Method for preparing blending liquid by utilizing yellow water, and application of blending liquid

A technology for mixing liquor and edible alcohol, which is applied in the preparation of alcoholic beverages, etc. It can solve the problems that are not conducive to the large-scale treatment of yellow water by enterprises, the poor decolorization effect of activated carbon, and the loss of flavor components, so as to achieve the retention of flavor components, short cycle time, and energy saving. The effect of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

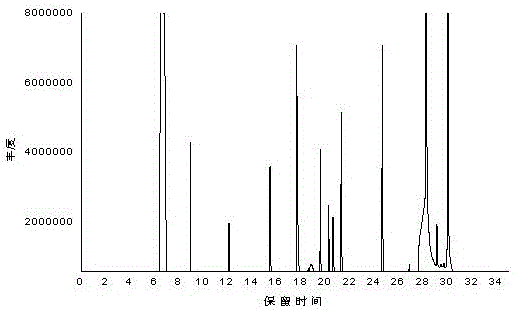

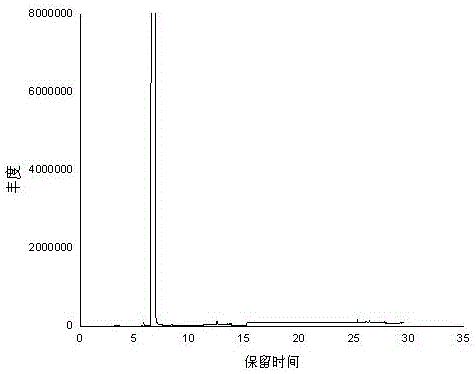

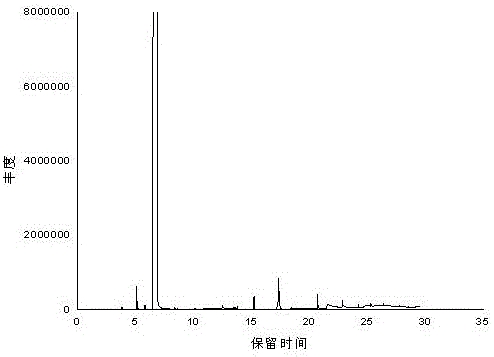

Image

Examples

Embodiment 1

[0026] A kind of method utilizing yellow water to make bartender liquid, comprises the following steps:

[0027] (1) Add attapulgite to 3L of fresh yellow water, the addition of attapulgite is 0.5% of the quality of fresh yellow water, then stir at room temperature for 6h, let stand to clarify and get the clear liquid, and obtain the first-level clear liquid 2.9 L;

[0028] (2) Microfilter the first-stage clear liquid with a 0.2 μm inorganic ceramic membrane to remove residual attapulgite particles, and the operating pressure is 0.3 MPa to obtain 2.88 L of the second-stage clear liquid;

[0029] (3) The second-stage supernatant was nanofiltered with an organic membrane with a molecular weight cut-off of 300, and the membrane pressure was controlled to be 1.5 MPa to finally obtain 2.6 L of colorless and transparent liquor.

Embodiment 2

[0031] (1) Add attapulgite to 6L of fresh yellow water, the addition of attapulgite is 0.6% of the fresh yellow water quality, then stir at room temperature for 6.5h, let stand to clarify and take the clear liquid, and obtain the first-level clear liquid 5.8L;

[0032] (2) Microfilter the first-stage clear liquid with a 0.2 μm inorganic ceramic membrane to remove residual attapulgite particles, and the operating pressure is 0.2 MPa to obtain 5.73 L of the second-stage clear liquid;

[0033] (3) The second-stage clear liquid is nanofiltered with an organic membrane with a molecular weight cut-off of 300, and the membrane pressure is controlled at 1.0 MPa to obtain 5.3 L of colorless and transparent liquor.

Embodiment 3

[0035] A kind of method utilizing yellow water to make bartender liquid, comprises the following steps:

[0036] (1) Add attapulgite to 9L of fresh yellow water, the addition of attapulgite is 0.8% of the fresh yellow water quality, then stir at normal temperature for 8h, let stand to clarify and get the clear liquid, obtain the first-level clear liquid 8.5 L;

[0037] (2) Microfilter the first-stage clear liquid with a 0.2 μm inorganic ceramic membrane to remove residual attapulgite particles, and the operating pressure is 0.5 MPa to obtain 8.32 L of the second-stage clear liquid;

[0038] (3) The second-stage supernatant was nanofiltered with an organic membrane with a molecular weight cut-off of 300, and the membrane pressure was controlled to be 2.0 MPa, and finally 7.6 L of colorless and transparent liquor was obtained.

[0039] The fresh yellow water in Embodiment 1 to Embodiment 3 is taken from the production workshop of Luzhou Laojiao Co., Ltd. Compared with the yell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com