Patents

Literature

209results about How to "Mild sour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technological process for preparing fermentation dehydrated beef using composite leaven

InactiveCN101248884AImprove organizational structureEnhance sensory effectFood preparationLactobacillusOrganoleptic

The invention provides a method for producing fermented beef jerky with compound leaven. The bacteria strain used in fermentation is lactobacillus casei and staphylococcus xylosus with volume ratio of 1:3 and volume of addition of 1-1.5%, the fermentation temperature is 20 DEG C, and the fermentation time is 5 days. The addition of lactobacillus casei reduces pH value of the product, improves safety, improves the texture of the product, and shortens fermentation period. At the same time, the addition of staphylococcus xylosus generates a large amount of flavoring substances during fermentation process, improves sensing effect of the product, and the final product has thick fragrance, good taste, and infinitive aftertaste. The inventive method is especially suitable for producing fermented beef jerky, as well as air dried sausage and sausage.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

Technology for preparing Suanjiang tofu from LAB (lactic acid bacteria) fermented yellow serofluid

ActiveCN105794995AReduce water useReduce manufacturing costCheese manufactureFood scienceLactobacillus plantarumContinuous production

The invention discloses a technology for preparing Suanjiang tofu from LAB (lactic acid bacteria) fermented yellow serofluid. The technology comprises the following steps: (1) a seed liquid is prepared from lactobacillus plantarum and inoculated to the yellow serofluid for fermentation, and Suanjiang is obtained; (2) the final pH value of the Suanjiang obtained in the step (1) is regulated to 3.8-4.0 with food-grade glacial acetic acid, and a tofu coagulant is obtained; (3) cooked soybean milk is prepared from soybeans through impurity removal, cleaning, soaking, mashing, residue removal and boiling; (4) the tofu coagulant obtained in the step (2) is added to the cooked soybean milk obtained in the step (3) in a segmented manner for curdling until a precipitation phenomenon is observed, a product is poured into a frame where tofu cloth is laid, and subjected to tight packaging with a mesh, flat covering, self-draining and pressurizing, pressure is kept, pressing is performed for a fixed period, and the Suanjiang tofu is obtained through forming. The technology has the advantages that the technology is simple, the operation is convenient, the stability is good, continuous production can be realized and the like, and technical support is provided for industrial mass production.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

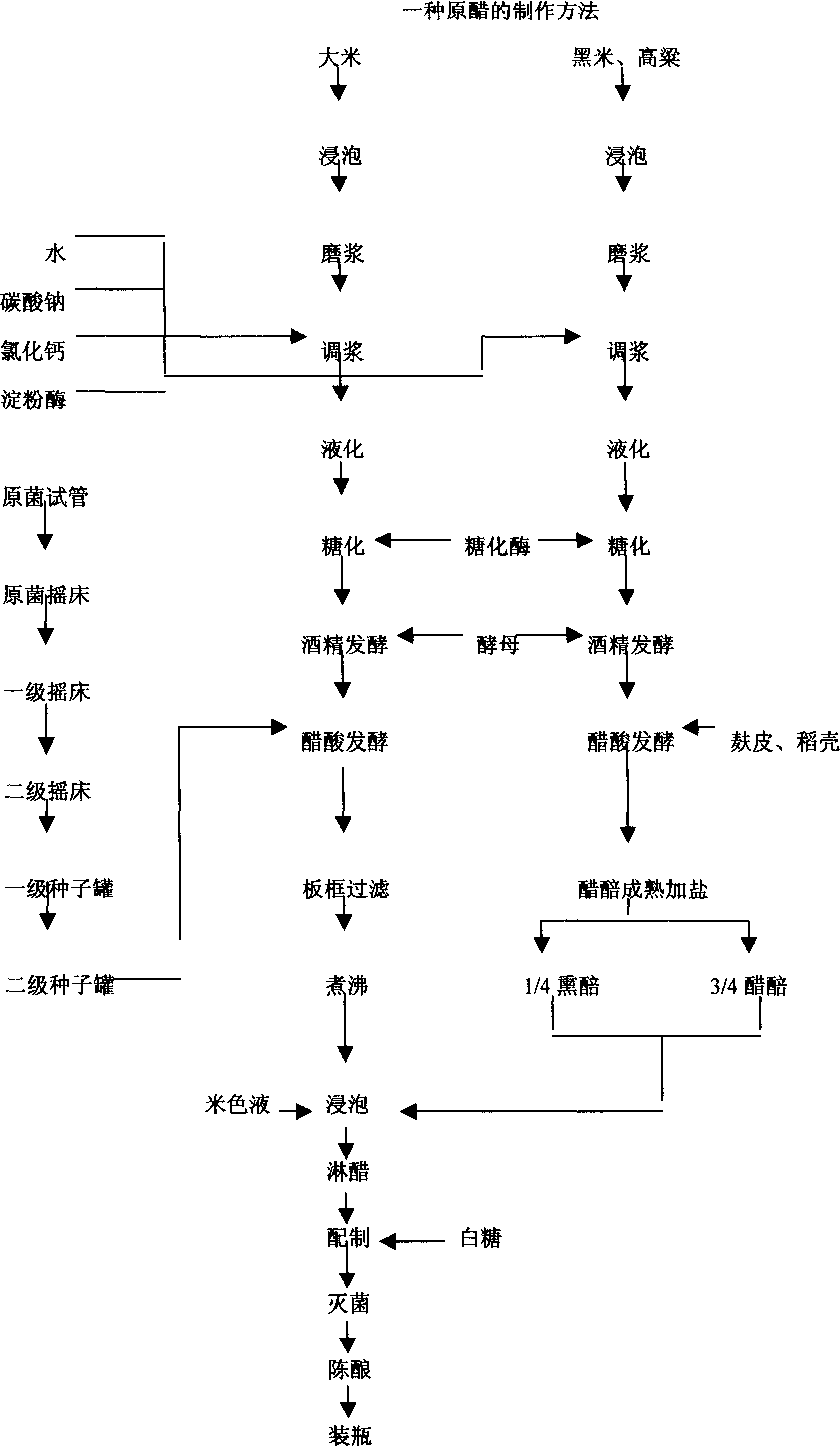

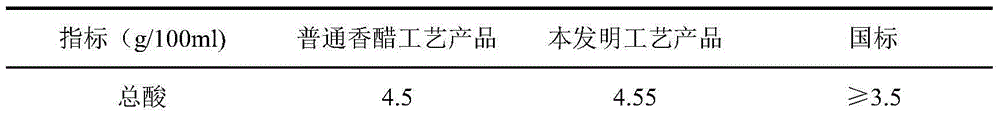

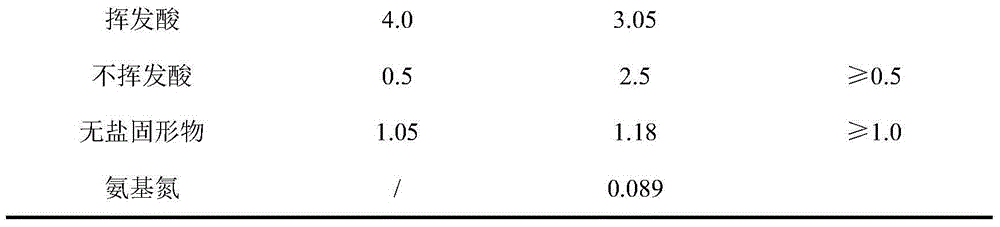

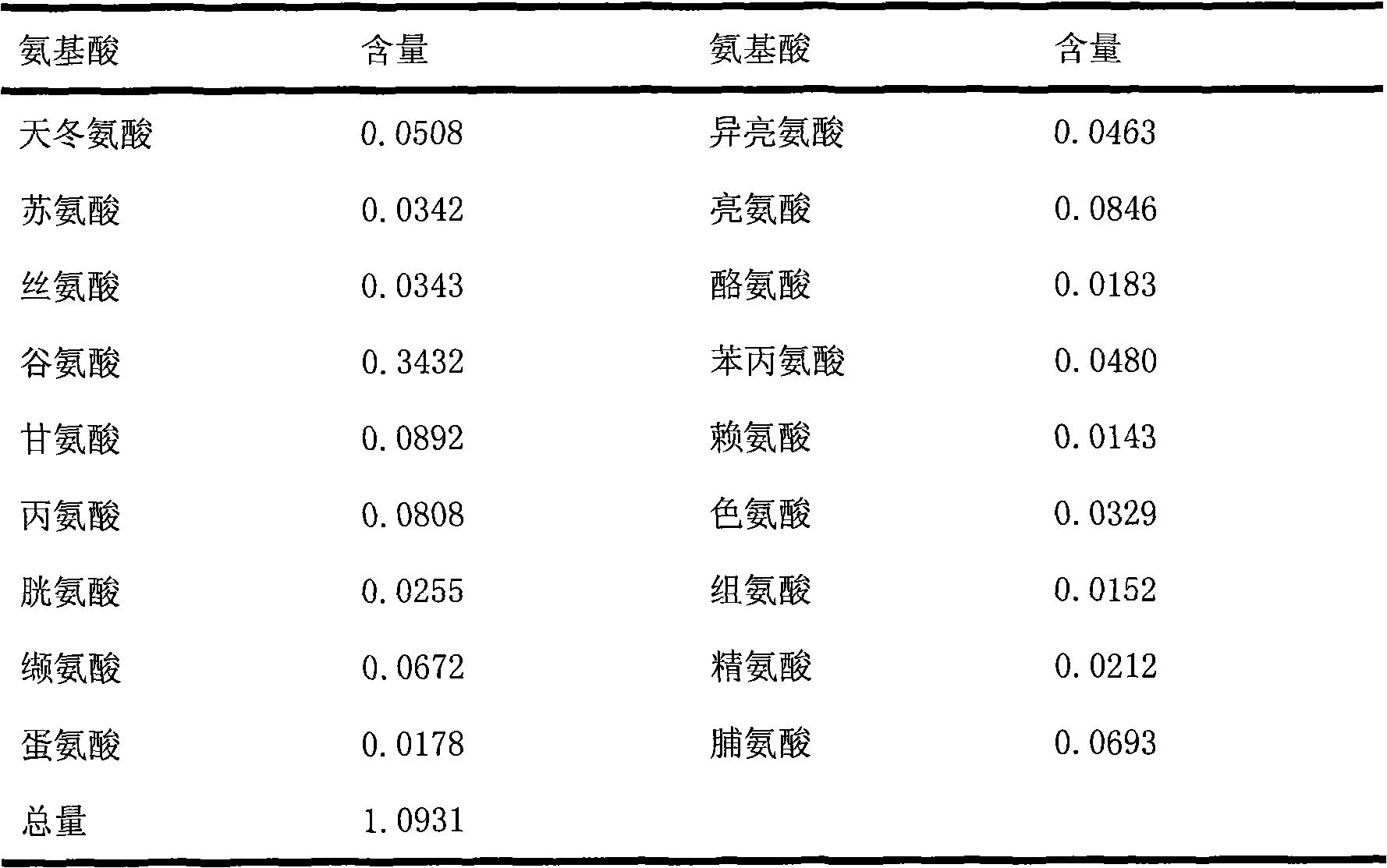

Vinegar making process

The present invention discloses vinegar making process, in which rice, sodium carbonate, salt, calcium chloride, alpha-amylase, sugar, saccharifying enzyme, yeast, water and rice hull or wheat bran in certain weight proportion are used as material. The made vinegar is brown, bight, fragrant, mildly sour and slightly sweet, and has total acid amount account with acetic acid not less than 4.0 g each 100 ml.

Owner:陈松

Method for making passion fruit vinegar

The invention relates to the technical field of food brewing, in particular to a method for making passion fruit vinegar by using passion fruit as a main raw material. The method specifically comprises following three steps: (1) the passion fruit is juiced to obtain passion fruit juice, then pectinase is added to the passion fruit juice, the sugar degree of the passion fruit juice is regulated, and the passion fruit juice is sterilized; (2) the passion fruit juice is subject to alcohol fermentation and acetic acid fermentation to obtain an initial product of the passion fruit vinegar; (3) the initial product of the passion fruit vinegar is aged, and then a finished product of the passion fruit vinegar can be obtained. The finished product of the passion fruit vinegar, which is made through adopting the method, has the advantages of well retention of nutritional components, greasing and natural taste, no bitter taste, steady quality and bright color; and meanwhile, as no artificial preparation is added to the passion fruit vinegar, the natural flavor of the passion fruit can be better retained.

Owner:CHONGQING UNIV

Process for producing orange fruit vinegar

InactiveCN1392240AKeep the flavorMaintains flavor with natural citrus fruit colorVinegar preparationNutritive valuesAcetic acid

The fruity organe vinegar is produced with fresh and ripe orange as main material and through peeling, squeezing to obtain juice, centrifugal separation, eliminating bitter, low temperature alcohol fermentation, acetic acid fermentation, aging, fitlering and sterilizing. It is superior to grain vinegar in components and nutritive value, has the special flavor and color of orange maintained.

Owner:湖南省农业科学院农产品加工研究所

Apple vinegar liquid fermentation process

ActiveCN102311908AReduce the likelihood of variationShorten the production cycleVinegar preparationBiotechnologyAcetic acid

The invention relates to a process for liquid submerged fermenting fruit vinegar. The invention is characterized in that apple concentrated juice is taken as a raw material, wine active dry yeast is added for alcoholic fermentation, acetic bacteria is inoculated for fermenting acetic acid, a segmentation technique is used during the process of acetic acid fermentation to segment strain liquid which accounts for 8%-15% of volume of a seeding tank for first-grade expansion culture and second-grade expansion culture, then the strain liquid enters into a fermentation cylinder for acetic acid fermentation which enables a continuous and cyclic usage of strains. The apple vinegar liquid fermentation process is capable of saving the process of culturing stains by a triangular flask in an early stage, shortening the fermentation period, saving the energy, raising the production efficiency and minimizing the possibility of strains variation. The process of the invention can be used for other fruit vinegar production.

Owner:广东天地壹号食品研究院有限公司

Method for making fermented crystal crisp sweet bamboo shoot

InactiveCN104431909AGreat tastePromote fermentationFood preparationBiotechnologyLactic acid bacterium

The invention discloses a method for making a fermented crystal crisp sweet bamboo shoot. According to the prepared bamboo shoot, low-salt curing and low-temperature slow freezing are conducted, two kinds of lactic acid bacteria are added for fermentation, seasoning, packaging and sterilization are conducted on the fermented bamboo shoot, and then the fermented crystal crisp sweet bamboo shoot which is crisp, refreshing, bright in color and lustre, rich in nutrient, unique in flavor, convenient to carry and capable of being eaten instantly is obtained. Due to the fact that low-salt curing, low-temperature slow freezing and fermentation are conducted, the original bright green color, the nutritive value and the crisp and refreshing taste of the bamboo shoot are reserved, the bamboo shoot and other auxiliary materials are fermented fully, and thus the quality and the flavor of the bamboo shoot are improved.

Owner:HUBEI UNIV OF TECH

The production process of papaya vinegar

InactiveCN102260625AFully fermentedObvious papaya fruity aromaMicroorganism based processesVinegar preparationAcetic acidFruit wine

The invention provides a papaya vinegar production process method, which comprises the following steps: (1) sorting, cleaning and removing nucleuses; (2) crushing and squeezing; (3) adding sugar, wherein the added amount of sugar is worked out according to a principle that 1 volume of alcohol is generated by 1.7 grams of white granulated sugar and 100 milliliters of fruit pulp; (4) fermenting, namely, adding fruit wine yeasts, keeping the water content in fermented grain between 60 to 66 percent, keeping room temperature between 25 and 28 DEG C, ending alcohol fermentation after the fermentedgrains is filled in a tank for 5 to 7 days, adding rice husk in an amount which is 18 to 22 percent based on the weight of the fermented grains and acetic acid bacterium seed fermented grains in an amount which is which is 18 to 22 percent based on the weight of the fermented grains in each tank, keeping the temperature in the tank between 37 to 39 DEG C, adding salt in an amount which is 5 to 10percent based on the weight of fermented grains in each tank, preventing the over oxidization of vinegar fermented grain, and continuing fermenting for 2 to 3 days; (5) spraying vinegar, namely transferring wine fermented grains into a wine spraying tank, spraying vinegar for three times to obtain primary vinegar, secondary vinegar and tertiary vinegar; and (6) aging, namely, filling the sprayed vinegar into ceramic jars, aging under closed and room temperature conditions for 3 to 6 months, and thus, obtaining the papaya vinegar. In the invention, full fermentation of acetic acid is ensured, and the effective health-care ingredients of the papaya are fully utilized.

Owner:HUBEI LIHUACUN WINE IND CO LTD

Apple vinegar fermentation production method

The invention discloses an apple vinegar fermentation production method. The apple vinegar fermentation production method comprises the steps that apple pulp is crushed and pulped into pulp with the granularity of 0.5-3 mm, then the pulp is subjected to alcohol fermentation, and yeast is kept after completion of alcohol fermentation to perform direct liquid acetic fermentation so as to obtain apple vinegar. The production efficiency and the raw material utilization ratio are high, the product flavor substance loss is reduced, and the obtained apple vinegar is strong in fruity flavor and rich in nutrition.

Owner:TIANDI YIHAO BEVERAGE JIANGMEN CITY

Production method of apple vinegar

ActiveCN102311910APromote conversionIncrease profitMicroorganism based processesVinegar preparationBiotechnologyAlcohol content

The invention provides a production method of apple vinegar. The method aims to treat semi-finished wine vinegar with acetic acid content of 2.0%-4.0% and alcohol content of 1%-3.9% during apple vinegar acetic acid fermentation, and due to influences of power failure, water failure, etc. on factors of temperature, air quantity, strains and the like, the semi-finished wine vinegar has incompletelyconverted alcohol and no longer increased acetic acid content. According to the method of the invention, 5%-35% of semi-finished wine vinegar is added into normal fermentation broth, and after fermentation under normal conditions, qualified apple vinegar can be obtained. The method provided in the invention promotes semi-finished product conversion, changes waste material into things of value andreduces production cost, and also shortens the fermentation period by 5-15h, thus improving production efficiency.

Owner:广东天地壹号食品研究院有限公司

Normal juice fruit vinegar immobilization preparation method

The invention provides a fossilization production method for natural-juice fruit vinegar. The invention determines through a variety of experiments that the fruits suitable for the fossilization production of the natural-juice fruit vinegar are pear, apple and grape, alcohol and acetic acid zymogen are active dry yeast and active acetic acid bacteria especially for fruit wine, and carriers for fossilizing the acetic acid bacteria are carbonized corncob and carbonized round wood chips. At the same time, the manufacturing technique and technical parameter of natural-juice fruit vinegar fossilization are determined through reaserch. The fossilization production method for the natural-juice fruit vinegar has the advantages of fast fermentation reaction speed, high equipment utilization rate and convenience for mechanized production. The products produced by the invention are natural and pure with good color and lustre, faint scent of table vinegar, full-bodied fragrance of fruits, gentle sour taste, clearness and transparency, and achieve the export quality requirement.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Method for producing sour bamboo shoots by virtue of multi-strain mixed fermentation

InactiveCN103445124AFast fermentationMild sourClimate change adaptationFood preparationSaline solutionsFermentation

The invention discloses a method for producing sour bamboo shoots by virtue of multi-strain mixed fermentation, which relates to a production method of foods. The method comprises the following steps of preparing a saline solution with the concentration of 9%-11%, boiling the water, adding seed solutions of lactobacillus delbrueckii and lactobacillus pentosus after the water is cooled, and uniformly mixing so as to obtain a sour bamboo shoot fermentation bacteria solution; selecting bamboo shoots with moderate tenderness, cutting off the roots of the bamboo shoots, removing shells of the bamboo shoots, cleaning, draining away water, cutting the bamboo shoots into two half parts from the middle of the bamboo shoots, adding the bamboo shoots into a pickle jar, and pouring the sour bamboo shoot fermentation bacteria solution into the pickle jar to flood the bamboo shoots; and covering a bamboo skin cover, putting four bamboo chips, which are crossed to form a # shape, on the bamboo skin cover, putting a cleaned and aired rock on the center of the #-shaped bamboo chips to seal the pickle jar, and carrying out fermentation for 5-7 days at 23-25 DEG C so as to obtain the sour bamboo shoots.

Owner:HEILONGJIANG PROV LIGHT INDAL SCI RES ACAD

Method for producing orignial nutrition type mulberry fruit vinegar

The present invention relates to food processing method and producing process of mulberry fruit vinegar. The mulberry fruit vinegar is produced with fresh mulberry and through the steps of sorting mulberry, cleaning, scalding in hot water, crushing, alcohol fermentation via adding alcohol yeast liquid in temperature controlling fermentation tank, continuous deep acetic fermentation via adding acetic acid yeast, blending, ageing in sealed acetification tank at 19 deg.c for 6 months, non-heating sterilizing with 100-800 W RE ultrasonic transducer, and packing. The present invention adopts low temperature fermentation and mycose protection to maintain the antioxidant matter, amino acids and other nutritious components. The mulberry fruit vinegar has the health functions of promoting blood circulation, softening blood vessel, improving gastrointestinal function, moistening skin, etc.

Owner:申琳 +3

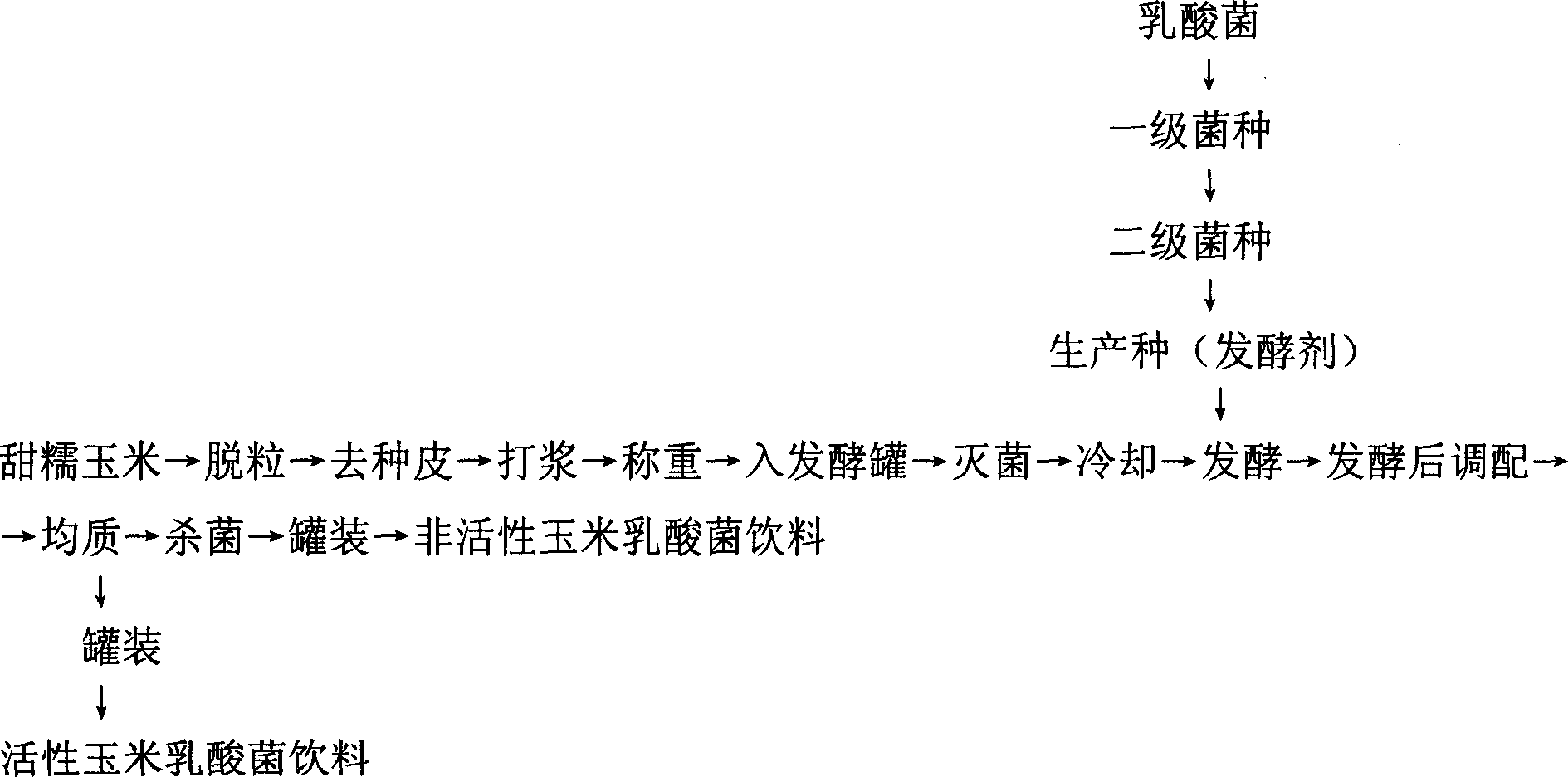

Technique for preparing beverage contg. lactic acid fermentation sweet waxy corn and product thereof

A lactobacillus fermented sweet glutinous corn beverage with special nutritive value and taste and health-care function is prepared from sweet glutinous corn through sterilizing, inoculating composite lactobacillus zymophyte, slow fermenting at medium temp in non-oxygen condition, mixing with auxiliary, homogenizing and high-temp sterilizing.

Owner:辽宁省农业科学院食品与加工研究所

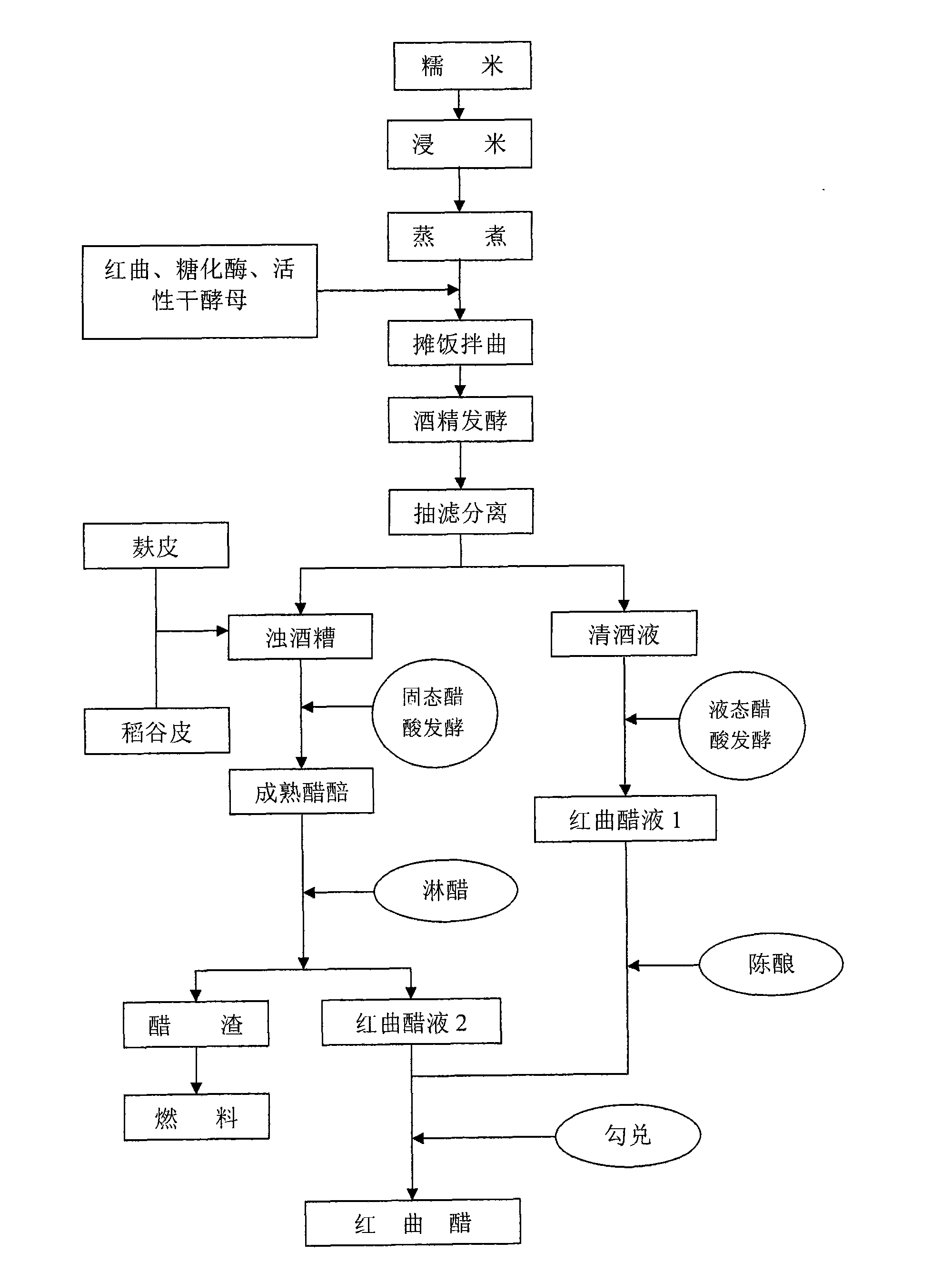

Clean production method for brewing monascus vinegar

InactiveCN101580793AShorten the fermentation cycleIncrease profitMicroorganism based processesVinegar preparationFiltrationFood flavor

The invention relates to a food processing method, in particular to a clean production method for brewing monascus vinegar. In order to realize the object, the technical proposal is characterized in that a filtration and separation step after the alcoholic fermentation step is added in the traditional methods such as sticky rice cooking, saccharification leaven, alcoholic fermentation, acetic acid fermentation and ageing and blending; two methods of liquid acetic acid fermentation and solid acetic acid fermentation are respectively adopted on the clear alcohol liquid and turbid grainstillage filtered and separated out of the monascus wine generated after alcoholic fermentation to prepare a monascue vinegar liquid 1 and a monascue vinegar liquid 2 respectively; and finally, the two vinegar liquids are blended to form the monascue vinegar. The method for brewing the monascus vinegar shortens the fermentation period, improves the utilization ratio of the raw material, improves the flavor of the monascus vinegar, complies with the requirements of clean production process, reduces the contamination from the headstream, realizes zero discharge of solid wastes, and solves the environmental pollution problem as a large amount of monascus grainstillag and vinegar slag are generated by the monascus vinegar brewing factory for brewing the vinegar.

Owner:YONGCHUN AGED VINEGAR

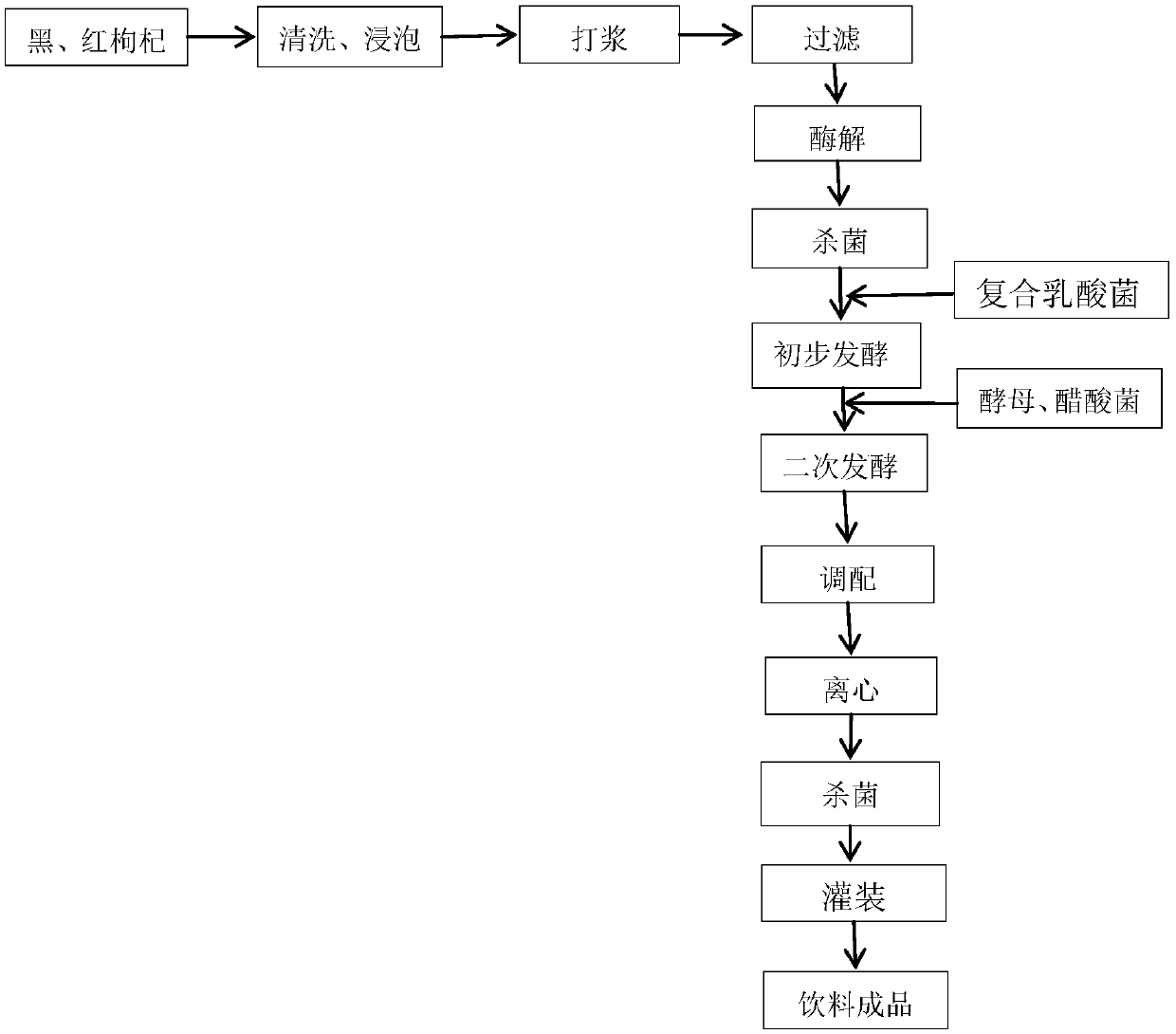

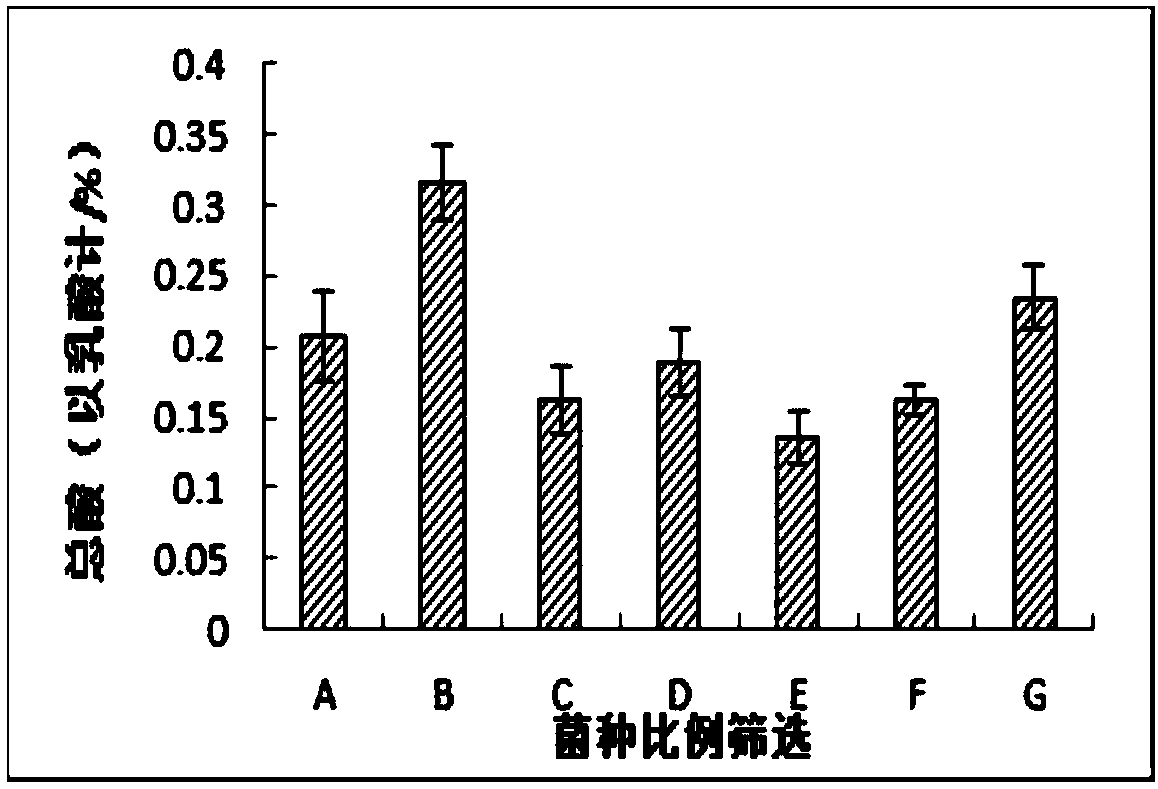

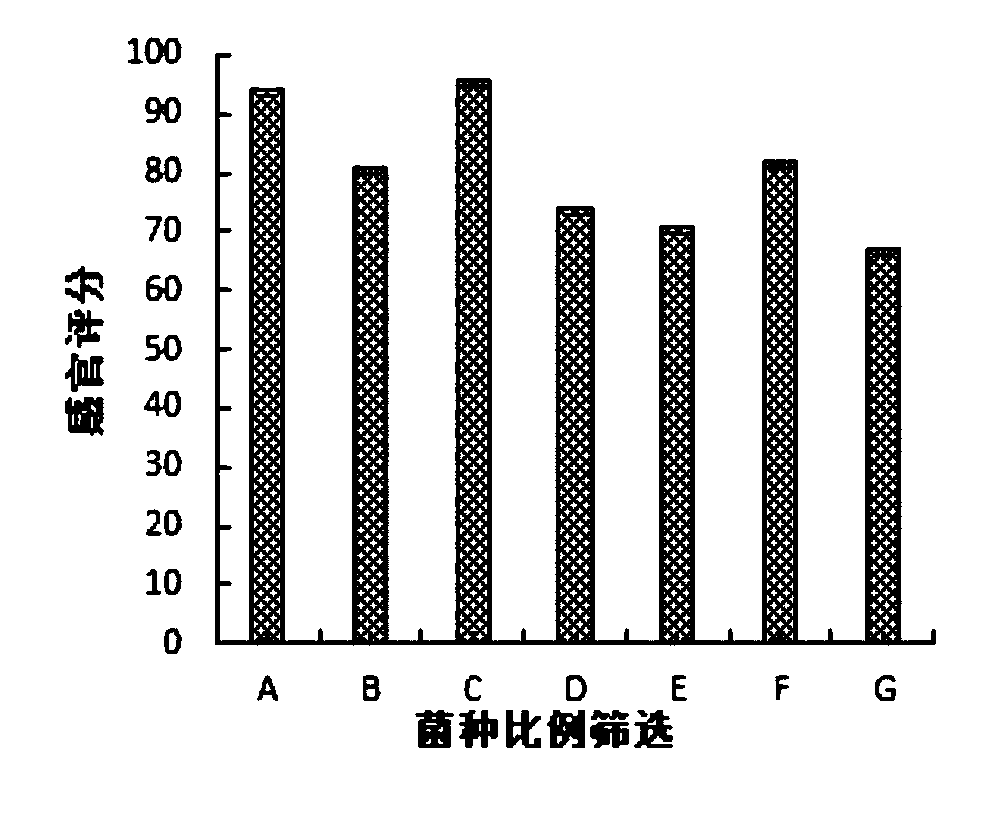

Black and red Chinese wolfberry fruit compound fermented beverage and preparation method thereof

InactiveCN109619352AImprove stabilitySolve difficult to recycleFood scienceEscherichia coliSaccharic acid

The invention discloses a novel black and red Chinese wolfberry fruit compound fermented beverage and a preparation method thereof and belongs to the processing field of microbial fermentation technologies of foods. The preparation method mainly comprises the steps of pretreatment of raw materials, juicing, ultrasonic assisted chitosan immobilized complex enzyme treatment, filtration, pasteurization, primary fermentation of a lactic acid bacterium composite leavening agent, secondary fermentation with active dry yeast and acetic acid bacteria, saccharic acid blending, centrifugation, pasteurization, filling and finished beverage. The preparation method is simple in process and low in processing cost, the prepared beverage has the flavor of Chinese wolfberry fruits and also has the smell produced through Chinese wolfberry fruit, a pleasant mellow aroma and soft sour, so that the beverage has more delicate taste, has no bad odor, homogeneous color and luster and good nutritional health-care functions; the total acid of the beverage is 2.83%, pH is 3.70, the aqueous protein of plants is 2.83g / L, the total phenol is 38.17mg / L, the carotenoid is 35.67ug / L, the alcoholic strength is 1% or below, and bacteria and escherichia coli are not detected out.

Owner:NINGXIA UNIVERSITY

Production method for edible vinegar

The invention relates to a method for producing table vinegar, which is to use water to fully moisten vinegar brewing raw materials, cook the raw materials, inoculate Daqu, Xiaoqu, bran koji, red koji and rice koji, and perform lactic fermentation, alcoholic fermentation, acetic fermentation, aging, heating aging, vinegar pouring and mixing to prepare table vinegar finished products. The invention applies the novel table vinegar brewing method through five types of koji, three types of fermentation and one type of aging. The brewed table vinegar has bright color and luster, transparent posture, rich koji flavor, tender and sour taste, coordinated five flavors and richer nutrition, and not only has the characteristics of spiced vinegar but also has the taste of mature vinegar.

Owner:吴德辉

Drink and thick slurry of ginger and date juice and preparation method of drink and thick slurry

InactiveCN104187981AImprove the status of deep processingIncrease incomeFood ingredientsSucroseSlurry

The invention discloses drink of ginger and date juice. The drink comprises the following components in percentage by mass: 1.00-10.00% of concentrated date juice, 0.50-5.00% of ginger juice, 5.00-40.00% of white sugar, 0.20-5.00% of brown sugar, 0.01-0.20% of sodium carboxymethylcellulose, 0.01-0.30% of xanthan gum, 0.01-0.20% of sucrose fatty acid ester, 0.01-0.30% of citric acid, 0.02-0.50% of sodium citrate, 0.010-0.20% of D-sodium erythorbate, 0.010-0.20% of salt, 0.002-0.04% of aspartame (containing phenylalanine), 0.002-0.04% of acesulfame, 0.001-0.02% of sucralose, 0.01-0.3% of potassium sorbate and the balance of pure water. The drink and thick slurry of ginger and date juice are prepared by gradually dissolving the components, sufficiently stirring and by adding different amounts of water to fix the volume.

Owner:天人果汁集团股份有限公司

Snow lotus fruit vinegar beverage

InactiveCN102334706AMild sourUnique flavorVinegar preparationFood preparationFlavorEconomic benefits

The invention relates to a beverage, in particular to a snow lotus fruit vinegar beverage, belonging to the technical field of food processing. The snow lotus fruit vinegar beverage is brewed through pure liquid state fermentation by taking snow lotus fresh fruits as raw materials, and the blended snow lotus fruit vinegar beverage has gentle sour, unique flavor and intense combined flavor of the snow lotus fruits and table vinegar. The snow lotus fruit vinegar beverage integrates nutrition and functions of the snow lotus fruits and the table vinegar, has a wide market prospect, greatly increases the economic benefits of planting the snow lotus fruits and provides a new approach for enriching the variety of vinegar beverages and promoting the fine and further processing of the snow lotus fruits.

Owner:曹洪

Preparation method for apple vinegar

InactiveCN101113404AKeep the flavorPreserves flavor with natural colorVinegar preparationAdditive ingredientCurative effect

The invention discloses a preparation method of apple vinegar, taking apple juice, brewing vinegar, honey, white granulated sugar and sorbic acid as raw materials. The components of the invention can bring relatively better curative effect by being controlled at the dosage weight of: 50-60g of the apple juice, 70-80g of the brewing vinegar, 15-20g of the honey, 15-20g of the white granulated sugar and 15-20g of the sorbic acid. The invention has natural color and luster, relatively higher purity and quality and very low cost. No other auxiliary ingredients are needed. Furthermore, the invention has fresh and intense apple flavor, soft sourness and good taste and lingering aftertaste.

Owner:杨志金

Staphylococcus xylosus I2 strain, composite ferment produced thereby and the use of ferment in meat ware

The invention relates to an xylose staphylococcus I2 strain, whose docket number in the Chinese Microbiological Culture Preservation Administration Commission Common Microbiological Center is CGMCC No.0919, the leaven can be applied into the production process for meat product e.g. fermentation sausage.

Owner:河南双汇投资发展股份有限公司

Production process for brewing apricot fruit vinegar from apricot peel pomace

InactiveCN101475900AEliminate pollutionIncrease profitMicroorganism based processesVinegar preparationCelluloseAlcohol content

The invention discloses production technology for brewing apricot fruit vinegar by utilization of apricot bark residue, which comprises: firstly, collecting the apricot bark residue into a stainless steel jar, adding water for stirring, adjusting the content of soluble solid to be between 7 and 9 DEG BX, adjusting the product temperature to be between 42 and 45 DEG C, and transferring an apricot skin residue mixture into an alcohol fermenter; secondly, simultaneously adding active dry yeast and mashed fruit cellulose complex enzyme, controlling the fermentation temperature to be between 28 and 32 DEG C and the fermentation time to be between 48 and 52 hours, and making alcohol fermentation finished when the sugar degree of juice is reduced to be less than or equal to 0.5 percent and the alcohol content of the juice reaches 5 to 7 percent; thirdly, transferring mash obtained in the prior step into an acetic acid fermenter, adding acetic acid bacteria for acetic fermentation, and controlling the fermentation temperature to be between 32 and 38 DEG C; and fourthly, obtaining finished products after the steps of brewing, aging, mixing, filtration, sterilization, filling and sealing in turn.

Owner:轮台县华隆农林业开发有限公司 +1

Production method of yellow water vinegar beverage

ActiveCN104357305AFully tap the potential valueReduce manufacturing costMicroorganism based processesVinegar preparationYeastSocial benefits

The invention discloses a production method of a yellow water vinegar beverage and belongs to the technical field of brewing. The production method comprises the following steps: carrying out biotransformation on yellow water by using lactic acid bacteria liquid to produce biotransformation liquid with a fragrant component of a vinegar beverage precursor; then, producing yellow water vinegar beverage-assistant rice wine by adopting special distiller's yeast; then mixing the yellow water biotransformation liquid with the assistant rice wine in a proportion of (7: 3); inoculating yeast; and controlling fermentation conditions to obtain the yellow water vinegar beverage. According to the production method disclosed by the invention, the brewing byproduct yellow water is thoroughly converted and utilized by combining microbiology, a brewing technique and a modern vinegar making technique, so that a novel beverage product with fragrances of vinegar and wine is produced. Therefore, zero emission of the yellow water is realized to achieve environmental protection to the maximum extent, but also the additional value in the white spirit industry is increased. The production method disclosed by the invention has huge economic and social benefits.

Owner:JIANGSU YANGHE BREWERY JOINT STOCK

Production method of fig fruit vinegar

InactiveCN102154089AKeep natural colorWith natural colorVinegar preparationAdditive ingredientAdditional values

The invention relates to a production method of fig fruit vinegar, which is characterized in that fresh figs are taken as a raw material, and the fig fruit vinegar can be prepared by juicing, centrifugal separation, low-temperature alcoholic fermentation, ageing, filtering and sterilizing. The production method of the fig fruit vinegar maintains the specific flavor of the figs, the fig fruit vinegar is natural in color and luster, higher in purity, good in quality and low in cost, and other assistant ingredients do not need to be added. The invention is adequate in the raw material, and has positive effects for improving the additional value of fig products, increasing income of fruit growers and promoting the development of fig industry.

Owner:WEIHAI XINYI BIOLOGICAL TECH

Production method for table vinegar

InactiveCN104195027ADark brownRich vinegarMicroorganism based processesVinegar preparationBranFermentation

The invention relates to a production method for table vinegar. The production method adopting rice and bran as raw materials comprises the following steps: mixing, material wetting, inoculating, primary fermentation, secondary fermentation, vinegar pouring, blending, sterilizing, inspecting and filling. The production method has the beneficial effect the table vinegar produced by virtue of the method disclosed by the invention is dark brown in color and luster, strong in vinegar smell, soft in sour, slightly sweet, clear in state and proper in concentration. And moreover, the method is easy to grasp, convenient to realize, long in fermenting and sterilizing time, capable of sufficiently sterilizing and high in safety.

Owner:重庆市武隆区曹氏醋厂

Noni fruit vinegar and production method thereof

InactiveCN101514319AImprove physical fitnessEnhance immune functionMicroorganism based processesVinegar preparationLactic acid fermentationMORINDA CITRIFOLIA FRUIT JUICE

The invention discloses noni fruit vinegar and a production method thereof, filtrate obtained by hot leaching of mixture of edible vinegar, noni fruit lactic acid fermentation undecanted wine, honey, arillus longan and matrimony vine is the noni fruit vinegar, the noni fruit lactic acid fermentation undecanted wine is prepared by steps of crushing selected noni fruit, and adding sugar, Lactobacillus bulgaricus and thermophilic streptococcus to ferment. The nonifruit vinegar provided by the present invention can maintain function and character of noni fruit, can improve body diathesis and immunization function, has efficacy of antioxidation and liver protection, and characteristic of mild sour flavour and non-stimulation, can be used as edible vinegar for cooking and being eaten together with rice or bread, can be drunk as beverage type and health care type edible vinegar, caters to human diet health care, diseases prevention and body-building trend, and has great exploitation potential. The invention has advantages of simple production method, and easily available raw material.

Owner:张海德 +1

One-step fermentation preparation method of passion fruit vinegar

InactiveCN106929385AEfficient use ofStrong smellMicroorganism based processesVinegar preparationAlcoholFruit juice

The invention discloses a one-step fermentation preparation method of passion fruit vinegar, and belongs to the technical field of food. The preparation method comprises the following steps of smashing whole passion fruits into pieces, obtaining enzymolysis juice, conducting one-step fermentation optimization with kombucha on the raw material of the enzymolysis juice to produce alcohol and vinegar, and obtaining the passion fruit vinegar. The preparation method has the advantages of simple preparation steps and easy realization, is beneficial to increasing production efficiency and product quality and reducing operation cost, and meets green chemistry requirements.

Owner:HEZHOU UNIV

Method for fermenting flavor chestnut kernel

The invention provides a method for fermenting flavor chestnut kernel, belonging to the technical field of food processing. The technology of the invention takes chestnut kernel and chestnut pulp as raw materials, and lactic acid bacteria and yeast leaven are added; by the fermentation action of compound strain, the flavor and the nutritional value of the chestnut kernel can be improved to prepare the lactic acid fermenting flavor chestnut kernel products. The invention has the advantages that fermentation engineering technology is adopted to develop a high-nutrition chestnut food with lacticacid fermenting flavor, soft acidity and abundant nutrition; meanwhile, the chestnut of the invention keeps inherent golden yellow of chestnut and is a novel and pure natural chestnut fermenting product. The fermenting method of the chestnut kernel of the invention can produce leisure chestnut food, such as fermented chestnut kernel, fermented chestnut cans and the like, has wide market development prospect and provides a new path for deep processing of chestnut.

Owner:JIANGSU ACAD OF AGRI SCI

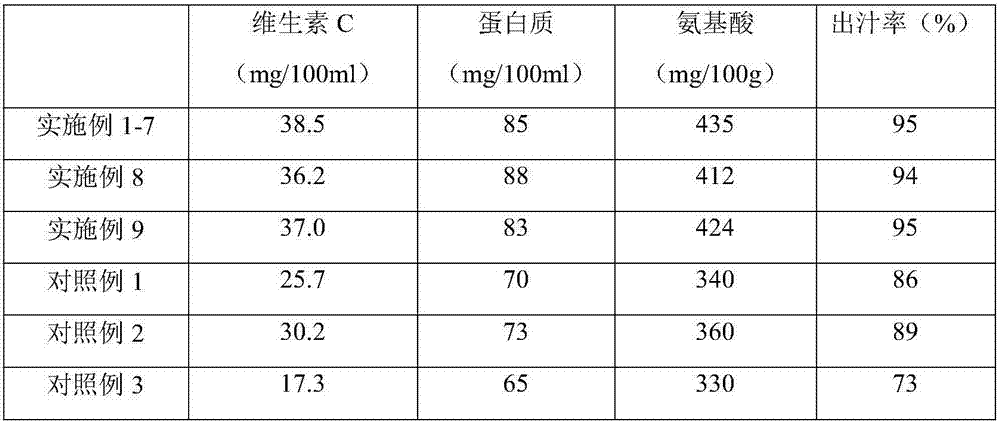

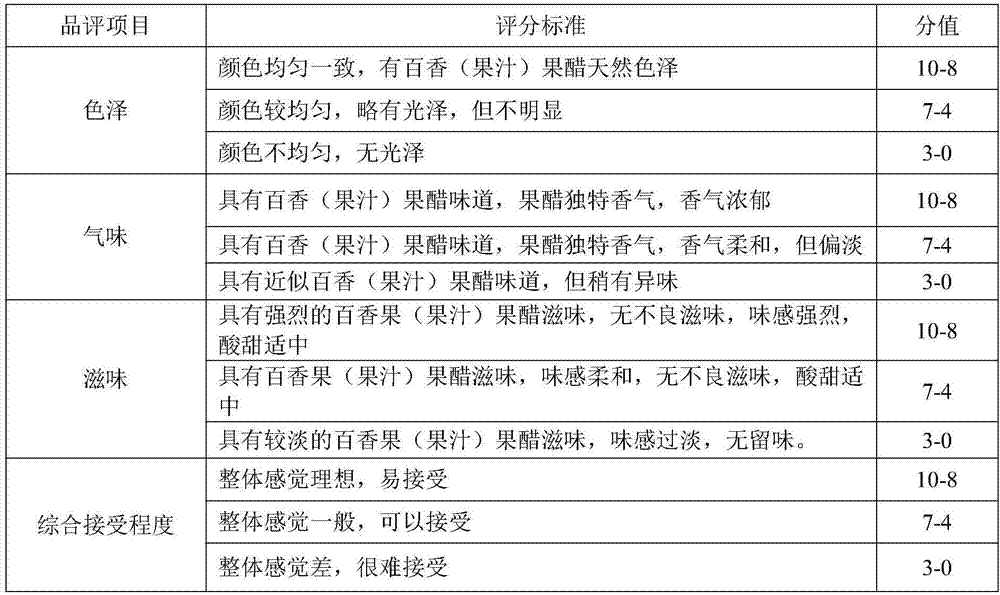

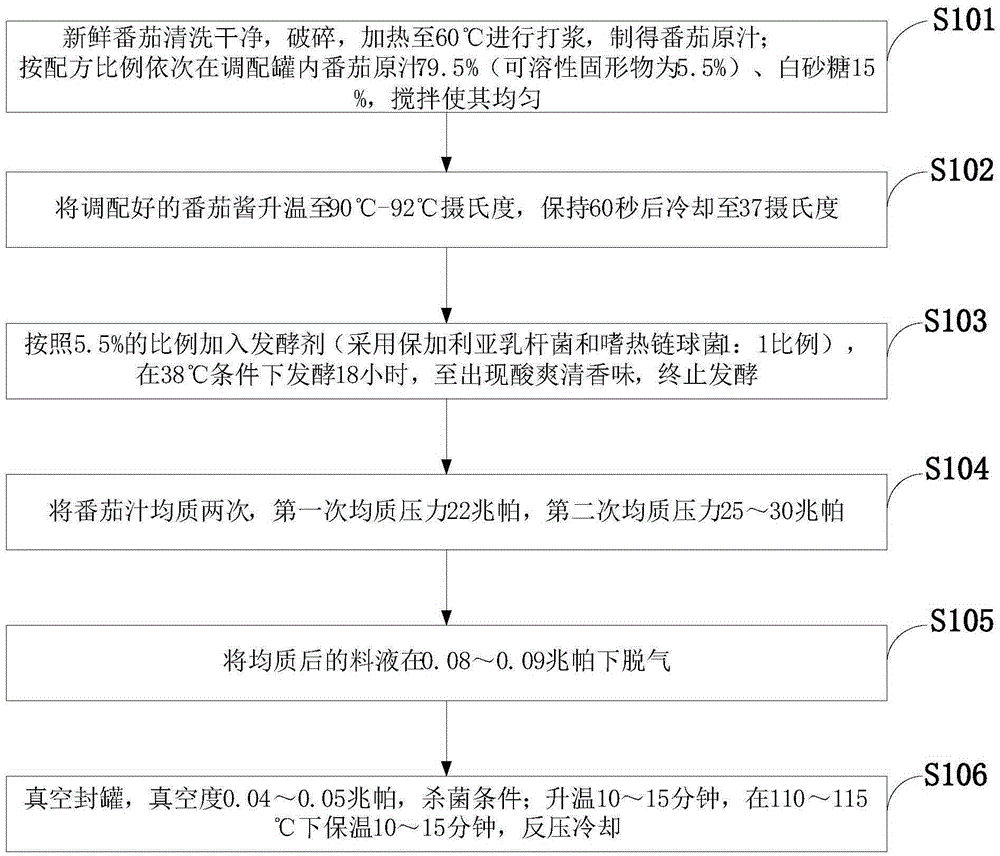

Fermented tomato juice beverage and preparation method thereof

The invention discloses a fermented tomato juice beverage and a preparation method thereof. The beverage comprises 79.5% of a tomato normal juice (with the soluble solid content of 5.5%), 15% of white granulated sugar, and 5.5% of a starter (adopting Lactobacillus bulgaricus and Streptococcus thermophilus according to a ratio of 1:1 to ferment). Lactobacillus bulgaricus and Streptococcus thermophilus are added, so the inherent fragrance of tomatoes is reserved, and the stink of the tomatoes and the burnt smell of tomato sauce blend beverages are effectively eliminated; multiple organic acids generated in the fermentation process are used to substitute added acids, so the sour taste is soft, plump and salubrious; a fermentation technology is carried out to make microbe metabolism generates extracellular polysaccharides, so the viscosity of the above product is increased, and addition of extra thickeners is avoided; and the fermentation technology treatment is carried out to make the product have multiple natural composite fragrance substances, so the product has plump mouthfeel, rich fragrance and unique flavor. The beverage and the preparation method guarantee healthiness, well make up defects of tomato juice beverages, and can further develop the tomato industry chain.

Owner:XINJIANG GUANNONG FRUIT & ANTLER GROUP

Nutritional wild fern root vinegar and preparation method thereof

InactiveCN103468558AHigh economic valueNourishing yin and aphrodisiacVinegar preparationAeonium glutinosumFermentation

The invention provides nutritional wild fern root vinegar and a preparation method thereof, and relates to the technical field of food processing. The nutritional wild fern root vinegar is prepared by the steps of adding nutritious traditional Chinese medicines into fern roots serving as main raw materials and sticky rice serving as auxiliary materials, conducting saccharification, alcoholization and acidification fermentation by a traditional solid fermentation process, and then mixing with various condiments. The nutritional wild fern root vinegar provided by the invention is faint in scent, strong, soft and lingering in sour, mellow and sweet, is a condiment and also is a nutritional health-care product.

Owner:BIJIE TIANHE FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com