Method for preparing glucose and fructose mixture from bagasse

A sugarcane bagasse and mixed liquor technology are applied in the field of sugarcane to achieve the effects of soft taste, low cost and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

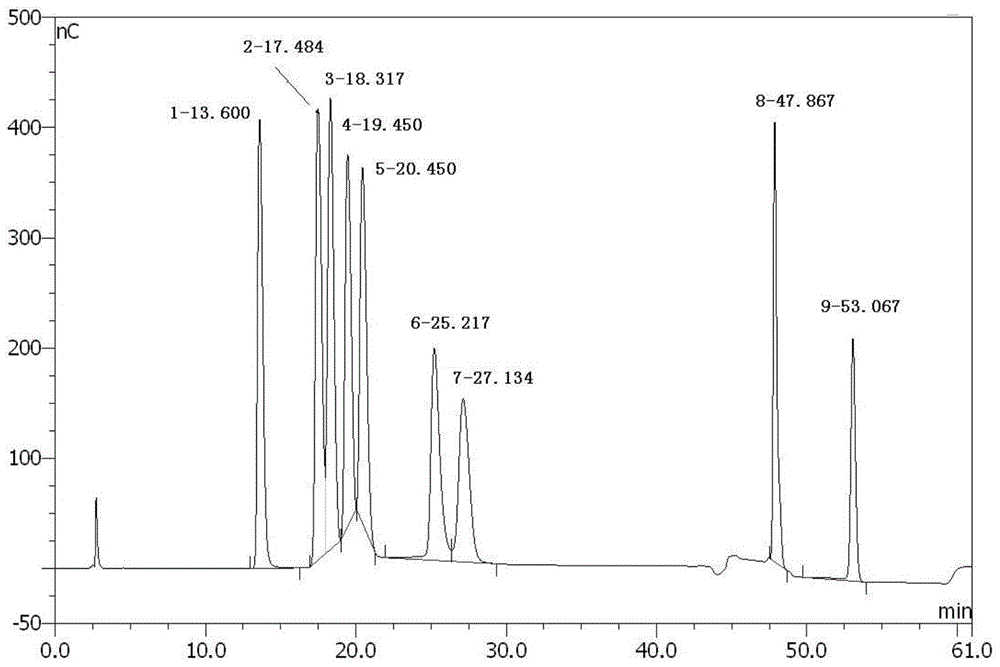

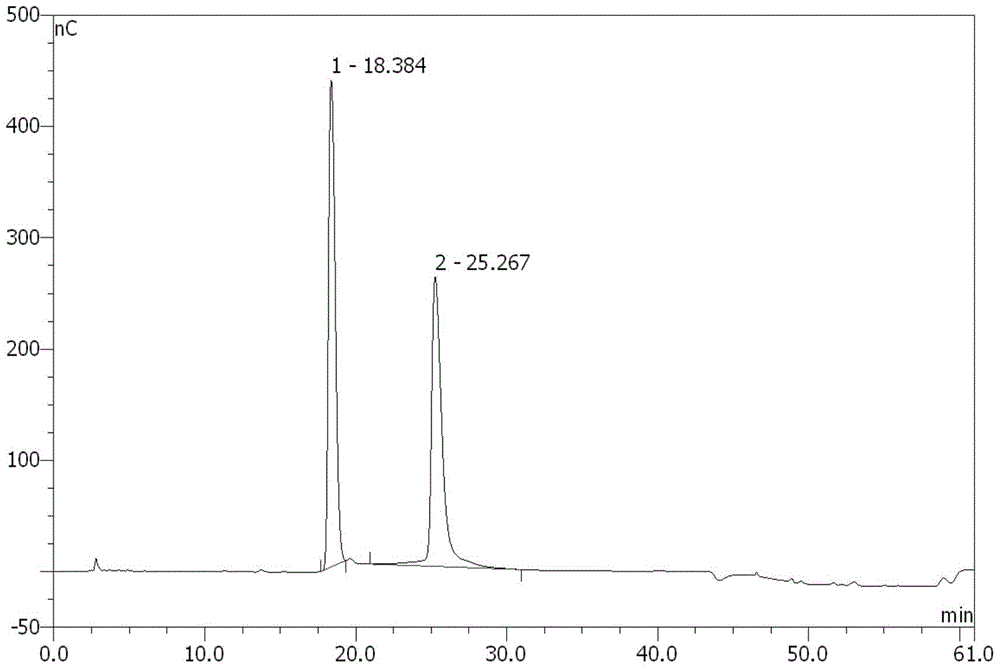

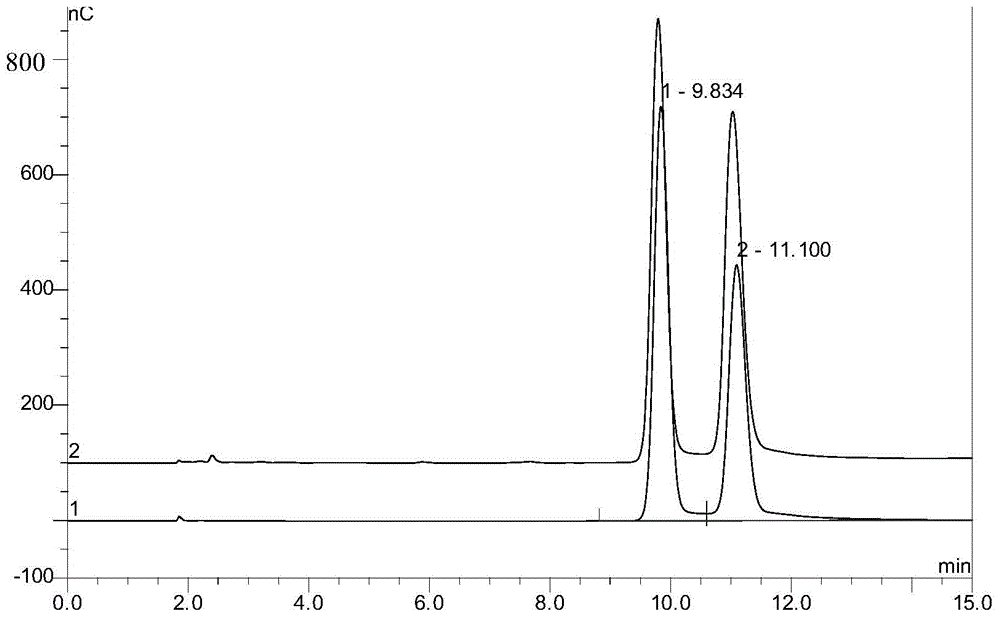

Image

Examples

Embodiment 1

[0034] Embodiment 1 enzymatic hydrolysis of bagasse to prepare the method for glucose and fructose mixed solution

[0035] 1) Activate the strain Bacillus aryabhattai GZ03 with an activation medium plate (1% peptone, 0.2% yeast extract, 1.5% agar powder, prepared in situ with seawater, sterilized at 121°C for 20 minutes before use), and pick a single The colony was inoculated in the seed medium (1% peptone, 0.2% yeast extract, prepared in situ with seawater, sterilized at 121°C for 20 minutes before use), and cultured at 28°C with shaking at 200r / min for 12h.

[0036] 2) Add the seed solution to the sugar-producing medium (containing 2% of bagasse powder sieved through a 60-mesh sieve, prepared in situ with seawater, and sterilized at 121°C for 20 minutes before use) according to the inoculation ratio of 2%, and continue at 28°C Under the condition, shake culture at 200r / min for 48h to obtain fermentation broth.

[0037] 3) The fermentation broth was centrifuged at 10000×g fo...

Embodiment 2

[0066] Similar to Example 1, the difference is that the culture temperature in steps 1) and 2) is 25°C, the content of yeast extract in the seed medium described in step 1) is 0.5%, and the bagasse powder in step 2) 2%, the culture time is 72h.

Embodiment 3

[0068] Similar to Example 1, the difference is that the culture temperature in steps 1) and 2) is 37°C, the content of yeast extract in the seed medium described in step 1) is 1.5%, and the bagasse powder in step 2) 5%, the culture time is 96h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com