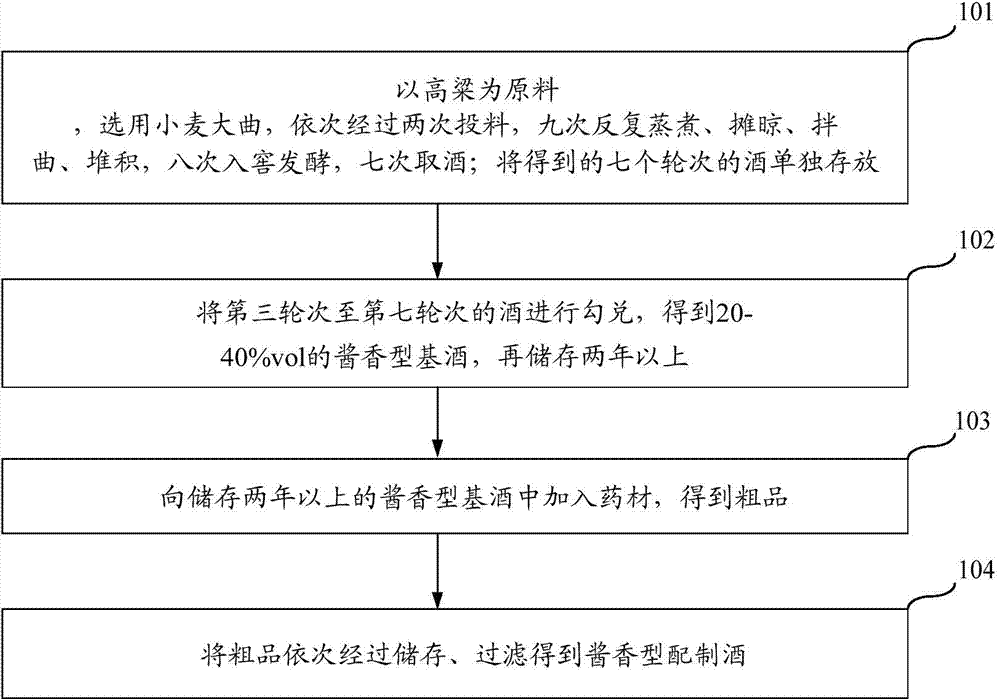

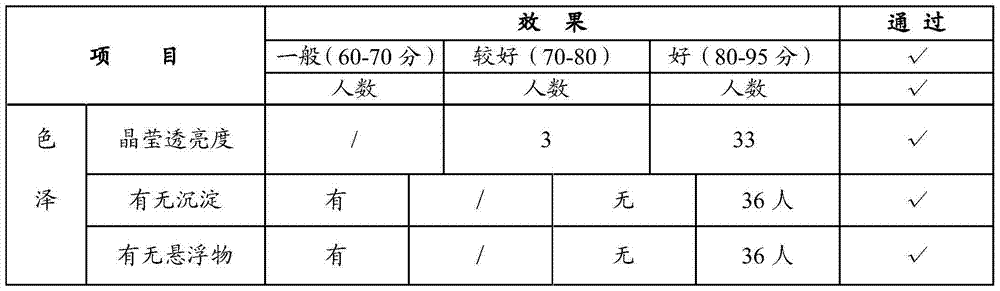

Maotai flavor type mixed liquor and preparation method thereof

ActiveCN103881883ASolve the single tasteElegant and rich aromaAlcoholic beverage preparationFlavorSorghum

The invention discloses Maotai flavor type mixed liquor and a preparation method thereof. The preparation method comprises the following steps: by taking sorghum as a liquor-making raw material and selecting wheat koji, sequentially feeding twice, performing repeated digestion, airing, koji mixing and accumulation for nine times, putting into a cellar for fermentation for eight times, taking the liquor for seven times, and independently depositing the obtained seven rounds of the liquor; further blending the liquor from the third round to the seventh round to obtain 20-40vol% Maotai flavor type base liquor, and further storing for above two years; adding medicinal materials into the Maotai flavor type base liquor which is stored for above two years to obtain a crude product; sequentially storing and filtering the crude product to obtain the Maotai flavor type mixed liquor. The Maotai flavor type mixed liquor disclosed by the invention provides a new flavor choice for consumers, solves the problem of single flavor of the existing mixed liquor and is considered to have the characteristics of elegant and strong fragrance, slight Maotai flavor, strong taste, small irritation, good palatability, shinning and bright color, no precipitate and no suspended matters by strict tasting tests of national and provincial tasting committees.

Owner:四川郎酒股份有限公司

Processing method of banana wine and product

The invention discloses a processing method of a banana wine. The method includes the following steps: cleaning banana, peeling, slicing, protecting color, juicing, treating with pectinase, centrifuging and separating, adjusting the components, inoculating yeast, conducting primary fermentation, primary fermentation after fermentation, ageing, filtering, bottling, sterilizing and obtaining a finished product. The method uses bananas as raw materials for brewing banana wine, which has pale yellow, clear and transparent color, luster, and no suspended solids or sediment; the banana wine has evident banana aroma and bouquet, rich mellow, harmonious aroma, pure taste, full and mellow body, sour-sweet taste and unique style. The wine with unique style is rich in nutrients, protein and a variety of amino acids and minerals, and is in line with the development direction of domestic and international low alcohol fruit juice wine. At the same time, the development of banana wine opens a new way for deep processing of local agricultural and sideline products, not only solves the issue of sales of banana, but also can increase the added values, and promote economic and social development.

Owner:GUANGXI UNIV

Pearl rice wine and preparation method thereof

InactiveCN103045439ANo suspended matterNo precipitationAlcoholic beverage preparationMicroorganism based processesYeastSuspended matter

The invention discloses pearl rice wine and a preparation method thereof, belonging to the technical field of wine making, and aiming at solving the problems of being complex in brewing technology, poor in mouth feel, insufficient in mellowest taste and yellowish in colour in the prior art. The pearl rice wine disclosed by the invention is composed of the following raw materials in part by weight: 84-113 parts of rice, 85-116 parts of water, 0.67-0.94 part of raw distiller yeast, 0.63-0.97 part of dried yeast, 0.52-0.89 part of white sugar, and 0.45-0.78 part of raw yeast. The invention further provides the preparation method of the pearl rice wine. The pearl rice wine prepared by the invention has the characteristics of being clear, transparent, free from suspended matters and precipitation, fragrant, pure, slightly sweet, long in smell, dry and comfortable in mouth feel and the like.

Owner:廖尔秀

Populus diversifoli schrenk alkaline soda water

InactiveCN107744081AImprove nutritional qualityImprove nutrientsNatural extract food ingredientsFood ingredient functionsNutrientPeppermints

The invention relates to populus diversifoli schrenk alkaline soda water. The populus diversifoli schrenk alkaline soda water has the advantages that after a populus diversifoli schrenk alkaline extracting solution is added into pure water, two or three of citric acid, honey and peppermint essence are added, so as to prepare the populus diversifoli schrenk alkaline soda water with various tastes;the natural populus diversifoli schrenk alkaline extracting solution is used for replacing the added sodium bicarbonate, trace elements, vitamins and the like in the traditional soda water, so that the nutrient quality of the soda water is improved; the thirst is relieved, the acid and alkaline degree in the human body is balanced, the poor digestion and constipation are relieved, the effects of beautifying and nourishing face are realized, the uric acid is favorably excreted, and then the function of preventing and controlling hyperuricemia or gout is realized; the problems of single mouth feel and lack of nutrients in the soda water are effectively relieved, the consumption tendency of people is met, and the nutritional matters required by the human body are supplemented; the technologyis simple, and the nutritional matters are further remained.

Owner:吐尔逊托乎提

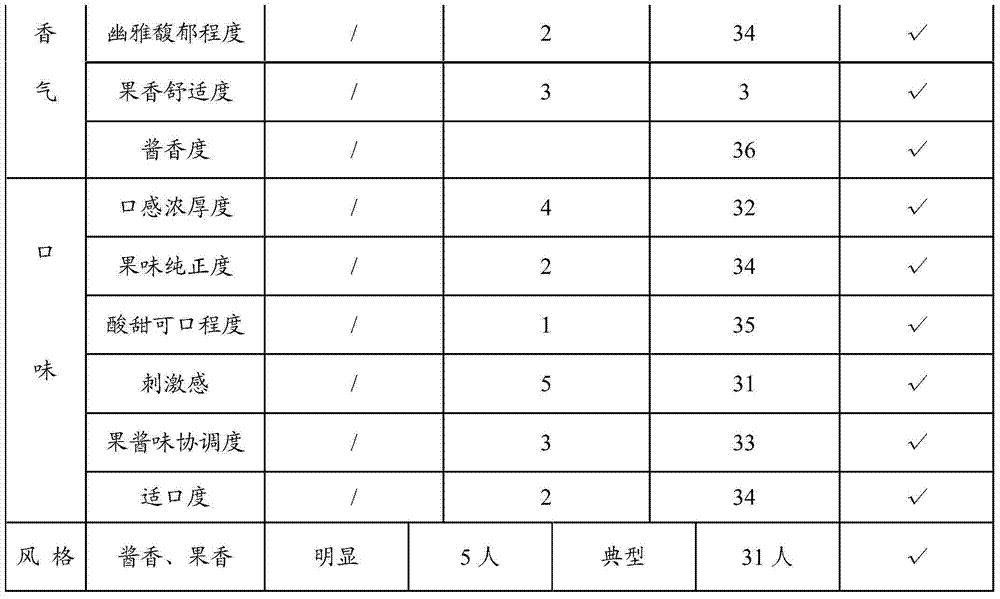

Preparation method of kiwifruit wine

The invention relates to a preparation method of kiwifruit wine. The kiwifruit wine prepared by the method disclosed by the invention is clear and transparent, free from suspension, free from precipitate, intense in fruit fragrance, pure and sweet, and is lingering in aftertaste. Physical and chemical indicators of the kiwifruit wine prepared by the method are consistent with related industry standards. Compared with the prior art, in the kiwifruit wine prepared by the method, the content of total acid is improved by 19.8%, the content of volatile acid drops by 33.3%, the content of total sugar is improved by 35.7%, the content of total sulfur dioxide drops by 18.4%, the content of dry extract is improved by 26.5% and the content of vitamin C is improved by 23.3%.

Owner:巫溪县灯霸宾馆

Preparation method of bamboo shoot wine

InactiveCN107557229ASimple processImprove processing efficiencyMicroorganism based processesAlcoholic beverage preparationYeastDistillation

The invention relates to a preparation method of bamboo shoot wine, and belongs to the technical field of food processing. The preparation method comprises following steps: A, newly harvested bamboo shoot is delivered into a pulverizer for crushing; B, crushed bamboo shoot is subjected to treatment for 60 to 120min at 121 to 135 DEG C so as to obtain bamboo shoot pulp; C, sorghum, glutinous rice,Chinese wolfberry, and the bamboo shoot pulp are mixed, and an obtained mixture is subjected to treatment for 30 to 60min at 105 to 125 DEG C so as to obtain a mixed slurry; D, cellulase and sweet osmanthus flower are added into the mixed slurry, an obtained mixed material is subjected to treatment for 20 to 30min at 45 to 55 DEG C; E, the mixed material is cooled to 25 to 35 DEG C, saccharomycescerevisiae is added, an obtained product is sealed in a jar, the temperature is maintained to be 28 to 35 DEG C, and natural fermentation is carried out for 8 to 12 days, wherein the adding amount ofsaccharomyces cerevisiae accounts for 0.4 to 1wt% of the total weight amount of the mixed slurry; and F, wine obtained via fermentation is subjected to distillation so as to obtain the bamboo shoot wine. According to the preparation method, husking and peeling of bamboo shoot are not necessary, the preparation method is simple, bamboo shoot processing efficiency is increased, and bamboo shoot freshness is ensured.

Owner:彭洪建

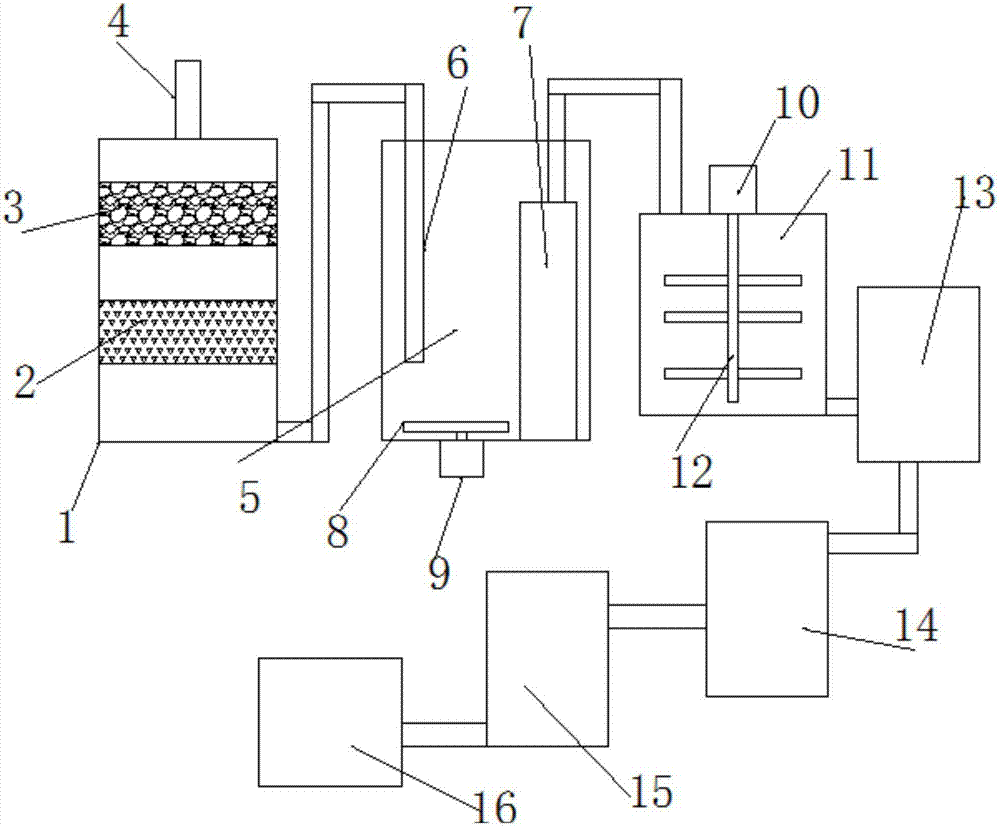

Coal chemical industry high-concentration wastewater treatment device

InactiveCN107244786AImprove biodegradabilityReduce pollutionTreatment involving filtrationMultistage water/sewage treatmentHigh concentrationActivated carbon filtration

The invention discloses a treatment device for high-concentration wastewater in the coal chemical industry, which comprises a purification box. A feed pipe is arranged in the middle of the upper end of the purification box. A stone filter layer and an activated carbon filter screen are arranged in the feed pipe sequentially from top to bottom. The purification box at the bottom of the filter layer is provided with a net pocket, and the water outlet on the lower right side of the purification box is connected to the liquid inlet pipe of the flocculation reaction device through a conduit, and a water pump is worn on the liquid inlet pipe. The invention has a simple and reasonable structure, guarantees the biochemical treatment effect, thereby reducing membrane fouling, low membrane cleaning frequency and long service life, and the MBR effluent is stable without suspended matter, which can ensure the deep treatment effect, and is also suitable for hydrolytic acidification. At the same time, the mixing of materials can be accelerated through the stirring frame, which greatly improves the hydrolysis efficiency and has strong practicability.

Owner:ZHENGZHOU JIACHEN CHEM TECH CO LTD

Preparation method of gelidium amansii and strawberry health-care vinegar

PendingCN111040923AGreat tasteReduce turbidityAlgae medical ingredientsVinegar preparationFragariaAlcohol content

The invention discloses a preparation method of gelidium amansii and strawberry health-care vinegar. The preparation method comprises the following ten steps: 1, pre-treatment of gelidium amansii; 2,treatment of strawberries; 3, adjustment of sugar degree; 4, adjustment of acidity; 5, sterilizing; 6, alcoholic fermentation; 7, adjustment of alcohol content; 8, acetic fermentation; 9, clarification treatment; and 10, filtering and bottling of clarified strawberry vinegar. The preparation method is used for preparing gelidium amansii and strawberry health-care vinegar.

Owner:YANTAI ENG & TECH COLLEGE YANTAI TECHNICIAN INST

Making method of fruit-flavored Baijiu

InactiveCN106635690AIncrease the fragranceThe wine is clear and transparentAlcoholic beverage preparationVacuum pumpingCapric triglycerides

The invention relates to the technical field of Baijiu production, in particular to a making method of fruit-flavored Baijiu. The making method comprises the following specific sptes: cleaning a fruit peel, spraying the fruit peel with a layer of caprylic capric triglyceride for water-curing treatment, completely impregnating a fruit in Baijiu, radiating the fruit by adopting infrared rays, separating the fruit from raw wine, repeatedly vacuum-pumping, filling nitrogen and oxygen and finally canning for sealing and storage. The fruit-flavored Baijiu obtained by the making method provided by the invention can effectively improve the mouth feeling and the fragrance of the Baijiu on the premise of ensuring that the alcohol content of original Baijiu is not reduced; the obtained fruit-flavored Baijiu is slightly spicy firstly and sweet later after entering a mouth, rich and prominent in fruit fragrance, durable in fragrance, clear and transparent and free from suspended matter and precipitation, and can generate a better pleasant feeling after people drink.

Owner:安徽缘酒酿造有限公司

Brewing technology for compound brandy

InactiveCN107557222AAppearance is clear and transparentBright appearanceDigestive systemAlcoholic beverage preparationTanninPassion fruit

The invention relates to the technical field of wine brewing and especially relates to a brewing technology for compound brandy. The brewing technology comprises the following steps: treating tartarybuckwheat, treating passion fruits, treating black brin, fermenting, distilling for the first time, standing, distilling for the second time, ageing, blending and filling. Through the special treatment for the raw materials and the suitable raw material ratio and brewing technology, the compound brandy brewed according to the technology looks clear, bright and transparent, is free from suspensionand sediment, is strong in fragrance and is proper in mixed fruit fragrance and wine fragrance; the content of total acids is as high as 0.233g / L; the total ester is as high as 0.258g / L; the maximal tannin content is as high as 621mg / L; and the total phenol is as high as 578mg / L.

Owner:贵州文松酒业有限公司

Tartary buckwheat health-care tea and its preparation method

InactiveCN101305759BIncrease contact areaFast absorptionTea substituesFood preparationPolygonum fagopyrumDisease

The invention discloses a tartarian buckwheat seed with high bioflavone content and a tartarian buckwheat health tea which has the same value as that of the tartarian buckwheat seed and is prepared from waste tartarian buckwheat leaves. The health tea is prepared by the steps as follows: preparing into a paste, shaping, drying, cutting, baking, parching and forming. The tartarian buckwheat healthtea has high flavone content, infusion resistance, and has verdant color, fresh fragrance, good clarity, and good taste after being infused; and it is a dietetic therapy health beverage suitable for preventing and treating diseases such as hyperglycemia, hypertension, hyperlipoidemia, etc. During processing, the tartarian buckwheat husk with an effect on the taste is removed, so the pure natural quality of the tartarian buckwheat is ensured, and the economic value of the tartarian buckwheat is improved.

Owner:CHENGDU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com