Normal juice fruit vinegar immobilization preparation method

A production method and fruit vinegar technology are applied in the immobilized production of original fruit vinegar and the scientific field of fruit vinegar acetic acid fermentation, which can solve the problems of long fermentation cycle, low product color, flavor and quality, and high production cost, and achieve fast fermentation reaction speed, The effect of facilitating mechanized production and high equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

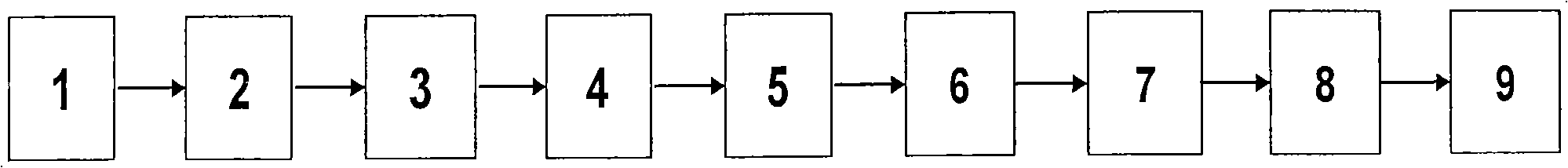

Image

Examples

Embodiment Construction

[0008] Rinse and drain the fresh and ripe fruits and squeeze the juice quickly (1), add 0.01-0.05% pectinase, enzymolyze at 50-55°C for 2 hours, add 0.05% citric acid to protect the color (2), treat at 80°C for 10 ~30 minutes, quickly cool to 15~25°C (3), inoculate 10~20g / 100L commercially available qualified active dry yeast for fruit wine, alcoholic fermentation at 15~25°C, fermentation cycle 5-7 days (4), Treat the alcohol fermentation liquid at 80°C for 10-30 minutes, cool to 30-35°C (5), filter the alcohol fermentation liquid with diatomaceous earth (6), carbonize the corn with a diameter of 2-4 cm and a length of 8-15 cm Cores or carbonized round wood chips are arranged vertically in the fermenter, and the filtered alcoholic fermentation liquid is pumped into the fermenter with 2-7% commercially available active acetic acid bacteria and immobilized carriers on the surface, and the temperature is controlled at 30-35°C Circulate fermentation, measure the acidity every 2-3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com